Porous intermetallic compound-ceramic catalyst carrier and preparation thereof

A technology of intermetallic compounds and ceramic catalysts, applied in the direction of catalyst carriers, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of difficult quality control, large back pressure, high equipment cost, etc., and reduce thermal stress and thermal stress. Fatigue damage, beneficial to filter impurities and exhaust, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

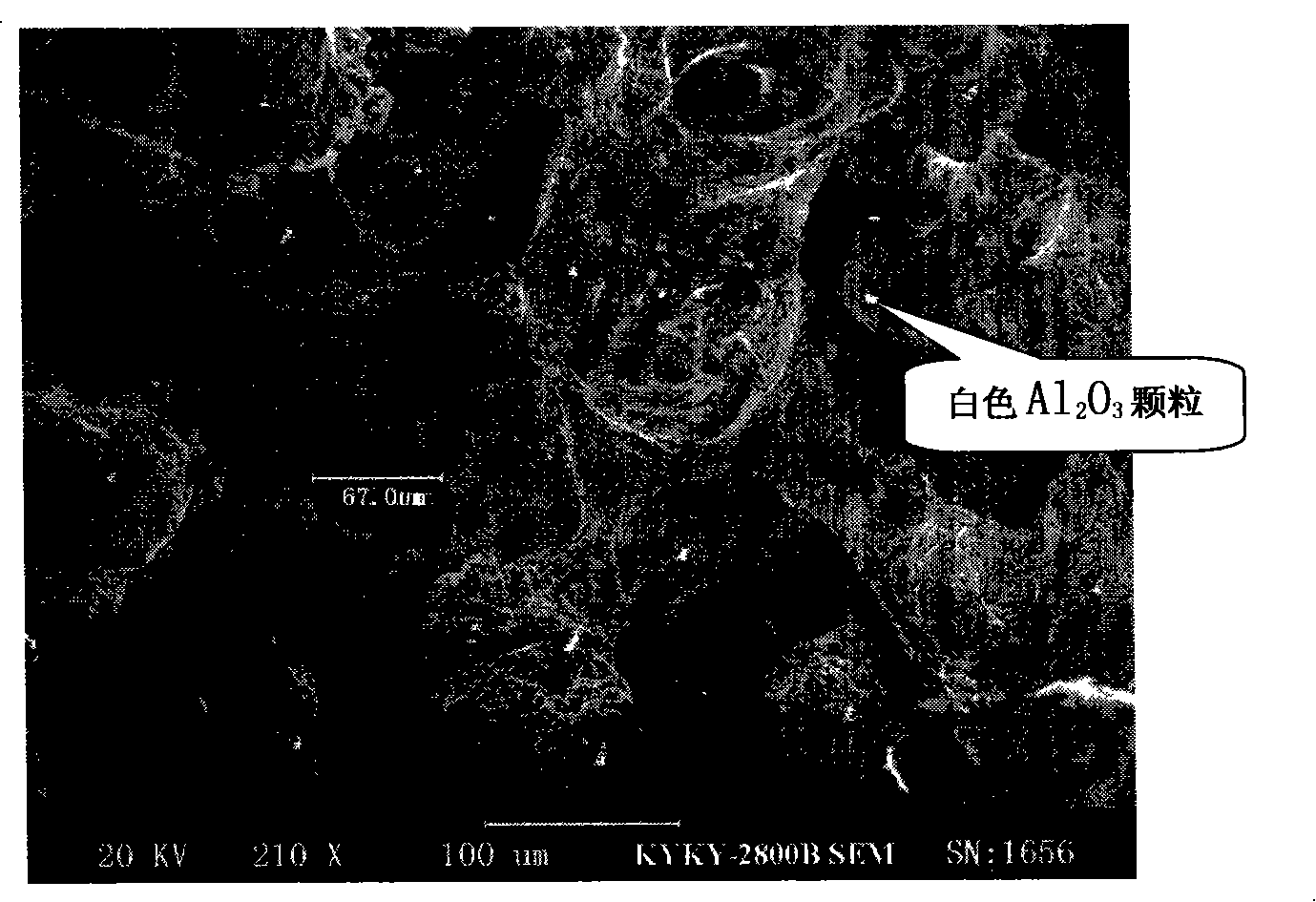

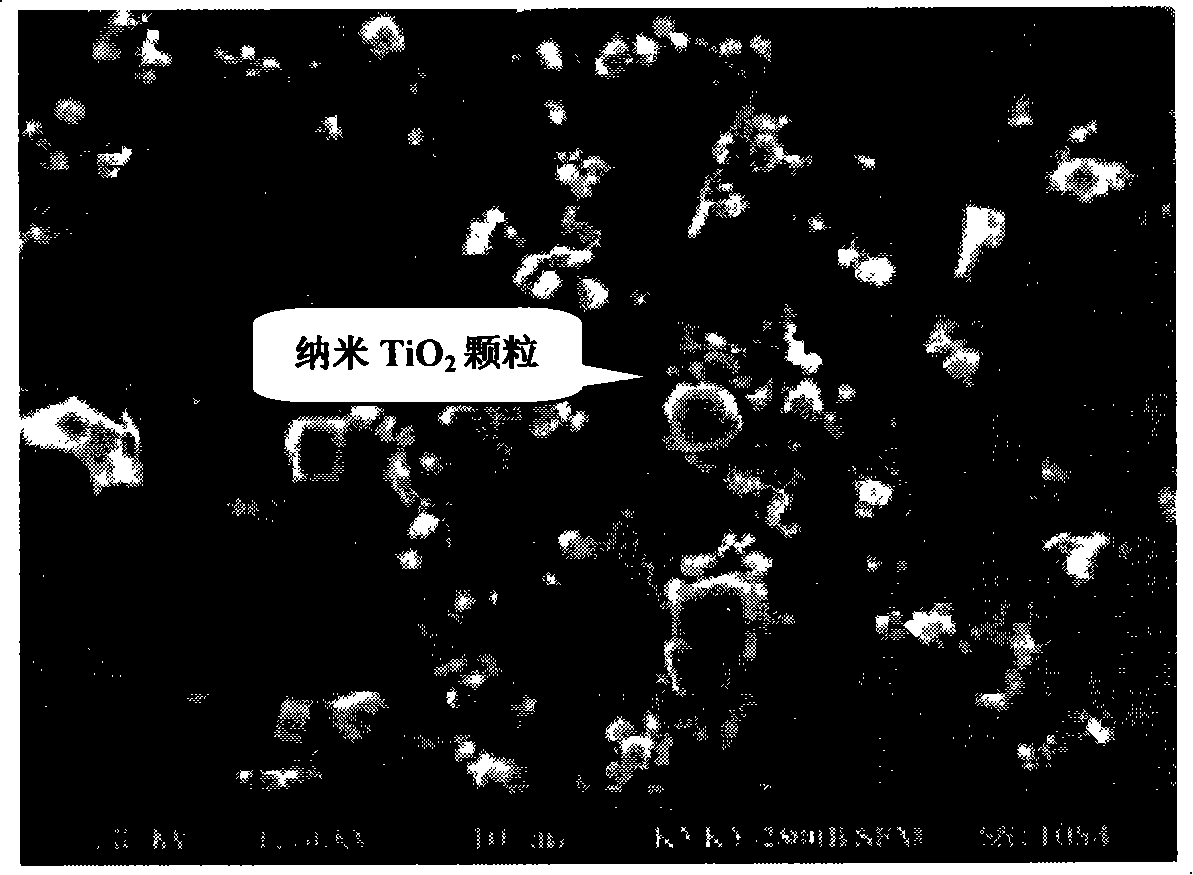

[0038] Prepare industrial pure Ni, Al, TiH 2 、Al 2 o 3 Powder, including: Ni, TiH 2 、Al 2 o 3 The particle size of the powder is 200 mesh, and the particle size of the Al powder is 100 mesh. The powder is sieved respectively, and the above powder is mixed according to: Ni: Al: TiH 2 :Al 2 o 3 =63.7%: 21.3%: 6.3%: 8.7% by mass ratio weighing and dry mixing, and then adding 4% absolute ethanol, wet mixing into mud. Using a compression molding method, the muddy mixture is made into a cylindrical compact with a diameter of Φ50 mm and a height of 100 mm. Dry the pressed embryos at 100°C for 4-8 hours to completely evaporate the ethanol. Then put the compact into a heating furnace at 300°C, and preheat for 0.5 hour. Turn on the plasma beam ignition device, adjust the plasma beam current to 100A, voltage to 40V, and beam column diameter to Φ5mm. Use plasma beam to initiate self-propagating high-temperature synthesis reaction, and NiAl+NiTi+TiAl / Al can be obtained after the ...

Embodiment 2

[0042] According to the ratio of raw materials: Ni: Al: TiH 2 :Al 2 o 3 =56.2%: 18.7%: 11.7%: 13.4% mass ratio weighing dry mixing, adding 6% absolute ethanol wet mixing into mud, other processes are the same as in Example 1. The performance of the obtained product is shown in Table 2.

[0043] Table 2

[0044]

Embodiment 3

[0046] Change the ratio of raw materials to Ni:Al:TiH 2 : Al 2 o 3 =48.6%: 16.2%: 16.7%: 18.5% mass ratio weighing dry mixing, adding 9% dehydrated alcohol wet mixing into mud, other processes are the same as in Example 1. The properties of the obtained product are shown in Table 3.

[0047] table 3

[0048]

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com