Low-temperature flue gas denitration agent and preparation method and application thereof

A technology of low temperature flue gas and denitrification agent, applied in the field of flue gas denitration purification, can solve the problems of low efficiency, frequent regeneration, low denitration efficiency, etc., and achieve the effect of solving technical bottlenecks, inhibiting carbon absorption performance, and enhancing denitration efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

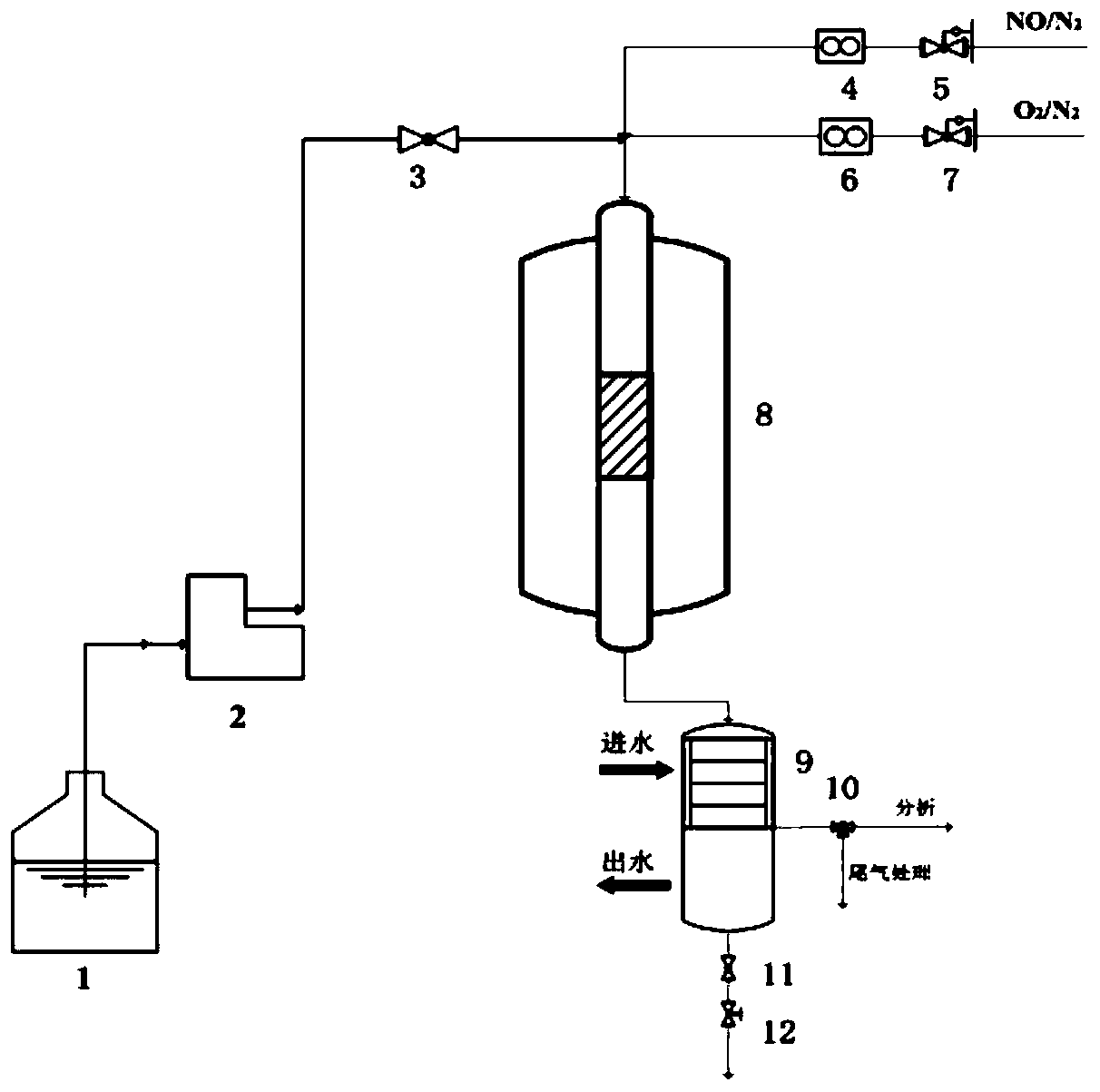

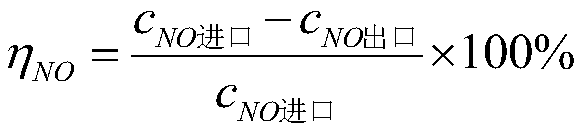

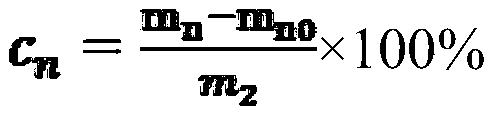

Method used

Image

Examples

Embodiment 1

[0039] Active components and content: Ca(OH) 2 (60wt.%), light CaCO 3 (10wt.%);

[0040] Auxiliary and content: Co 2 o 3 (2wt.%);

[0041] Carbon source and content: activated carbon (10wt.%);

[0042] Binder and content: kaolin (13wt.%), cement (5wt.%).

[0043] Concrete preparation method is:

[0044] 1), weigh 7g Co(NO 3 ) 2 ·6H 2 O, dissolved in 10g of deionized water to prepare a solution, weighed 10g of 200-mesh activated carbon powder, evenly impregnated the solution on the activated carbon component, dried in an oven at 110°C for 2h, and then put it in a muffle furnace under nitrogen Decompose under the atmosphere, the temperature is 400 ℃, the time is 2h;

[0045] 2), weigh 60g of Ca(OH) with particle size of 200 mesh 2 , 10g 200 mesh particle size light CaCO 3, take by weighing 13g of kaolin with a particle size of 200 mesh, 5g of cement with a particle size of 200 mesh, and mix them uniformly with the sample prepared in step 1), and add deionized water o...

Embodiment 2

[0048] Active components and content: CaO (60wt.%), light CaCO 3 (10wt.%);

[0049] Auxiliary and content: Co 2 o 3 (2wt.%);

[0050] Carbon source and content: activated carbon (10wt.%);

