Patents

Literature

91results about How to "Meet the needs of installation and use" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

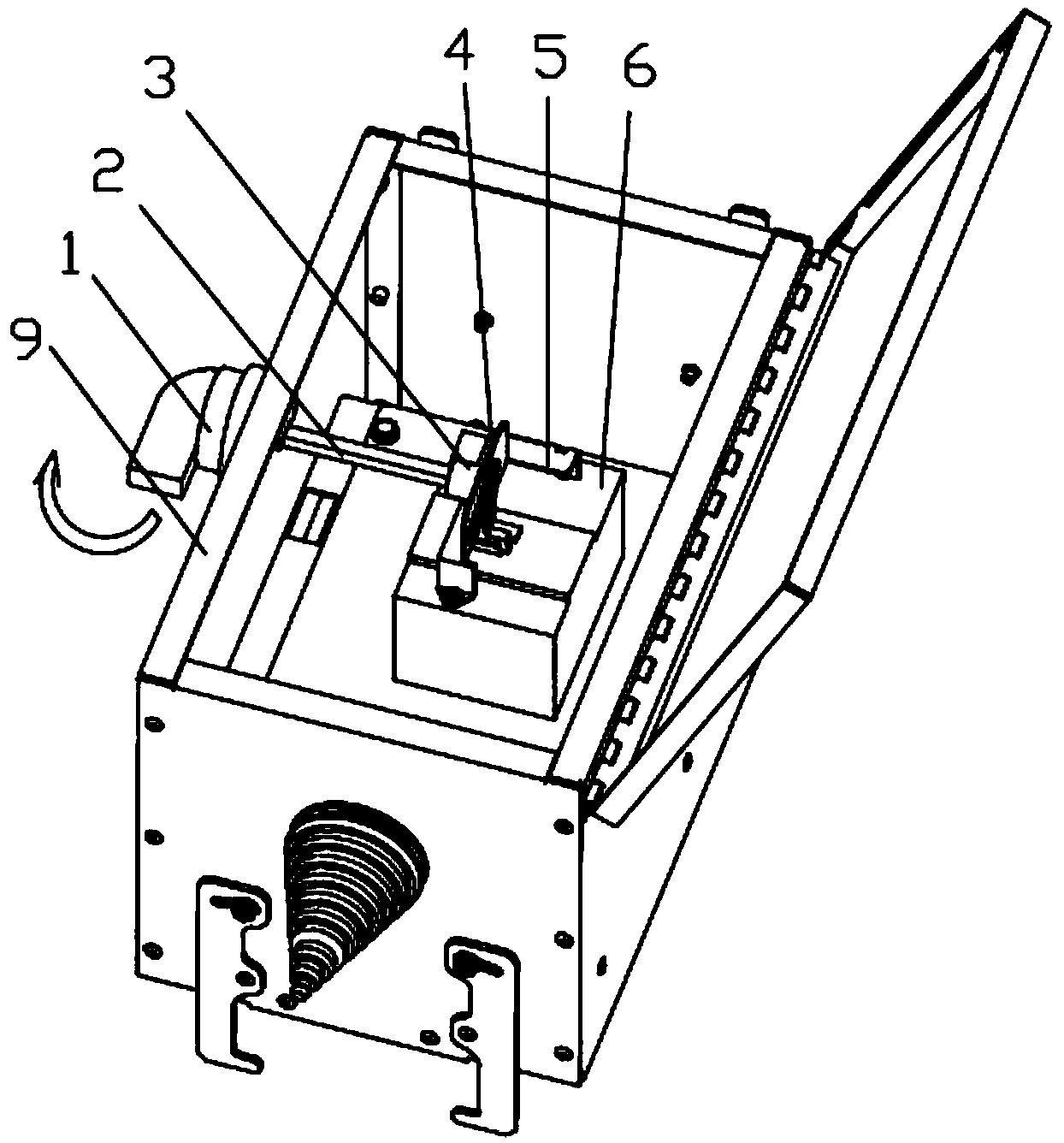

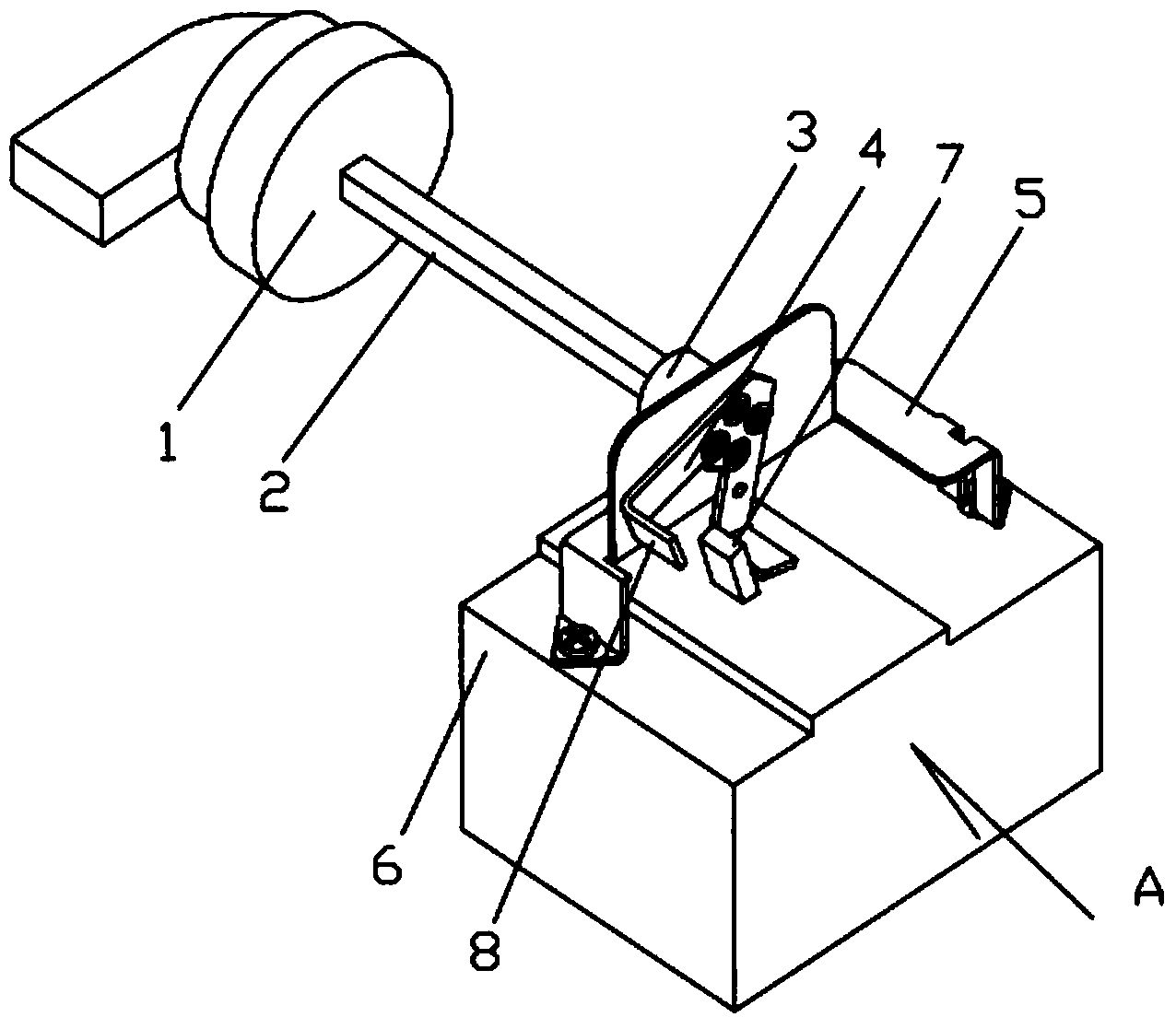

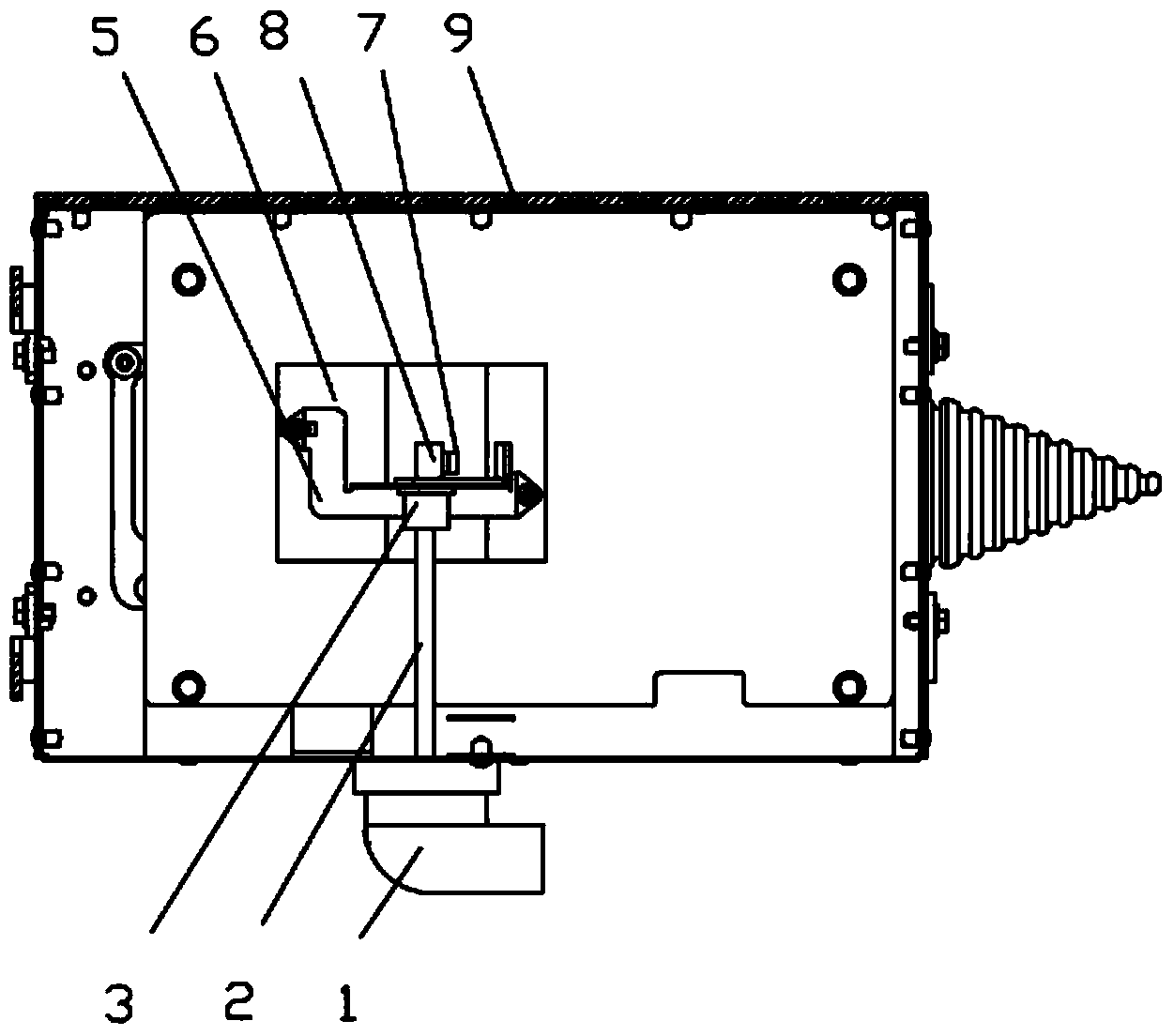

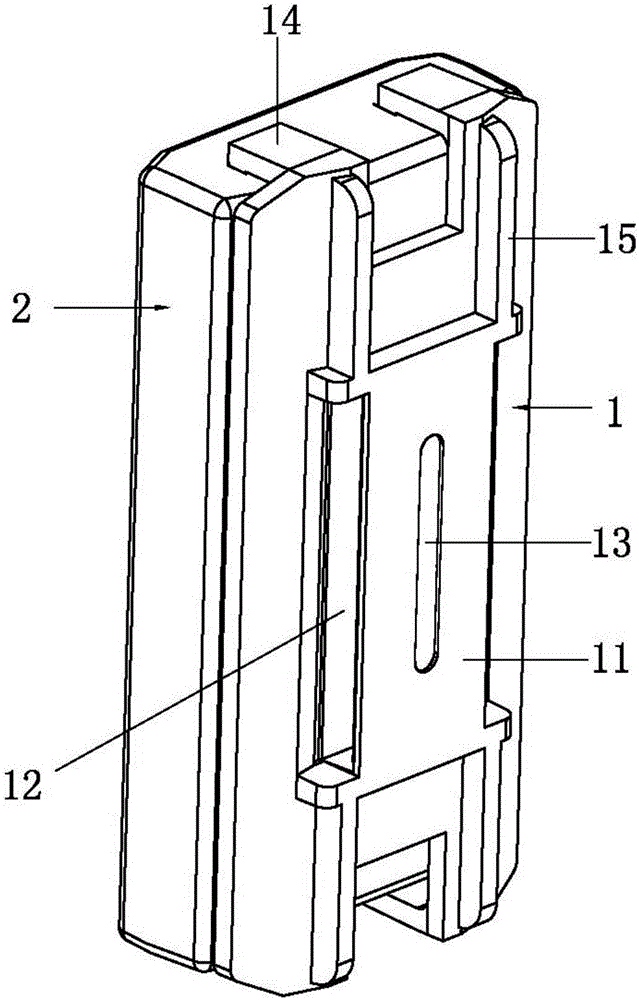

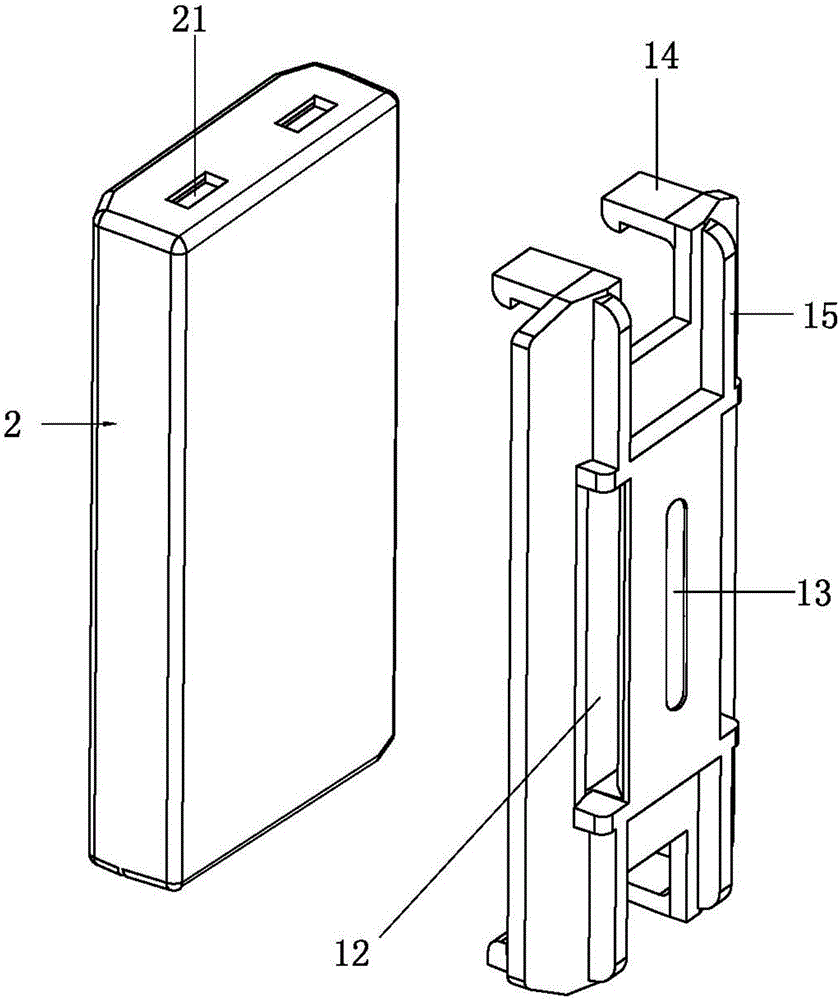

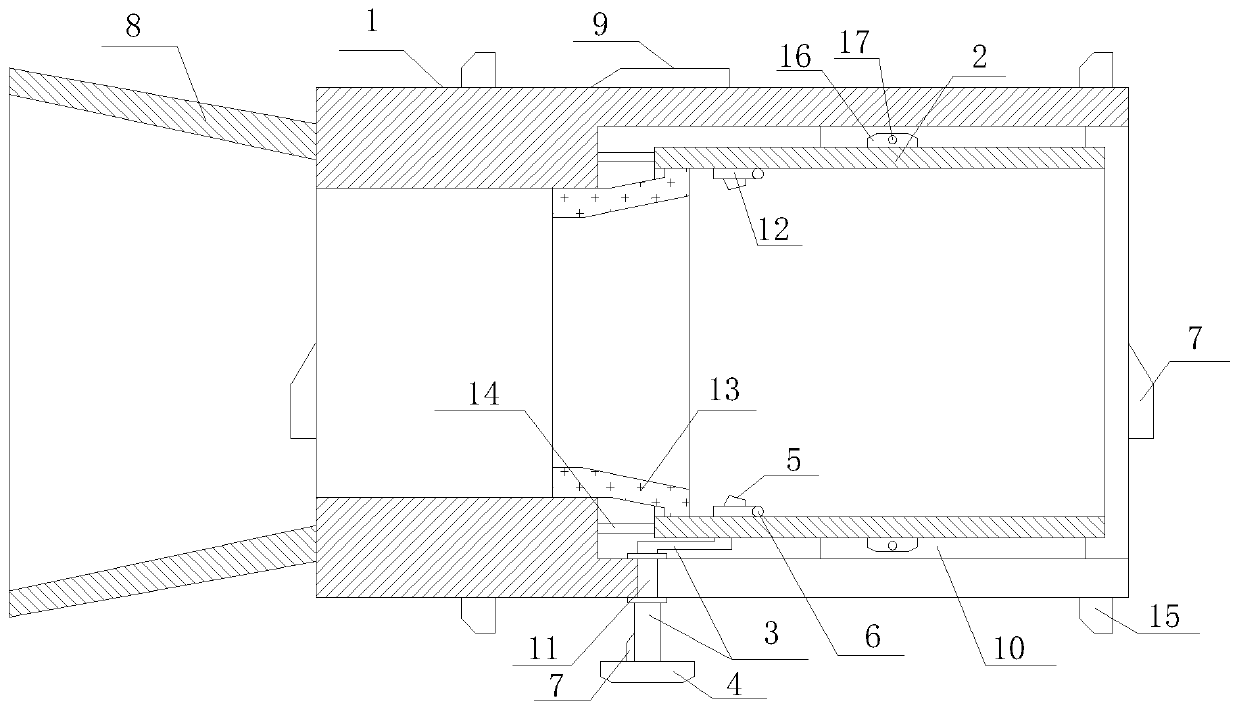

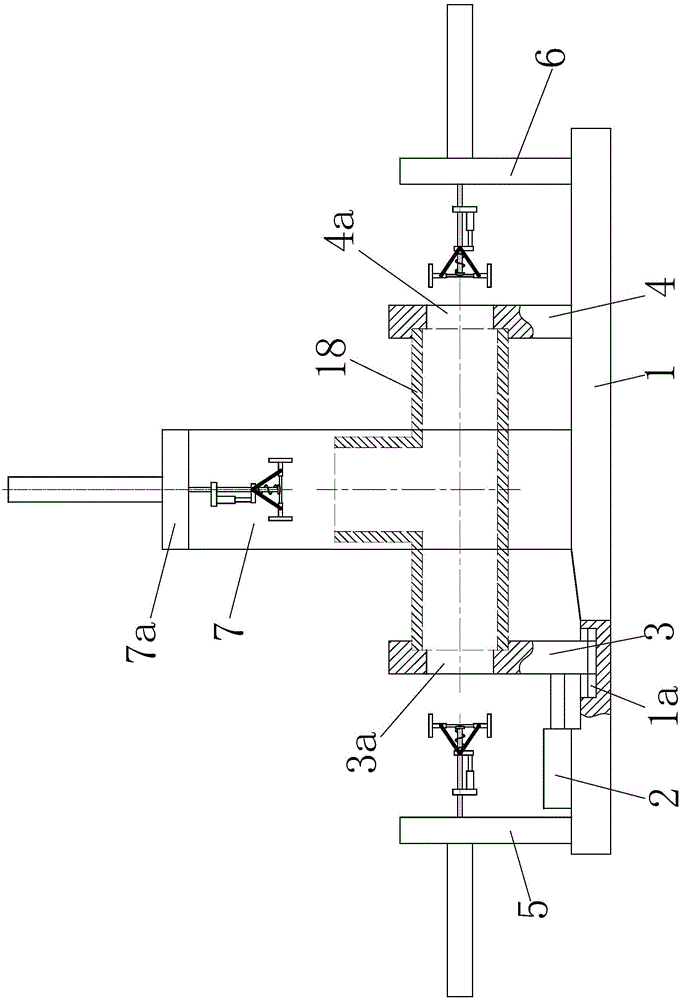

Bus duct plug box

ActiveCN104242196ACompact structureMeet the needs of installation and useBus-bar installationElectrical connectionEngineering

The invention relates to a bus duct plug box and belongs to the technical field of electrical connection facilities. The plug box comprises a breaker arranged in a box body, the breaker is provided with a switching gate handle extending out of the upper surface of the breaker, a main rotary shaft is supported in the box body, one end of the main rotary shaft extends out of one side of the box body, the outer extending end of the main rotary shaft is fixedly connected with a rotary handle, the inner extending end of the main rotary shaft is fixedly connected with guide jaws, and the lower ends of the guide jaws horizontally extend to form poking fingers located on the two sides of the switching gate handle respectively. Due to adoption of the sideward arrangement structure, the upper portion of the breaker does not need to have space for holding rocker supports and other actuation components and the structure is compact. Additionally, points where the poking fingers exert force on the switching gate handle are gradually moved downwards in the poking process, the length of a resistance arm of the switching gate handle is reduced while the lengths of power arms of the guide jaws are kept unchanged, and it is guaranteed that follow-up performance of the switching gate handle is better.

Owner:镇江西门子母线有限公司

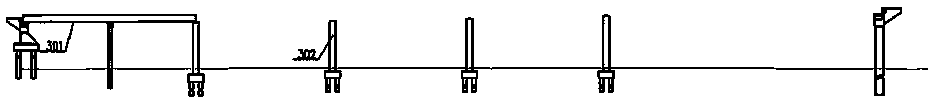

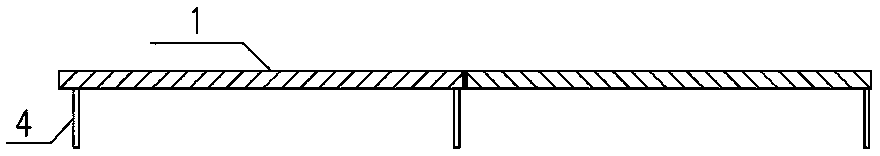

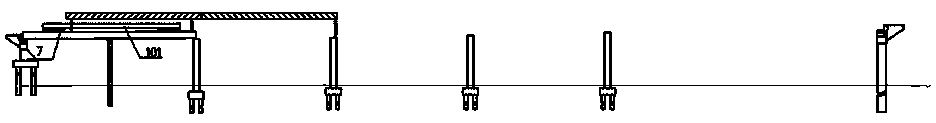

Method for constructing reinforced concrete combined beam in under-beam beam transporting mode

ActiveCN108004932AImprove the state of stressMeet the needs of installation and useBridge erection/assemblyBridge materialsReinforced concreteStressed state

The invention discloses a method for constructing a reinforced concrete combined beam in an under-beam beam transporting mode. The method includes the steps that a steel truss is mainly used for connecting prefabricated steel beam units, a girder of a lifting device is formed to substitute a bridge girder erection machine, and the construction cost of a middle-small-span assembled bridge is reduced. Multiple rows of slings are used in a matched mode in the construction process for installation of steel beams, the stress state of the girder in the construction process can be effectively improved, the installation and use requirements of the reinforced concrete combined beam can be met, cost can be prevented from being increased, no construction process needs to be added, the beneficial effects that the method is simple, and construction is convenient and quick are achieved, practicability is quite high, and application prospects are wide.

