Patents

Literature

47results about How to "Excellent flex fatigue resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

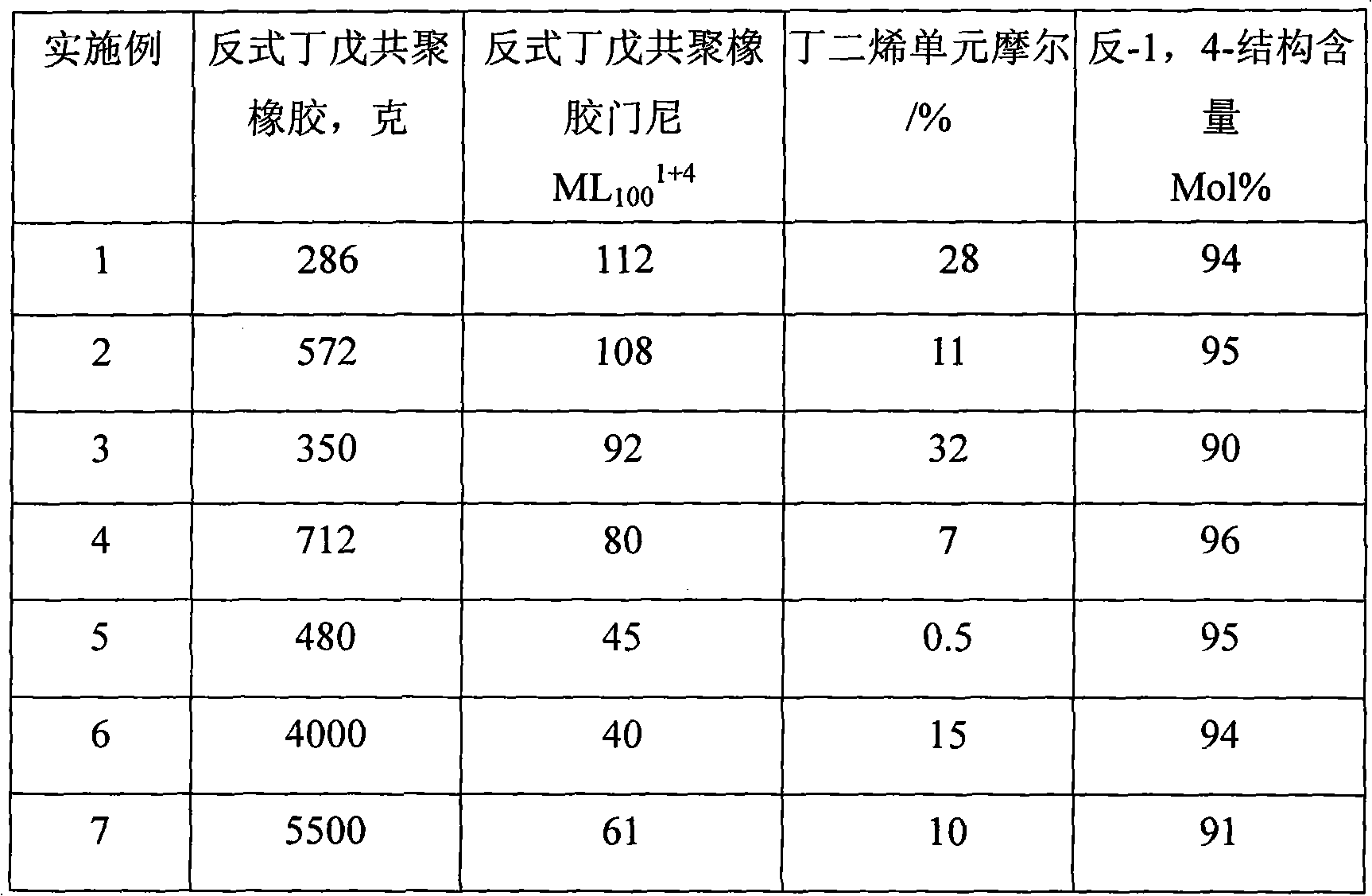

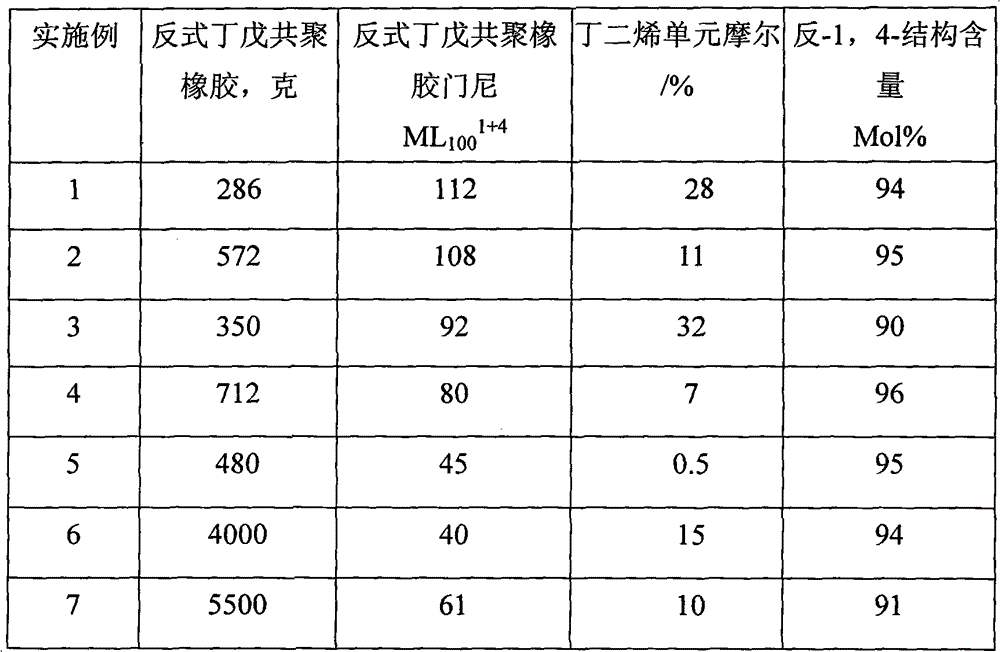

Trans-1, 4-structured butadiene-isoprene copolymer rubber and preparation method thereof

A trans-1, 4-structured butadiene-isoprene copolymer rubber and a preparation method thereof. A Ziegler-Natta catalytic system containing MgCl2 loaded titanium and an organic aluminium compound is used to catalyze butadiene and isoprene for copolymerization synthesis of the butadiene-isoprene copolymer with trans 1, 4-structure greater than 90%; and the copolymer rubber comprises, by molar fraction, 20-99.5% of an isoprene unit and 0.5-80% of a butadiene unit. One preparation method of the trans copolymer rubber is by maintaining a feeding ratio of butadiene to isoprene, and catalyzing butadiene and isoprene for copolymerization synthesis of trans copolymer rubber with gradient composition at 0-90 DEG C. A second preparation method of the trans copolymer rubber is by maintaining the concentration of butadiene in reaction materials, and catalyzing butadiene and isoprene for copolymerization synthesis of trans copolymer rubber with relatively uniform composition at 0-90 DEG C. The trans copolymer rubber has characteristics of low heat, good abrasion resistance and excellent flex and fatigue resistant performance, and is suitable rubber products for dynamic usage.

Owner:QINGDAO UNIV OF SCI & TECH +1

Ultra-wearable rubber formulation for sports shoes sole

