Lithium-sulfur battery positive electrode material and preparation method thereof

A cathode material and a technology for sulfur batteries, which are applied in the field of cathode materials for lithium-sulfur batteries and their preparation, can solve the problems of reduced Coulomb efficiency, reduced utilization rate of active materials, poor electrical conductivity, etc., achieve simple preparation steps and equipment, and improve cycle Stable and easy to use in industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

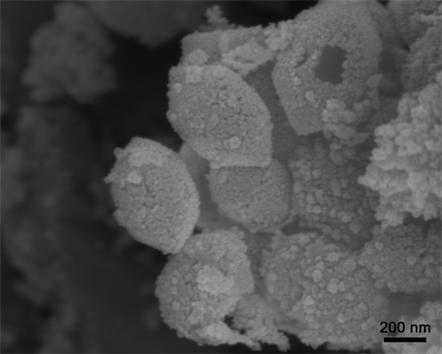

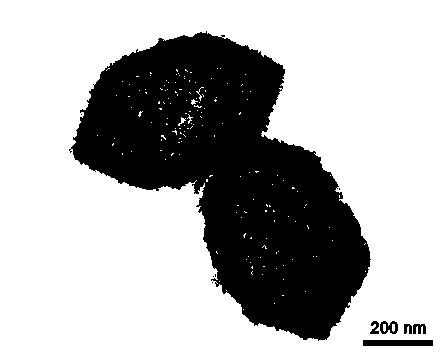

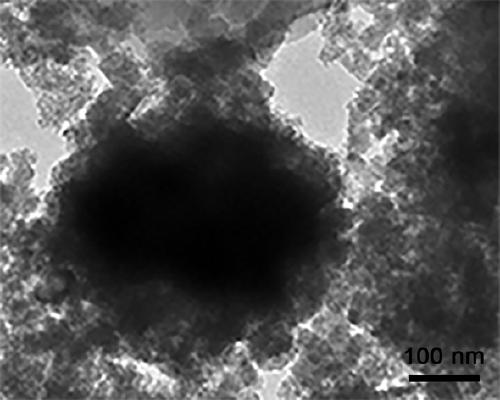

[0035] A lithium-sulfur battery positive electrode material, the positive electrode material includes a hollow positive electrode carrier material: cobalt-iron double hydroxide and sulfur particles filled in the carrier material.

[0036] A preparation method of lithium-sulfur battery cathode material, comprising the following steps:

[0037] Step 1. Stir and mix the iron source, fumaric acid and N,N-dimethylformamide solution to obtain a mixed solution; transfer the mixed solution to an autoclave, heat up to 80~100°C, and react for 2~5 h, cooled to room temperature, centrifuged, collected the precipitate, and obtained the precursor Fe-MOFs material;

[0038] Step 2. Fully wash the Fe-MOFs obtained in Step 1 with DMF solution, and dry at a temperature of 75-85°C for 12-24 h, and set aside;

[0039]Step 3, ultrasonically disperse the Fe-MOFs material obtained in step 2 in absolute ethanol to obtain solution A, dissolve the cobalt source and urea with a molar ratio of 2 to 3:1 ...

Embodiment 2

[0048] A lithium-sulfur battery positive electrode material, the positive electrode material includes a hollow positive electrode carrier material: cobalt-iron double hydroxide and sulfur particles filled in the carrier material.

[0049] A preparation method of lithium-sulfur battery cathode material, comprising the following steps:

[0050] Step 1. Prepare the precursor Fe-MOFs material by solvothermal method, specifically stirring and mixing the iron source, fumaric acid and N,N-dimethylformamide solution to obtain a mixed solution; transfer the mixed solution to high pressure In the kettle, the temperature was raised to 100 ° C, reacted for 3 h, cooled to room temperature, centrifuged, washed with DMF solution three times, and dried at 80 ° C for 12 h to obtain the Fe-MOFs material;

[0051] Step 2. Fully wash the Fe-MOFs obtained in Step 1 with DMF solution, and dry at a temperature of 75-85°C for 12-24 h, and set aside;

[0052] Step 3, ultrasonically disperse the Fe-MO...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com