Intelligent type double-body warehouse used for storing granulated materials

An intelligent technology for granular materials, applied in large containers, loading/unloading, conveyors, etc., can solve the problems of high cost, large land occupation, slow detection of harm, etc., to reduce occupied space, facilitate miniaturization, The effect of compact and simplified structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

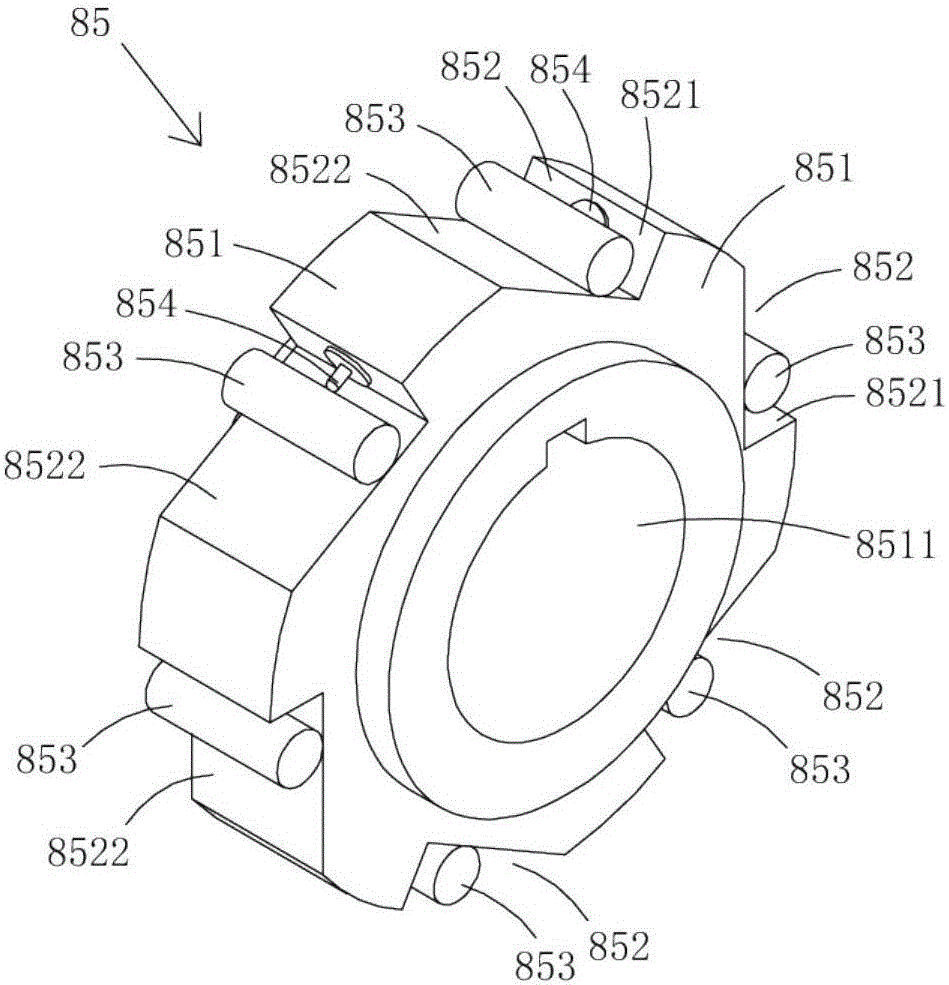

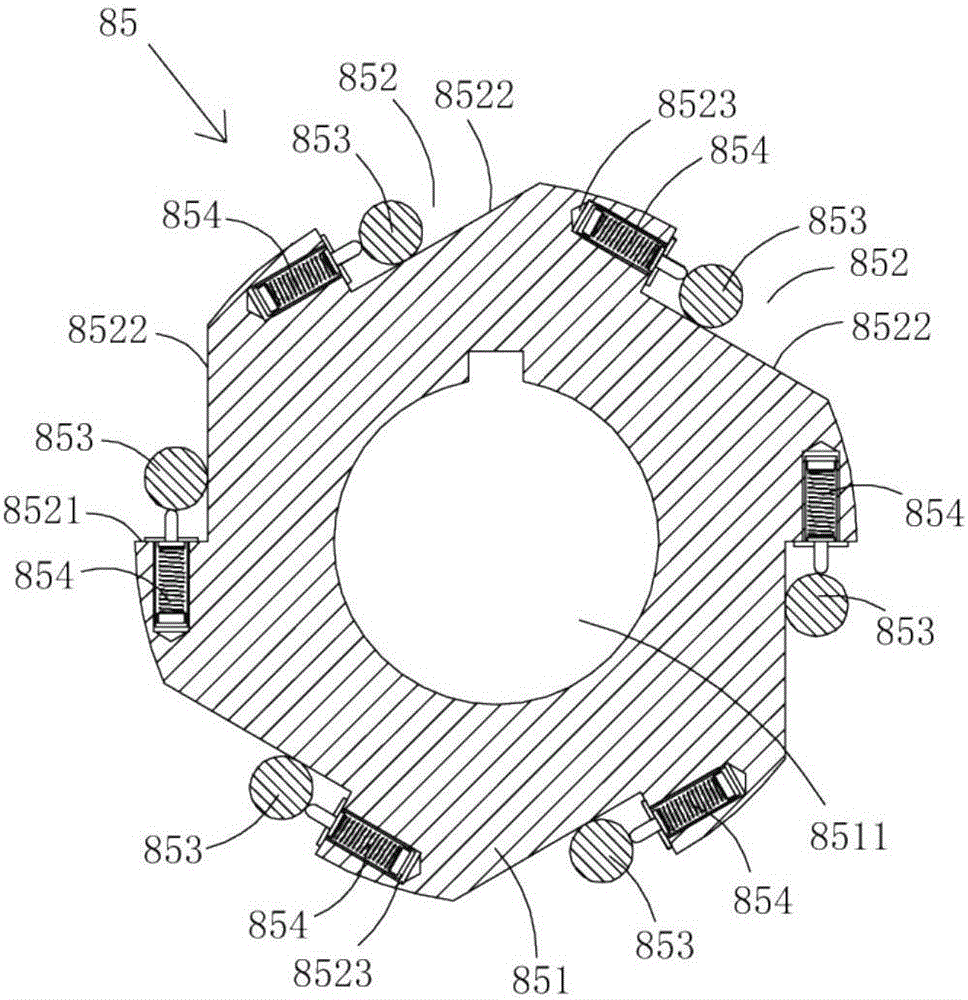

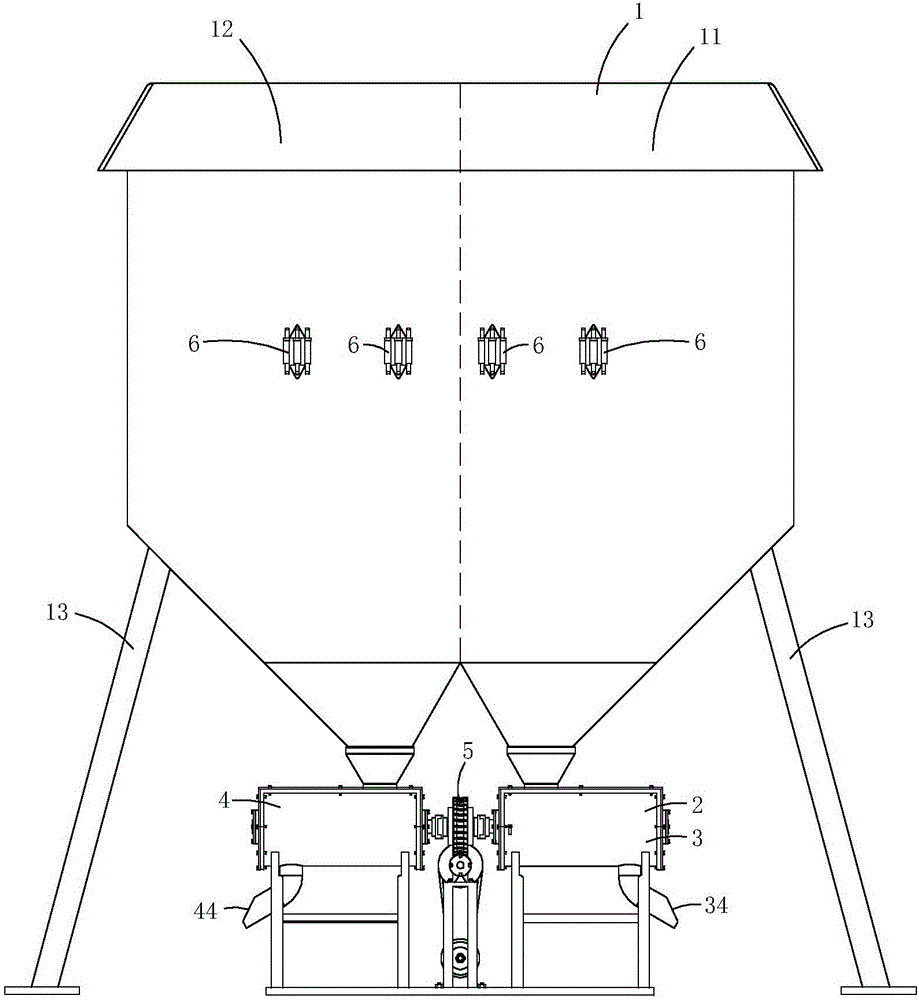

[0035] Figure 1 to Figure 18 One specific embodiment of the invention is shown.

[0036] This embodiment is an intelligent dual-body warehouse material for storing granular materials, see Figure 1 to Figure 6 As shown, it includes a double-body warehouse 1 and a discharge device 2 arranged under the double-body warehouse.

[0037] The double-body warehouse 1 has a first warehouse 11 and a second warehouse 12 adjacent to each other, and the first warehouse and the second warehouse are located on the same straight line; the bottom of the first warehouse is conical, and the center of the bottom has a first outlet; The bottom of the second warehouse is also conical, with a second outlet at the center of the bottom. In this embodiment, four supporting pillars 13 are arranged at the lower part of the double-body warehouse, and the double-body warehouse stands on the ground through the four supporting pillars. In practice, it is also possible not to support the pillars, but dire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com