Covalent organic framework material rich in zwitterions as well as preparation method and application of covalent organic framework material

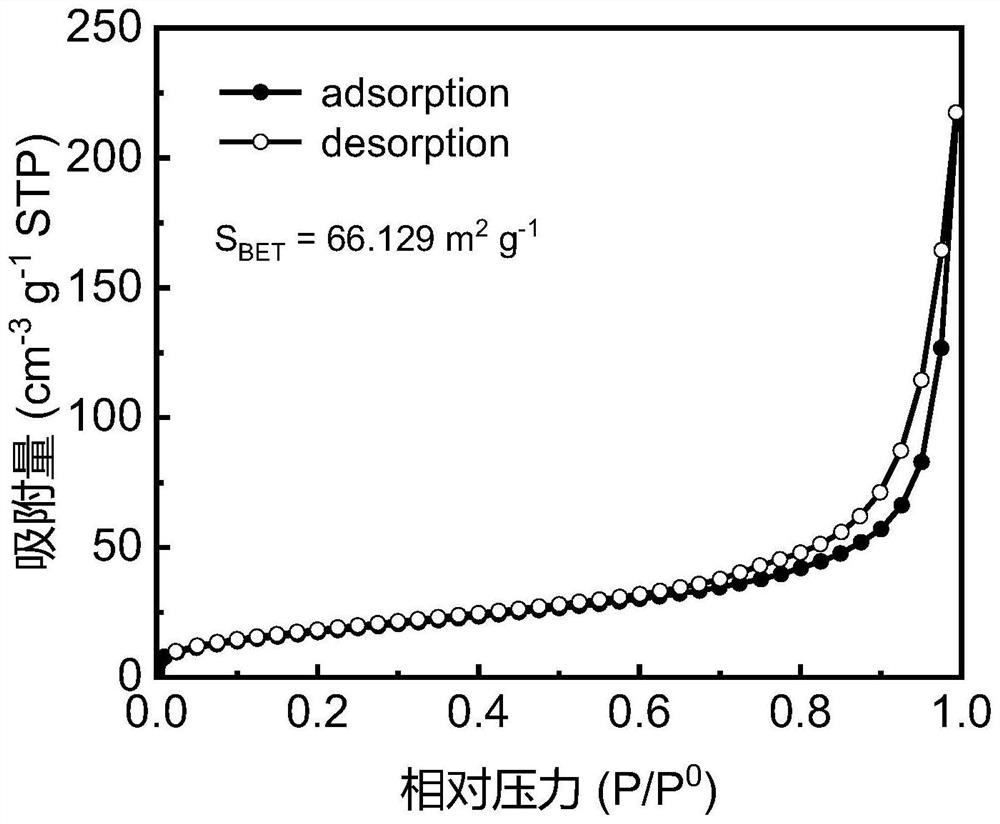

A covalent organic framework and zwitterion technology, applied in the application of lithium-sulfur battery cathode materials, the field of preparation of covalent organic framework, can solve the problems of large specific surface area, high thermal stability, lack of research, etc., to achieve low density, High thermal stability, effect of promoting catalytic conversion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