Owner:HENAN PROVINCIAL COMM PLANNING & DESIGN INST CO LTD +2

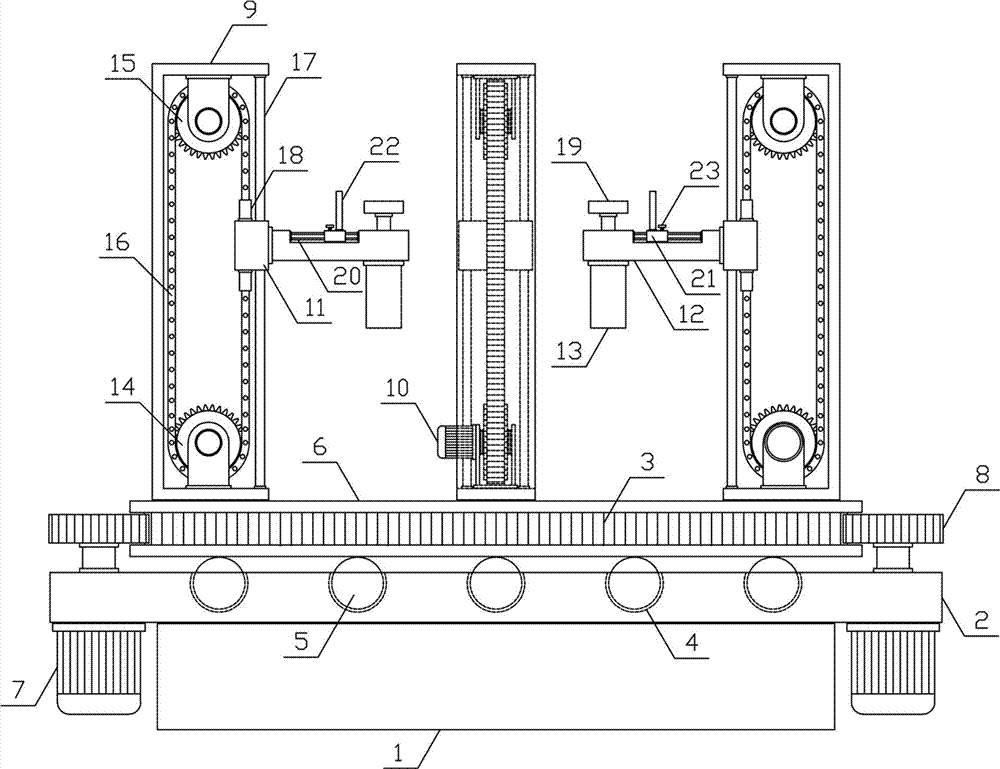

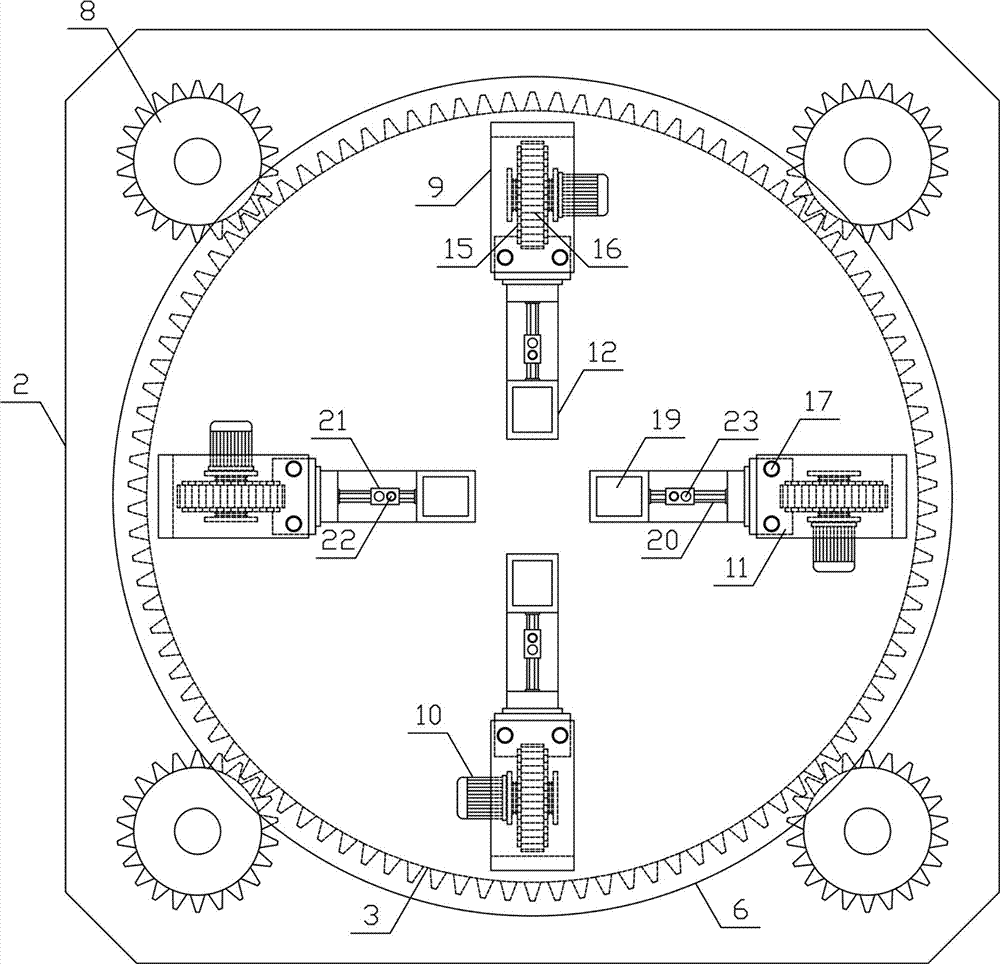

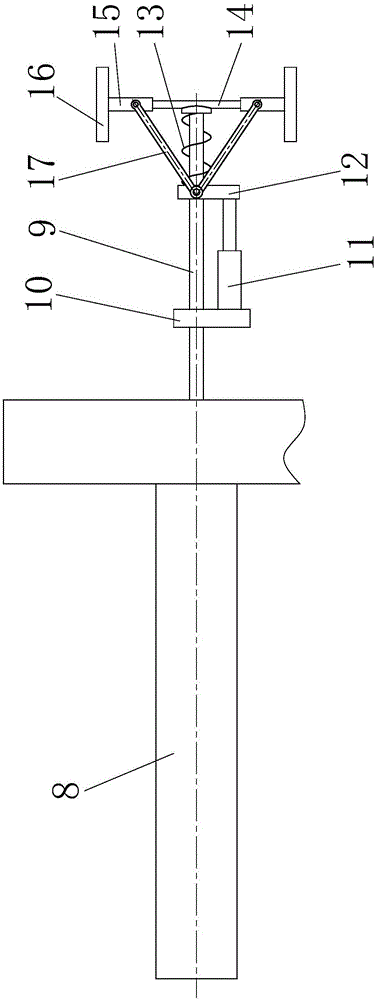

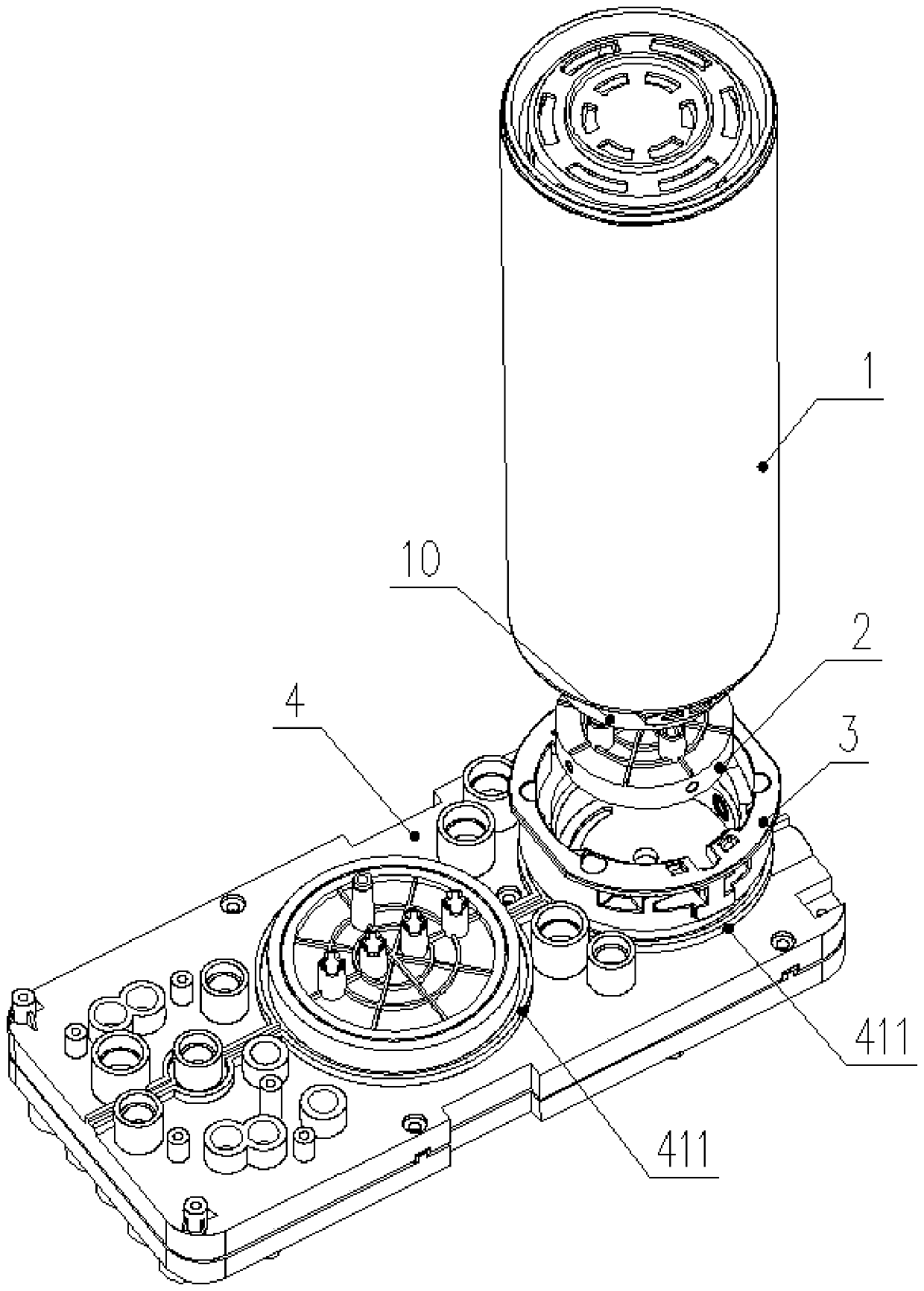

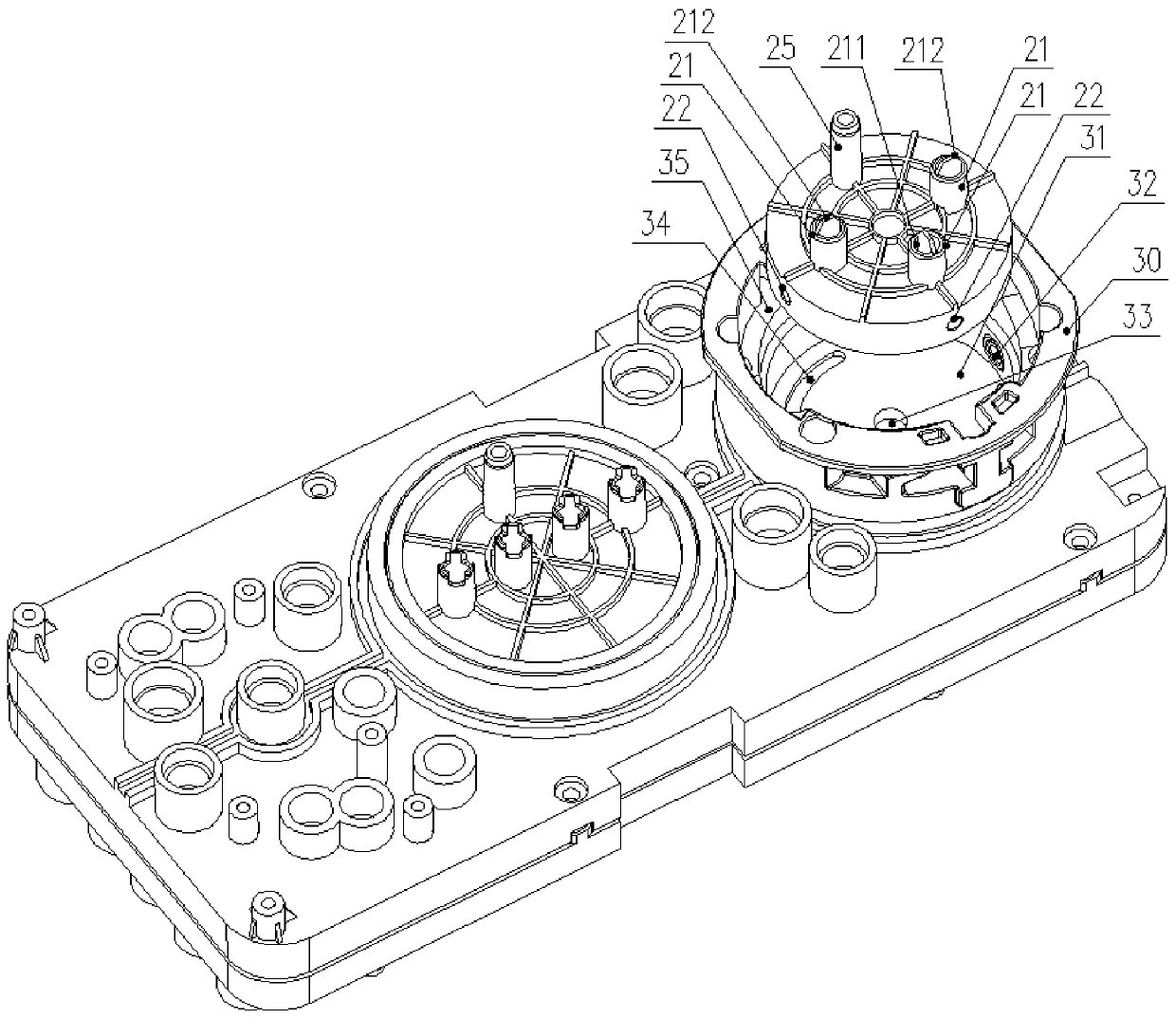

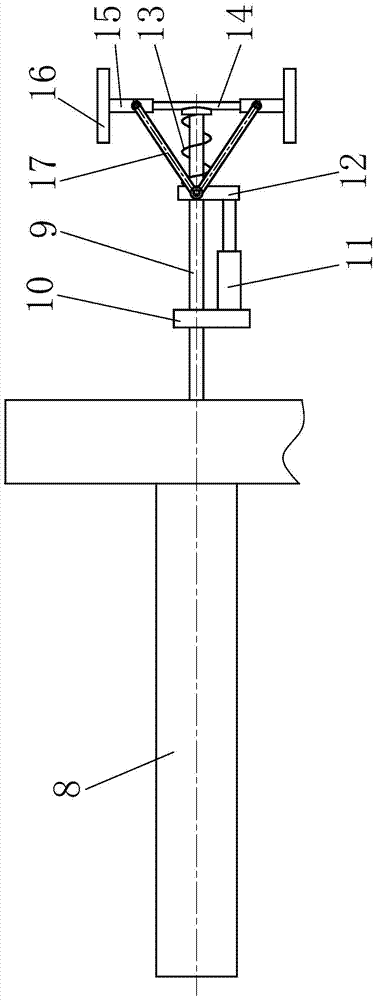

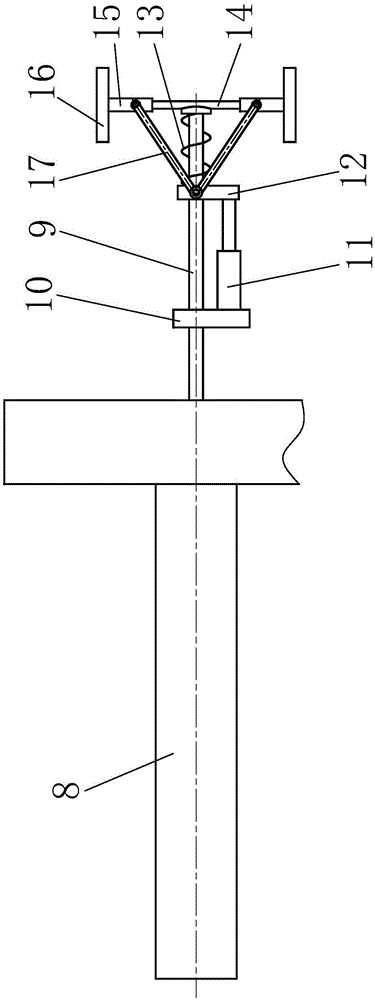

Bottom cover lifting rotary mounting mechanism

InactiveCN107127547ASimple structureAccurate and efficient installationMetal working apparatusSprocketEngineering

The invention discloses a bottom cover lifting and rotating installation mechanism, which belongs to the field of installation auxiliary mechanical equipment. The invention includes a fixed base, a driving base, a rotating gear disc and a lifting installation mechanism. The driving base is horizontally arranged on the upper side of the fixed base, the rotating gear disc is horizontally arranged on the upper side of the universal ball of the bearing plate of the driving base, and the output end of the rotating motor The driving gear is installed horizontally, and there are several groups of lifting installation mechanisms installed vertically and symmetrically on the outer side above the circular plate of the rotating gear. The main sprocket and the auxiliary sprocket are meshed and connected by a transmission chain, and the guide plate slides vertically on the lifting guide rod. , the lifting plate is horizontally arranged on one side of the guide plate, and the output end of the installation cylinder is horizontally arranged with an installation pressing plate. The invention has a reasonable structural design, can quickly and efficiently lift and install bottom covers of various sizes and specifications stably and accurately, improves the efficiency and quality of bottom cover installation, and meets the needs of installation and use.

Owner:TONGXIANG TANGCHAO ADVERTISEMENT CO LTD

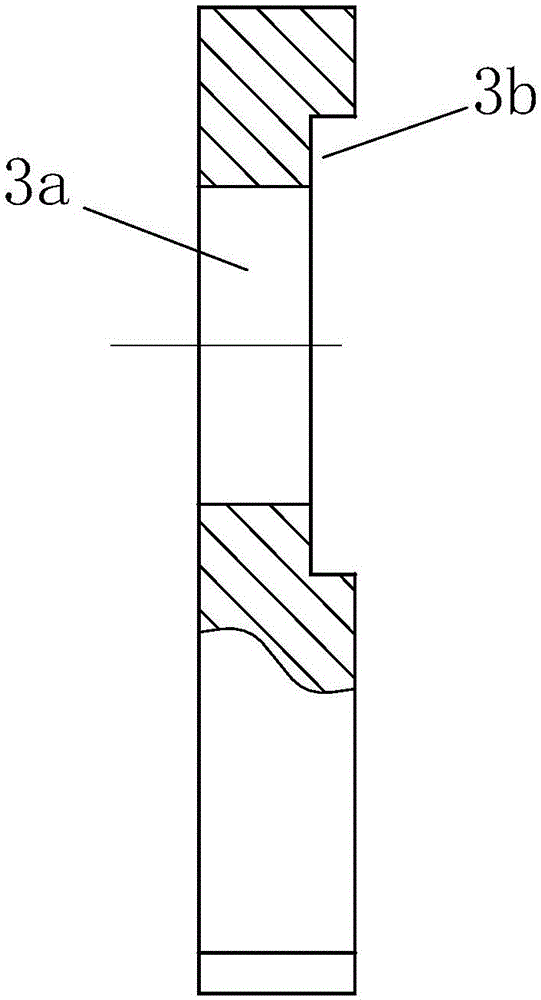

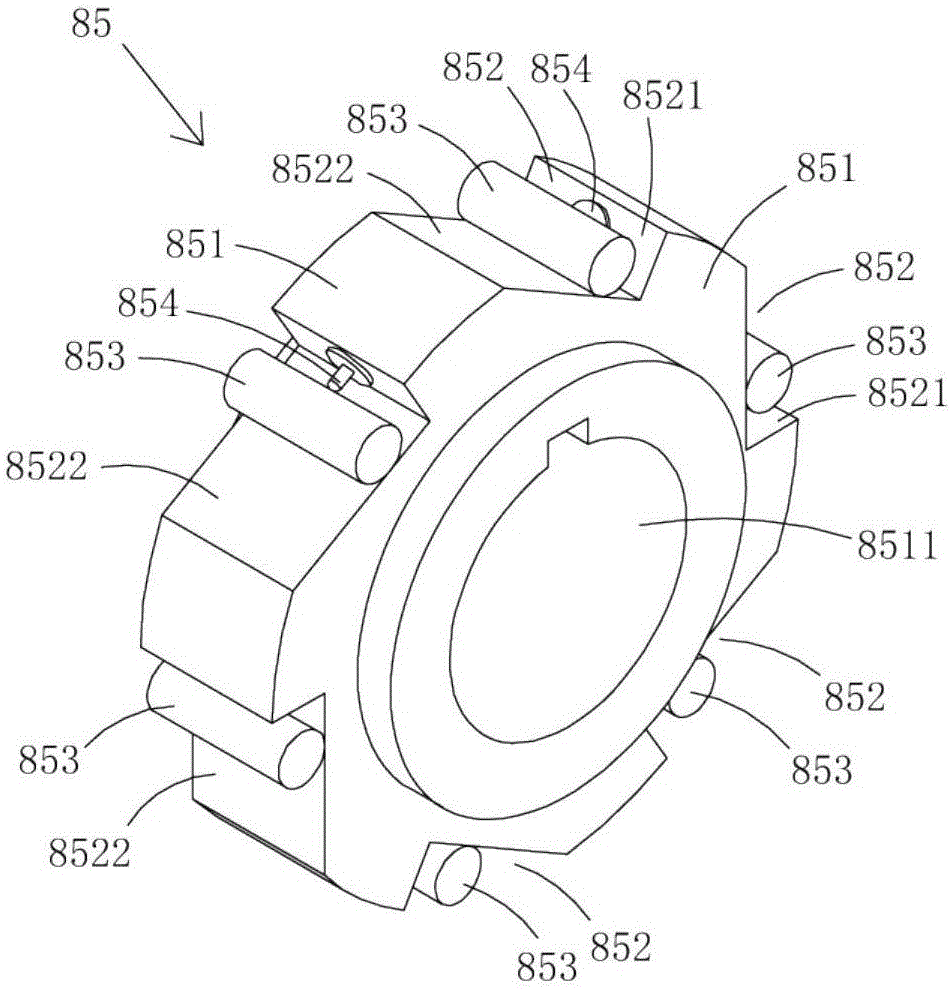

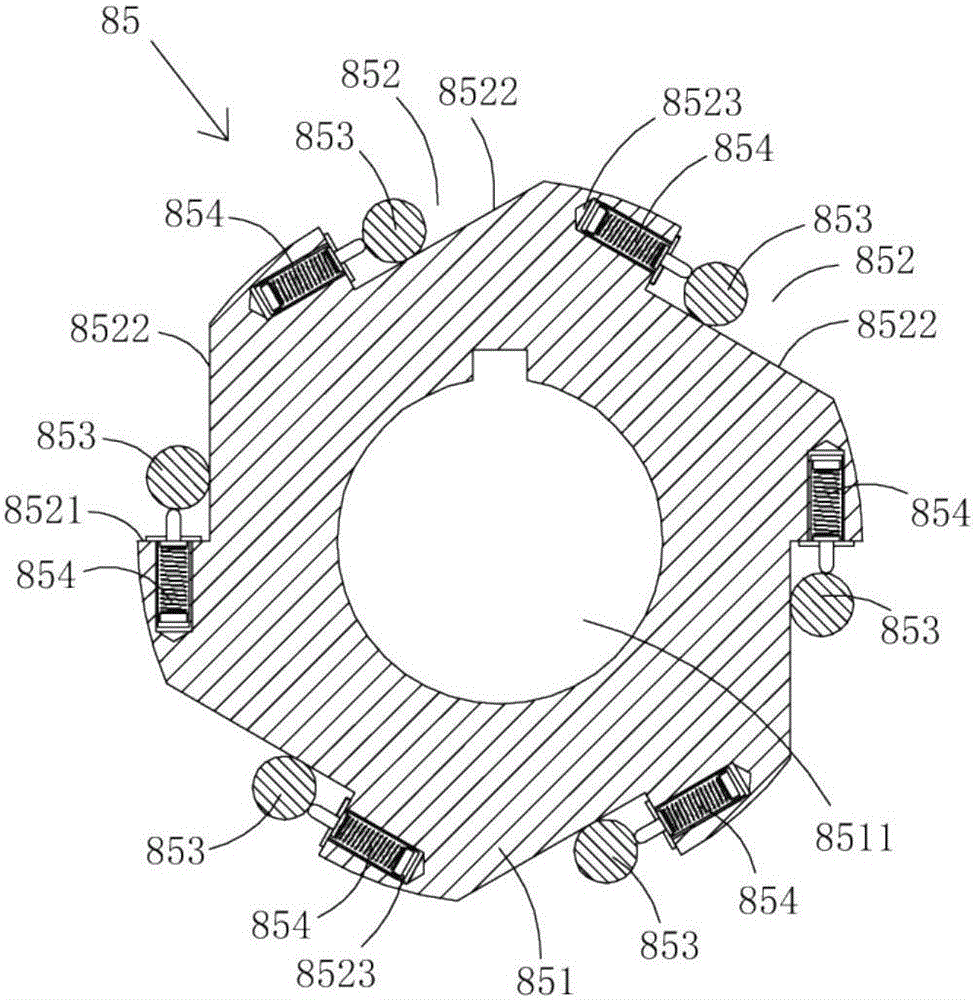

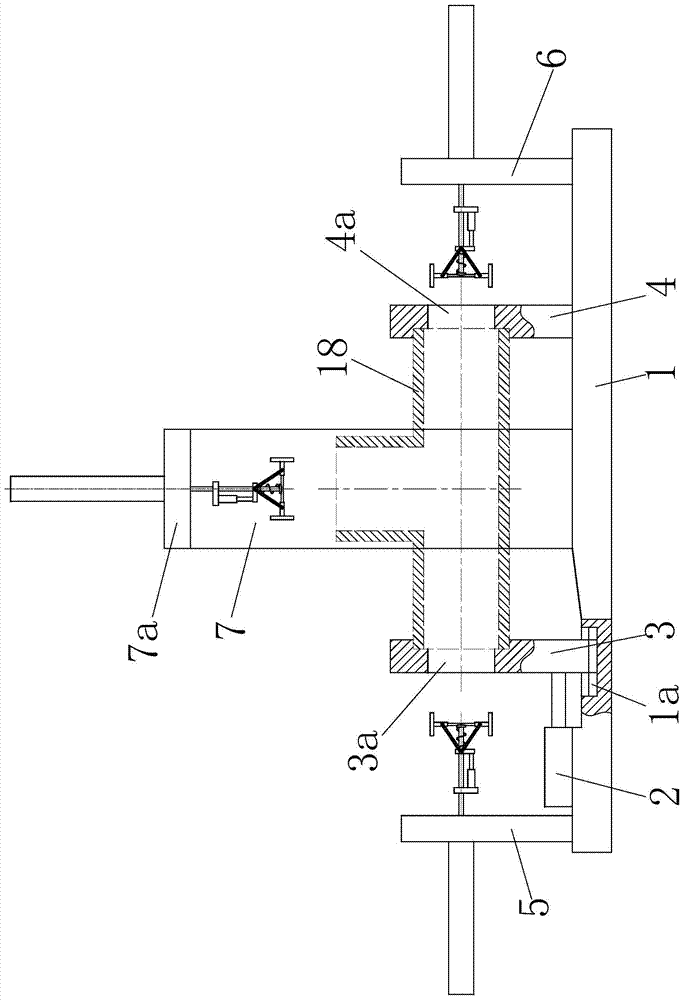

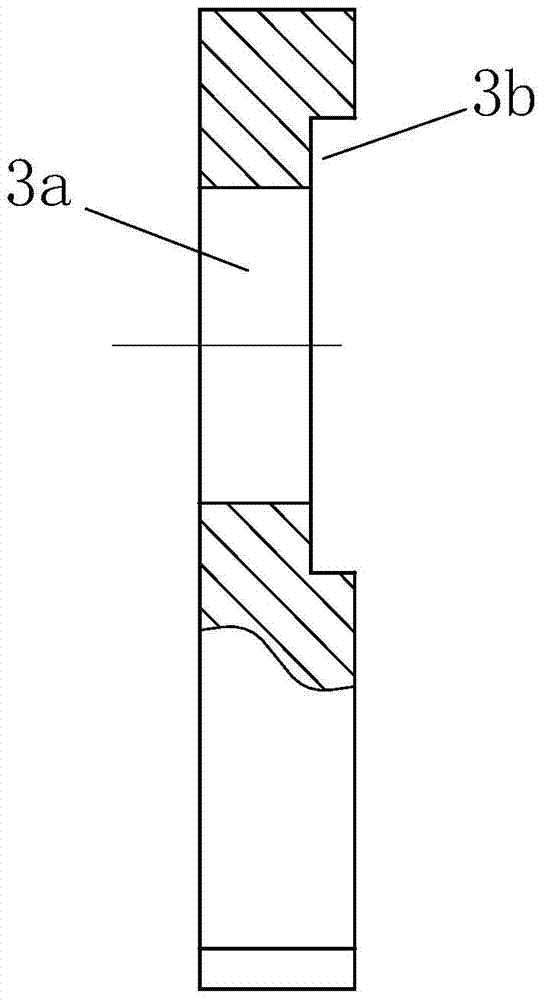

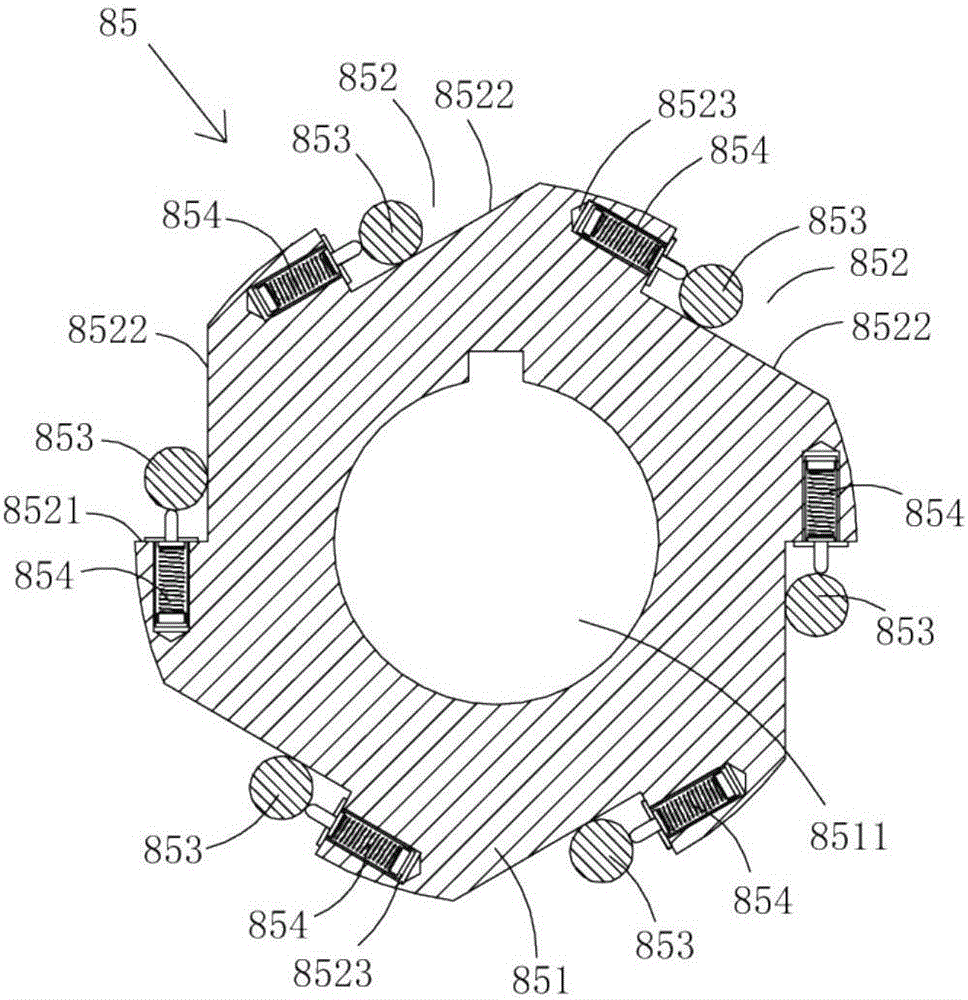

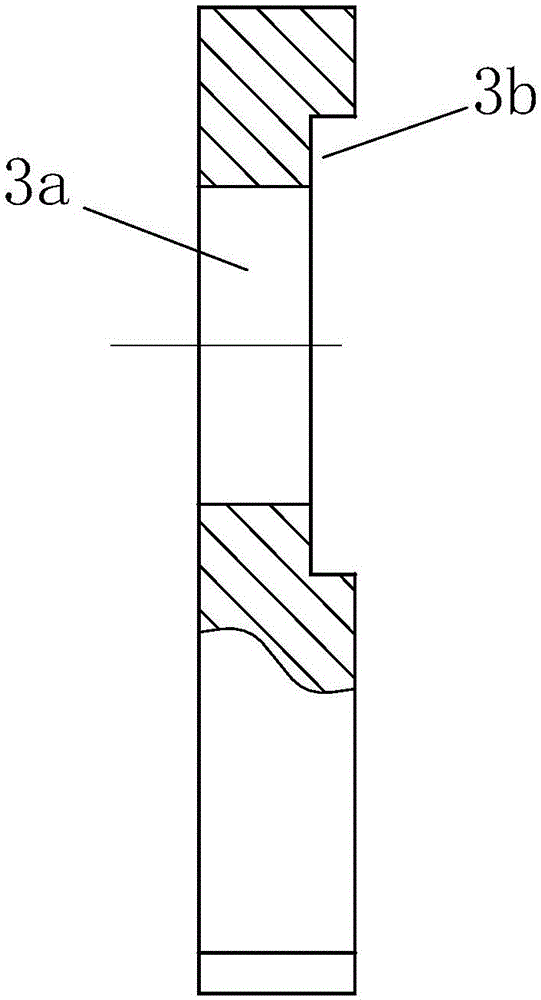

Shaft tube end clamping mounting mechanism

ActiveCN108673076AClamp firmlyReasonable structural designMetal working apparatusEngineeringMechanical equipment

The invention discloses a shaft tube end clamping mounting mechanism, belonging to the field of mounting auxiliary mechanical equipment. The lower side of an adjustment rotation shaft is horizontallyand rotatably arranged on a rotating base. A lower translation bracket is horizontally fixed on an upper side of the adjustment rotation shaft, and an upper translation bracket is vertically fixedly disposed on an upper side of a translation base. A lifting bracket is slidably disposed on an upper translation guide rod along the horizontal direction, and a lifting guide plate is slidably disposedon a lifting guide rod in the vertical direction. A tube clamping mechanism is horizontally disposed on one side of the lifting guide plate, the upper side of the adjustment rotation shaft is horizontally and fixedly provided with a rotating bevel gear. The upper side of a limiting rotation plate is fixedly provided with a limiting rack matched with a limiting gear, and a tension spring is disposed between the middle of the limiting rotation plate and a fixed base. Structural design of the shaft tube end clamping mounting mechanism is reasonable, the ends of shaft tubes of various sizes and specifications can be firmly clamped and fixed, and the shaft tubes can be smoothly adjusted and translated according to the needs, so that the shaft tube can be accurately mounted to meet the needs ofmounting and use.

