A thin-walled one-arrow five-star satellite bracket and its assembly method

A thin-walled structure, satellite technology, used in artificial satellites, transportation and packaging, space navigation equipment, etc., can solve the problems of artificial technical level limitations, large correction workload, high docking accuracy requirements, and avoid damage to rivets and connections. Hole, avoid datum deviation, ensure the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

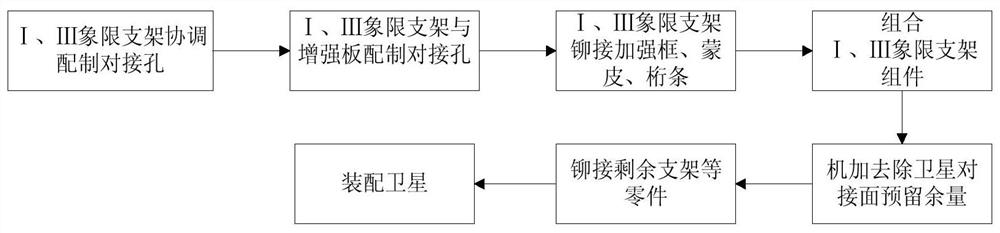

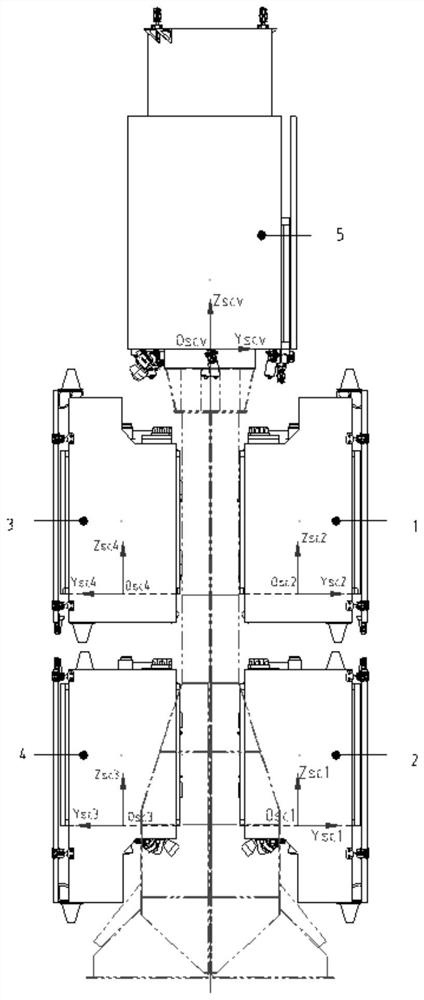

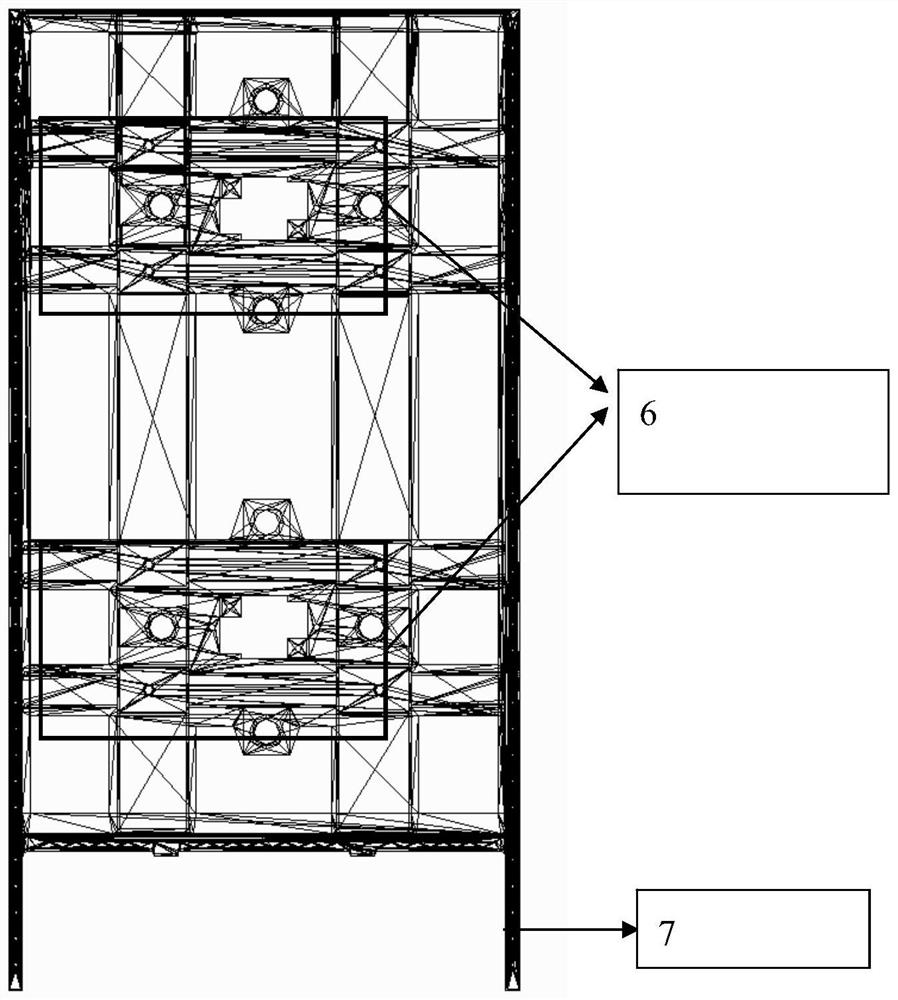

[0040] The material of the shell assembly of the five-star satellite bracket assembly is all 7050 sheets, T7451 state, and the total height is 1875mm. A reinforcement frame, 2 pieces of transverse plate reinforcement frame, 2 pieces of skin, 4 pieces of stringers, 4 pieces of bent plate, total length 974mm, total width 650mm, skin wall thickness 2mm, rib wall thickness 4mm; satellite adapter Ⅰ, Ⅲ The four satellite docking surfaces on the quadrant support require that the flatness is not greater than 0.2mm, and the roughness is not greater than 3.2μm; the step difference of the end face of the support assembly is not greater than 0.2mm. According to the traditional technological process: machine-added first and then assembled, after multi-part coordinated riveting assembly, due to riveting deformation and assembly errors, it cannot meet the high-precision coordination requirements of the satellite mounting surface.

[0041] The present invention breaks the traditional technolo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com