Preparation method of conjugated microporous polyaniline modified battery current collector and application of conjugated microporous polyaniline modified battery current collector in lithium-sulfur battery

A technology of conjugated microporous and polyaniline, applied in the application of lithium-sulfur batteries, the field of preparation of conjugated microporous polyaniline modified battery current collectors, can solve the problem that the stability of conductive polymers needs to be further improved, and the polarity cannot be improved. The strong chemical adsorption energy of lithium polysulfide and the irregular pore size distribution of conductive polymers have achieved the effects of facilitating ion/electron transfer, inhibiting the shuttle effect, and hindering the shuttle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0031] It should be noted that the present invention evaluates the performance of the prepared modified current collector through the stability, cycle life and change of sulfur loading of the lithium-sulfur battery. The specific method is as follows:

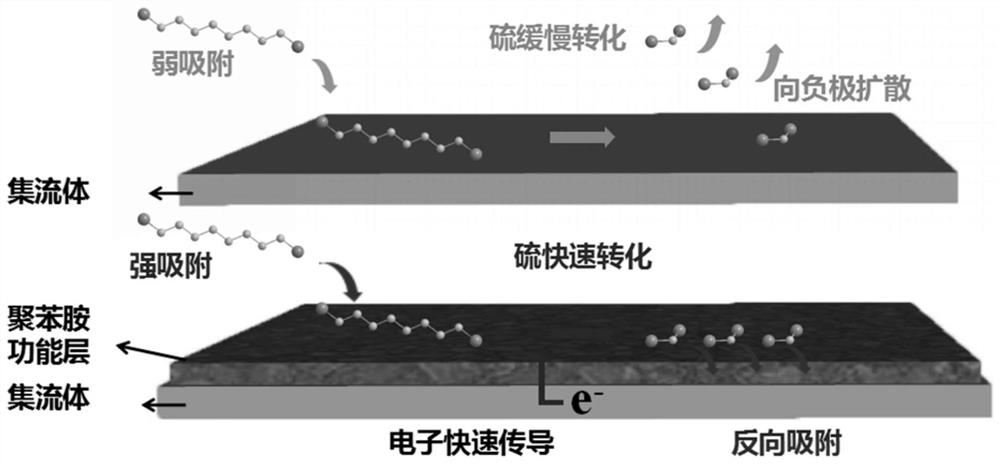

[0032] For the conductive polyaniline functional layer of the lithium-sulfur battery current collector, the positive electrode reaction of the lithium-sulfur battery is optimized through a simple commercial electrode modification method, so as to achieve the effect of improving the overall performance of the lithium-sulfur battery.