Owner:南通天福机械有限公司

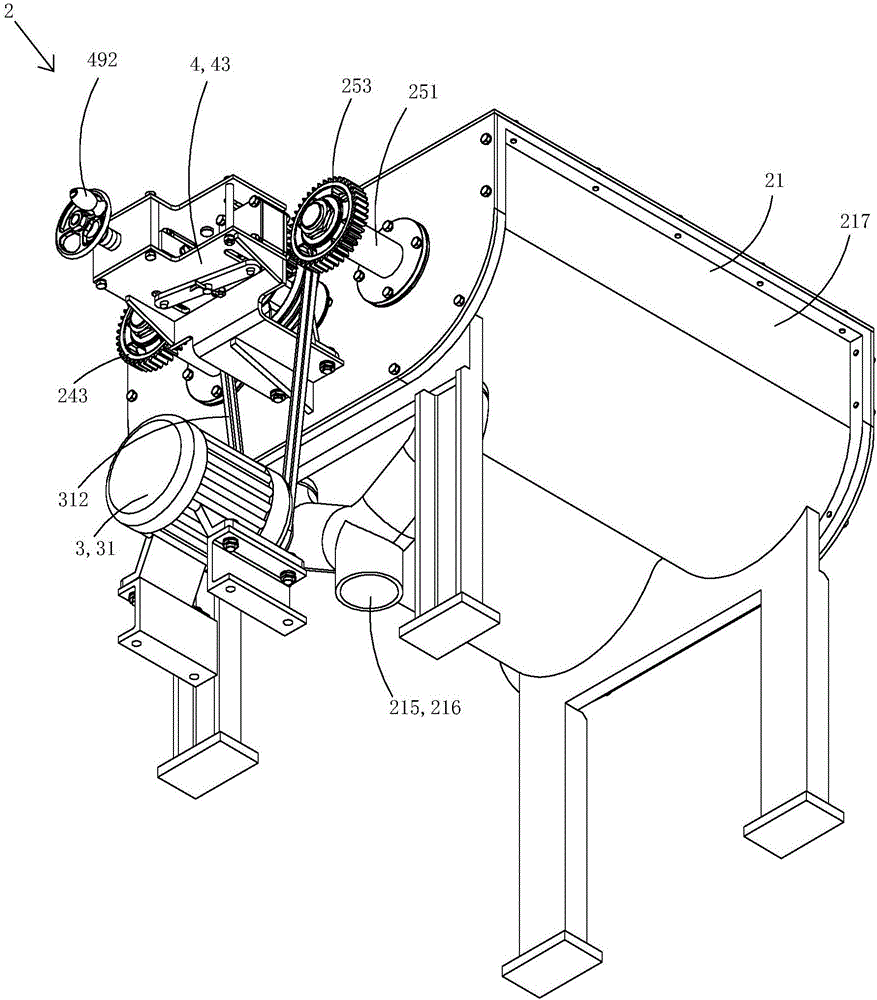

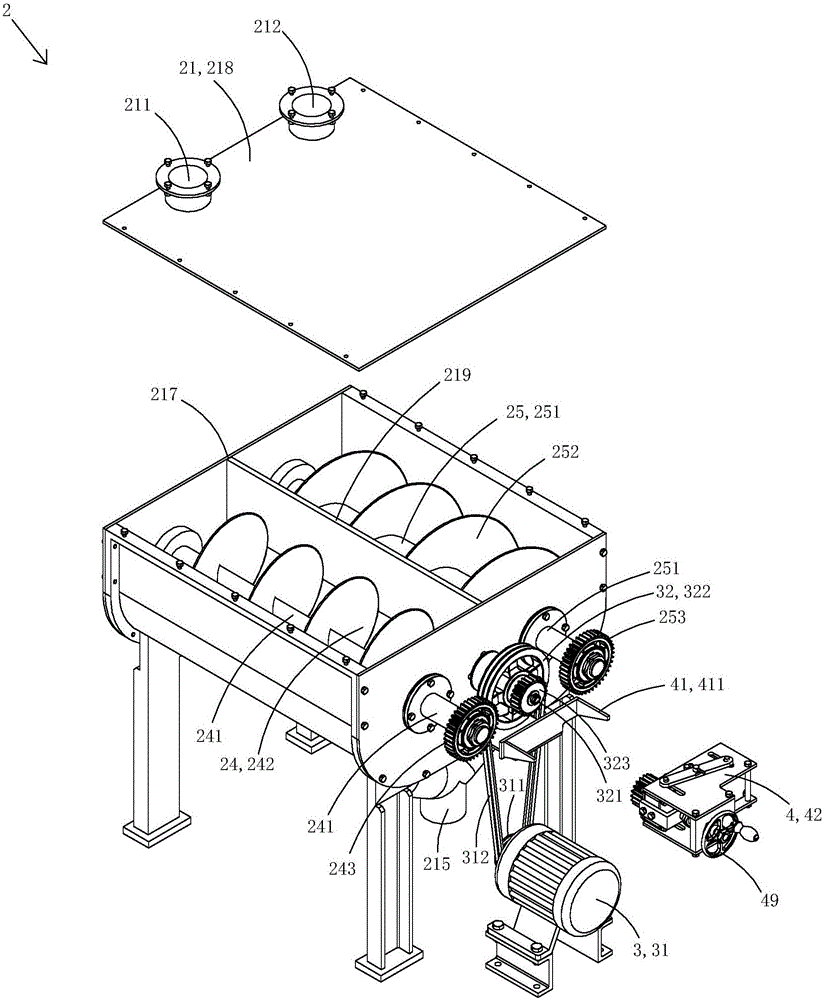

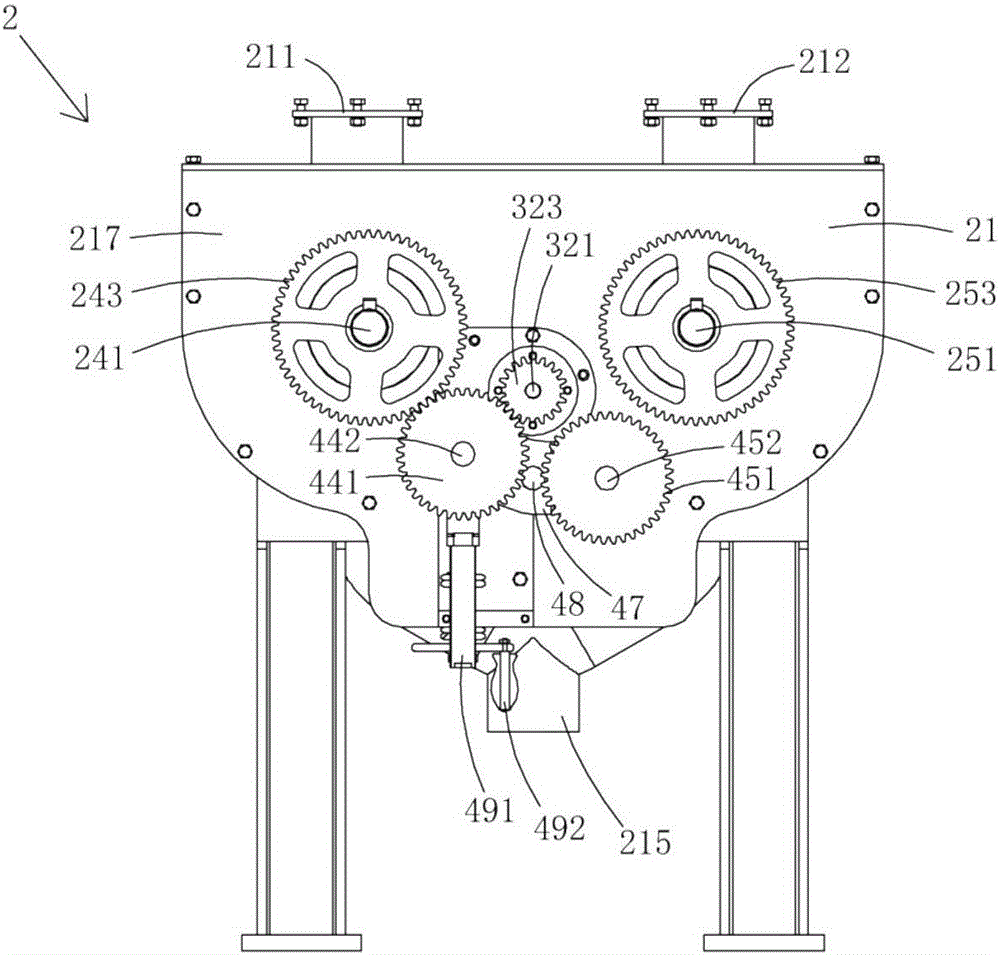

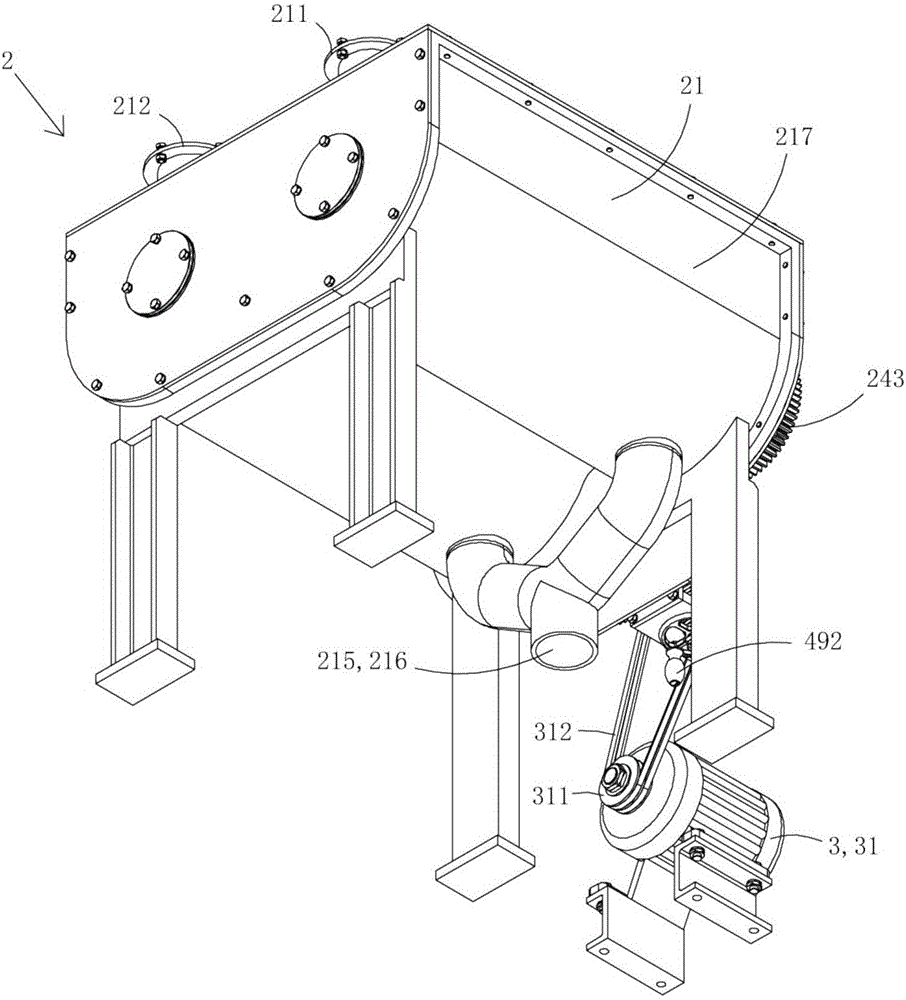

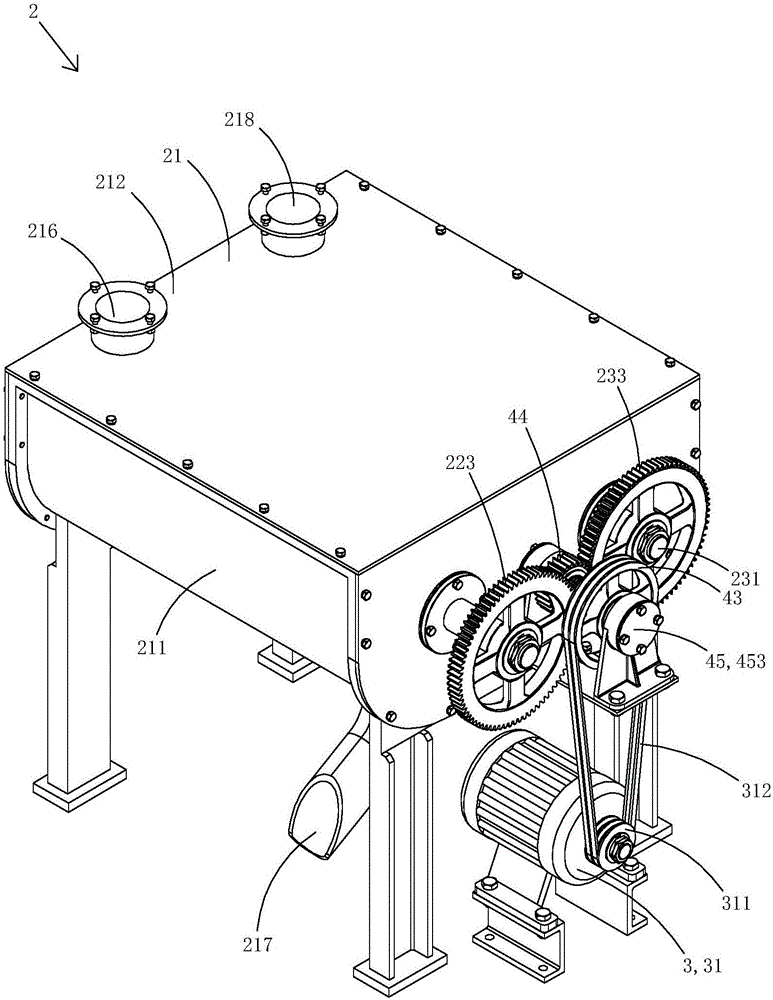

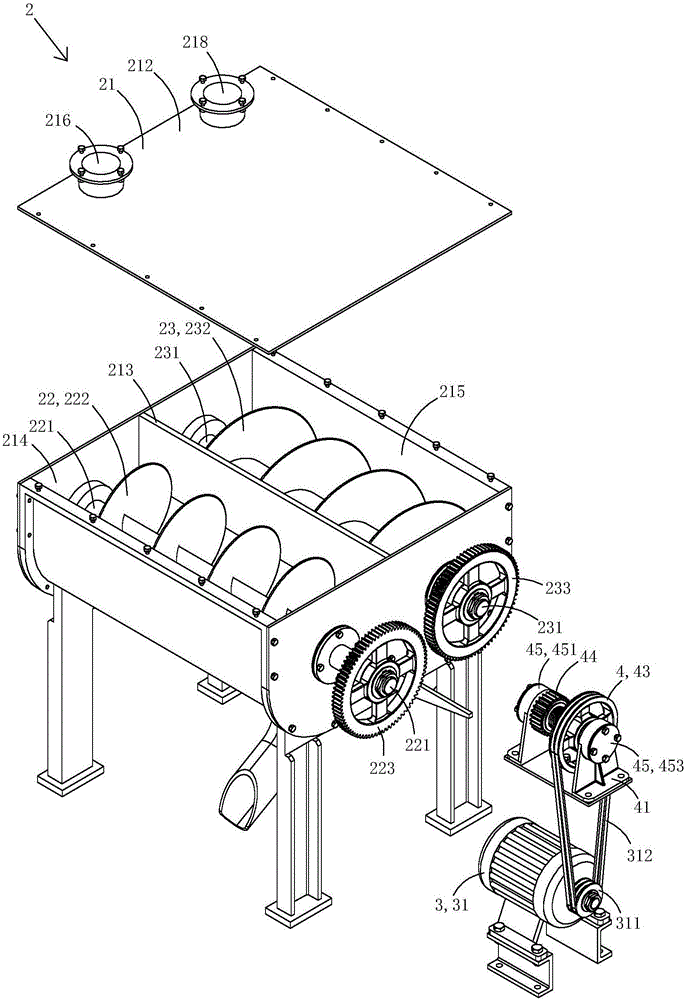

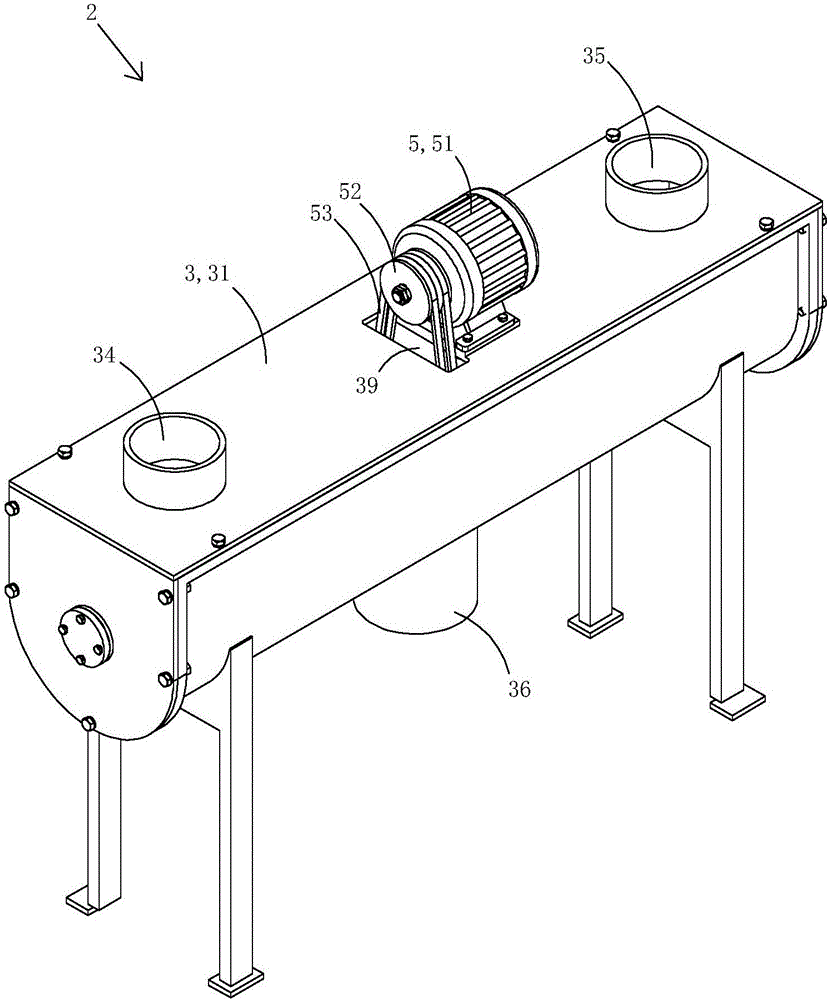

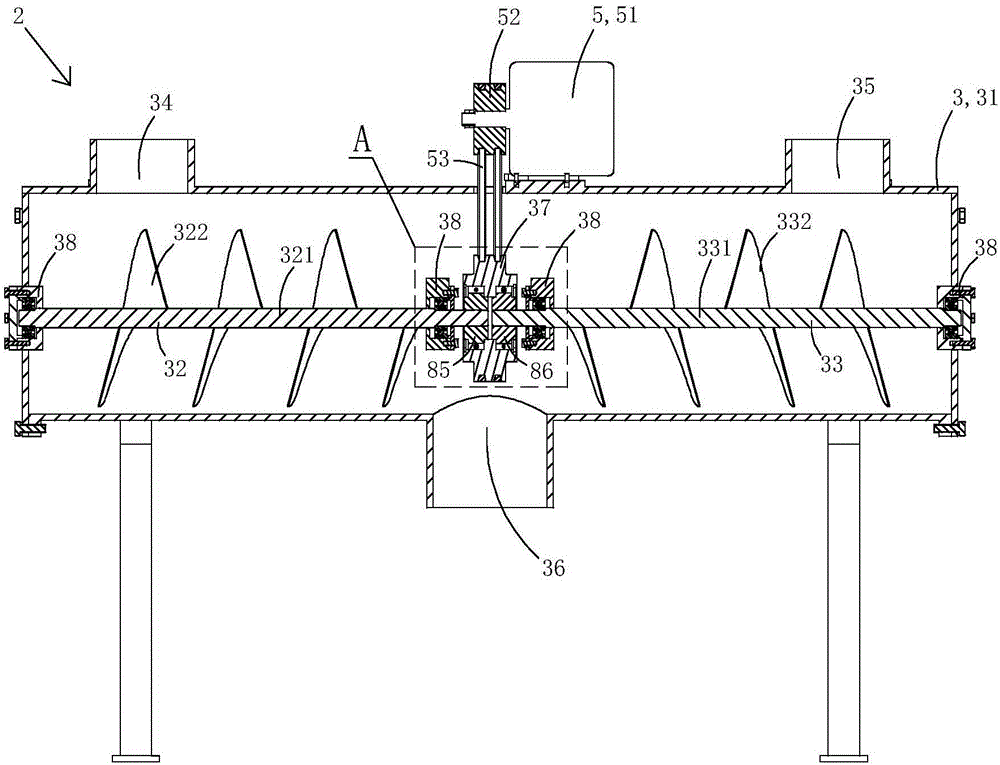

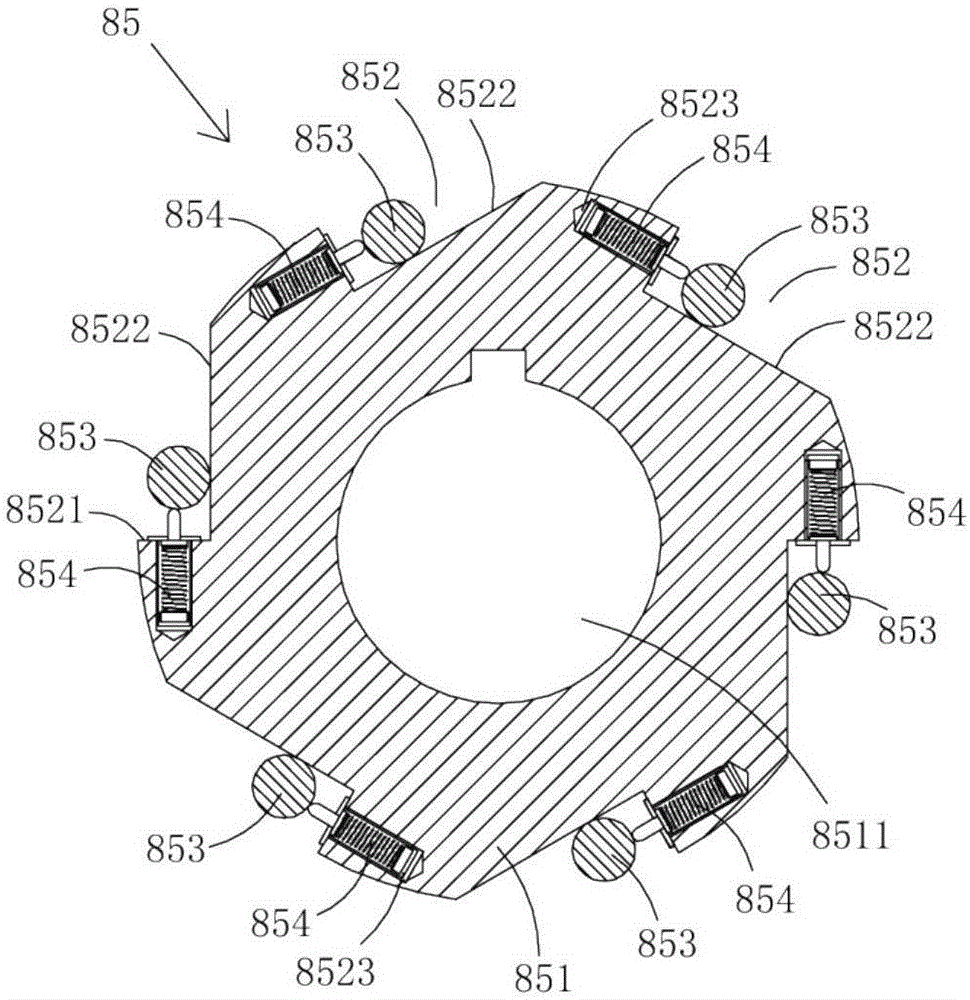

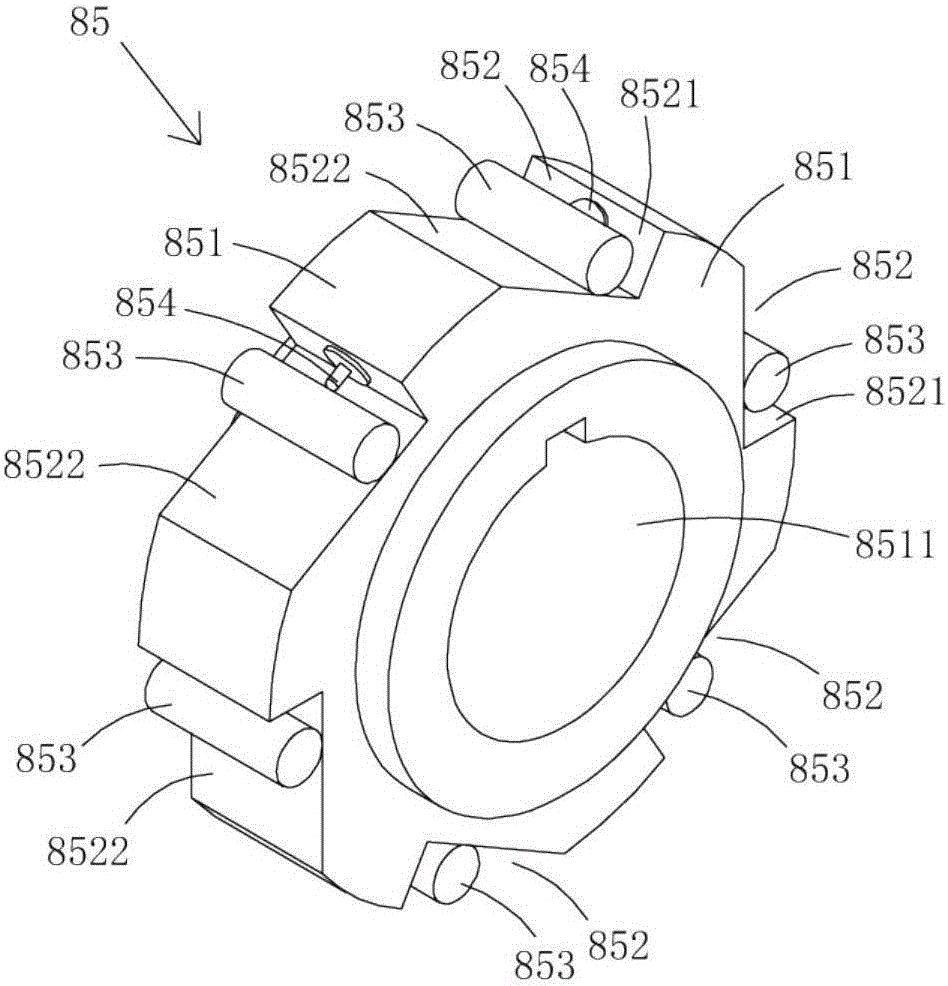

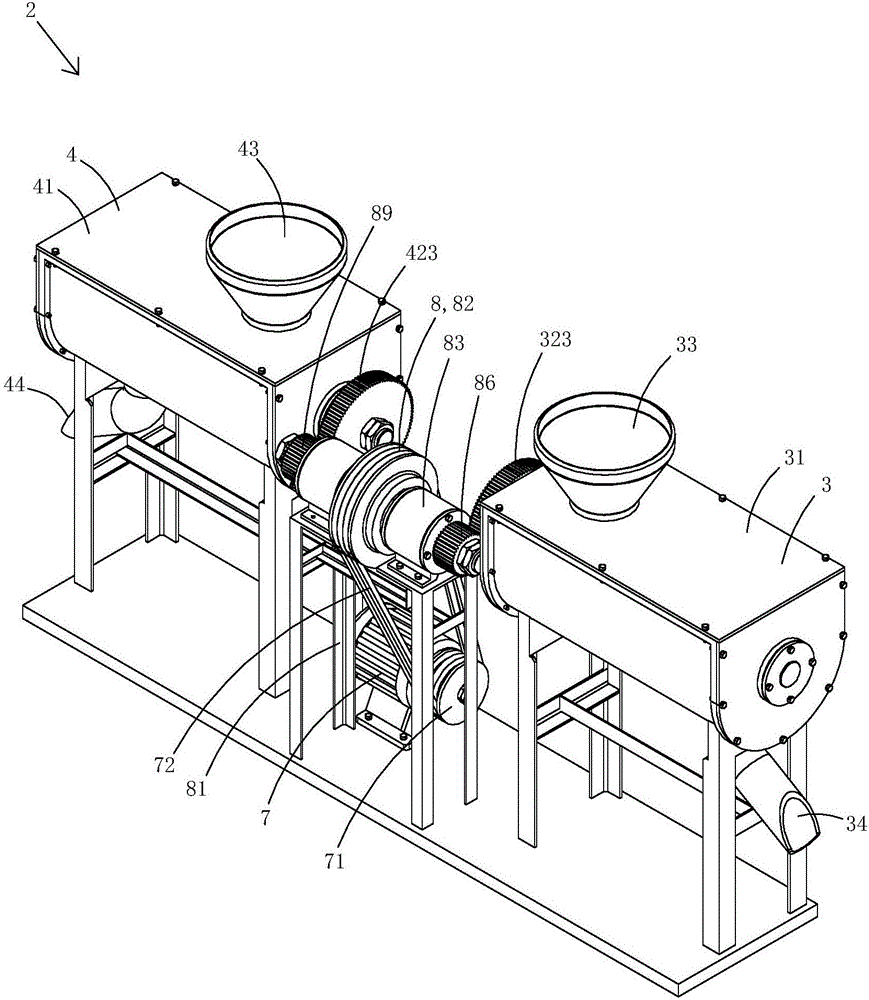

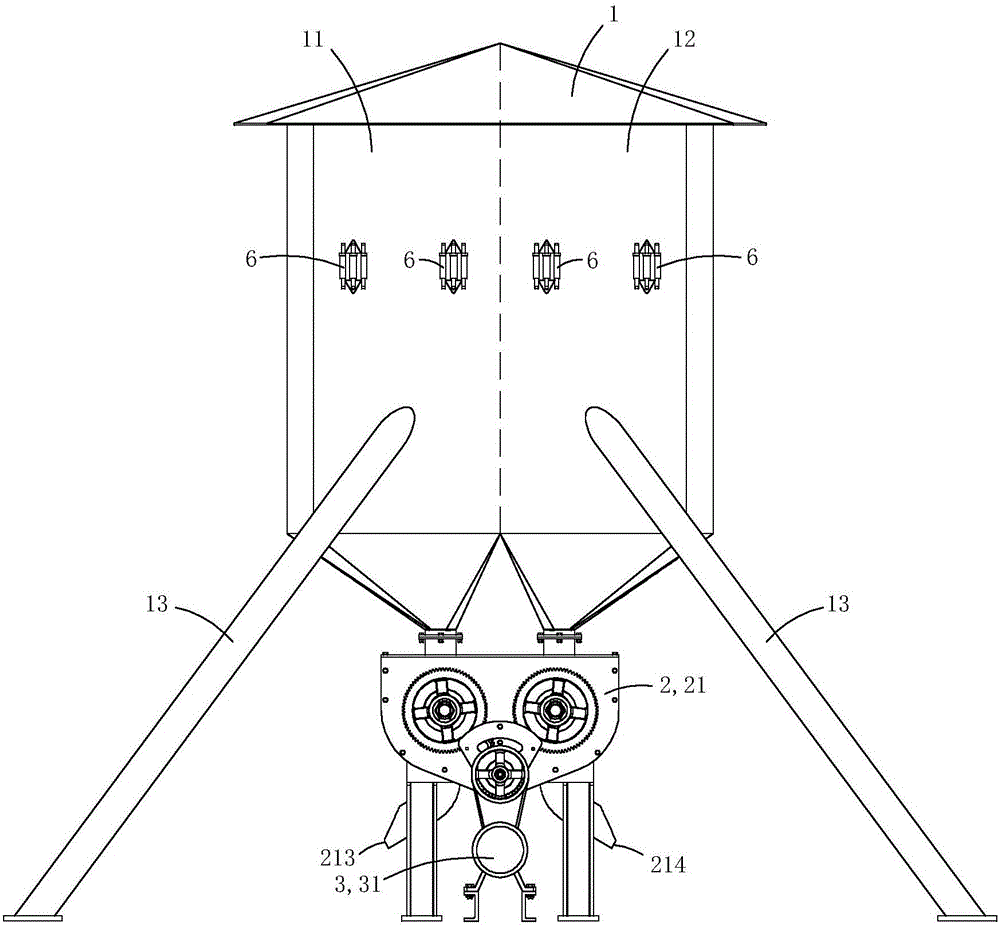

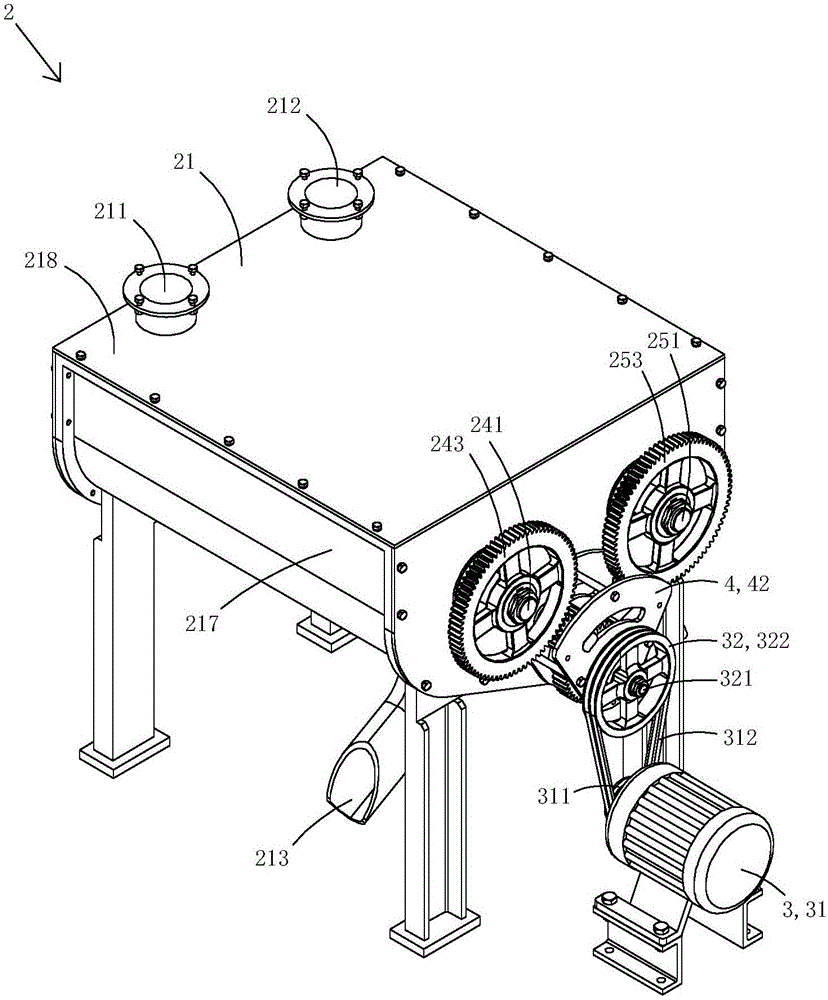

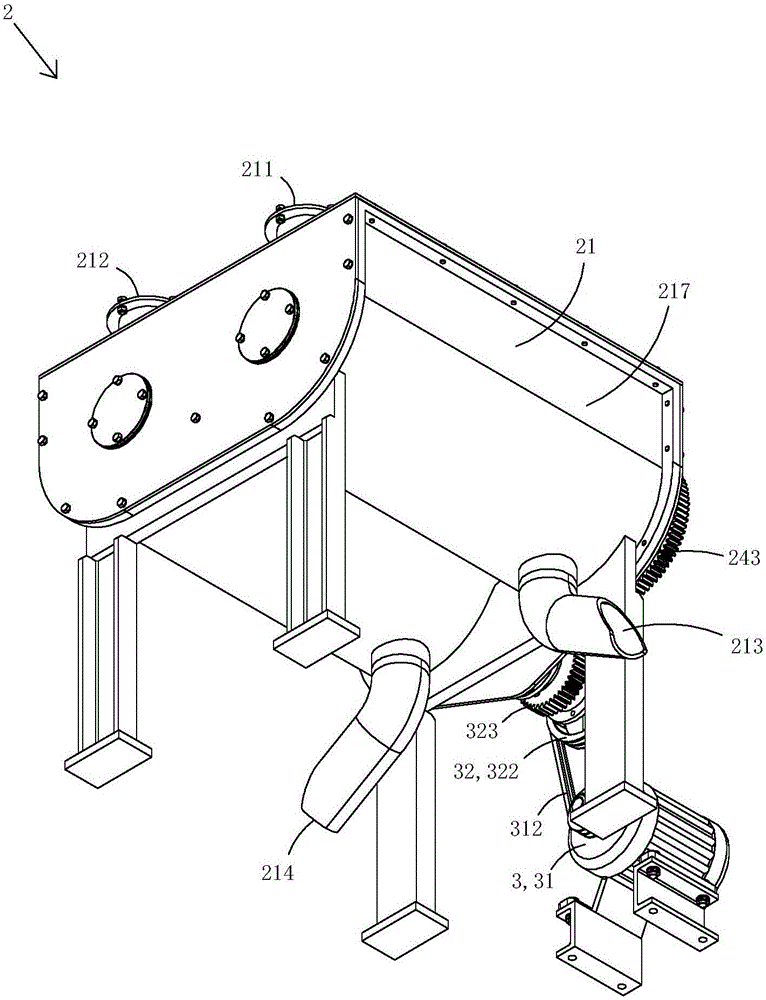

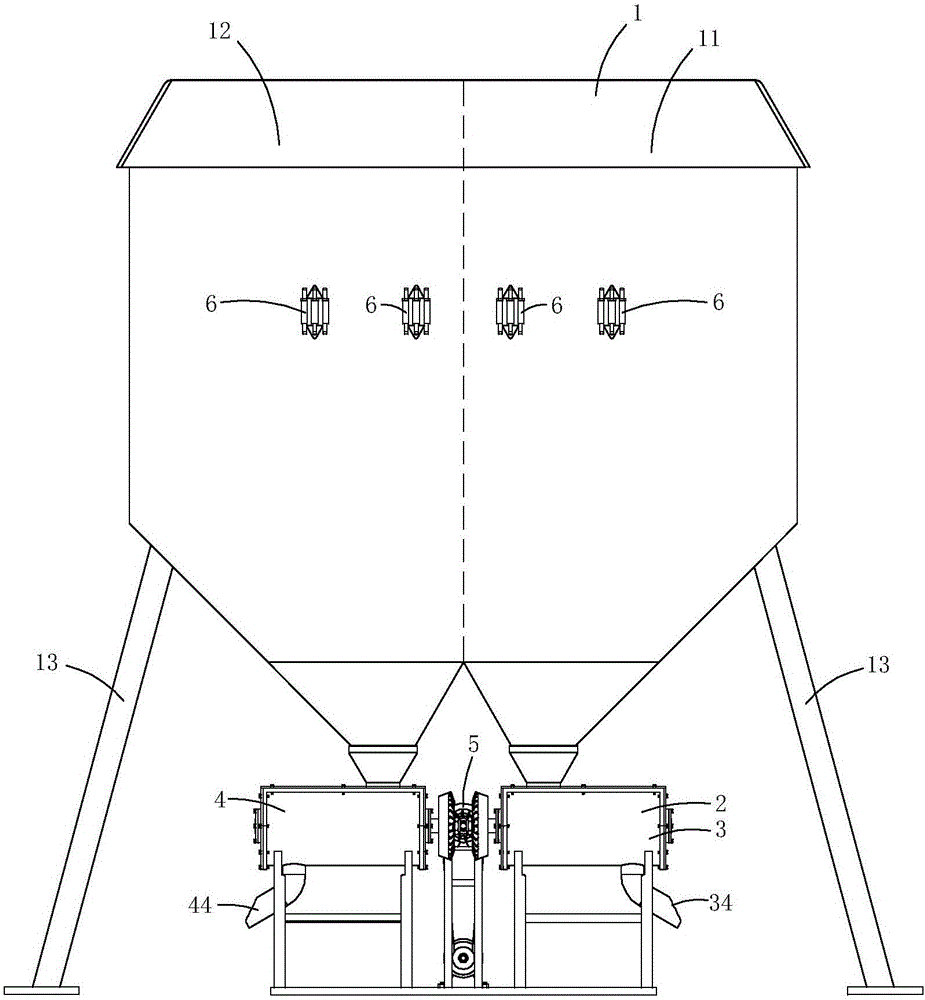

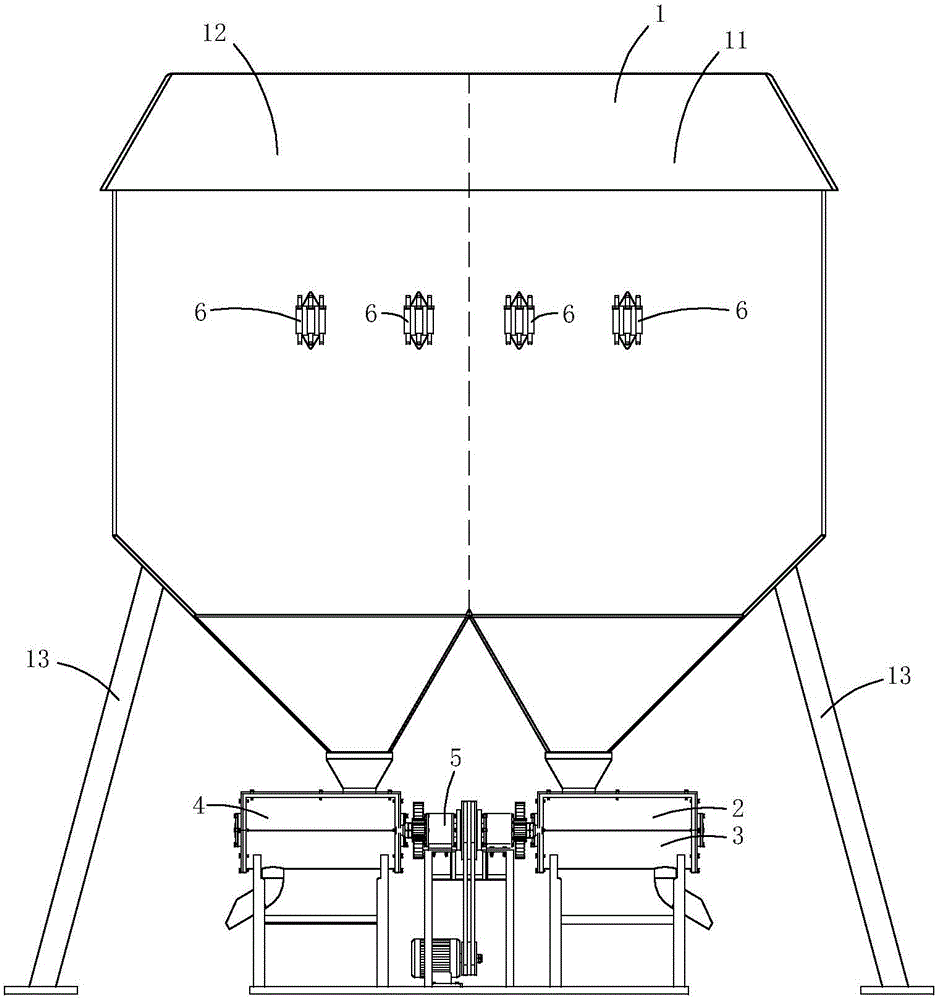

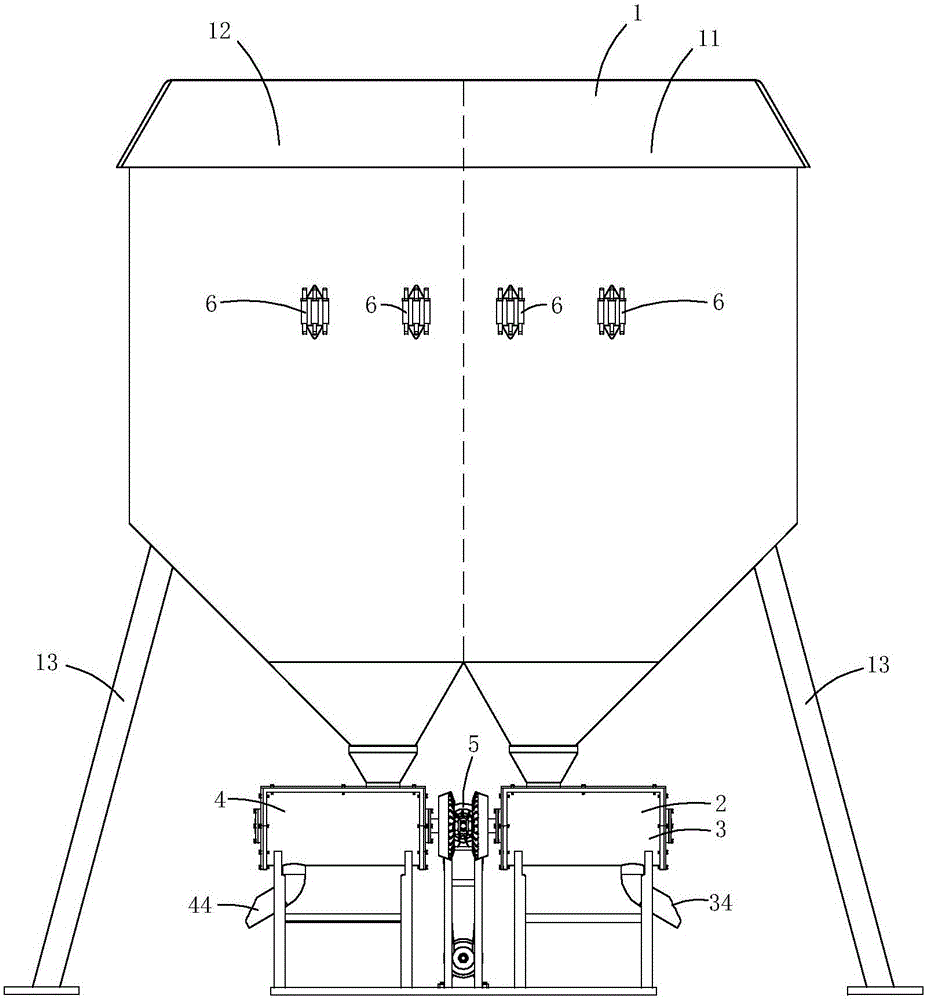

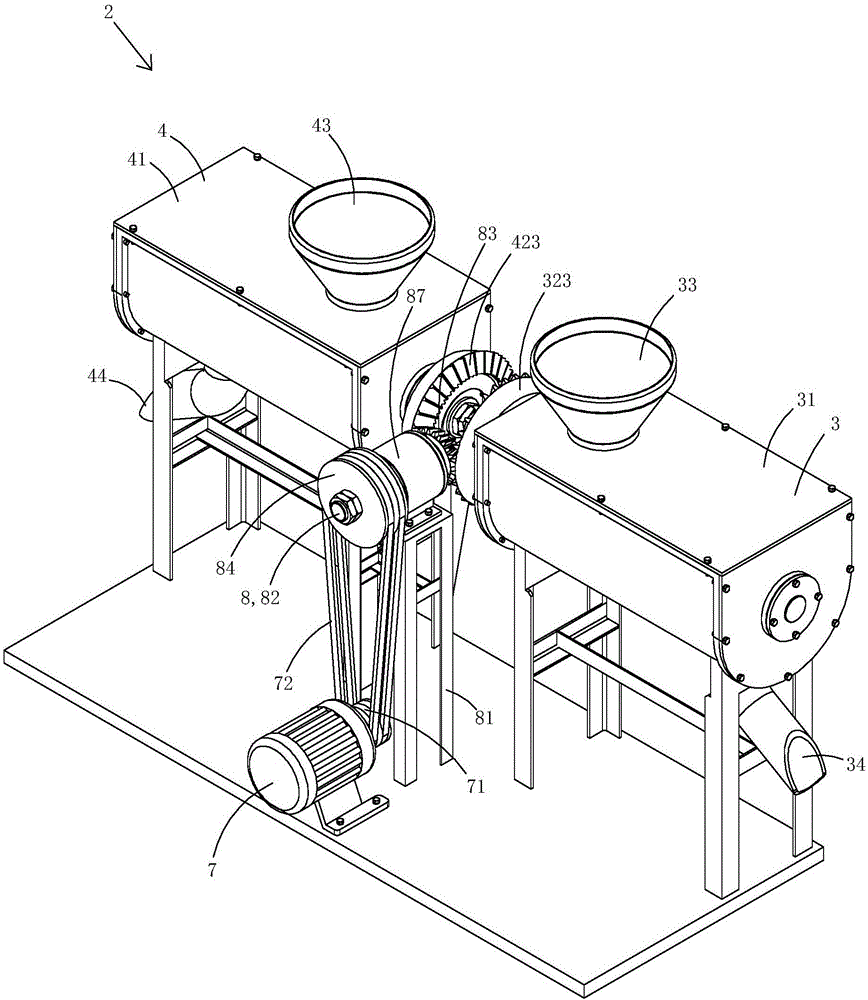

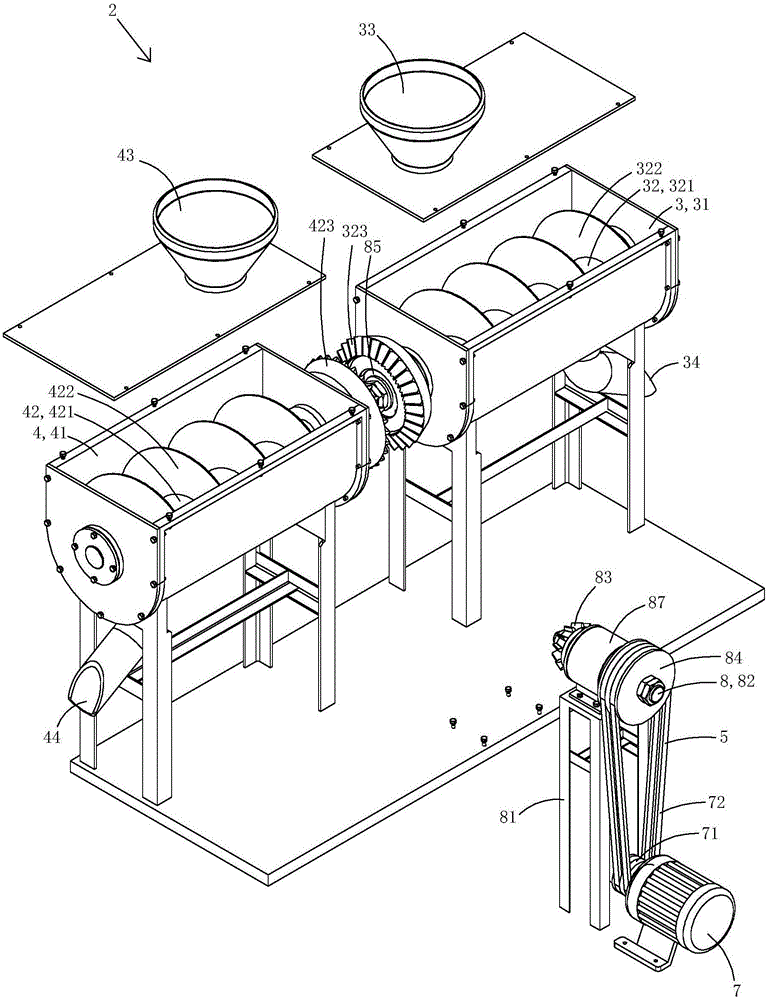

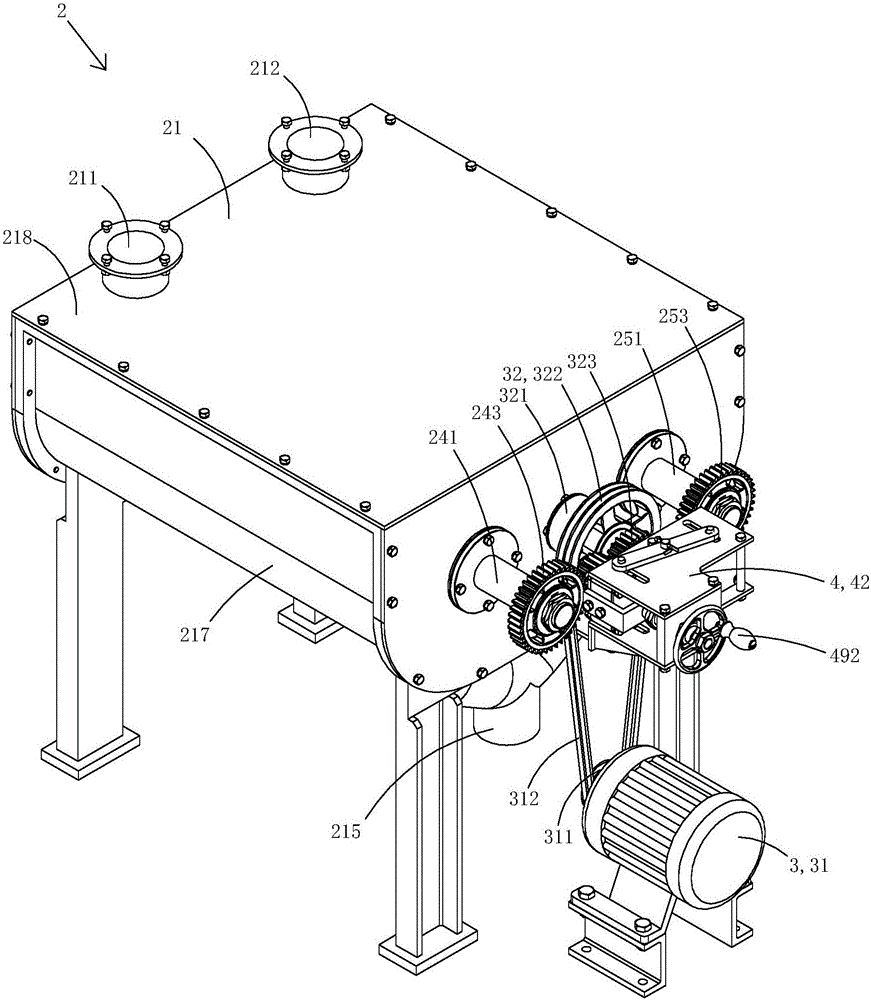

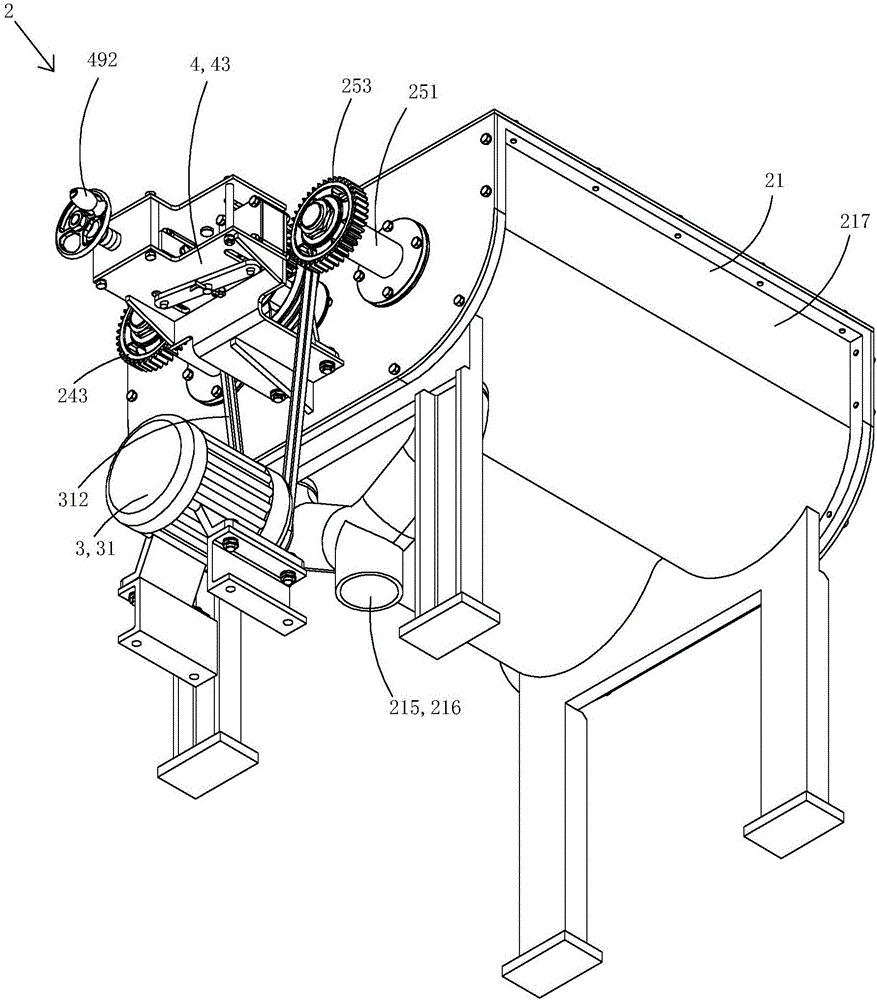

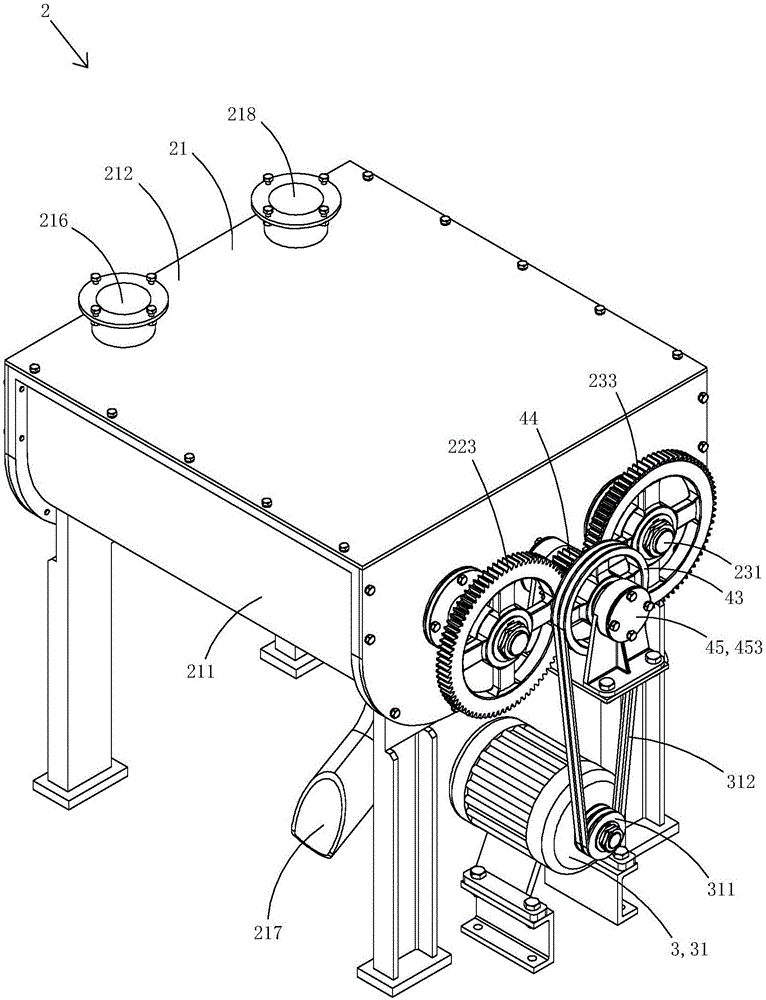

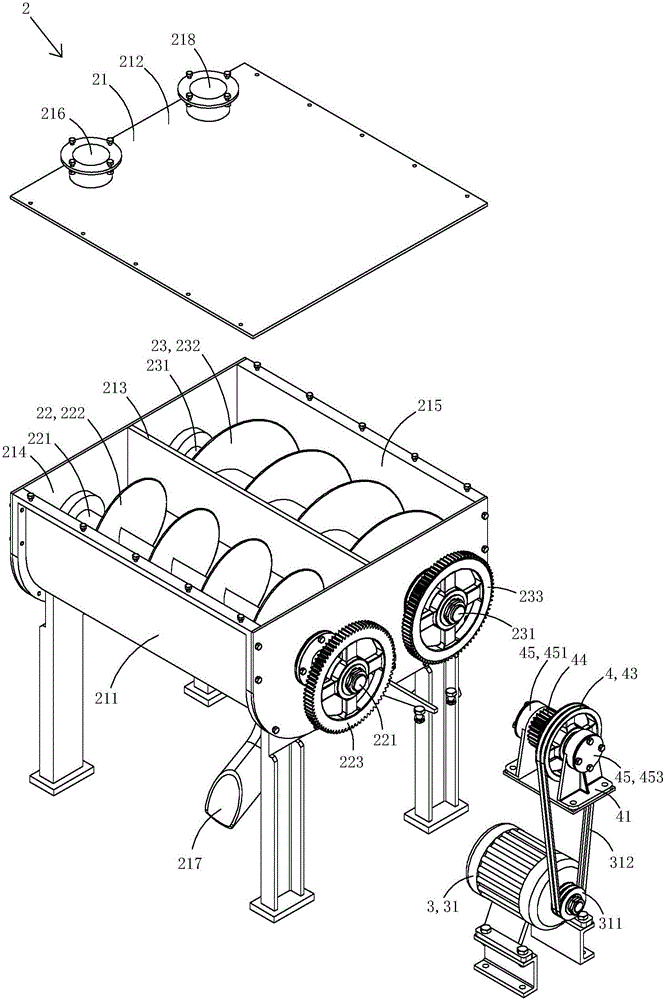

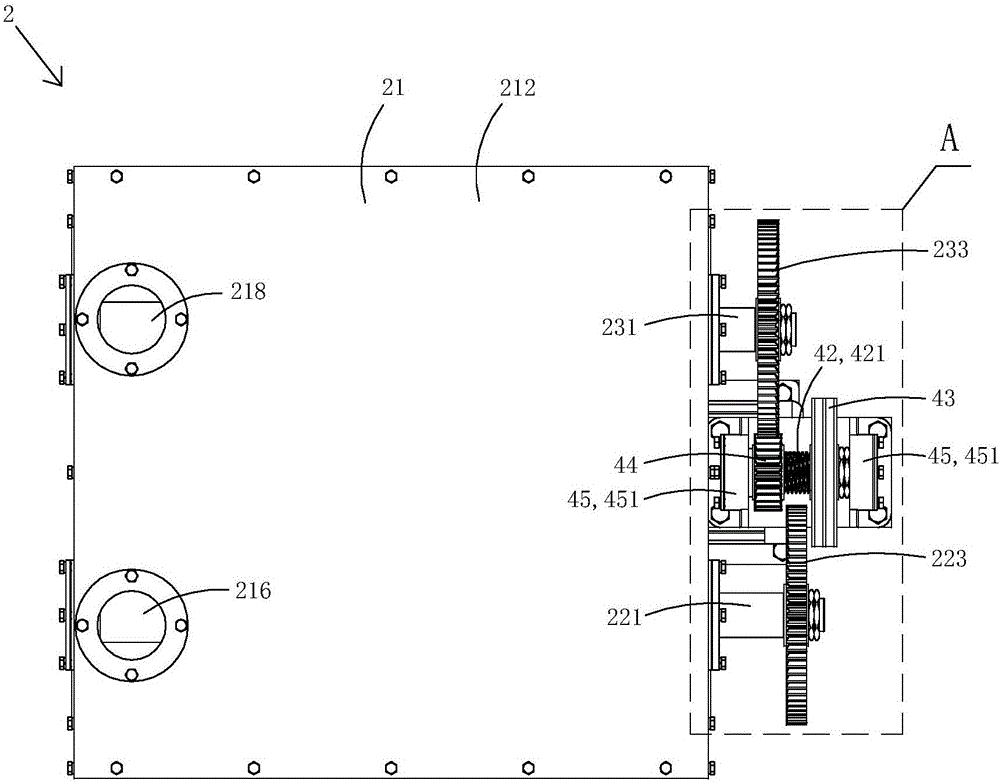

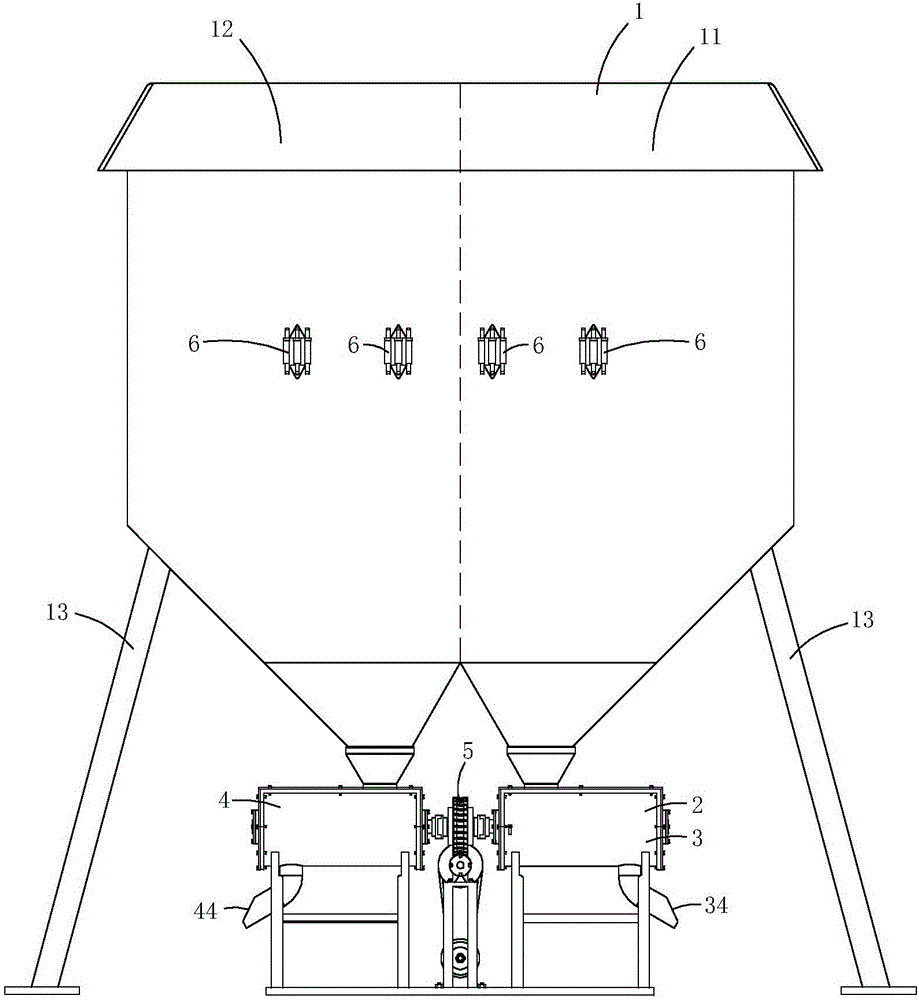

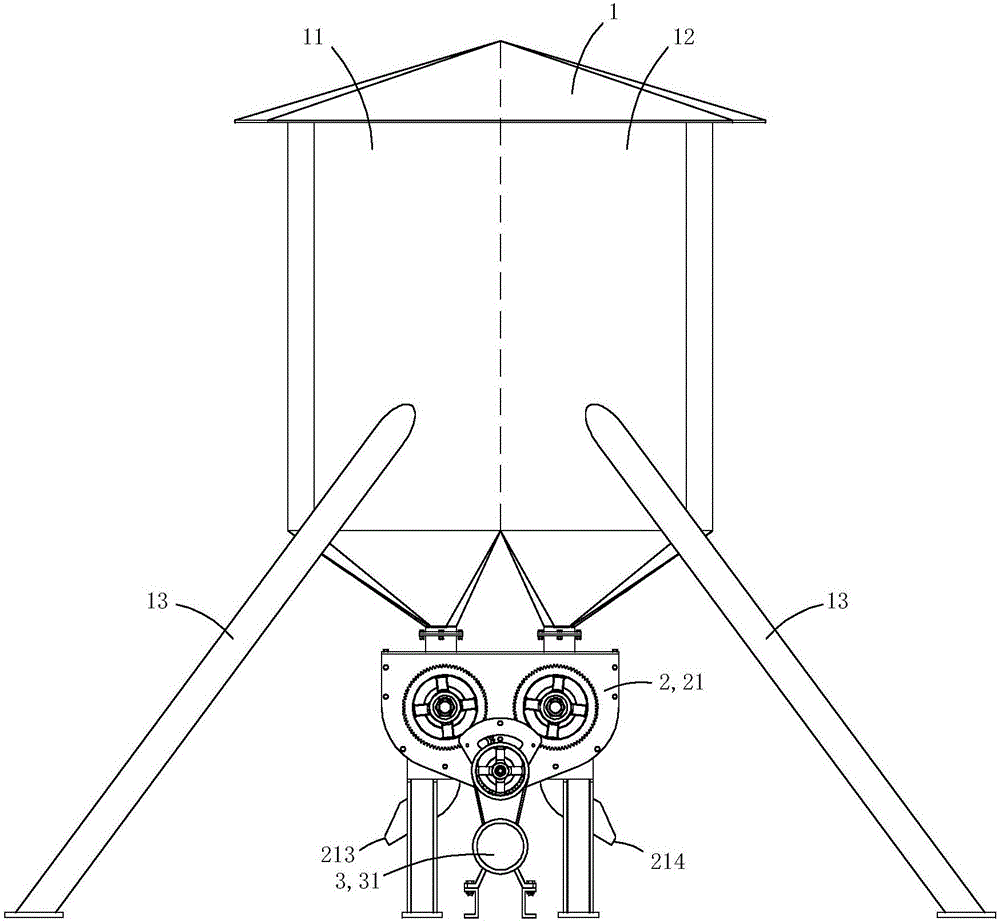

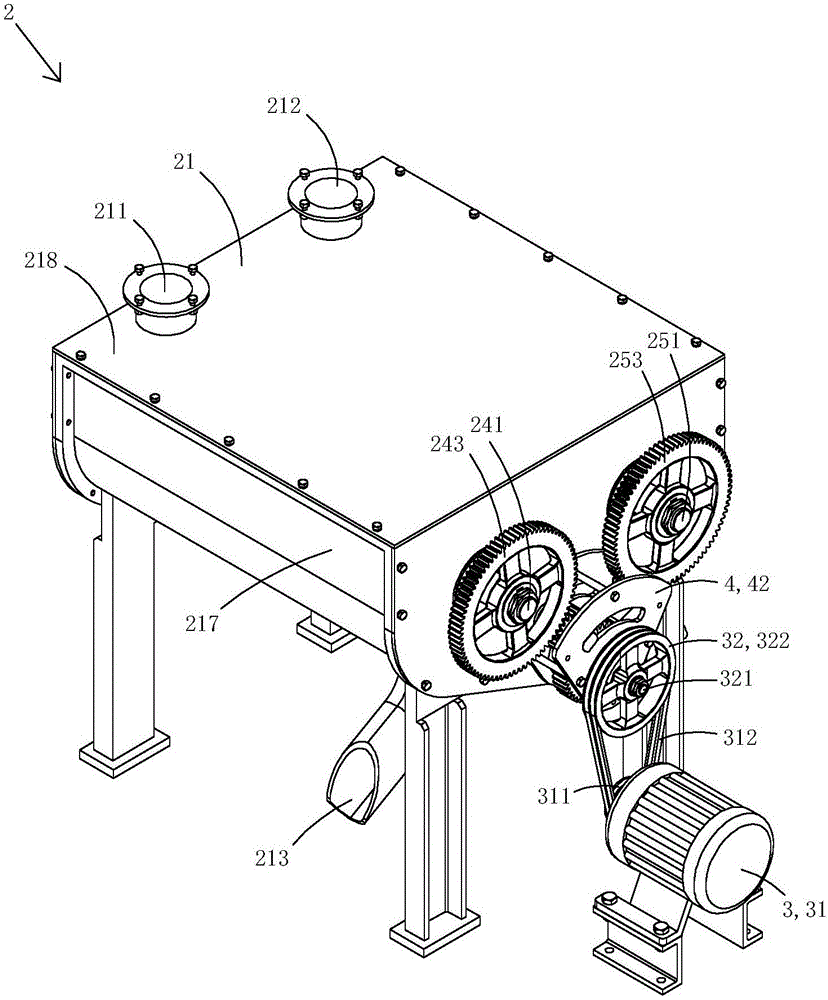

Dual-body electric grain discharge device

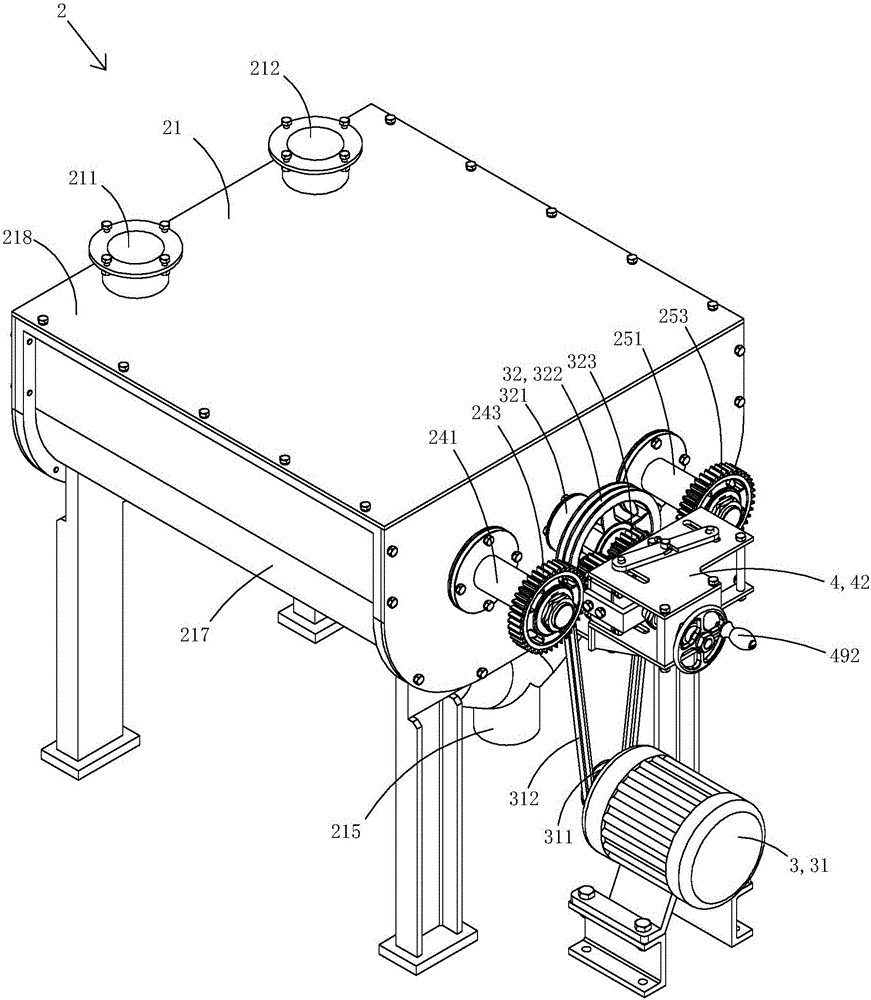

InactiveCN106395418AMeet the needs of installation and useCompact and simplified structureConveyorsLarge containersDrive wheelDrive motor