The invention discloses a superwear-resisting rubber formulation of sport sole, and is characterized in that the formulation according to parts by weight comprises 80 parts of polybutadiene rubber, 20 parts of natural gum STR-5L, 1 part of uniform tackiness resin, 45-48 parts of white carbon black, 3.5 parts of softening oil, 3-3.2 parts of coupler, 5.2-5.8 parts of activator, 1 part of zinc stearate, 1 part of antifog agent, 1.9-2.1 parts of sulphur, and 1.65-1.95 part of accelerating agent, an ideal raw material functional combination can be obtained after applying the rubber formulation for sports shoes, which makes the sport shoe rubber sole having superwear resistance which is superior to ordinary rubber sole, and has a plurality of excellent properties such as wet-skid resistance, impact resistance and the like.

Owner:ANTA CHINA

Rubber tire tread and milling process thereof

The invention discloses a rubber tire tread and a milling process thereof. The rubber tire tread comprises the following components in parts by weight: 70-110 parts of natural rubber, 0-15 parts of styrene-butadiene rubber, 5-20 parts of tread rubber powder, 1.5-2.5 parts of stearic acid, 1-2 parts of sulfur powder, 2-18 parts of white carbon black, 12-15 parts of carbon block, 2-30 parts of aromatic oil, 1-8 parts of zinc oxide, 4-7 parts of an anti-aging agent, 1-4 parts of pine tar, 1-4 parts of an accelerating agent, 0.2-1 part of an anti-reversion agent and 2-5 parts of a binding agent. A three-section milling process is adopted, and the milling process can improve the abrasive resistance, tear resistance and chunking and chipping resistance of the tire tread.