[0051] Binder and content: kaolin (13wt.%), cement (5wt.%).

[0052] Concrete preparation method is:

[0053] 1), weigh 7g Co(NO 3 ) 2 ·6H 2 O, dissolved in 10g of deionized water to prepare a solution, weighed 10g of 200-mesh activated carbon powder, evenly impregnated the solution on the activated carbon component, dried in an oven at 110°C for 2h, and then put it in a muffle furnace under nitrogen Decompose under the atmosphere, the temperature is 400 ℃, the time is 2h;

[0054] 2), weigh 60g of CaO with particle size of 200 mesh, 10g of light CaCO with particle size of 200 mesh 3 , Weigh 13g of kaolin with a particle size of 200 mesh, 5g of cement with a particle size of 200 mesh, and mix them evenly with the sample prepared in step 1), and add 54g of deionized water by weight...

Embodiment 3

[0057] Active components and content: Ca(OH) 2 (70wt.%);

[0058] Auxiliary and content: Co 2 o 3 (2wt.%);

[0059] Carbon source and content: activated carbon (10wt.%);

[0060] Binder and content: kaolin (13wt.%), cement (5wt.%).

[0061] Concrete preparation method is:

[0062] 1), weigh 7g Co(NO 3 ) 2 ·6H 2 O, dissolved in 10g of deionized water to prepare a solution, weighed 10g of 200-mesh activated carbon powder, evenly impregnated the solution on the activated carbon component, dried in an oven at 110°C for 2h, and then put it in a muffle furnace under nitrogen Decompose under the atmosphere, the temperature is 400 ℃, the time is 2h;

[0063] 2), weigh 70g of Ca(OH) with particle size of 200 mesh 2 , take by weighing 13g of kaolin with a particle size of 200 mesh and 5g of cement with a particle size of 200 mesh, mix them evenly with the sample prepared in step 1), add 35g of deionized water, and knead in a kneader for 1h;

[0064] 3) Extrude the sample knea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com