The invention discloses a dual-body electric grain discharge device which comprises a box body which is internally provided with a first grain discharge channel and a second grain discharge channel, a first screw used for discharging grains stored in the first grain discharge channel, a second screw used for discharging grains stored in the second grain discharge channel and a drive device used for driving the first screw and the second screw to rotate; the drive device is composed of a drive motor with a drive wheel, a transmission wheel group which is rotationally arranged on the outer wall of the box body and a linkage switching device arranged on the outer wall of the box body; the drive motor drives the transmission wheel group to rotate through the drive wheel; and the transmission wheel group singly drives the first screw or the second screw to rotate through the linkage switching device. According to the dual-body electric grain discharge device, the structure is more compact and more reasonable, and the cost is effectively lowered.

Owner:SUZHOU JUNFENGCHEN ELECTRONICS TECH

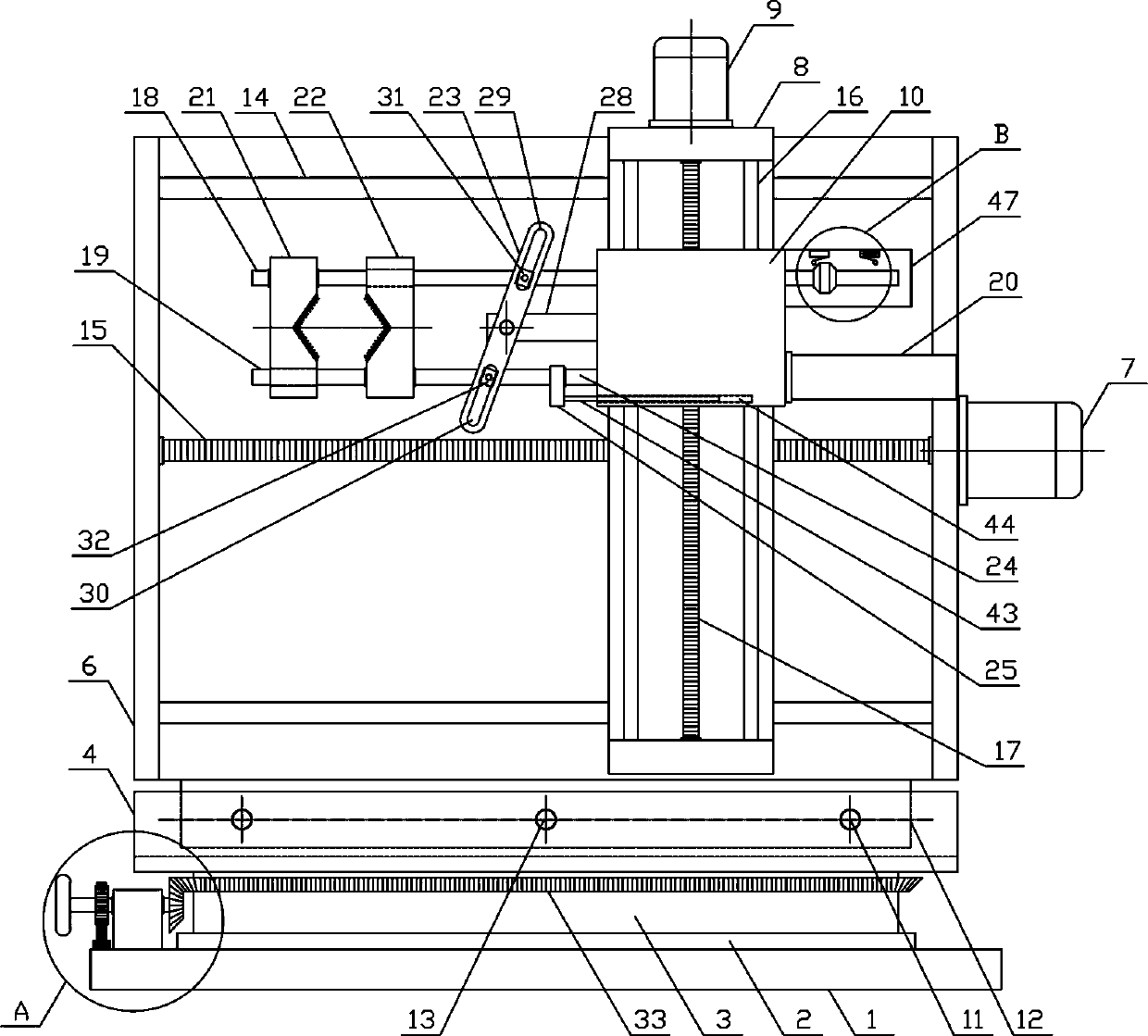

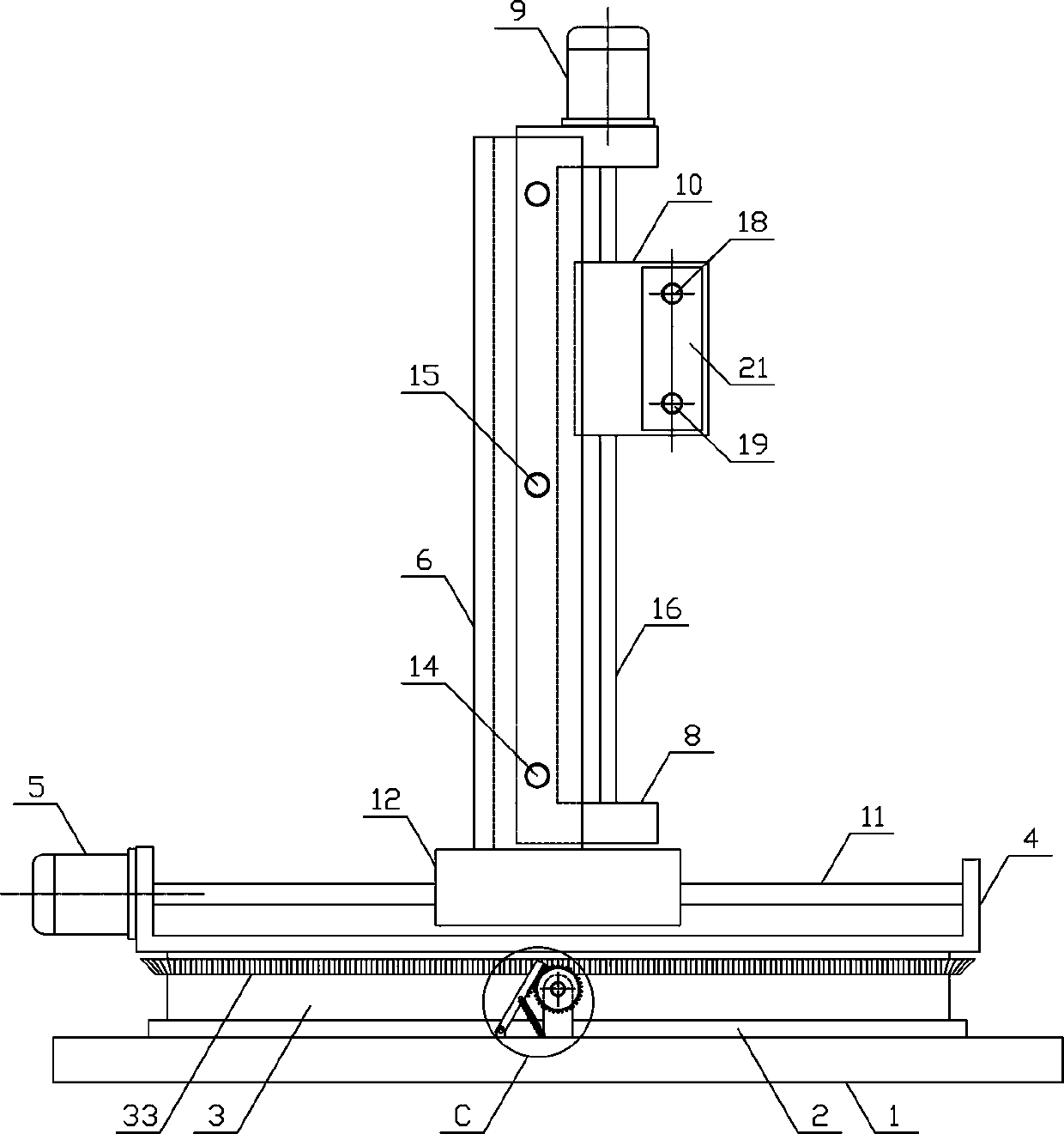

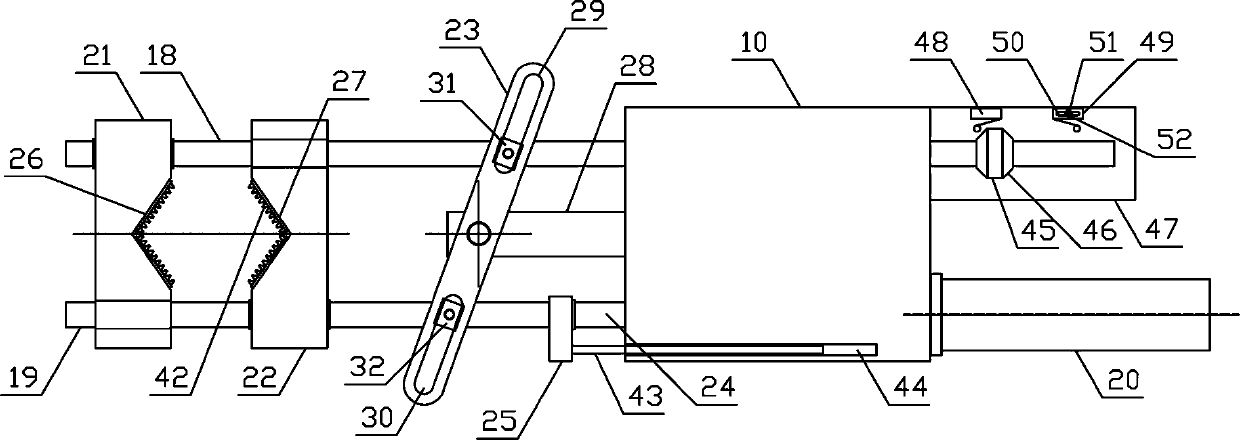

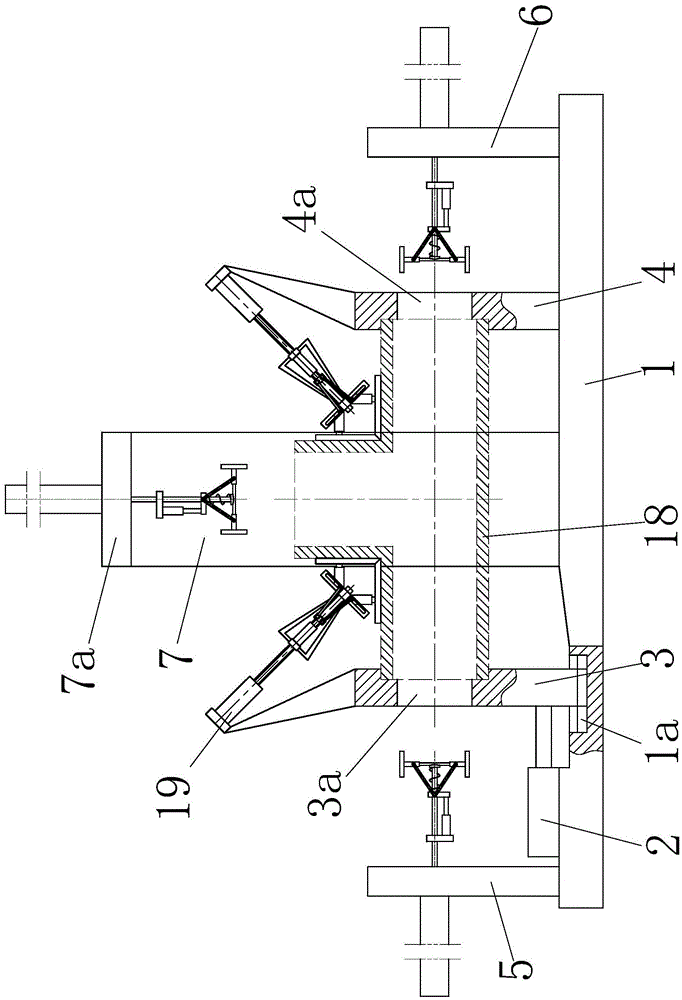

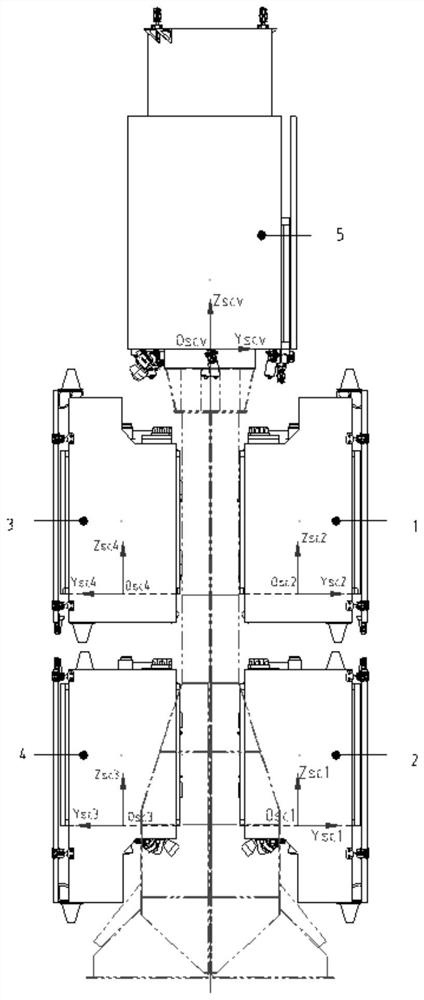

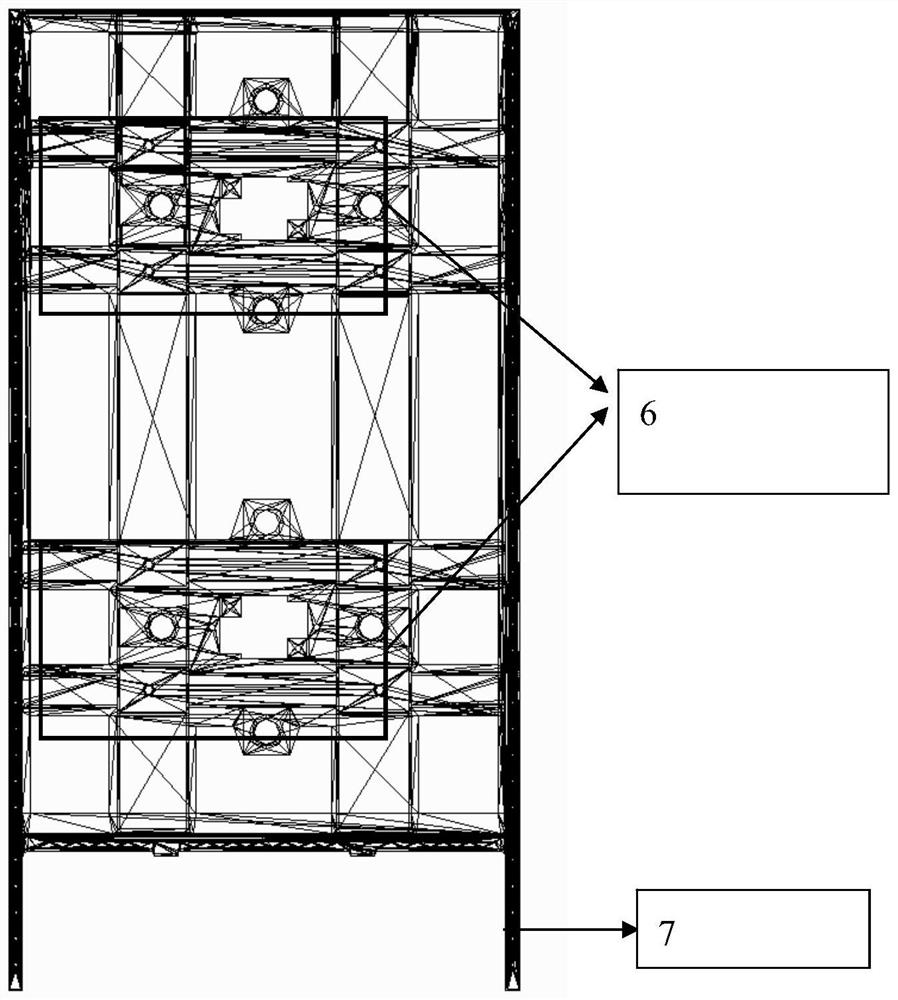

Automatic correction machine of three-way air channel for ship

The invention relates to an automatic correction machine of a three-way air channel for a ship. The automatic correction machine comprises a bottom plate, a compressing and locating device, a left fixed plate, a right fixed plate, a rear vertical plate, internal correctors and external correctors. The compressing and locating device is arranged in the middle of the upper end of the bottom plate, and the upper end of the rear vertical plate horizontally extends forwards to form an extending portion. The three internal correctors are horizontally arranged in the middle of the left fixed plate, horizontally arranged in the middle of the right fixed plate and vertically arranged in the middle of the extending portion respectively. The two external correctors are arranged on the left portion and the right portion of the compressing and locating device respectively. The automatic correction machine has the beneficial effects of being reasonable in structural design, high in automation degree, convenient to operate and control and the like. Through cooperation of external correction plates and internal correction plates, automatic correction treatment on the three-way air channel is achieved, and the three-way air channel is prevented from being damaged in the correction process, so that the machining precision of the three-way air channel is ensured.

