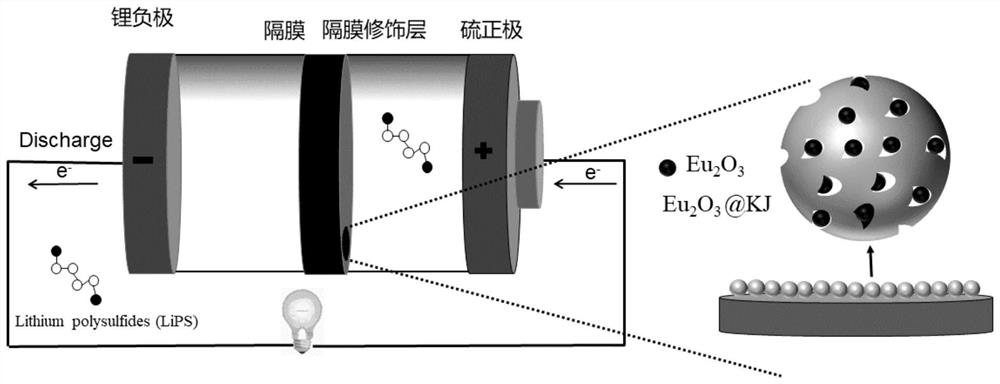

Porous carbon loaded europium oxide material as well as preparation method and application thereof

A technology of porous carbon and europium oxide, applied in electrical components, non-aqueous electrolyte storage batteries, circuits, etc., can solve the problems of complex production of positive electrode composite materials, high material production costs, and difficulty in industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

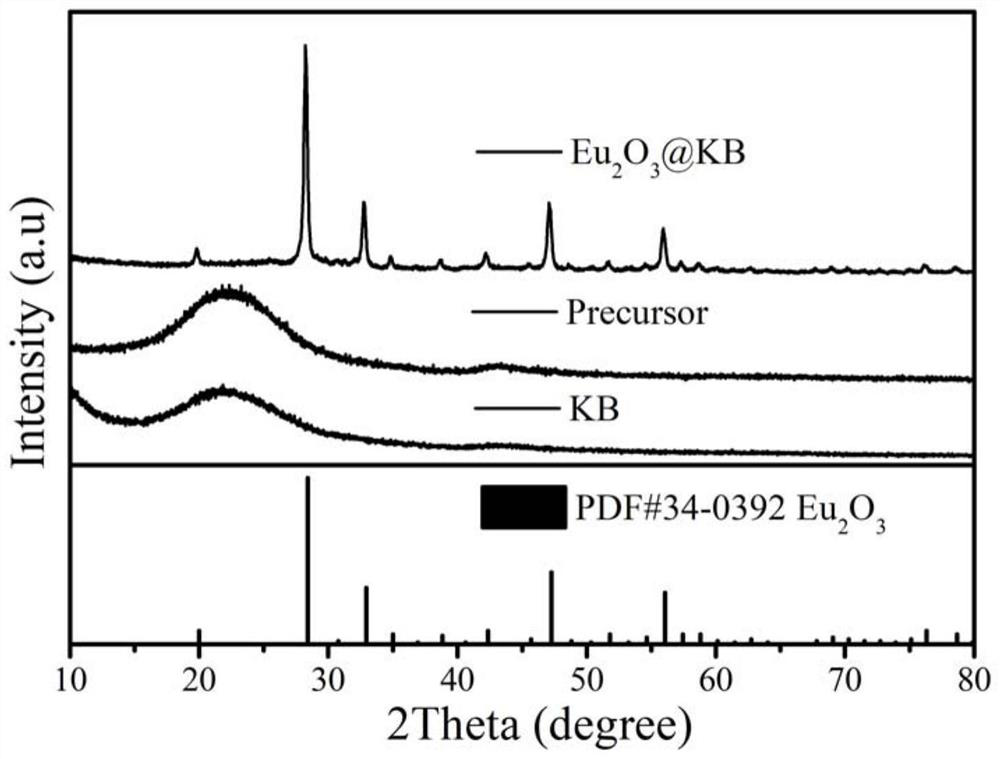

Embodiment 1

[0045]A porous carbon-supported europium oxide material. The main raw materials required for the experiment are porous carbon and europium nitrate, wherein the mass proportion of porous carbon (Ketjen black) is 60%, and the mass proportion of europium nitrate is 40%.

