Preparation method of catalyst for butylene oxidative dehydrogenation to produce butadiene

An oxidative dehydrogenation and catalyst technology, applied in physical/chemical process catalysts, chemical instruments and methods, organic chemistry, etc., can solve the problems of poor preparation reproducibility and easy loss of components, achieve high selectivity and improve preparation repeatability. performance, the effect of enhancing electron cloud density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

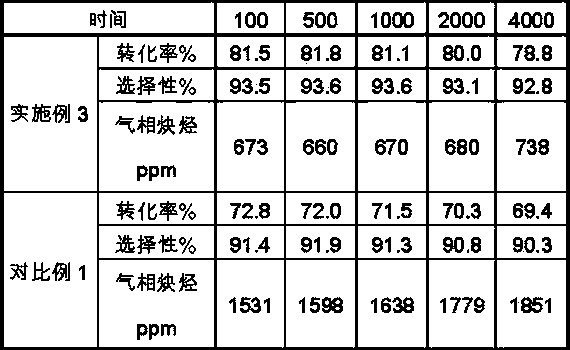

Examples

Embodiment 1

[0028] Take 46.0g iron oxide (Fe 2 o 3 ), 20.0g magnesium oxide (MgO), 8.0g zinc oxide (ZnO), 1.6g manganese oxide (MnO 2 ) and 0.8g P 2 o 5 , and then added 3.0 g of glucose, and then mixed in a ball mill for 120 minutes, sifted >200 mesh powder (standard sieve), and calcined at 700 ° C for 6 hours to obtain composite oxide catalyst A.

[0029]

Embodiment 2

[0031] Take 24.0g iron oxide (Fe 2 o 3 ), 8.0g magnesium oxide (MgO), 10.0g zinc oxide (ZnO), 1.0g manganese oxide (MnO 2 ) and 2.0g P 2 o 5 , and then add 3.0g of polyvinyl alcohol, then mix in a ball mill for 30 minutes, sieve >200 mesh powder (standard sieve), and bake at 700°C for 8 hours to obtain composite oxide catalyst B.

[0032]

Embodiment 3

[0034] Take 36.2g iron oxide (Fe 2 o 3 ), 8.0g magnesium oxide (MgO), 11.0g zinc oxide (ZnO), 1.0g manganese oxide (MnO 2 ) and 2.0g P 2 o 5 , and then added 5.0 g of glucose, and then mixed in a ball mill for 60 minutes, screened the >150 mesh part powder (standard sieve), and calcined at 750 ° C for 6 hours to obtain composite oxide catalyst C.

[0035]

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| volume ratio | aaaaa | aaaaa |

| volume ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com