Owner:ALEN GRP ANHUI ZHONGRUN HEAVY IND

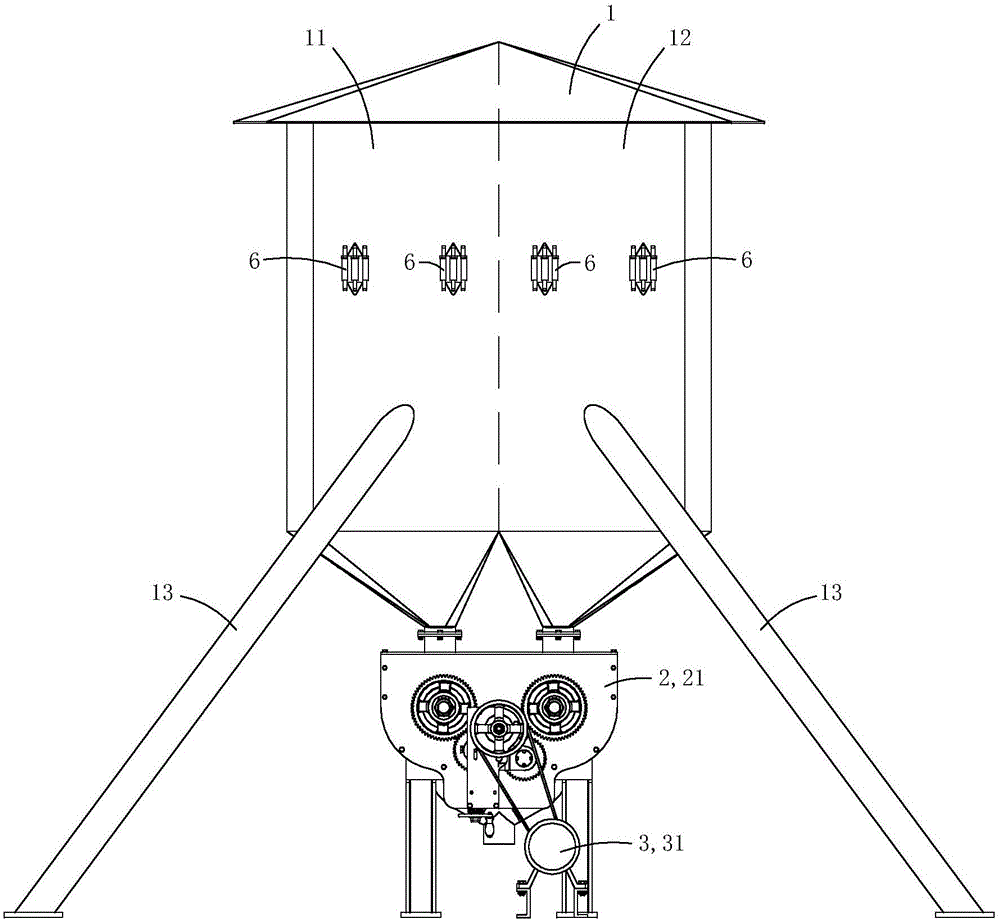

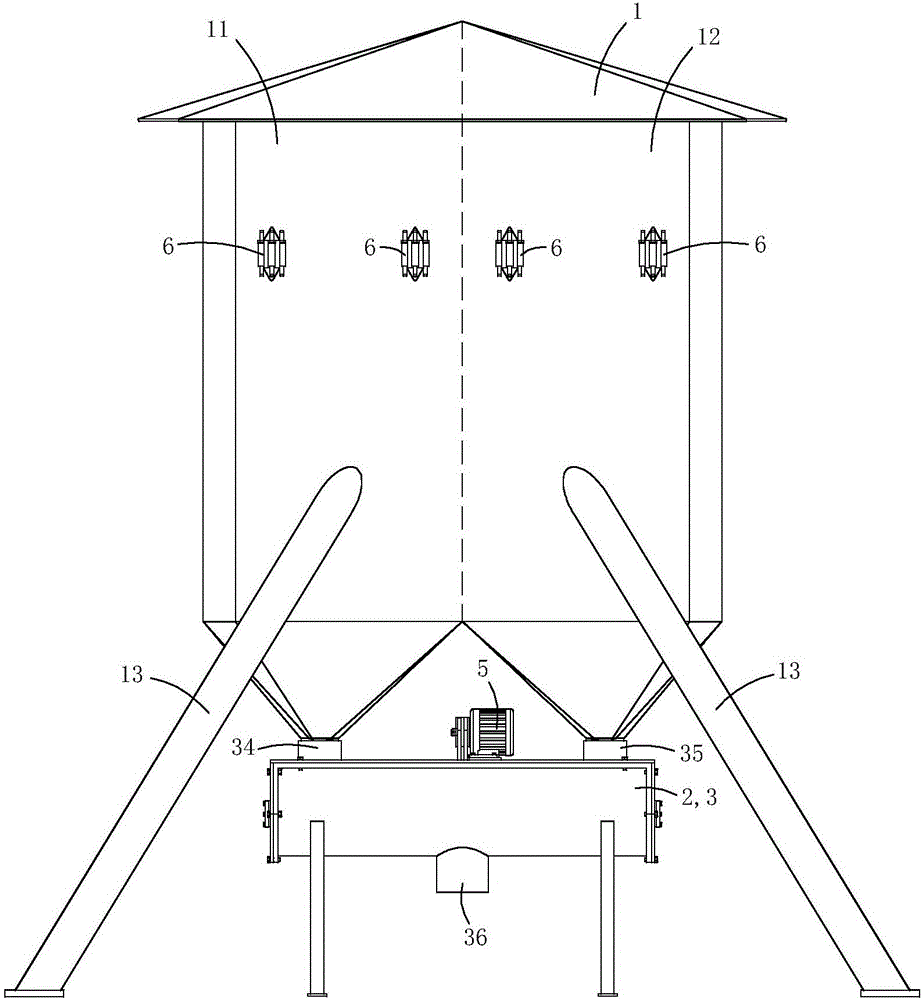

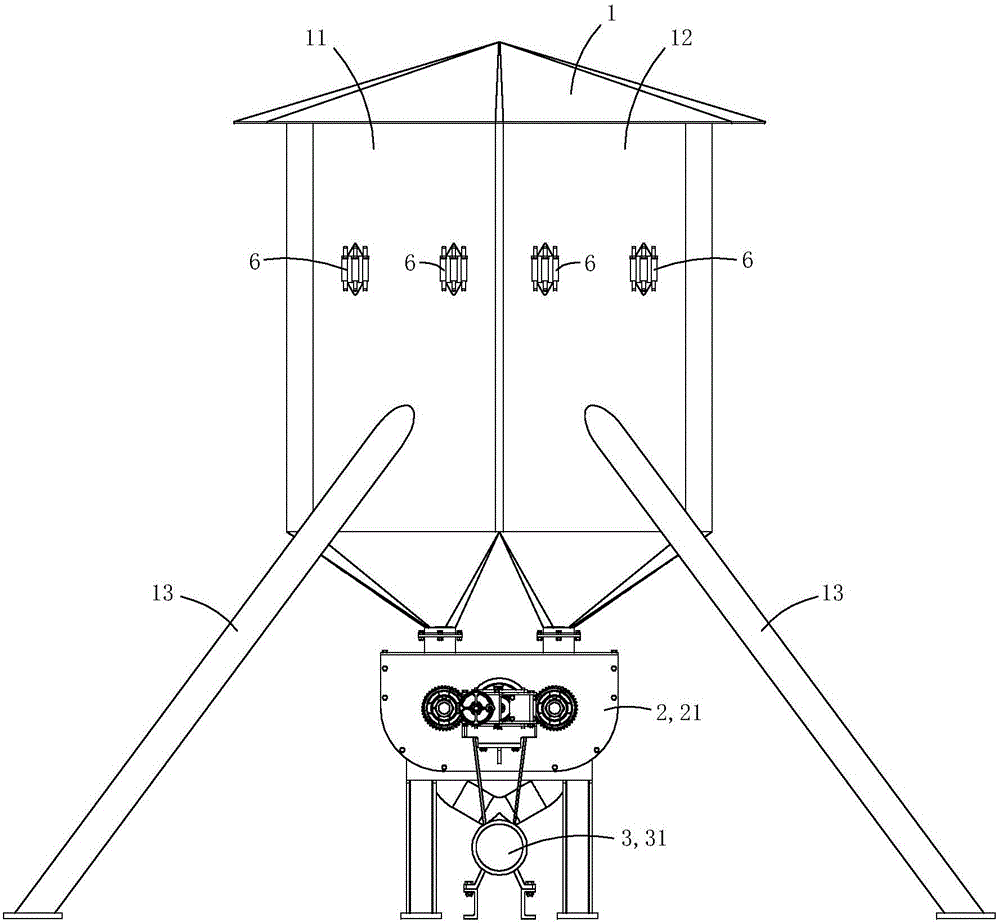

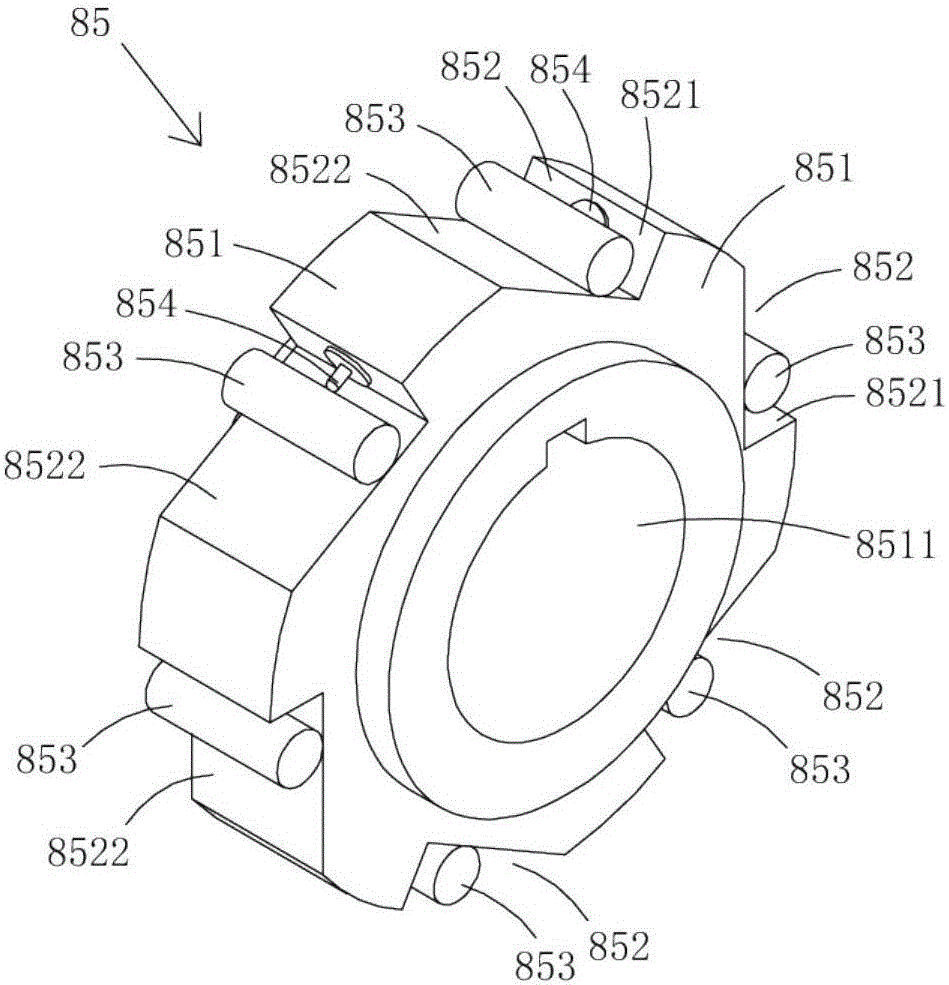

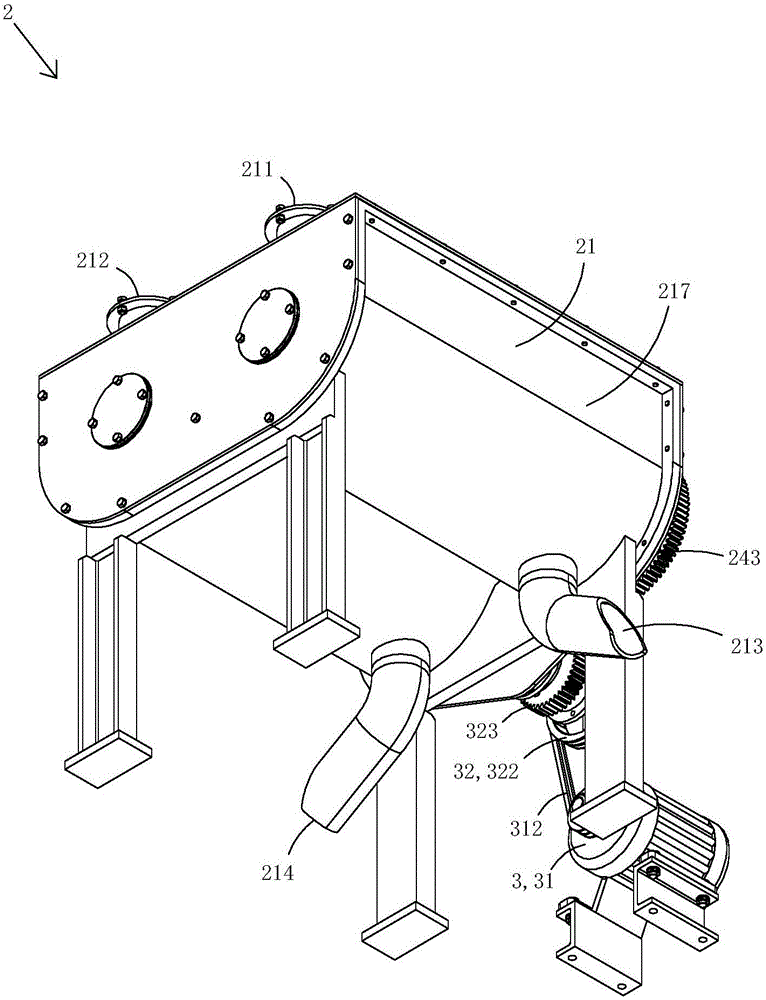

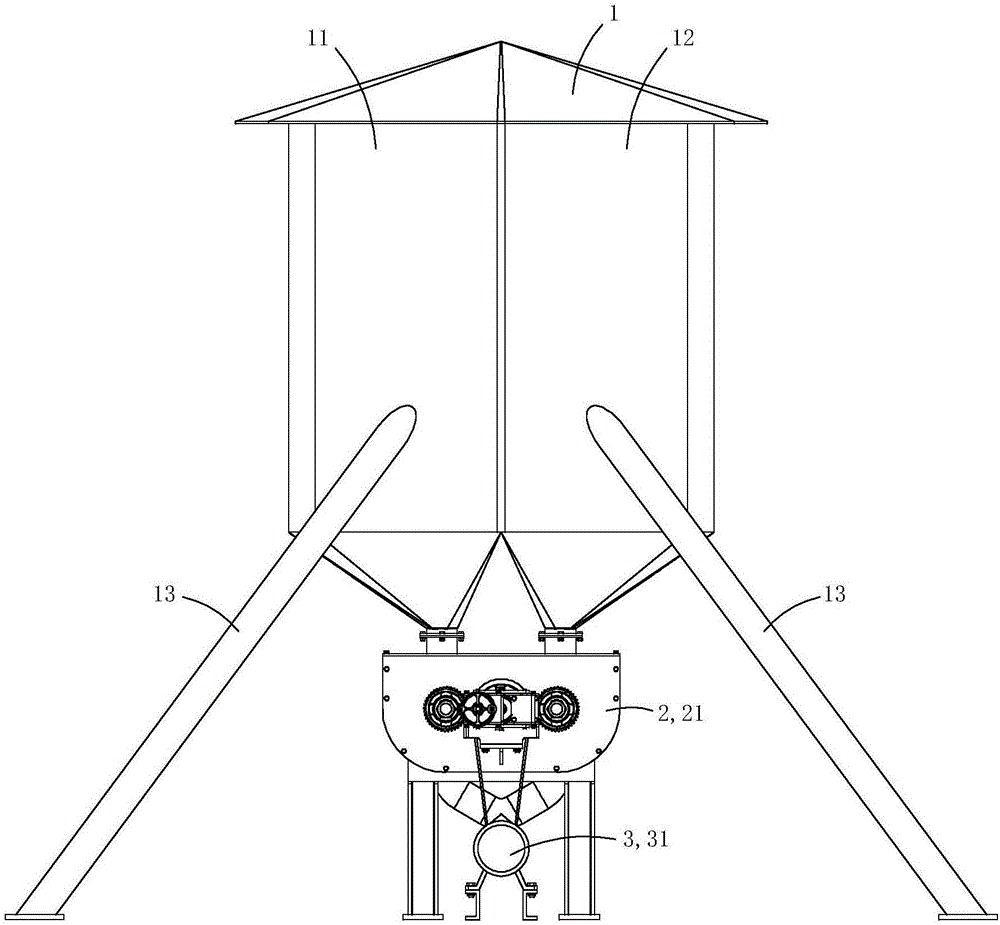

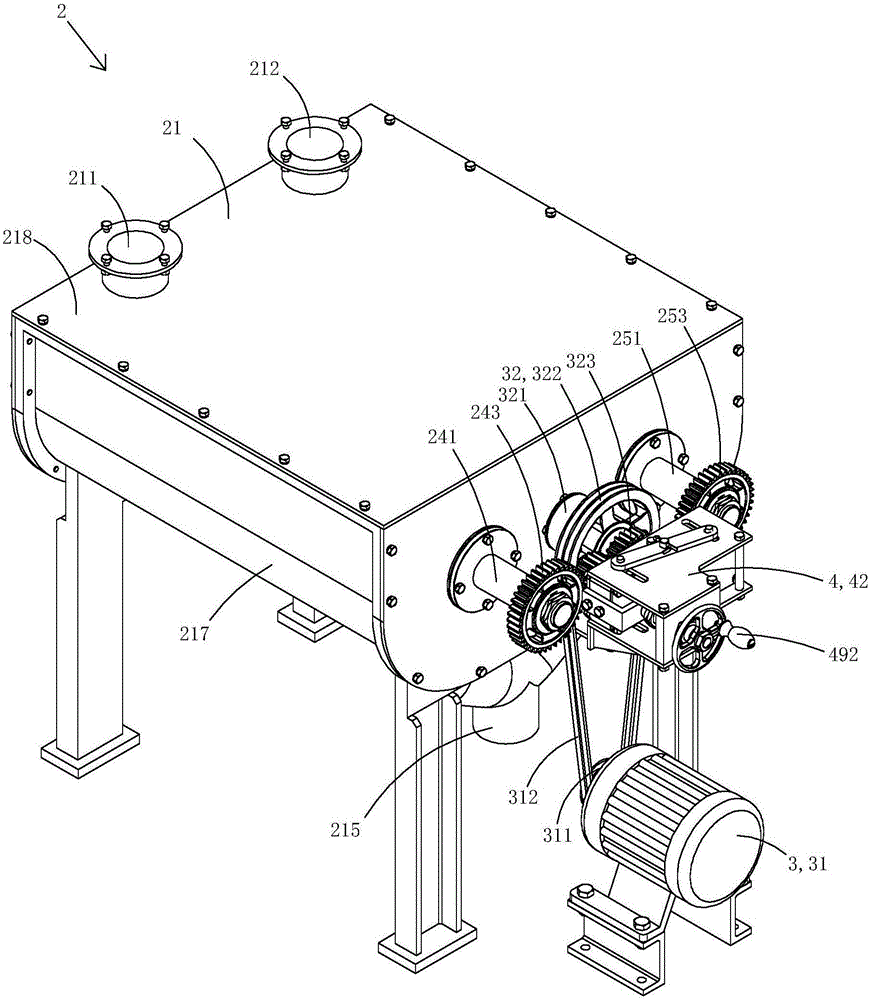

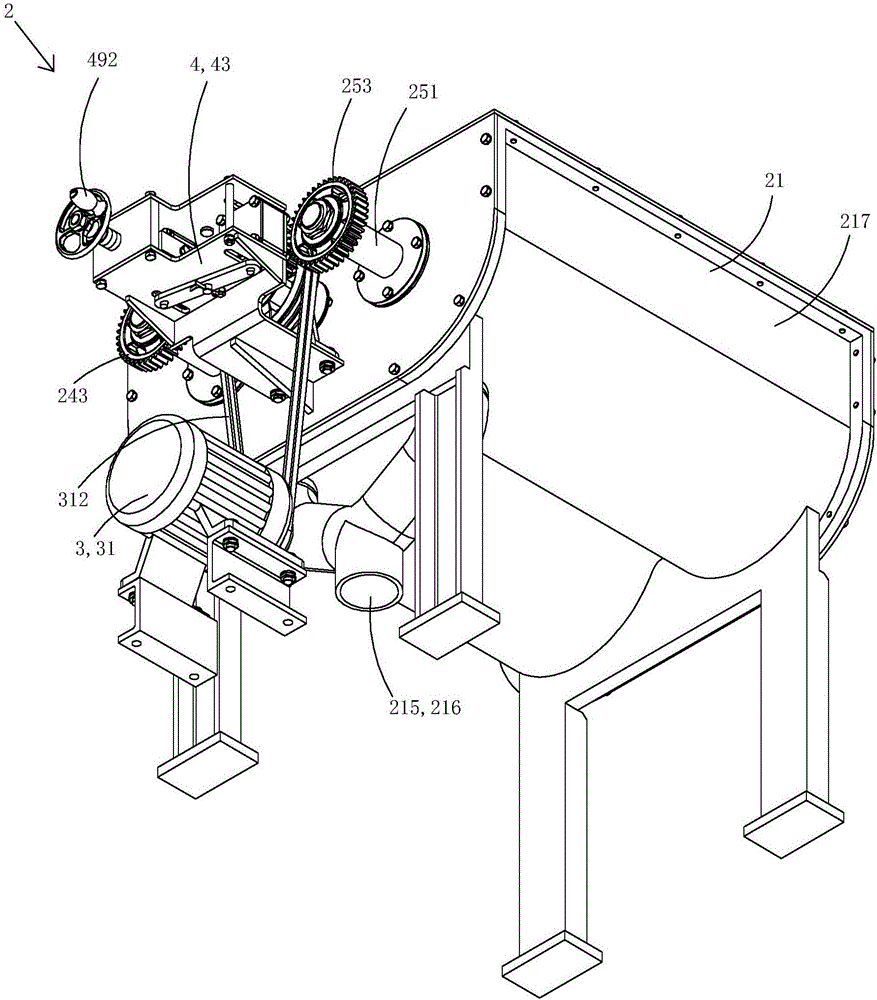

Electric grain unloading type double-body barn provided with linkage switching device

InactiveCN106586600AMeet the needs of installation and useHave the ability to move autonomouslyLoading/unloadingDrive wheelDrive shaft

The invention discloses an electric grain unloading type double-body barn provided with a linkage switching device. The electric grain unloading type double-body barn comprises a double-body warehouse and a grain unloading device arranged below the double-body warehouse. The double-body warehouse is provided with a first warehouse body and a second warehouse body which are arranged side by side. The first warehouse body and the second warehouse body are each internally provided with one or more information acquisition instruments. The grain unloading device comprises a first auger, a second auger and a driving device. The first auger comprises a first driven gear, and the second auger comprises a second driven gear. The driving device comprises a driving motor provided with a driving wheel, a transmission wheel set and the linkage switching device. The transmission wheel set comprises a transmission shaft, a transmission belt wheel and a transmission gear, wherein the transmission belt wheel and the transmission gear are fixedly arranged on the transmission shaft. The linkage switching device comprises a rack body, a first linkage gear assembly, a second linkage gear assembly, a reverse linkage assembly and a switching driving mechanism. In the process when the switching driving mechanism drives the first linkage gear assembly to perform reciprocating motion, the second linkage gear assembly is driven to perform reciprocating motion synchronously through a linkage plate. The electric grain unloading type double-body barn is compact and reasonable in structure.

Owner:SUZHOU BEITENGTE ELECTRONICS TECH

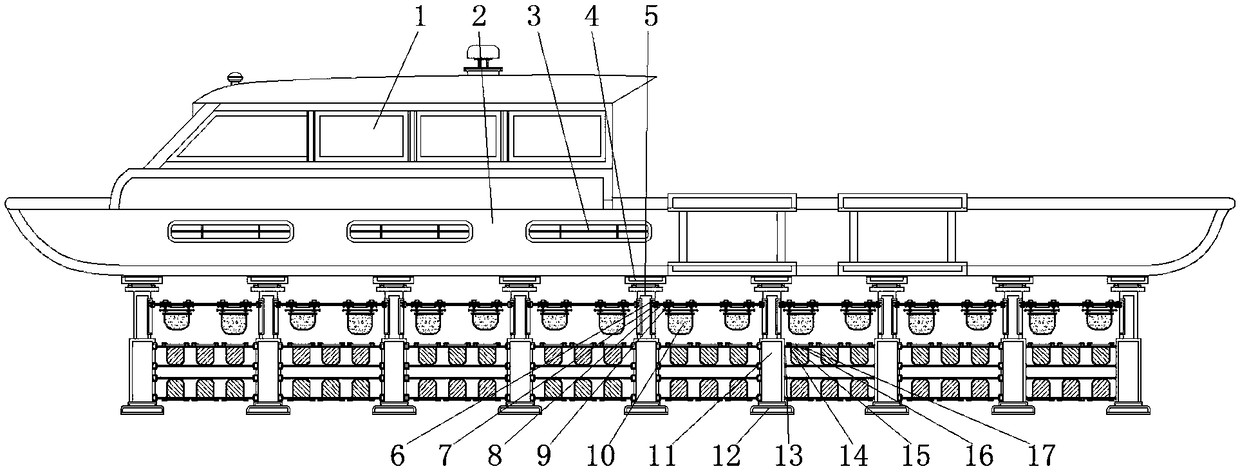

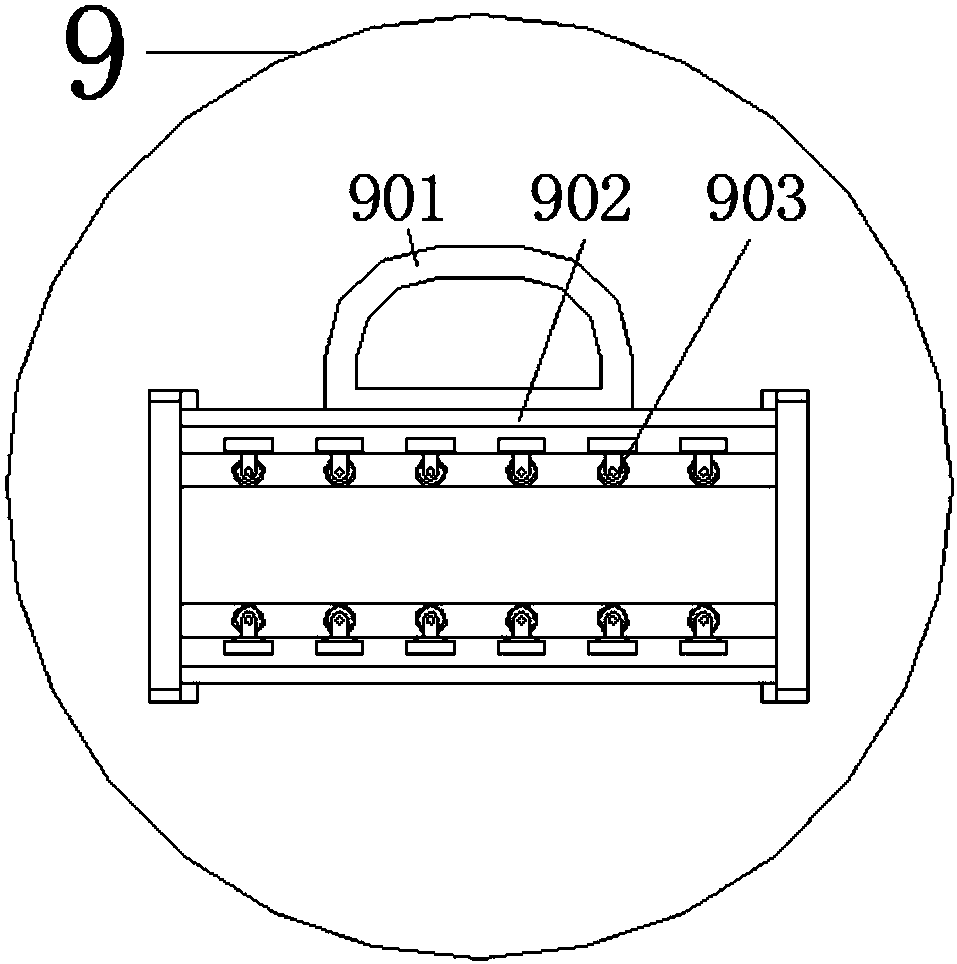

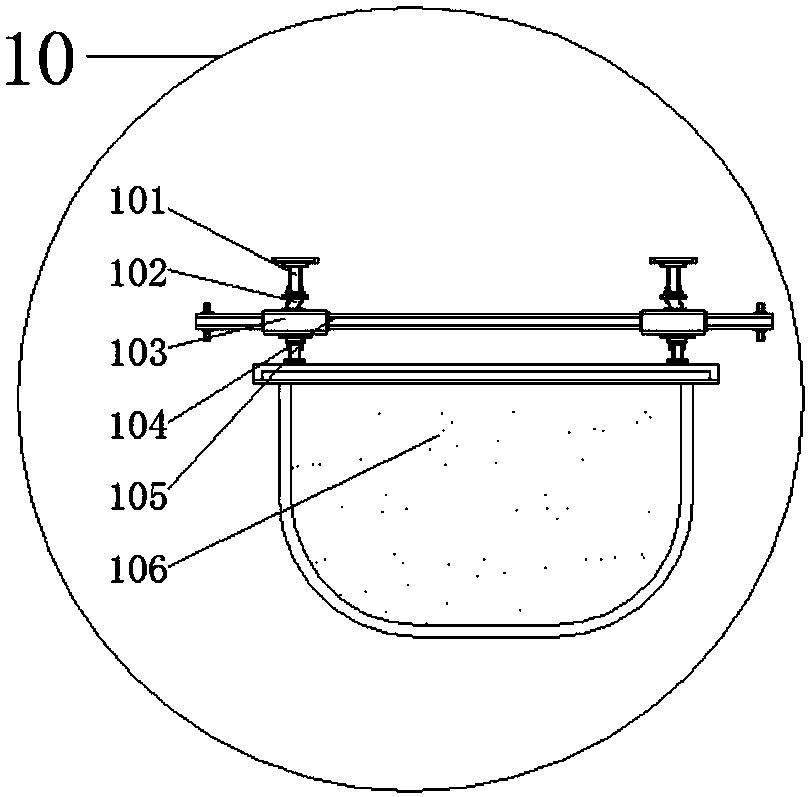

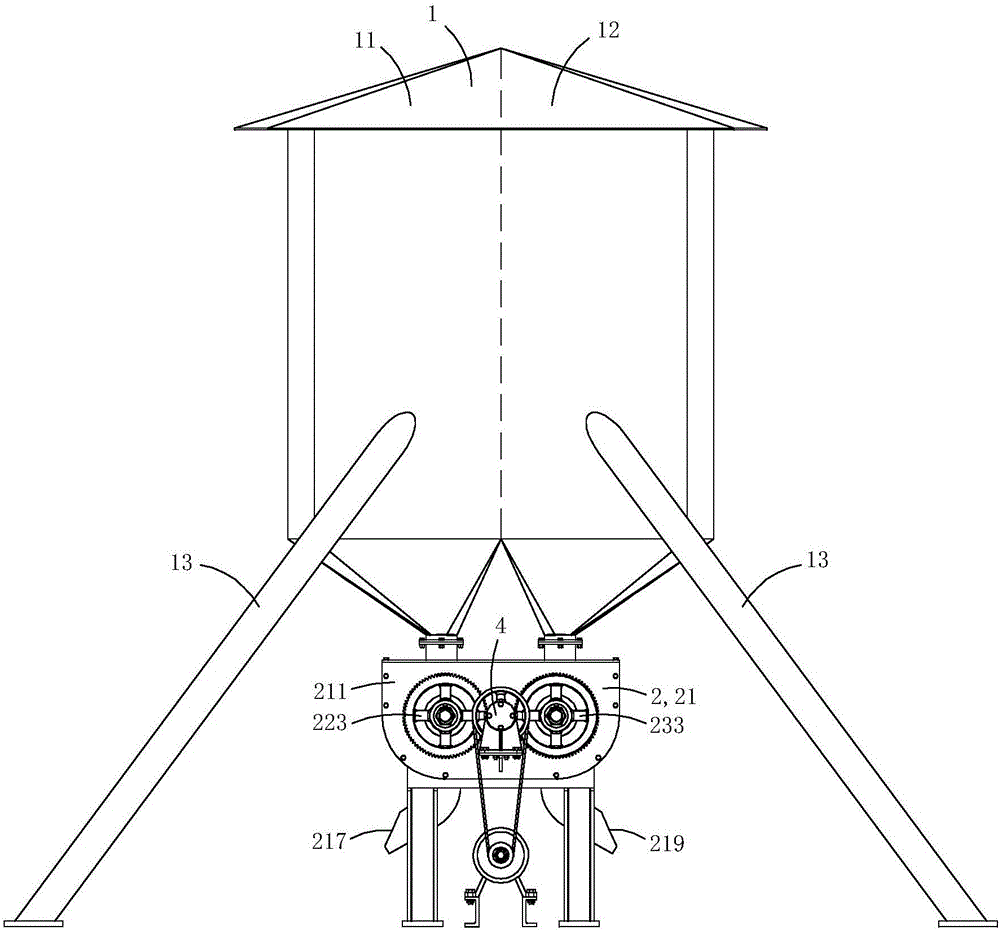

Platform type ship with undersea aquaculture function

InactiveCN108313220AReduce impactImprove stabilityClimate change adaptationVessel partsMarine engineeringEngineering

The invention discloses a platform type ship with an undersea aquaculture function. The platform type ship comprises a cockpit, damping support frames, shaft sleeves and aquaculture seal covers. A platform ship body is mounted on the lower side of the cockpit, transparent windows are embedded to the outer side of the platform ship body, the platform ship body is arranged on one side of the dampingsupport frames, supporting legs are embedded to bottom ends of the shaft sleeves, connection rods are fixedly connected to ports of two sides of each shaft sleeve, rotating shafts are arranged on upper sides of the connection rods, fastening plates are fixedly connected to outer sides of the rotating shafts, the connection rods are mounted on lower sides of the aquaculture seal covers, and the aquaculture seal covers are connected with aquaculture cages through the connection rods. The platform type ship with an undersea aquaculture function has advantages that by arrangement of movable sleeves and adjustable feed hoppers, gaps of the movable sleeves can be adjusted according to requirements to meet mounting and utilization requirements of the adjustable feed hoppers in different models,and accordingly an application range of the platform type ship is expanded; in addition, the platform type ship is simple in structure, low in manufacturing cost and suitable for large-scale production.

Owner:南安市妹族智能科技有限公司

Self-unloading double-body barn

InactiveCN106717614AMeet the needs of installation and useCompact and simplified structureMowersHarvested fruit hanging devicesDrive shaftDrive motor

The invention discloses a self-unloading double-body barn. The self-unloading double-body barn comprises a double-body warehouse and a grain unloading device. The double-body warehouse is provided with a first warehouse and a second warehouse. The grain unloading device comprises a box body with a first grain unloading cavity and a second grain unloading cavity, a first auger for unloading grain stored in the first grain unloading cavity, a second auger for unloading grain stored in the second grain unloading cavity, and a driving device for driving the first auger and the second auger to rotate. The first auger comprises a first rotary shaft, a first spiral plate and a first driven gear. The second auger comprises a second rotary shaft, a second spiral plate and a second driven gear. The driving device comprises a driving motor and a clutch linkage device. The clutch linkage device comprises a frame body, a transmission shaft, a clutch transmission gear, a belt wheel and a horizontal movement limiting part. The clutch transmission gear is in screw joint with an external thread part of the transmission shaft. The clutch transmission gear is located in a first transmission station when moving to one end of the external thread part, and the clutch transmission gear is located in a second transmission station when moving to the other end of the external thread part. The self-unloading double-body barn is compact and reasonable in structure.