[0046] The above-mentioned porous carbon-supported europium oxide material can be obtained by the following steps:

[0047] (1) Weigh 200 mg of Ketjen Black into a glass beaker, add 80 ml of absolute ethanol and sonicate for 2 hours.

[0048] (2) Add 0.1mol / L Eu(NO 3 ) 3 Solution, the magnetic stirring time is 0.5h.

[0049] (3) Add concentrated ammonia water, adjust the pH value to 8.5, and magnetically stir for 1 h.

[0050] (3) The obtained solution is separated, washed, and dried to obtain a precursor.

[0051] (4) The obtained precursor was calcined at 900°C for 2 hours in a nitrogen atmosphere, and the heating rate was 5°C / min to obtain a composite material Eu 2 o 3 @KB.

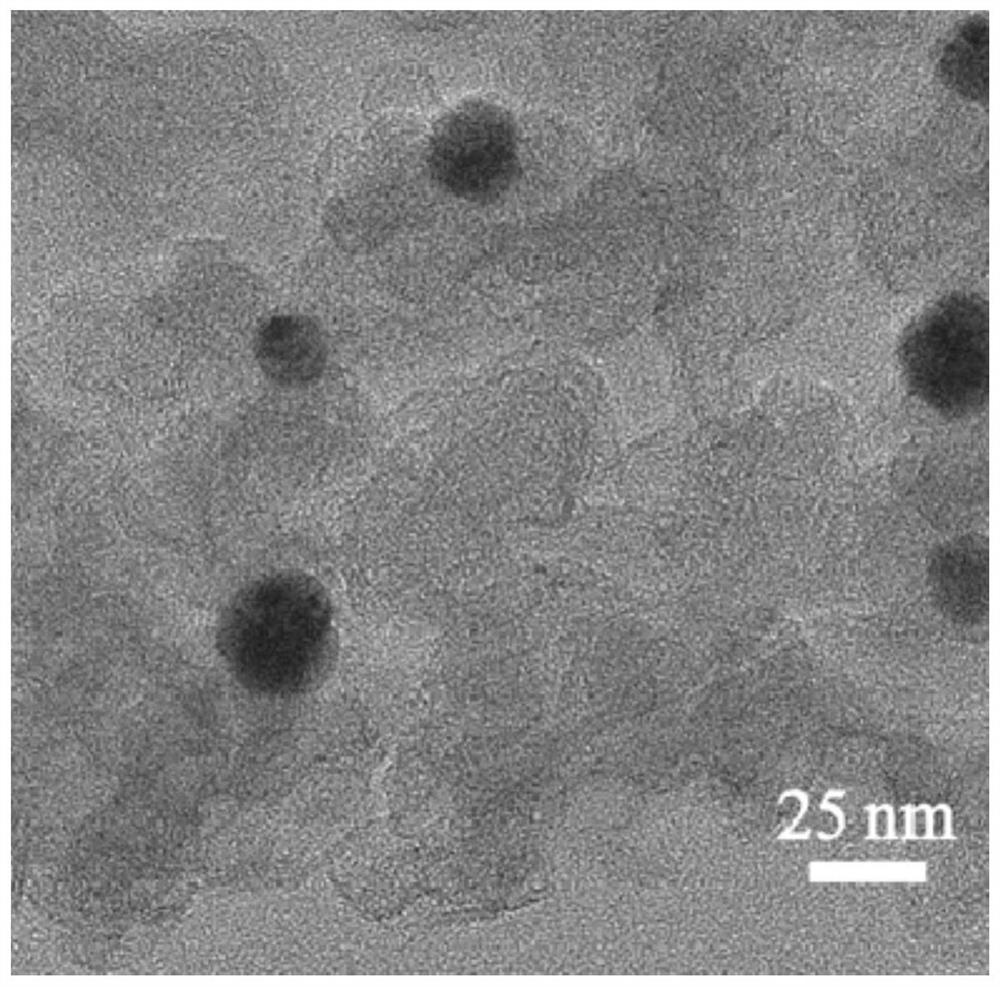

[0052] The porous carbon-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com