A method for removing impurities and improving quality of solid waste pyrolysis liquid phase product and product

A pyrolysis liquid and product technology, applied in the preparation of liquid hydrocarbon mixtures, biological raw materials, liquid carbon-containing fuels, etc., can solve the problems of inconvenient separation and utilization, achieve effective disposal, reduce the generation of pollutants, and ensure effective absorption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

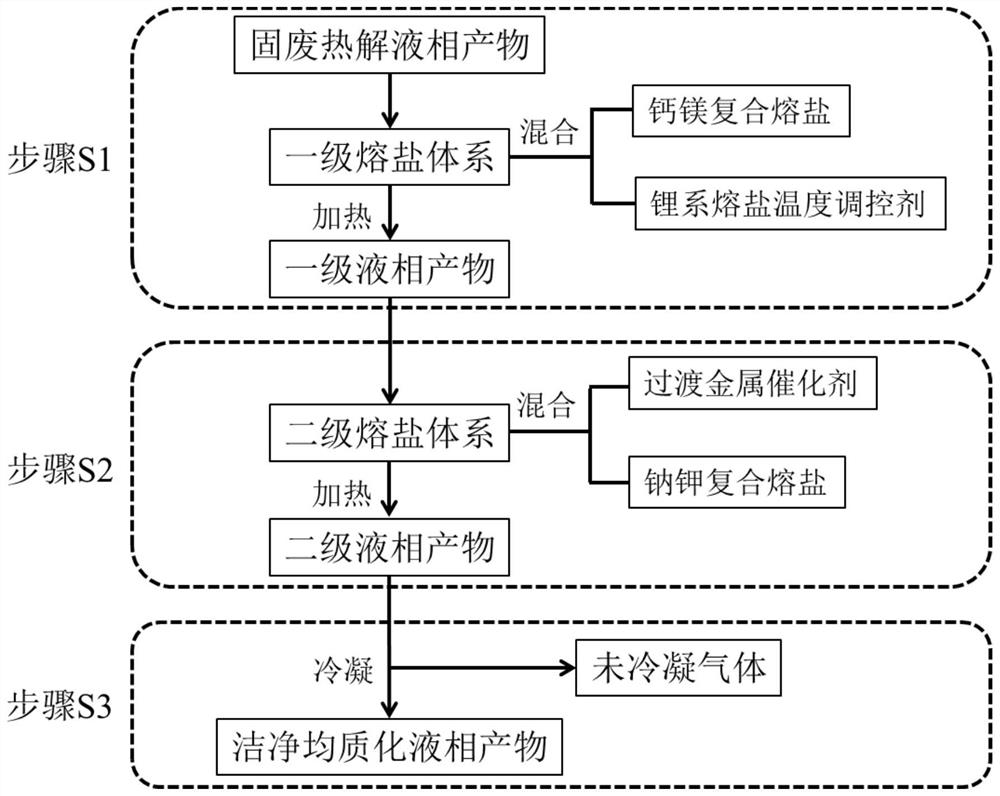

Method used

Image

Examples

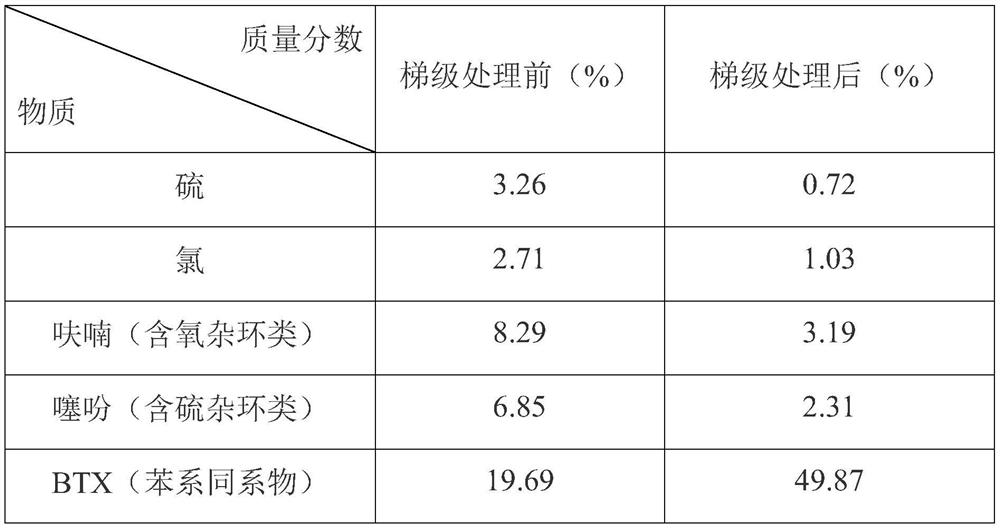

Embodiment 1

[0036] (a) LiOH and LiHCO 3 Mix according to the mass ratio of 1:1 to obtain lithium-based molten salt temperature regulator, Ca(OH) 2 and Mg(OH) 2 Mixing according to the mass ratio of 1:1 to obtain calcium-magnesium composite molten salt, and then mixing the above-mentioned lithium-based molten salt temperature regulator and calcium-magnesium composite molten salt according to the mass ratio of 1:2 to obtain a primary molten salt system;