Owner:SUZHOU BEITENGTE ELECTRONICS TECH

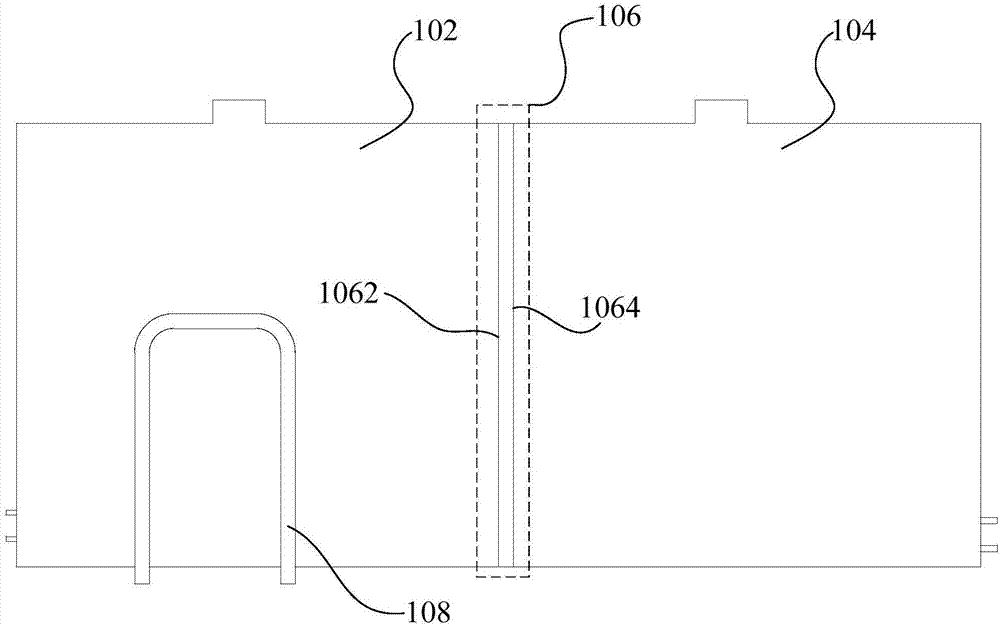

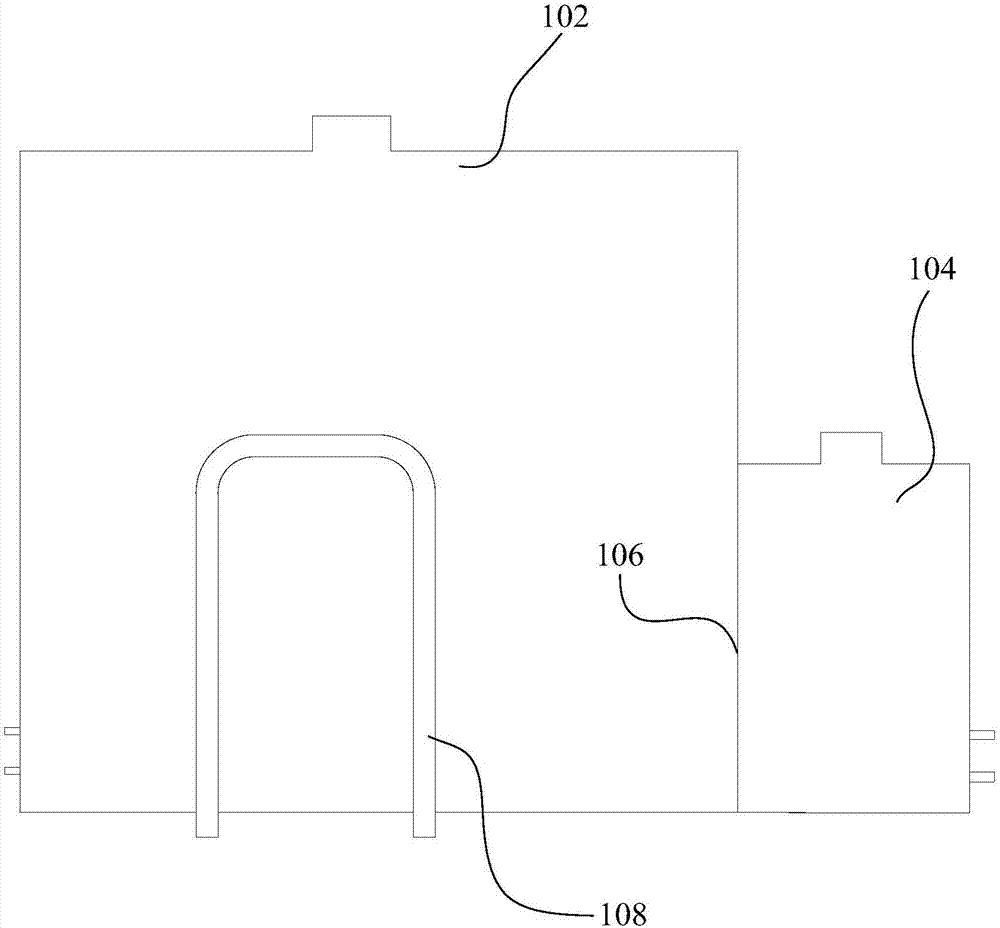

Dual-cavity fuel tank and mining dump truck

InactiveCN107458218ANot easy to looseImprove stabilityUnderstructuresFuel supplyLower gradeFuel tank

The invention provides a dual-cavity fuel tank and a mining dump truck. The dual-cavity fuel tank comprises a tank body, a partition body structure arranged in the tank body to form a first cavity and a second cavity in the tank body, and a heating device attaching to the outer wall face of the first cavity and / or arranged in the first cavity, wherein the first cavity is used for accommodating high-grade fuel, the second cavity is used for accommodating low-grade fuel, and the first cavity and the second cavity can be respectively connected with an engine to provide high-grade fuel or low-grade fuel for the engine. The dual-cavity fuel tank is compact in structure and easy to install, installing space is effectively saved, and the high-grade fuel can be rapidly heated, so that the mining dump truck can use the high-grade fuel in most operation time when working in a cold region, and the fuel use cost is effectively reduced.

Owner:SANY HEAVY EQUIP

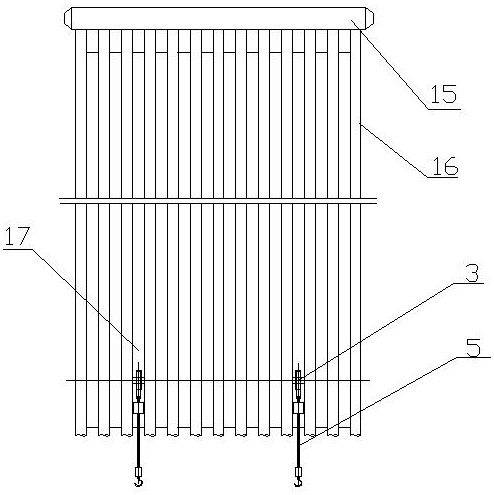

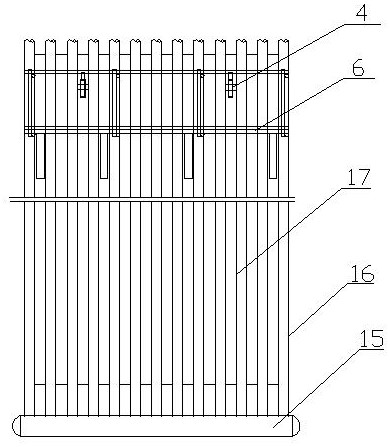

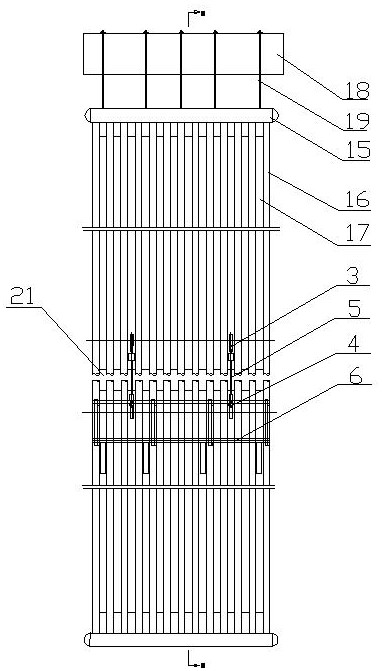

High-altitude assembly mounting device for boiler membrane water-cooled wall and mounting method of high-altitude assembly mounting device

ActiveCN113048461AMeet the needs of installation and useReduce areaWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMechanical engineering

The invention relates to a high-altitude mounting process for a boiler membrane water-cooled wall, in particular to a high-altitude assembly mounting device for the boiler membrane water-cooled wall and a mounting method of the high-altitude assembly mounting device. The high-altitude assembly mounting device comprises a hanging device component, an upper-section water-cooled wall group, a lower-section water-cooled wall group, an upper-section rigid beam, a lower-section rigid beam, an upper-section lifting lug assembly, a lower-section lifting lug assembly, a chain block and an operation platform component. The upper-section water-cooled wall group is arranged on the lower portion of the hanging device component and is connected with the hanging device component, and the upper-section rigid beam is arranged on the side face portion of the upper-section water-cooled wall group and is fixedly connected with the upper-section water-cooled wall group. According to the high-altitude mounting method of the boiler membrane water-cooled wall, the sectional water-cooled wall is small in size, light in weight and safe and convenient to hoist, and the mounting and using requirements of mounting engineering enterprises for the boiler membrane water-cooled wall are greatly met.

Owner:HENAN INSTALLATION GRP

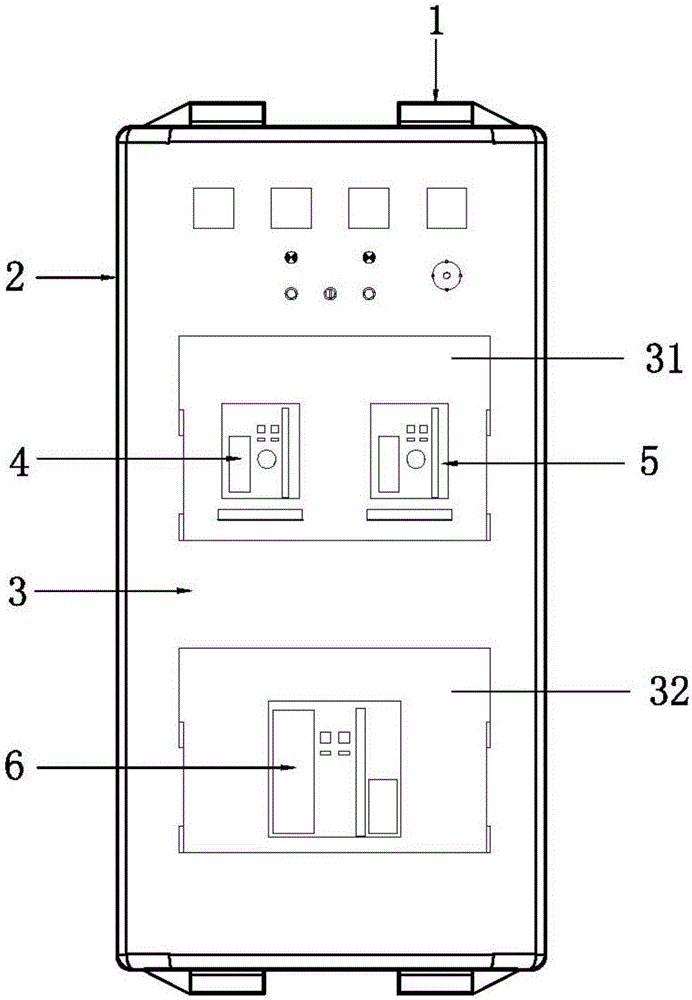

Compact photovoltaic control cabinet easy to install

InactiveCN106300072AIngenious structural designVarious installation methodsSubstation/switching arrangement detailsElectricityMultiple function

The invention discloses a compact photovoltaic control cabinet easy to install. The compact photovoltaic control cabinet comprises a multifunctional back frame, a cabinet body, a cabinet door arranged on the cabinet body, a PLC arranged in the cabinet body, a commercial power switch module, a photovoltaic power switch module and a pumping irrigation control module. The multifunctional back frame is provided with a through groove mounting hole, upper and lower edges of the multifunctional back frame are provided with clamping pins, and clamping positions matching the clamping pins are disposed on the cabinet body. The compact photovoltaic control cabinet is advantageous in that, structure design is delicate and reasonable, the purpose of fixation on an installing column via a steel band going through the through groove, or fixation to a wall surface via screws being screwed into installation holes is achieved, different installation and use demands of users are met, and the cabinet body and the multifunctional back frame are in a split structure, and therefore traditional installation processes are greatly simplified, installation is firm, stability is good, reliability is high, convenience is brought to installation and use, the whole structure is simple and compact, the size is small, cost is low, easy achievement is allowed, and wide popularization and application are facilitated.

Owner:SICHUAN SHUWANG TECH

Double-body barn with information acquisition instruments

InactiveCN106717619AMeet the needs of installation and useHave the ability to move autonomouslyAgriculture tools and machinesMeasurement devicesElectric machineryDrive motor

The invention discloses a double-body barn with information acquisition instruments. The double-body barn comprises a double-body warehouse and a grain unloading device, wherein the double-body warehouse is provided with a first warehouse and a second warehouse; each of the first warehouse and the second warehouse is internally provided with one information acquisition instrument; the grain unloading device comprises a grain unloading box and a driving device; the grain unloading box comprises a box body, a first packing auger, a second packing auger, a first feeding hole, a second feeding hole, a discharging hole and a belt wheel; the first packing auger comprises a first rotary shaft, a first spiral plate and a first unidirectional overrunning clutch; the second packing auger comprises a second rotary shaft, a second spiral plate and a second unidirectional overrunning clutch; spiral directions of the first spiral plate and the second spiral plate are opposite; the first unidirectional overrunning clutch and the second unidirectional overrunning clutch are arranged in shaft holes of the belt wheel; when rotating frontward, a driving motor drives the first rotary shaft to rotate by the first unidirectional overrunning clutch; when rotating backward, the driving motor drives the second rotary shaft to rotate by the second unidirectional overrunning clutch. The double-body barn disclosed by the invention has a relatively compact and reasonable structure.

Owner:SUZHOU BEITENGTE ELECTRONICS TECH

Grain unloading device used for logistics granary

InactiveCN106672651AMeet the needs of installation and useCompact and simplified structureConveyorsLarge containersGear driveDrive shaft

The invention discloses a grain unloading device used for a logistics granary. The grain unloading device comprises a first grain unloading box, a second grain unloading box and a drive device, wherein the first grain unloading box comprises a first box body and a first packing auger; the drive device comprises a drive motor and a clutch transmission mechanism; the clutch transmission mechanism comprises a belt wheel, a first transmission shaft, a first one-way overrunning clutch, a second transmission shaft and a second one-way overrunning clutch; the drive motor drives the belt wheel to rotate back and forth; a locking direction of the first one-way overrunning clutch is reverse to that of the second one-way overrunning clutch; when the drive motor forwardly rotates, the belt wheel drives the first transmission shaft through the first one-way overrunning clutch, so that a first transmission gear drives a first driven gear to rotate; and when the drive motor backwardly rotates, the belt wheel drives the second transmission shaft through the second one-way overrunning clutch, so that a second transmission gear drives a second driven gear to rotate. The grain unloading device is relatively compact and reasonable in structure.

Owner:SUZHOU BEITENGTE ELECTRONICS TECH

Electric unloading granary with real-time grain monitoring function

InactiveCN106717635AMeet the needs of installation and useHave the ability to move autonomouslyMeasurement devicesMowersDrive wheelGear drive

Owner:SUZHOU BEITENGTE ELECTRONICS TECH

An air amplifier for electric vehicles

InactiveCN108979948BMeet the needs of installation and useEliminate the influence caused by the aerodynamic layout structureWind motor controlWind motor combinationsAudio power amplifierElectric vehicle

The invention relates to an air amplifier for electric vehicles. The air amplifier comprises a guide hood, a backflow liner tube, diversion branch pipes, a diversion fan, spray ports, angle sensors, an air speed sensor, a diversion hood and a control circuit. The guide hood covers the backflow liner tube; the diversion hood is connected with the front end face of the guide hood; the sidewall of the guide hood is communicated with the tail end of the diversion branch pipe via a guide port; the front end face of one diversion branch pipe is communicated with the diversion fan; the front end of at least one another diversion branch pipe is communicated with the spray port; the spray ports are distributed evenly in the inner surface of the backflow liner tube around the axis of the backflow liner tube; each turnplate mechanism is provided with at least one angle sensor. The air amplifier has the advantages that the requirement on installation and use of different types of electric vehiclescan be effectively met; natural air flow can be effectively increased to carry out pressurizing and accelerating.

Owner:李素梅 +2

Dual-body logistics granary with information acquisition instruments

InactiveCN106629120AMeet the needs of installation and useHave the ability to move autonomouslyLarge containersLoading/unloadingLogistics managementDrive shaft

The invention discloses a dual-body logistics granary with information acquisition instruments. The dual-body logistics granary comprises a dual-body warehouse and a grain unloading device, wherein the dual-body warehouse is provided with a first warehouse and a second warehouse; at least one information acquisition instrument is arranged in each of the first warehouse and the second warehouse; the grain unloading device comprises a first grain unloading box, a second grain unloading box and a drive device; the first grain unloading box comprises a first box body and a first auger; the first auger comprises a first rotary shaft, a first spiral plate, a first one-way overrunning clutch and a first driven gear; the second grain unloading box comprises a second box body and a second auger; the second auger comprises a second rotary shaft, a second spiral plate, a second one-way overrunning clutch and a second driven gear; the drive device comprises a drive motor and a transmission mechanism; the transmission mechanism comprises a transmission shaft, a transmission gear and a belt wheel; the drive motor drives the first rotary shaft to rotate through the first one-way overrunning clutch while rotating forwards; and the drive motor drives the second rotary shaft to rotate through the second one-way overrunning clutch while rotating backwards. The dual-body logistics granary disclosed by the invention is low in cost and occupies less space.

Owner:SUZHOU JUNFENGCHEN ELECTRONICS TECH

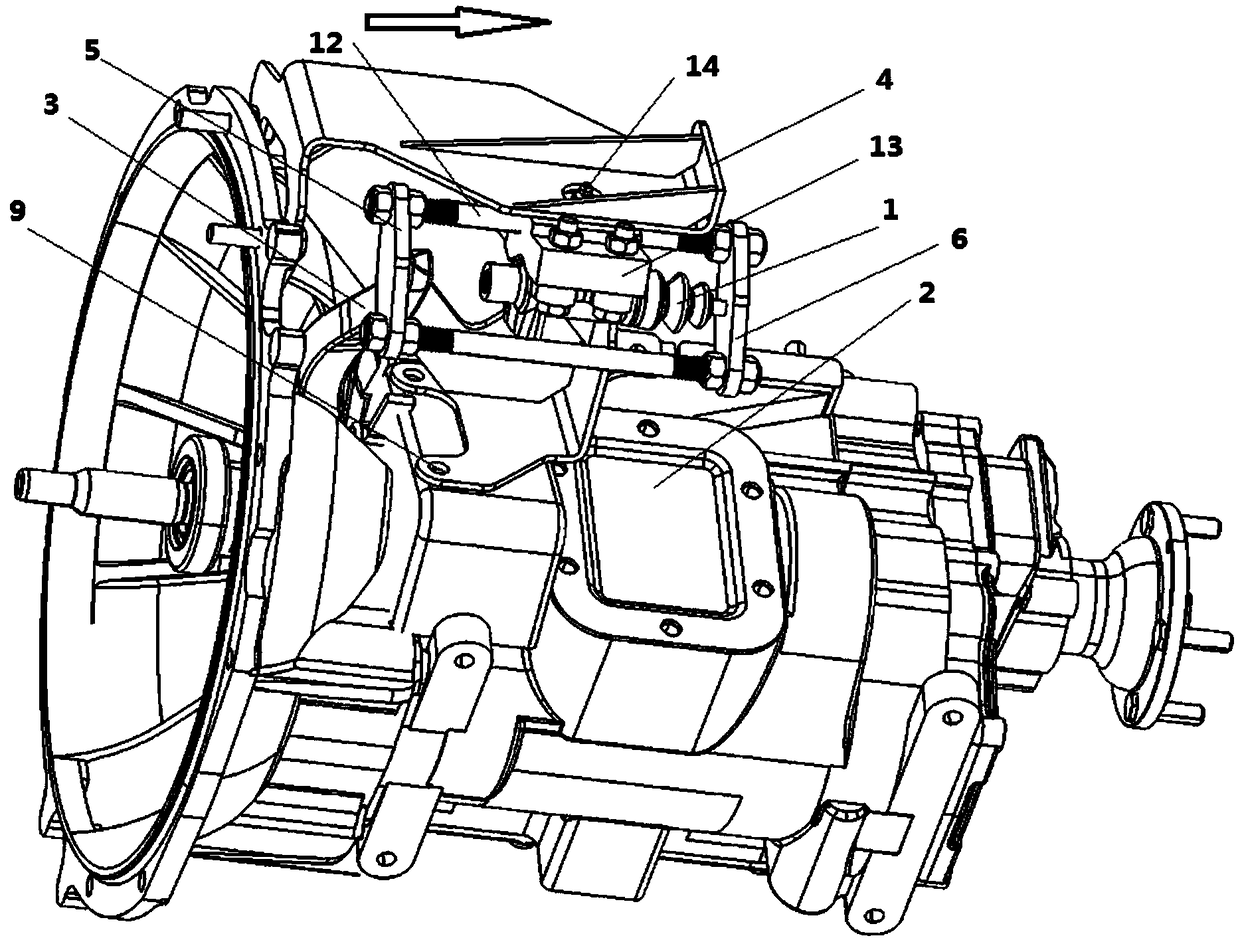

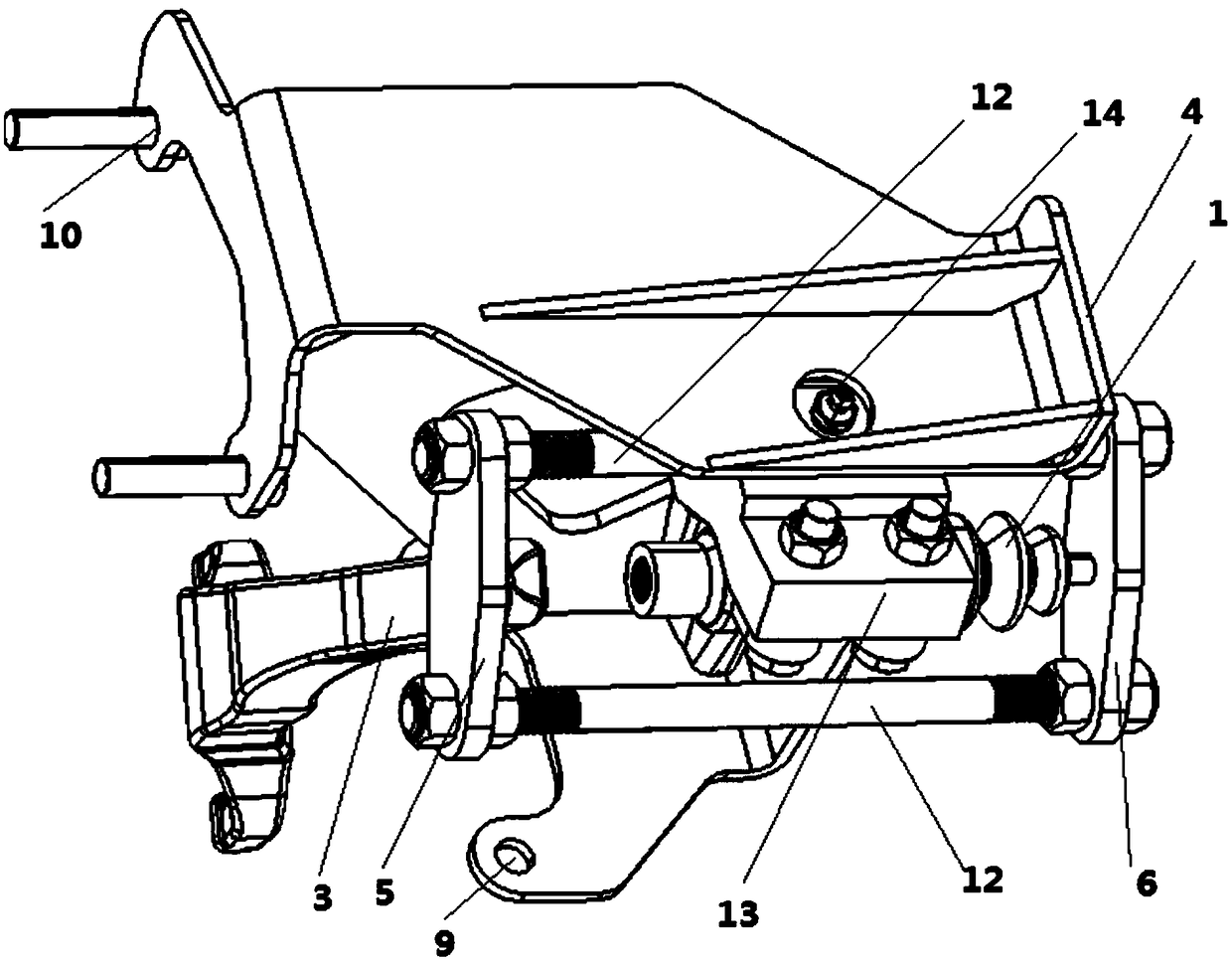

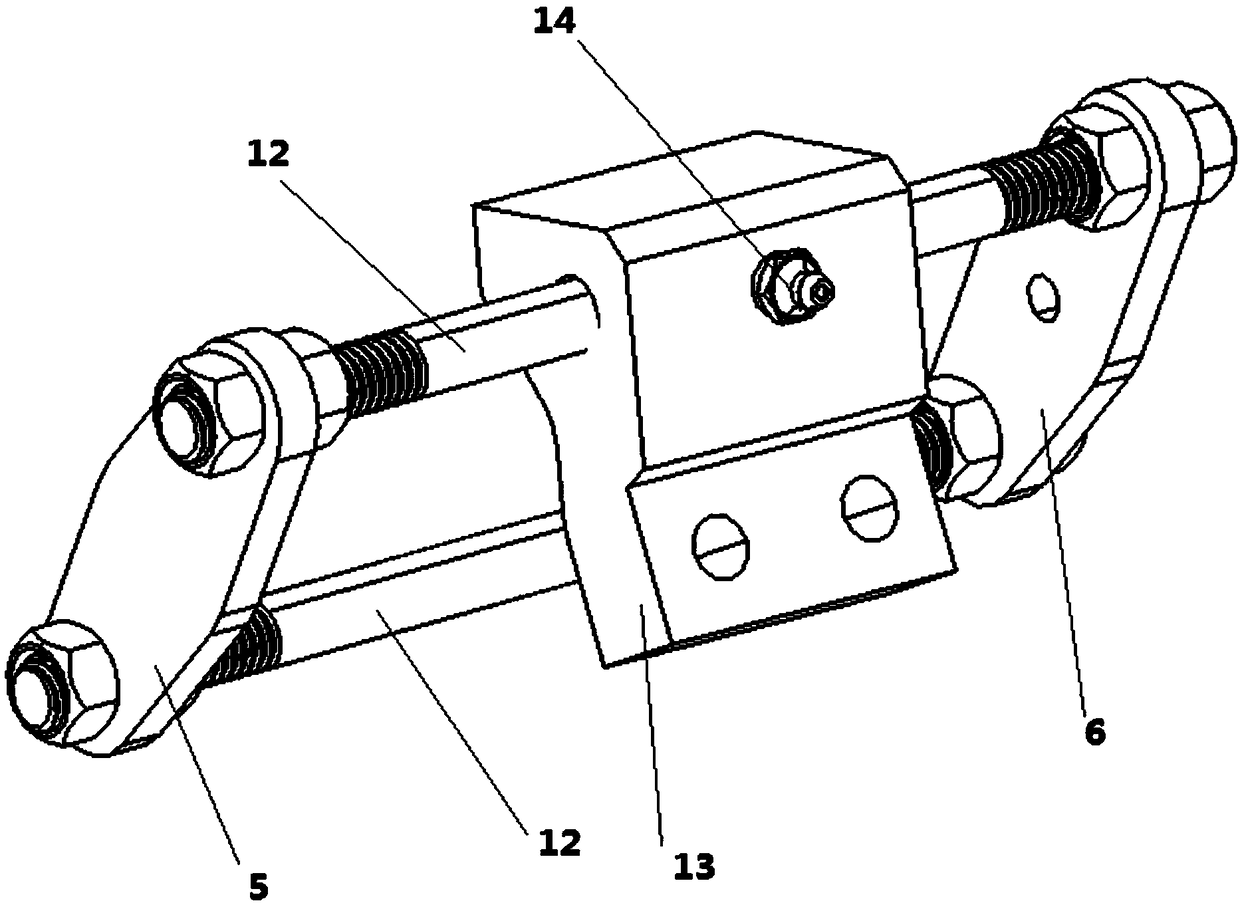

A clutch cylinder thrust conversion mechanism

The invention provides a thrust conversion mechanism of a clutch slave cylinder. The clutch slave cylinder is fixedly mounted on a clutch slave cylinder bracket; the clutch slave cylinder bracket is fixedly connected with a transmission side and a steering wheel side; the thrust conversion mechanism is provided with an inner thrust plate and an outer thrust plate, which are driven by the clutch slave cylinder; a separation shifting fork is located between the inner thrust plate and the outer thrust plate; a thrust of the clutch slave cylinder is converted into a pulling force of the separation shifting fork through a design structure of a fixed bracket, the inner thrust plate and the outer thrust plate, so that installation and utilization requirements of the clutch slave cylinder are met when relative positions of the clutch slave cylinder and the separation shifting fork do not accord with the direction of the needed thrust.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Logistics granary with information acquirer

InactiveCN106672649AMeet the needs of installation and useHave the ability to move autonomouslyConveyorsLarge containersLogistics managementEngineering

The invention discloses a logistics granary with an information acquirer. The logistics granary comprises a double-body warehouse and a grain unloading device; the grain unloading device includes a first grain unloading box, a second grain unloading box and a driving device; the first grain unloading box includes a first box body and a first auger; the driving device includes a driving motor and a clutch transmission mechanism; the clutch transmission mechanism includes a belt wheel, a first transmission shaft, a first one-way overrunning clutch, a second transmission shaft and a second one-way overrunning clutch; the driving motor drives the belt wheel to perform reciprocating rotation; a locking direction of the first one-way overrunning clutch is opposite to a locking direction of the second one-way overrunning clutch; when the driving motor forwards rotates, the belt wheel drives the first transmission shaft through the first one-way overrunning clutch so as to drive a first driven gear through a first transmission gear; and when the driving motor reversely rotates, the belt wheel drives the first transmission shaft through the second one-way overrunning clutch so as to drive a second driven gear through a second transmission gear. The logistics granary is more compact and reasonable in structure.

Owner:SUZHOU BEITENGTE ELECTRONICS TECH

Double-body logistics granary with information acquisition function

InactiveCN106717632AMeet the needs of installation and useHave the ability to move autonomouslyAgriculture tools and machinesMeasurement devicesClutchDrive motor

The invention discloses a double-body logistics granary with an information acquisition function. The double-body logistics granary comprises a double-body warehouse and a grain unloading device, wherein the double-body warehouse comprises a first warehouse and a second warehouse; at least one information acquirer is arranged in each of the first warehouse and the second warehouse; the grain unloading device comprises a first grain unloading box, a second grain unloading box and a driving device; the first grain unloading box comprises a first box body and a first packing auger; the first packing auger comprises a first rotating shaft, a first helical plate, a first one-way overrunning clutch and a first driven gear; the second grain unloading box comprises a second box body and a second packing auger; the second packing auger comprises a second rotating shaft, a second helical plate, a second one-way overrunning clutch and a second driven gear; the driving device comprises a driving motor and a transmission mechanism; the transmission mechanism comprises a transmission shaft, a transmission gear and a belt wheel; when the driving motor rotates clockwise, the first one-way overrunning clutch drives the first rotating shaft to rotate; when the driving motor rotates anticlockwise, the second one-way overrunning clutch drives the second rotating shaft to rotate. The double-body logistics granary is relatively low in cost and occupies a relatively small space.

