Speed change control mechanism and medium-pressure servo gear shifting power-assistance air cylinder thereof

A booster cylinder and medium pressure technology, which is applied to mechanical equipment, components with teeth, belts/chains/gears, etc., can solve problems such as lack of follow-up function, inability to realize control feel, and high cost of vehicle manufacturers. Achieve the effect of improving the control experience, good versatility, and enhancing the control feel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

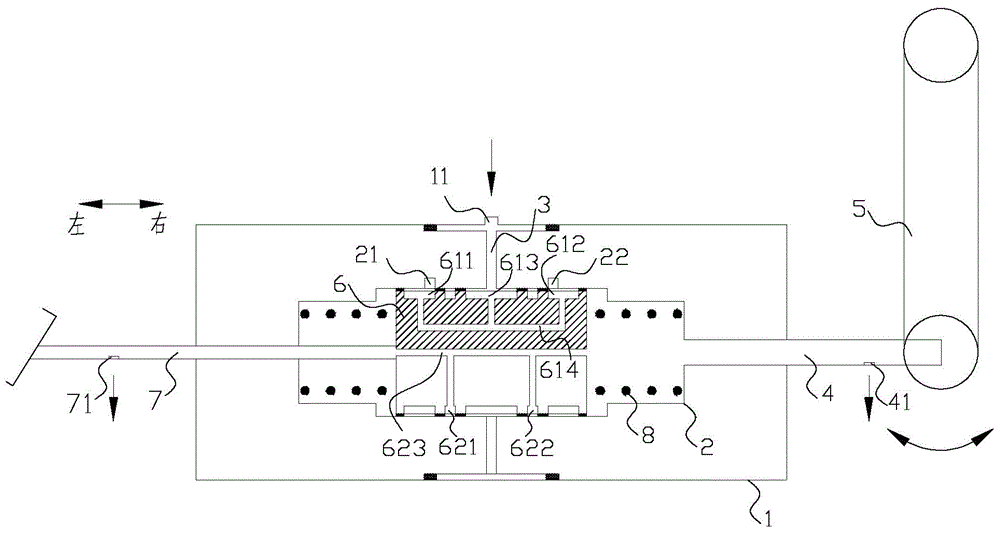

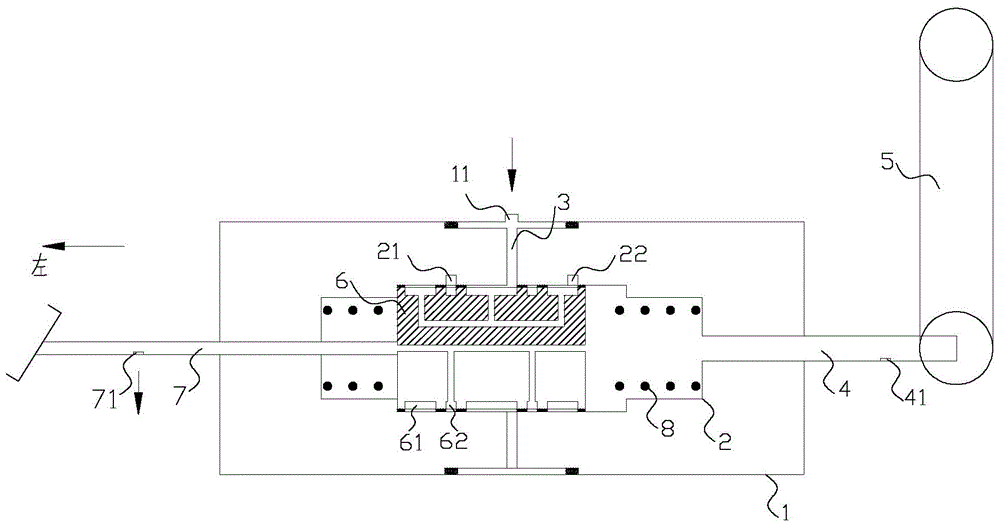

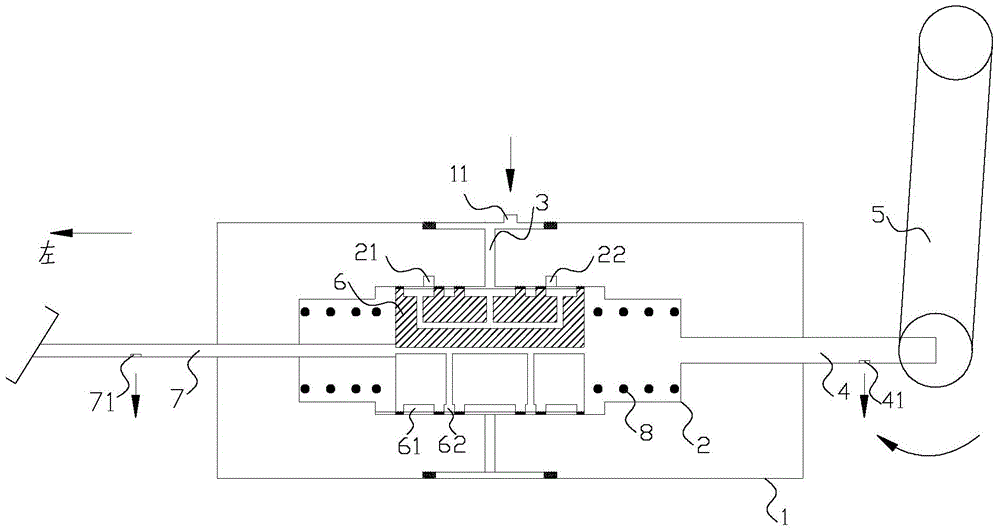

[0039] The core of the present invention is to provide a medium-pressure servo shift booster cylinder, which realizes the follow-up function during the shifting process, so that the operator can perceive the execution state of the shifting action during the shifting process, thereby improving the control experience. In addition, another object of the present invention is to provide a transmission operating mechanism using the air cylinder.

[0040] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0041] It should be noted that the orientation word "outside" in this article refers to the direction from the center of the cylinder to up, down, left, right, etc., and "inside" refers to the direction from the cylinder's up, down, left, right, etc. Pointing to the direction of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com