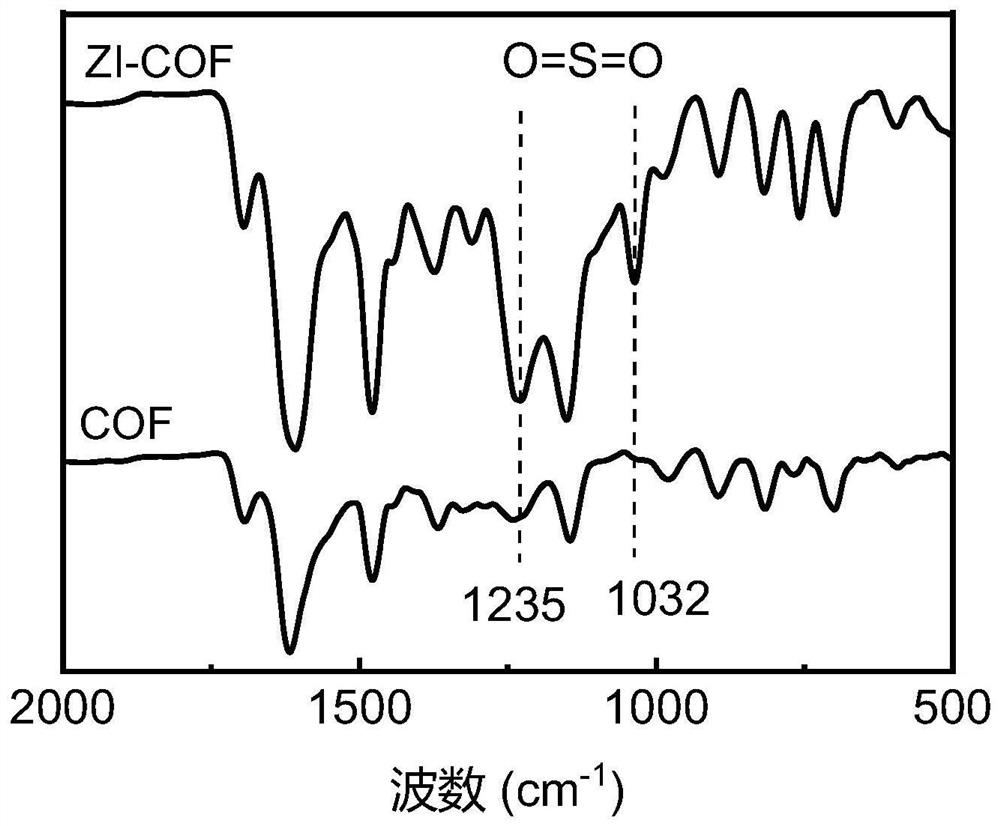

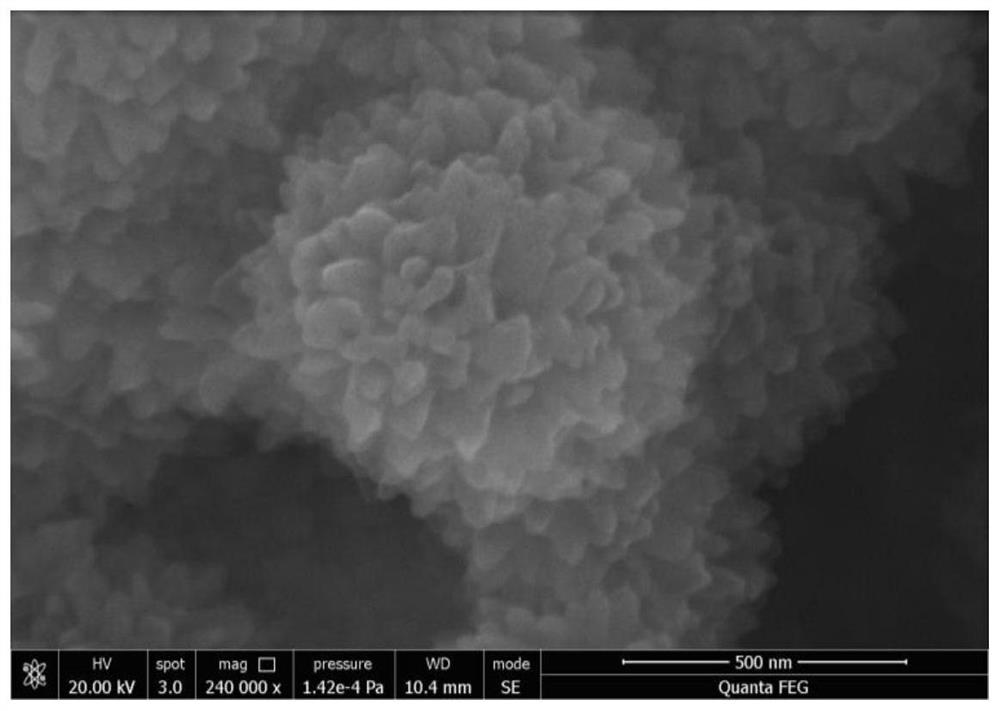

[0035](1) Preparation of zwitterionic covalent organic framework materials: put 81.1mg (ie 0.5mmol) of trimesaldehyde and 214mg (0.75mmol) of 3,8-diamino-6-phenylphenanthridine in a 25ml thick-walled pressure bottle In the medium, vacuumize, fill with argon, add 1,4-dioxane (3.125ml), mesitylene (3.125ml) and acetic acid aqueous solution (1.25ml, 6mol / L), ultrasonic 5min to make it fully dispersed, After performing three cycles of liquid nitrogen freezing (each cycle includes a "freezing-thawing" step, the freezing is freezing at liquid nitrogen -196°C for 5 minutes, and thawing is standing for 15 minutes under natural conditions to return to room temperature), Filled with argon, heated to 120°C in an oil bath, reacted at constant temperature for 3 days, cooled, filtered, the solid was repeatedly washed with 1,4-dioxane, and dried in vacuum at 60°C for 12 hours to obtain a covalent organic framework COF.

[0036] (2) Add 0.05g of the above-mentioned COF, 0.1g of propane sulton...

Embodiment 2

[0047] Other steps are the same as in Example 1, except that the constant temperature reaction time is replaced by 5 days by 3 days.

Embodiment 3

[0049] Other steps are the same as in Example 1, except that 150 mg of sublimed sulfur powder is replaced by 175 mg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com