Owner:SUZHOU JUNFENGCHEN ELECTRONICS TECH

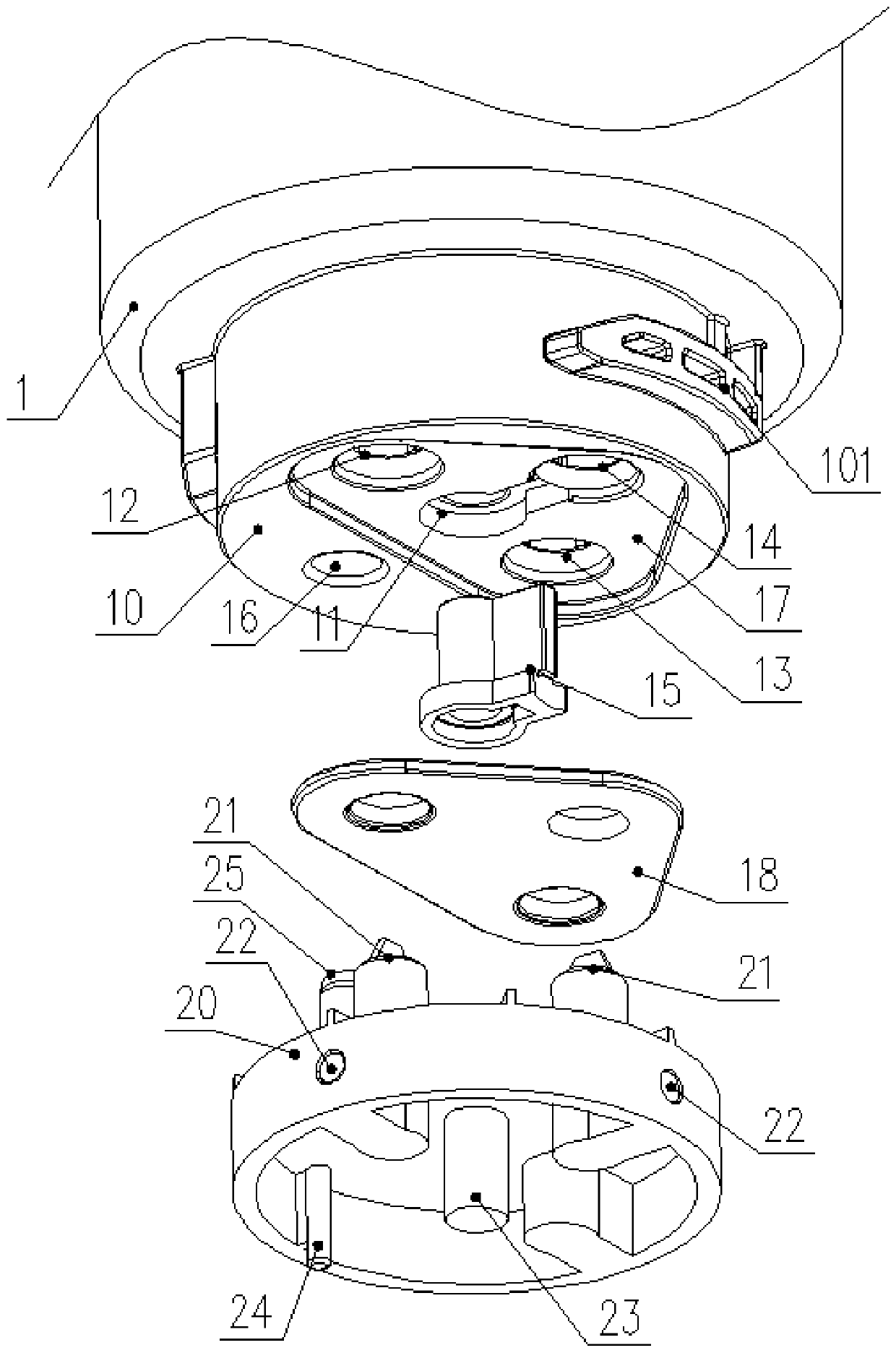

Filter element and filter device

PendingCN109985434AImprove installation versatilityGuaranteed stabilityFiltration separationWater channelWater flow

The invention provides a filter element. The installation end of the filter element is provided with a first water-passing hole, a second water-passing hole and a third water-passing hole, the installation end further comprises a water diversion hole, and a connecting water channel is arranged between the water diversion hole and the first water-passing hole for communicating; a sealing member isdetachably installed at the first water-passing hole; and when the sealing member is installed in the first water-passing hole position, a water flow passing through the first water-passing hole position is guided by the connecting water channel for diversion by the water diversion hole. The invention also provides a filter device using the filter element. According to the filter element providedby the invention, the water diversion hole and the sealing member are arranged, so that the positions of the water-passing holes of the filter element can be adjusted to a certain extent according todifferent installation structures, and the installation universality of the filter element can be effectively improved.

Owner:GUANGDONG WAPU TECH CO LTD

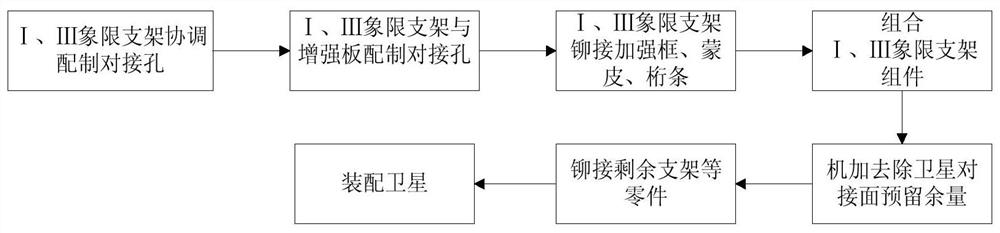

A thin-walled one-arrow five-star satellite bracket and its assembly method

ActiveCN109466798BGuaranteed manufacturing precisionMeet the needs of installation and useCosmonautic partsArtificial satellitesFlight testRocket

The invention relates to a one-rocket five-satellite satellite bracket with a thin-wall structure and an assembly method thereof, which adopt a scheme of firstly coordinating assembly and then mechanically guarantee, thereby avoiding the reference deviation of a satellite installation surface caused by deformation led by assembly, ensuring the precision of the satellite installation surface and the manufacturing and processing precision of the one-rocket five-satellite satellite bracket, and meeting the requirements of satellite installation and use. The one-rocket five-satellite satellite bracket with the thin-wall structure and the assembly method thereof are successfully applied to model products and proved to be correct and reliable by completing flight test verification,. According tothe one-rocket five-satellite satellite bracket with the thin-wall structure and the assembly method thereof, a rubber tire is arranged, so that the stability of the bracket in the process of removing the allowance is ensured, and trembling is avoided. A process hole is arranged when a L-shaped connecting plate is connected with the lower end surface of a second reinforcing frame in the assemblyprocess, and the L-shaped connecting plate is connected with the lower end surface of the second reinforcing frame through a process nail, so that the stability of the whole satellite bracket in the process of removing the allowance is ensured, and the damage to a rivet and a connecting hole in the process of removing the allowance is avoided.

Owner:CAPITAL AEROSPACE MACHINERY +1

Double-body electric grain unloading granary with real-time monitoring function

InactiveCN106576627AMeet the needs of installation and useCompact and simplified structureAgriculture tools and machinesMeasurement devicesDrive wheelElectric machinery

The invention discloses a double-body electric grain unloading granary with a real-time monitoring function. The double-body electric grain unloading granary comprises a double-body warehouse and a grain unloading device arranged below the double-body warehouse, wherein the double-body warehouse is provided with a first warehouse and a second warehouse which are arranged side by side; at least one information acquirer is arranged in each of the first warehouse and the second warehouse; the grain unloading device comprises a box body in which a first grain unloading channel and a second grain unloading channel are formed, a first packing auger, a second packing auger and a driving device for driving the first packing auger and the second packing auger to rotate; the first warehouse communicates with the first grain unloading channel; the second warehouse communicates with the second grain unloading channel; the driving device comprises a driving motor with a driving wheel, a transmission wheel group arranged on the outer wall of the box body in a rotatable manner and a linkage switching device arranged on the outer wall of the box body; the driving motor drives the transmission wheel group to rotate through the driving wheel; and the transmission wheel group drives the first packing auger or the second packing auger to rotate through the linkage switching device. The double-body electric grain unloading granary occupies a relatively small space and is relatively low in cost.

Owner:SUZHOU JUNFENGCHEN ELECTRONICS TECH

A correction device for a three-air channel for a ship

ActiveCN105107876BQuality assuranceReasonable structural designMetal-working feeding devicesPositioning devicesEngineeringAutomation

Owner:ALEN GRP ANHUI ZHONGRUN HEAVY IND

Grain unloading device with augers

PendingCN106348048AMeet the needs of installation and useCompact and simplified structureLoading/unloadingDrive shaftGear wheel

The invention discloses a grain unloading device with augers. The grain unloading device with the augers comprises a box body, a first auger, a second auger and a driving device, wherein the box body is provided with a first grain unloading cavity and a second grain unloading cavity; the first auger is used for unloading grain stored in the first grain unloading cavity; the second auger is used for unloading grain stored in the second grain unloading cavity; the driving device is used for driving the first auger and the second auger to rotate; the first auger comprises a first rotating shaft, a first spiral plate and a first driven gear; the second auger comprises a second rotating shaft, a second spiral plate and a second driven gear; the driving device comprises a driving motor and a clutch linkage device; the clutch linkage device comprises a frame body, a driving shaft, a clutch driving gear and a belt wheel; the driving shaft is provided with an external thread part; the clutch driving gear is spirally connected with the external thread part of the driving shaft; and the clutch driving gear is positioned at a first driving station when moving to one end of the external thread part, and is positioned at a second driving station when moving to the other end of the external thread part. The grain unloading device with the augers is compact and reasonable in structure.

Owner:SUZHOU JUNFENGCHEN ELECTRONICS TECH

Intelligent type double-body warehouse used for storing granulated materials

PendingCN106586597ACompact and simplified structureReasonable structureConveyorsLarge containersClutchDrive motor

The invention discloses an intelligent type double-body warehouse used for storing granulated materials. The intelligent type double-body warehouse comprises a double-body warehouse and a material unloading device. The double-body warehouse is provided with a first warehouse body and a second warehouse body. The first warehouse body and the second warehouse body are each internally provided with one or more information acquisition instruments. Each information acquisition instrument comprises a barrel shell, a main gear, advancing rolling tubes, subsidiary gears and original power motors. The material unloading device comprises a first material unloading box, a second material unloading box and a driving device. The first material unloading box comprises a first box body and a first auger. The second first material unloading box comprises a second box body and a second auger. The driving device comprises a driving motor and a clutch transmission mechanism. The clutch transmission mechanism comprises a rack body, a worm, a belt wheel, a worm wheel, a first one-way overrunning clutch, a first transmission shaft, a second one-way overrunning clutch and a second transmission shaft. When the driving motor rotates forwards, the first auger is driven by the first one-way overrunning clutch to rotate; and when the driving motor rotates backwards, the second auger is driven by the second one-way overrunning clutch to rotate. The intelligent type double-body warehouse is compact and reasonable in structure.

Owner:SUZHOU BEITENGTE ELECTRONICS TECH

Electric discharge barn

InactiveCN106665002AMeet the needs of installation and useCompact and simplified structureAgriculture tools and machinesHarvested fruit hanging devicesElectric dischargeGear drive

The invention discloses an electric discharge barn, comprising a double-body bin and a grain discharge device; the grain discharge device comprises a first screw, a second screw and a driving device; the first screw comprises a first driven gear, the second screw comprises a second driven gear, a driving device comprises a driving motor with a driving wheel, and a linkage switching device, the linkage switching device comprises a frame, a transmission wheel set, a guide plate and a linkage gear component, the transmission wheel set includes a transmission shaft, a transmission belt wheel and a transmission gear, the guide plate is provided with a guide hole, the linkage gear component comprises a linkage gear and a guide part for limiting the linkage gear reciprocating back and forth along the guide hole, the guide part is arranged in the guide hole, the transmission gear drives the first driven gear to rotate through the linkage gear when the guide part slides to one end of the guide hole, and the transmission gear dries the second driven gear to rotate through the linkage gear when the guide part slides to the other end of the guide hole. The electric discharge barn is compact and reasonable in structure.

Owner:卢永英

Dual-body electric unloading granary

PendingCN106395415AMeet the needs of installation and useCompact and simplified structureLoading/unloadingDrive wheelEngineering

The invention discloses a dual-body electric unloading granary. The dual-body electric unloading granary comprises a dual-body granary and an unloading device, wherein the dual-body granary is provided with a first granary body and a second granary body; the unloading device comprises a box body in which a first unloading channel and a second unloading channel are arranged, a first packing auger used for unloading grain stored in the first unloading channel, a second packing auger used for unloading grain stored in the second unloading channel and a driving device used for driving the first packing auger and the second packing auger to rotate; the first granary body communicates with the first unloading channel, and the second granary body communicates with the second unloading channel; the driving device comprises a driving motor with a driving wheel, a transmission wheel set and a linked switching device; and the driving motor drives the transmission wheel set to rotate through the driving wheel, and the transmission wheel set drives the first packing auger or the second packing auger to rotate through the linked switching device. The dual-body electric unloading granary occupies a small space and is low in cost.

Owner:SUZHOU BEITENGTE ELECTRONICS TECH

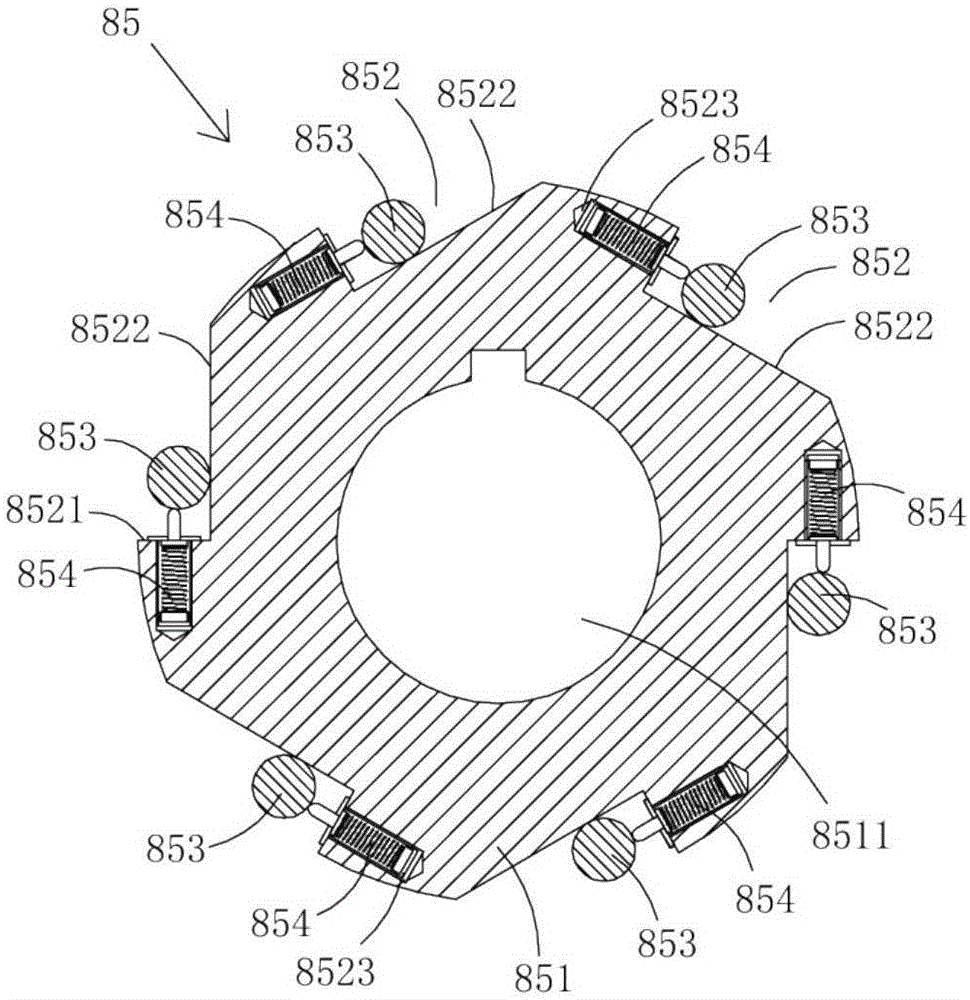

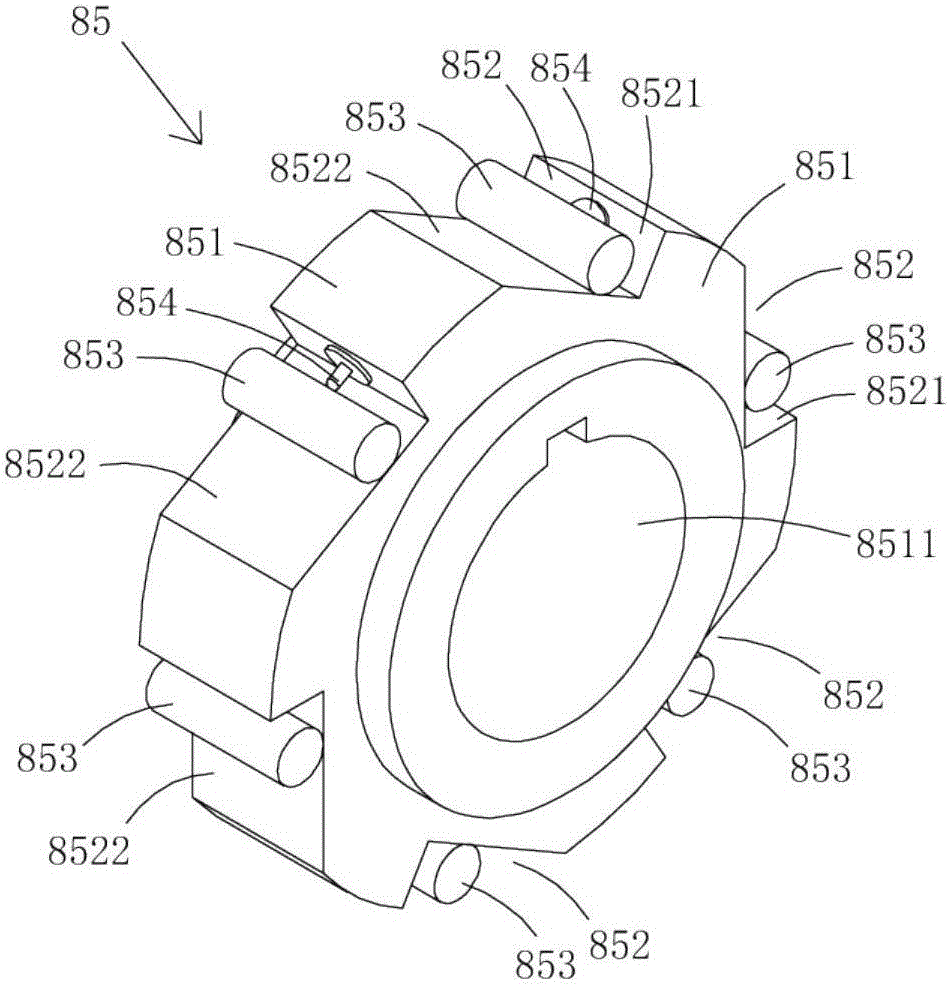

Correction device of three-way wind channel for ship

ActiveCN105107876AQuality assuranceReasonable structural designMetal-working feeding devicesPositioning devicesEngineeringAutomation

The invention relates to a correction device of a three-way wind channel for a ship. The device comprises a baseplate, a pressing positioning device, a left fixed plate, a right fixed plate, a back standing plate and correctors, wherein the pressing positioning device is mounted in middle of the upper end of the baseplate; the left fixed plate, the right fixed plate and the back standing plate are respectively and correspondingly fixed at the left part, the right part and the back part of the baseplate; the upper end of the back standing plate forwards horizontally extends to form an extension part; three correctors are provided; and the three correctors are horizontally mounted in middle of the left fixed plate, horizontally mounted in middle of the right fixed plate and vertically mounted in middle of the extension part. The device has such advantages as reasonable structure design, high automation degree and convenience for control, can synchronously realize the correction of three positions of the three-way wind channel, guarantees the quality of the three-way wind channel, and guarantees the three-way wind channel to satisfy actual installation and use demands.

Owner:ALEN GRP ANHUI ZHONGRUN HEAVY IND

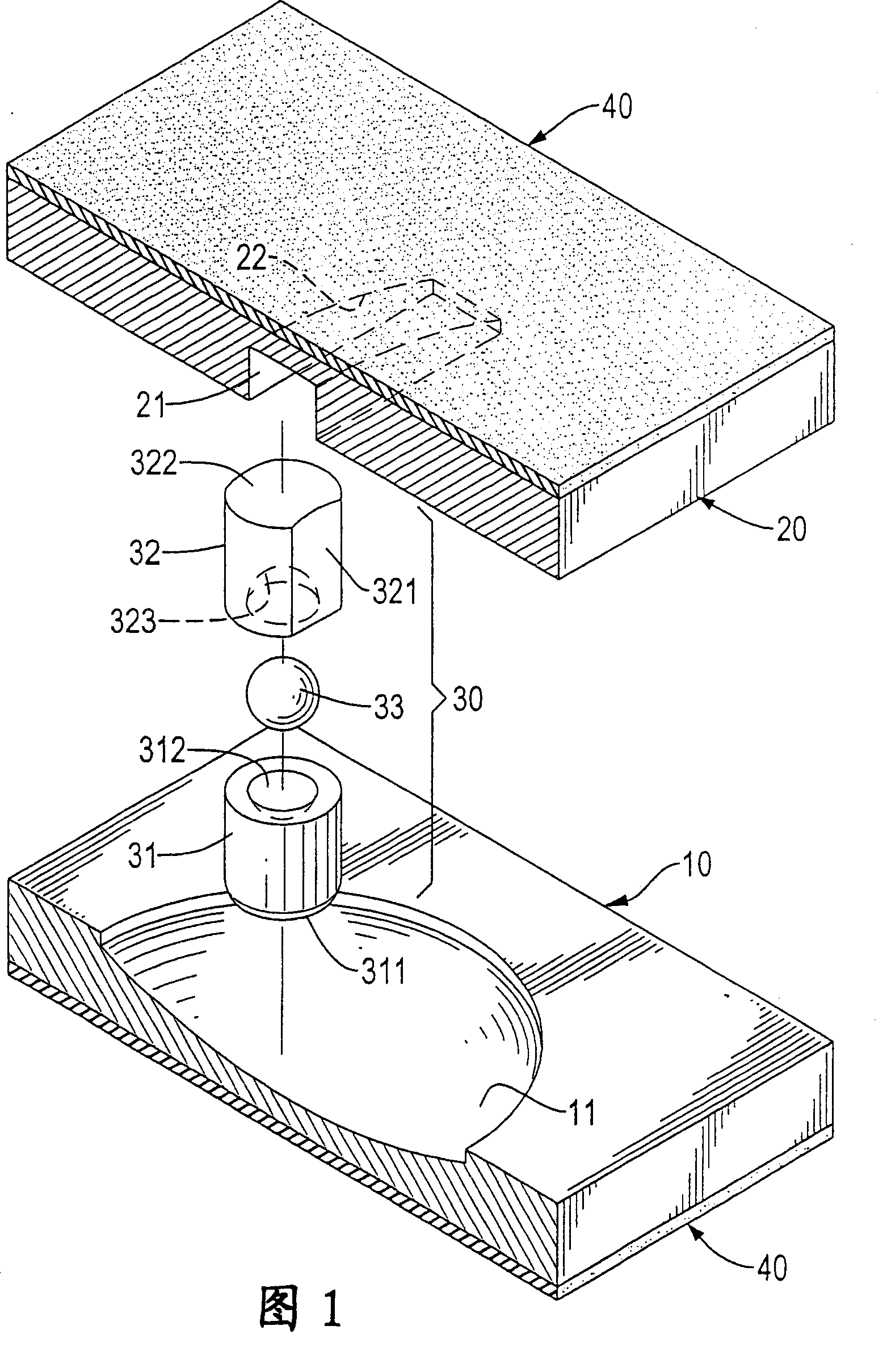

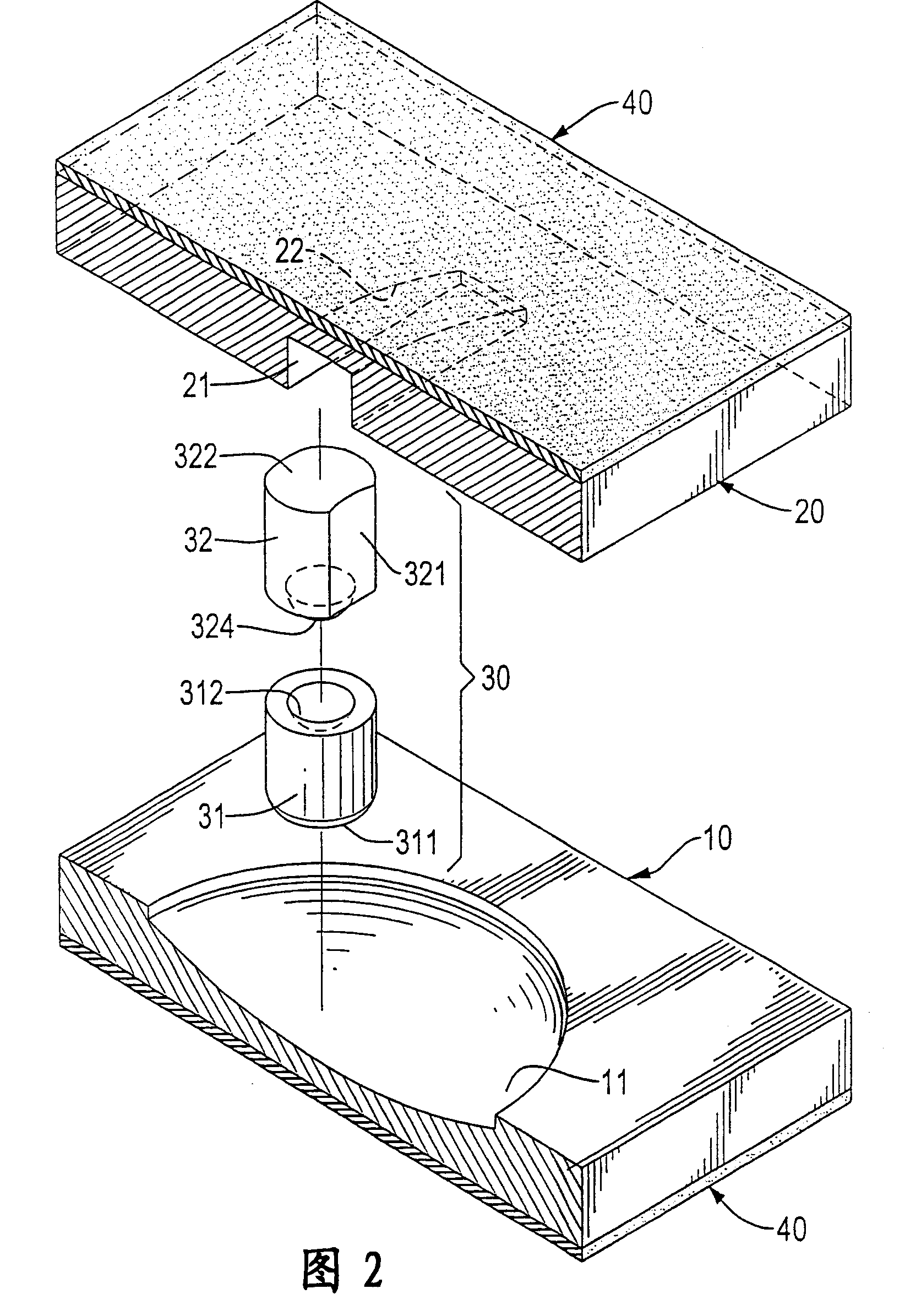

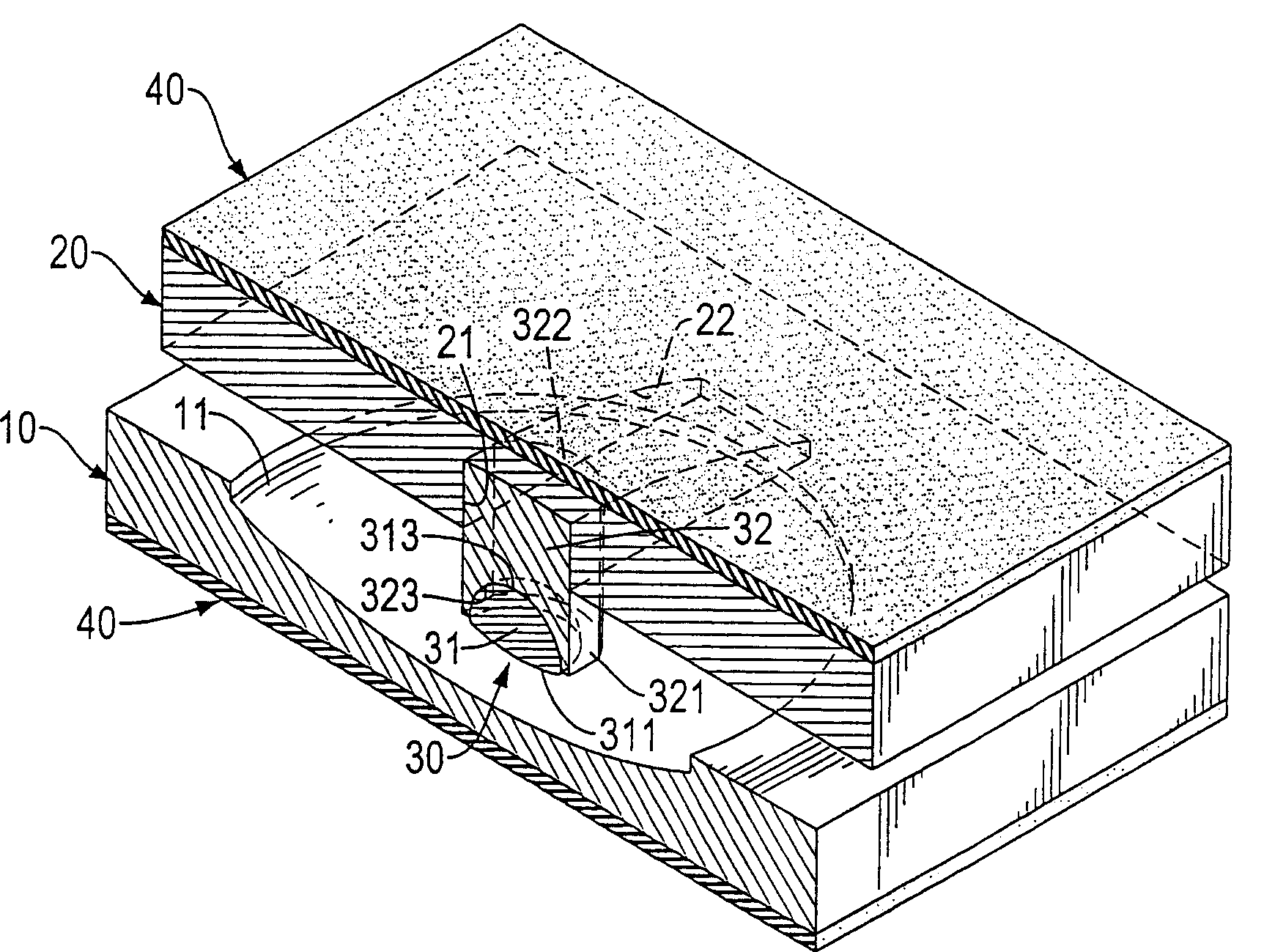

Shock isolator with multiaspect different frequencies

InactiveCN101153504BIncrease flexibilityImprove use valueProtective buildings/sheltersShock proofingEngineeringMechanical engineering

The invention is a multi-way shock isolator having different frequencies, which has a first base and a second base arranged separately in parallel, wherein, a movable slide connecting device is arranged between the first base and the second base. The invention is mainly provided with a gliding mechanism taking the form of arc-shaped curved surface contact between the first base and the slide connecting device, a gliding mechanism taking the form of one-way contact between the slide connecting device and the second base, and a universal connecting mechanism arranged on the slide connecting device, thereby producing different shock insulation and vibration reduction frequencies and displacement amounts, enabling the shock isolator to be adapted for key instruments, bridges or bar-shaped buildings, and also simplifying the structure of the prior shock isolator and reducing cost.

Owner:蔡崇兴

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com