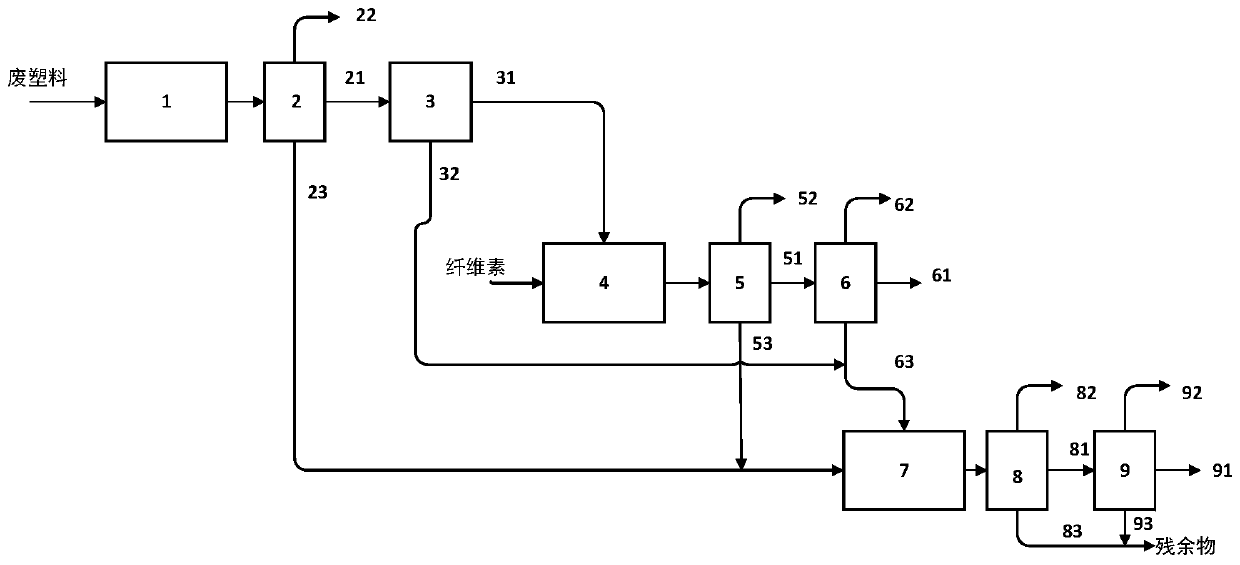

A method of processing waste plastics and cellulose

A technology for waste plastics and cellulose, which is used in hydrotreating process, petroleum industry, preparation of liquid hydrocarbon mixtures, etc., can solve problems such as large gaps in process conditions, reduce the amount of insoluble matter, improve the conversion rate, promote dissolution and The effect of catalytic conversion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056]Select a total of 2g of a mixture of 50wt% HDPE, 30wt% PET, and 20wt% PS as the raw material for the reaction of waste plastics, and add it to the slurry bed catalytic cracking reactor A, under the catalytic action of catalyst 1-A. For the catalytic cracking reaction, the amount of catalyst 1-A added is 12% of the total mass of waste plastics. The reaction conditions for the catalytic cracking reaction are as follows: the reaction temperature is 455°C, the reaction time is 60 minutes, and the stirring rate is 440 rpm. It is necessary to feed hydrogen gas into the catalytic reactor A, the hydrogen partial pressure is 2.8MPa, and the product after the reaction is separated to obtain liquid product I, gas I and insoluble matter I; the liquid product I is cooled to room temperature and then passed into tetrahydrofuran and cyclohexane mixed solvent for extraction, the mass ratio of tetrahydrofuran and cyclohexane mixed solvent to liquid product I is 1.8:1, wherein the mass rat...

Embodiment 2

[0059] Just change the reaction condition of the catalytic cracking reaction that carries out in the slurry bed catalytic cracking reactor A among the embodiment 1: temperature of reaction is 460 ℃, and the reaction times is 110 minutes, and stirring rate is 480 rev / mins, needs in the reaction to Pass into hydrogen in the slurry bed catalytic cracking reactor A, hydrogen partial pressure is 3.6MPa, the condition of slurry bed catalytic cracking reactor C carrying out deep catalytic cracking reaction is changed: reaction temperature is 575 ℃, and reaction time is 120 minutes, The stirring rate is 500 rpm, and the reaction needs to feed hydrogen into the slurry bed catalytic cracking reactor C, and the hydrogen partial pressure is 7.4MPa.

Embodiment 3

[0061] Just change the catalyst 1-A in the embodiment 1 into the catalyst 1-B, and the others are the same as the embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com