Trans-1, 4-structured butadiene-isoprene copolymer rubber and preparation method thereof

A technology of isoprene and butadiene, applied in the field of trans-1, can solve the problems of low catalytic efficiency and low trans content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

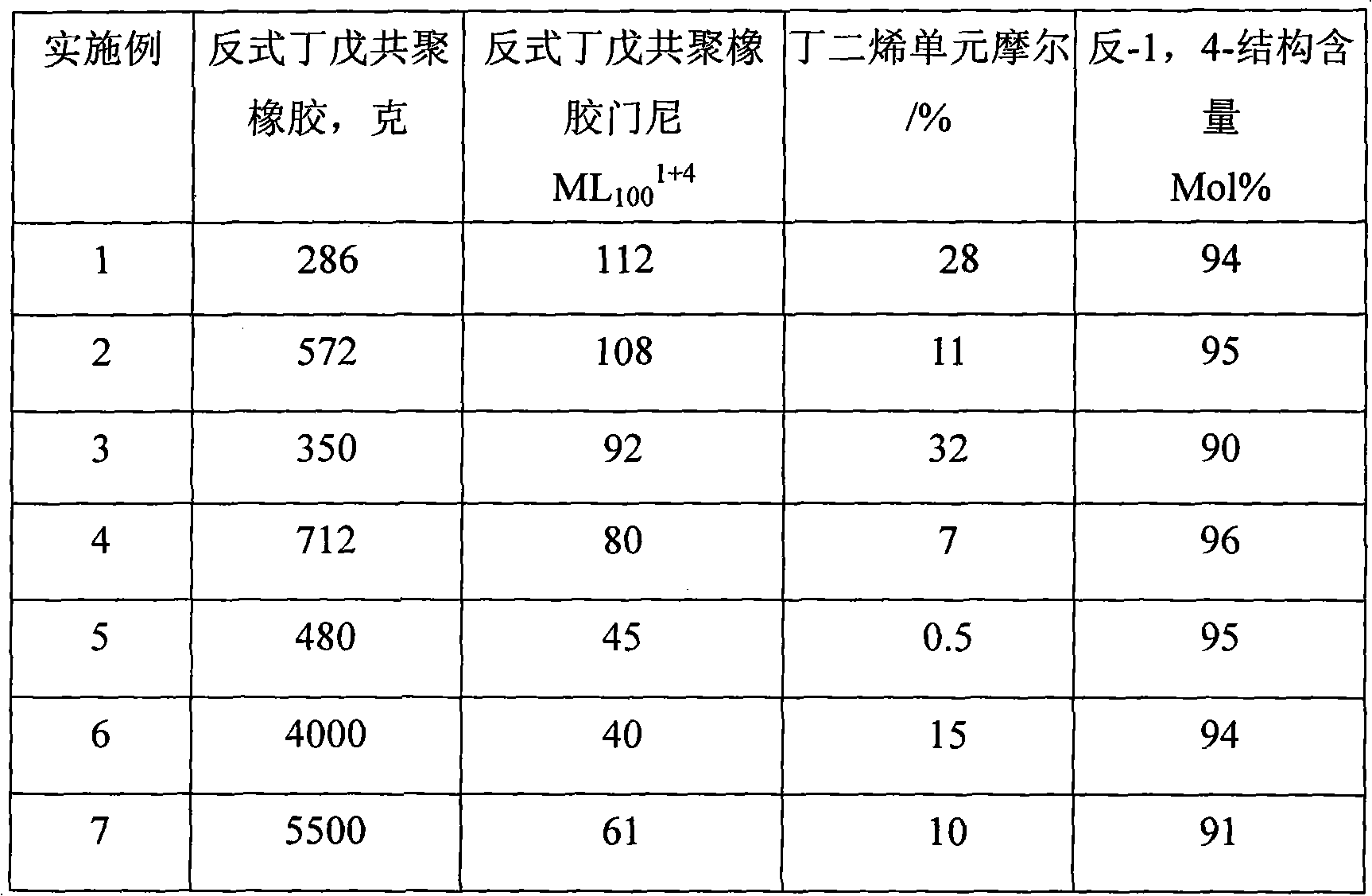

Examples

Embodiment 1

[0020] Example 1 Add 1500mL isoprene monomer successively to a 5L reaction device, add 200ml butadiene, 15mmol triisobutylaluminum and 0.43g heterogeneous Ziegler-Natta catalyst (wherein the titanium compound is selected from TiCl4 ; The mass content of titanium is 2.0%), the copolymerization temperature is 30° C., and the copolymerization time is 20 hours. Terminate the reaction with 500 ml of 1 wt% acidified ethanol, remove unreacted monomers, and dry to obtain 286 grams of rubber material. The characteristics are shown in Table 1. The trans-1,4-butadiene-isoprene copolymer rubber can be used in tire products, or in shock-absorbing materials and the like.

Embodiment 2

[0022] Operation is the same as in Example 1, except that the copolymerization time is 60 hours. The results are shown in Table 1.

Embodiment 3

[0024] Add 1500mL isoprene monomer, 500ml butadiene, 17mmol triisobutylaluminum and 0.8g heterogeneous Ziegler-Natta catalyst (wherein the titanium compound is selected from TiCl 4 ; The mass content of titanium is 3.0%), the polymerization temperature is 70° C., and the copolymerization time is 10 hours. Terminate the reaction with 400 ml of 1 wt% acidified ethanol, remove unreacted monomers, and dry to obtain 350 g of trans-1,4-butylene copolymer rubber material. The characteristics are shown in Table 1. The trans-1,4-butadiene-isoprene copolymer rubber can be used in tire products, or in shock-absorbing materials and the like.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com