[0037] (b) The mixture of sawdust pyrolysis liquid phase products and rubber pyrolysis liquid phase products is introduced into the primary molten salt system by means of argon gas, heated to 400 ° C and kept for 40 minutes, so as to achieve low temperature removal of impurities and obtain Primary liquid phase product;

[0038] (c) Fe 2 (CO 3 ) 3 : Cr 2 o 3 ·xCO 2 ·yH 2 O: NiCO 3 According to the mass ratio of 1:1:1 mixed to obtain the transition metal catalyst, the Na 2 CO 3 and K 2 CO 3 Mixing according to the mass ratio of...

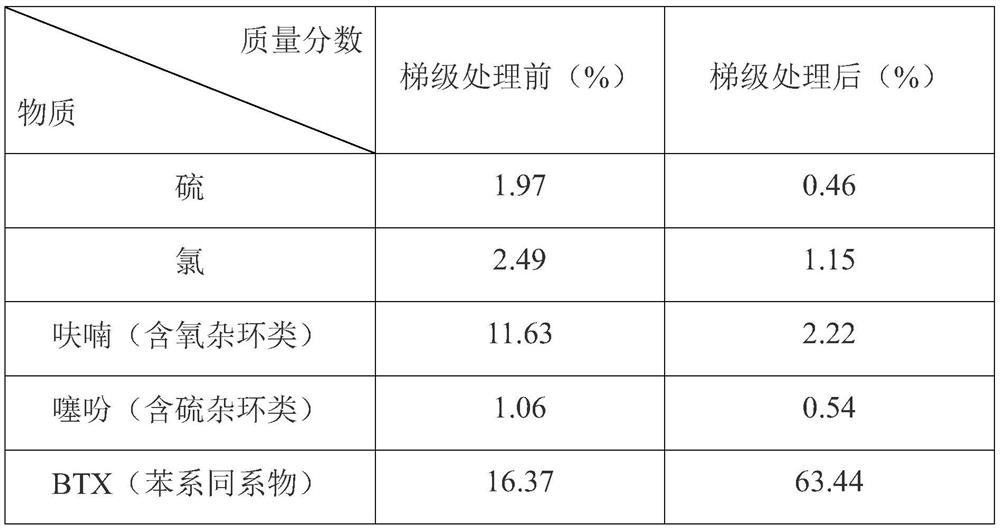

Embodiment 2

[0045] (a) LiOH single substance is used as a lithium-based molten salt temperature regulator, and Ca(OH) 2 and Mg(OH) 2 Mixing according to a mass ratio of 1:1 to obtain a calcium-magnesium composite molten salt, and then mixing the above-mentioned lithium-based molten salt temperature regulator and calcium-magnesium composite molten salt according to a mass ratio of 1:4 to obtain a primary molten salt system;

[0046] (b) Introduce the mixture of wood chip pyrolysis liquid phase products and plastic pyrolysis liquid phase products into the primary molten salt system by means of argon gas, heat to 600°C and keep it warm for 20 minutes, so as to achieve low temperature removal of impurities and obtain Primary liquid phase product;

[0047] (c) Fe 2 (CO 3 ) 3 : NiCO 3 According to the mass ratio of 1:1 mixed to obtain the transition metal catalyst, the Na 2 CO 3 and K 2 CO 3 Mixing according to the mass ratio of 1:1 to obtain sodium-potassium composite molten salt, and...

Embodiment 3

[0055] (a) LiHCO 3 A single substance is used as a lithium-based molten salt temperature regulator, and Ca(OH) 2 and Mg(OH) 2 Mixing according to the mass ratio of 2:1 to obtain calcium-magnesium composite molten salt, and then mixing the above-mentioned lithium-based molten salt temperature regulator and calcium-magnesium composite molten salt according to the mass ratio of 2:5 to obtain a primary molten salt system;

[0056] (b) Introduce the mixture of wood chip pyrolysis liquid phase products, plastic pyrolysis liquid phase products and rubber pyrolysis liquid phase products into the primary molten salt system by means of helium gas carrying, heat to 600°C and keep it warm for 30min, to This achieves low-temperature removal of impurities and obtains a first-level liquid phase product;

[0057] (c) NiCO 3 A single substance acts as a transition metal catalyst, Na 2 CO 3 and K 2 CO 3 Mixing according to the mass ratio of 1:1 to obtain sodium-potassium composite molten...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com