Method for synthesizing neopentyl glycol through catalytic hydrogenation of hydroxyvaleraldehyde

A technology of hydroxyvaleraldehyde and neopentyl glycol, applied in the preparation of hydroxyl compounds, chemical instruments and methods, preparation of organic compounds, etc., can solve problems such as no more than 95%, and achieve good catalytic conversion, good selectivity and general efficiency. The effect of permeability and high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

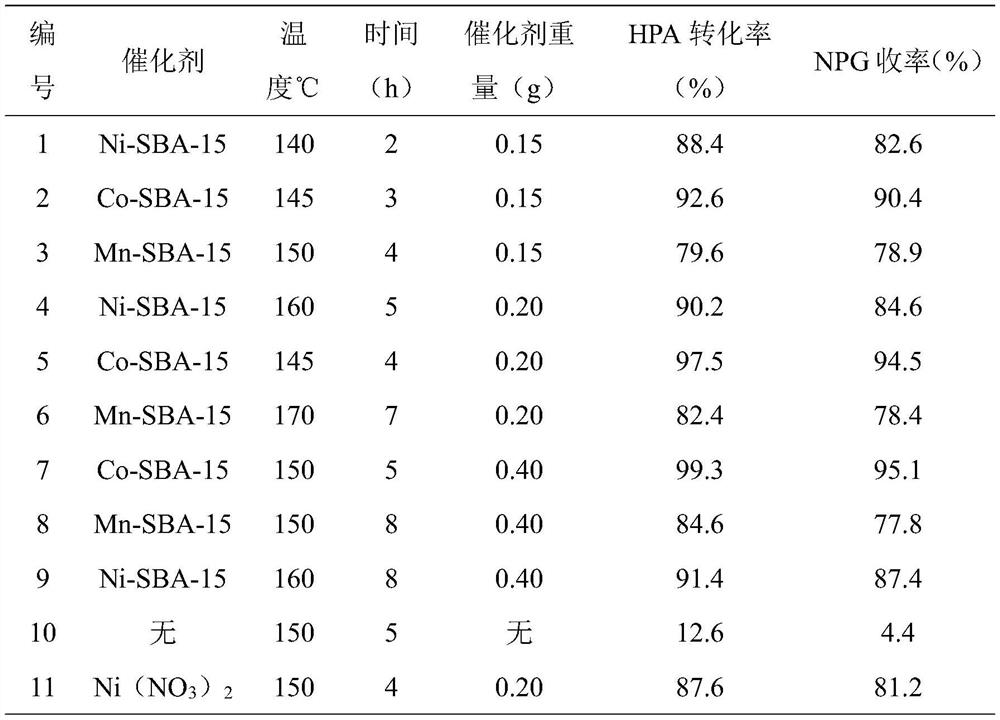

Examples

Embodiment 1

[0031] Dissolve 0.8g of P123 in 25ml of 2M hydrochloric acid and stir with a magnet until completely dissolved. At this time, the solution is clear and transparent with a little foam on it. Then weigh 1.7g TEOS and add it dropwise to the hydrochloric acid solution, stir at a constant temperature of 40°C for 4 hours, weigh the required proportion of cobalt nitrate and dissolve it in 30ml of water, add it dropwise to the above solution and then stir at a constant temperature of 40°C 20 hours. The obtained mixed solution was transferred into a polytetrafluoroethylene crystallization bottle, and hydrothermally reacted in a 90°C oven for 2 days. After natural cooling, the pH of the mixed solution was raised to 7.5 by dropping ammonia water under stirring conditions, and then It was introduced into a polytetrafluoroethylene crystallization bottle again, crystallized again in an oven at 90°C for 2 days, cooled naturally, washed with suction, and dried at room temperature to obtain a ...

Embodiment 2

[0034] I. First install the instrument and device, and check its safety performance, especially the airtightness of the autoclave and gas storage tank.

[0035] II. Weigh 5 grams of hydroxyvaleraldehyde powder and dissolve it in 20 ml of ethanol to prepare HPA ethanol solution. Add to autoclave.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com