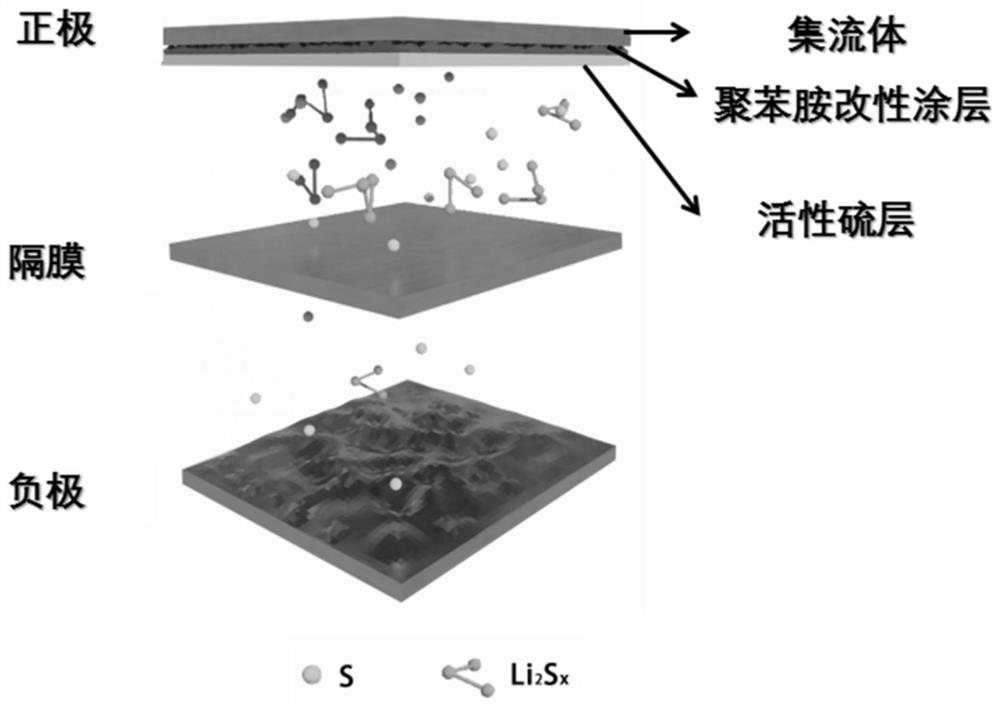

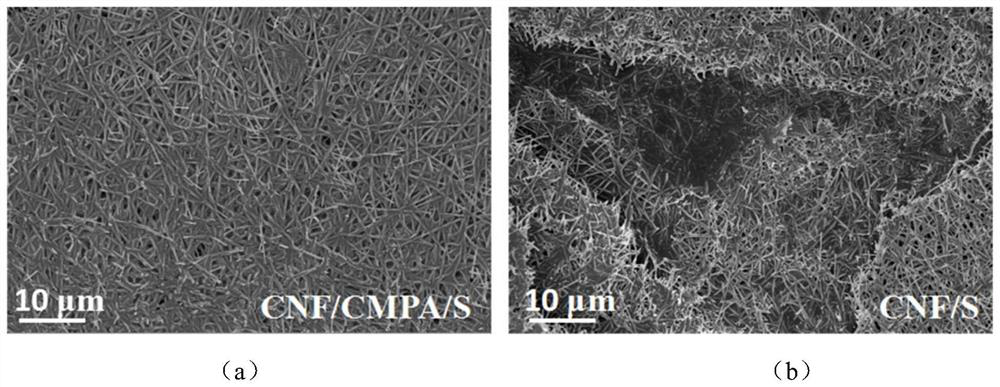

[0033] The current collector with conjugated microporous polyaniline modified coating prepared by the present invention can realize the function of adsorbing polysulfides to suppress the shuttle effect and buffer and protect the structure of the current collector, and can also ensure efficient electron transmission from the external circuit ; When applied to lithium-sulfur batteries, the current col...

Embodiment 1

[0051] Step 1: Dissolve 0.5g of tris(4-bromoaniline) and 0.5g of p-phenylenediamine in 30mL of anhydrous tetrahydrofuran solution, heat and stir at 60°C for 1.5h to form a solution to be reacted;

[0052] Step 2, add sodium persulfate (0.3g), XPhos (0.045g), Pd(dba) to step 1 gained solution to be reacted 2 (0.045g), NaOtBu (3.5g) and NaF (0.5g) and insert nitrogen, vacuumize, stir at 65°C for 48h, and carry out the polymerization reaction of polyaniline;

[0053] Step 3, after the polymerization reaction in step 2 is completed, the product is washed with 200mL CHCl 3 , ethanol, methanol and boiling water to remove catalysts, impurities and oligomers, and then Soxhlet extraction with methanol for 24 hours, tetrahydrofuran for 24 hours and chloroform for 24 hours, then vacuum dried at 60°C for 48 hours, and triturated to obtain micro Porous polyaniline powder (CMPA, Conjugatedmicroporous polyaniline), hereinafter all use CMPA to refer to the synthesized microporous polyaniline...

Embodiment 2

[0064] Step 1: Dissolve 0.5g of tris(4-bromoaniline) and 0.5g of p-phenylenediamine in 30mL of anhydrous tetrahydrofuran solution, heat and stir at 60°C for 1.5h to form a solution to be reacted;

[0065] Step 2, add sodium persulfate (0.5g), XPhos (0.08g), Pd(dba) to step 1 gained solution to be reacted 2 (0.08g), NaOtBu (4g) and NaF (0.5g) and insert nitrogen, vacuumize, stir at 50°C for 48h, and carry out the polymerization reaction of polyaniline;

[0066] Step 3, after the polymerization reaction in step 2 is completed, the product is washed with 200mL CHCl 3 , ethanol, methanol, and boiling water to remove catalysts, impurities, and oligomers, then Soxhlet extraction with methanol for 24 hours, THF for 24 hours, and chloroform for 24 hours for 72 hours, then vacuum-dried at 60°C for 48 hours, and triturated to obtain micro Porous polyaniline powder (CMPA, Conjugatedmicroporous polyaniline), hereinafter all use CMPA to refer to the synthesized microporous polyaniline;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com