Owner:SHANDONG YONGTAI CHEM GROUP

Prepn of polyether-type polyurethane as shoe sole material

InactiveCN1453299AImprove mechanical propertiesSimple processing technologySolesShoe industryPolyurethane elastomer

the present invention is preparation process of polyether-type polyurethane as shoe sole material. Polyether polyol with high activity and low unsaturation degree is synthesized with water as foaming agent and bimetal cyanide as catalyst; and isocyanate capped modified semi-prepolymer is prepared with small molecule modifier containing active hydrogen. The modified semi-prepolymer and the Polyether polyol are further produced into the porous polyurethane elastomer through mixing, casting, foaming and demolding. The material has high tensile strength, tearing strength, elongation and permanent deformation performance, and rather high low temperature embrtittlement and bending performance, and can meet the requirement as shoe material.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

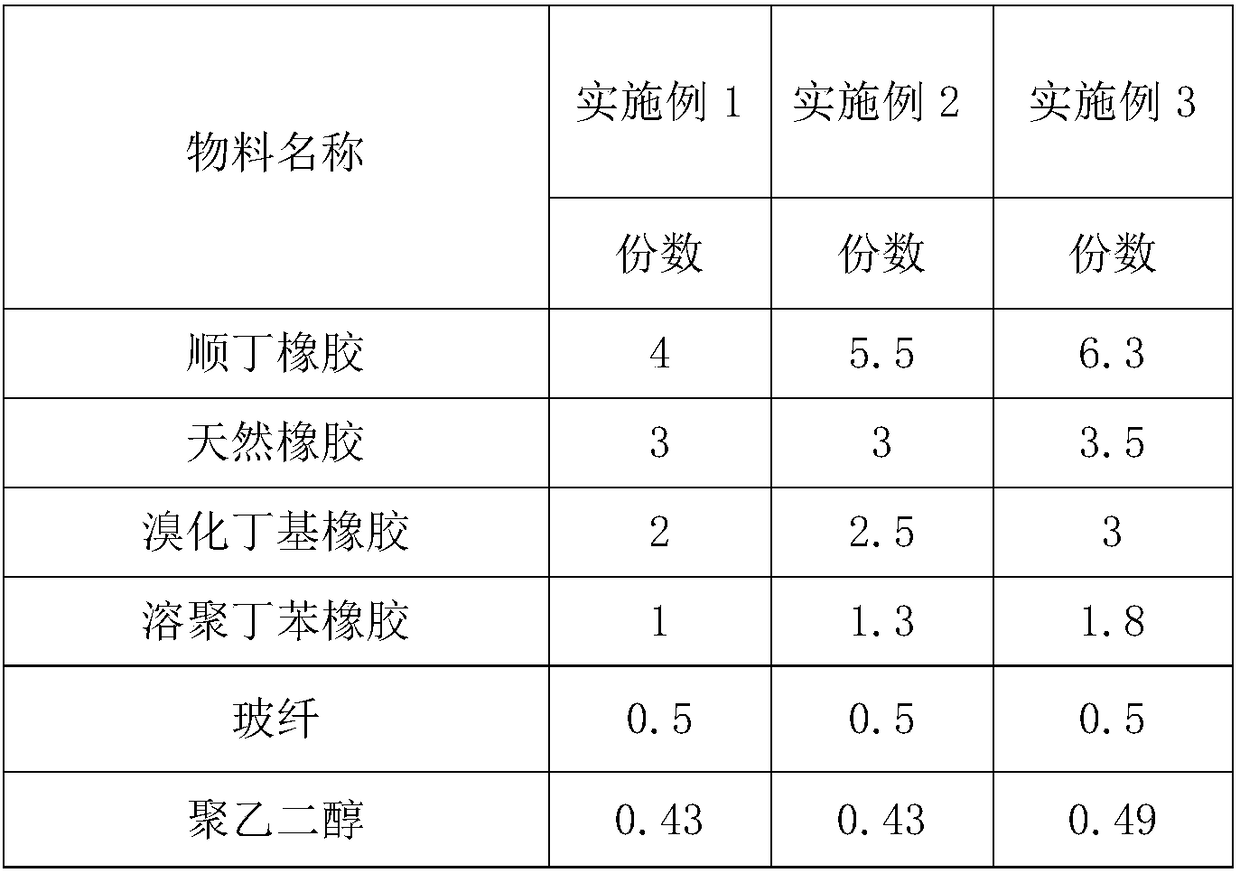

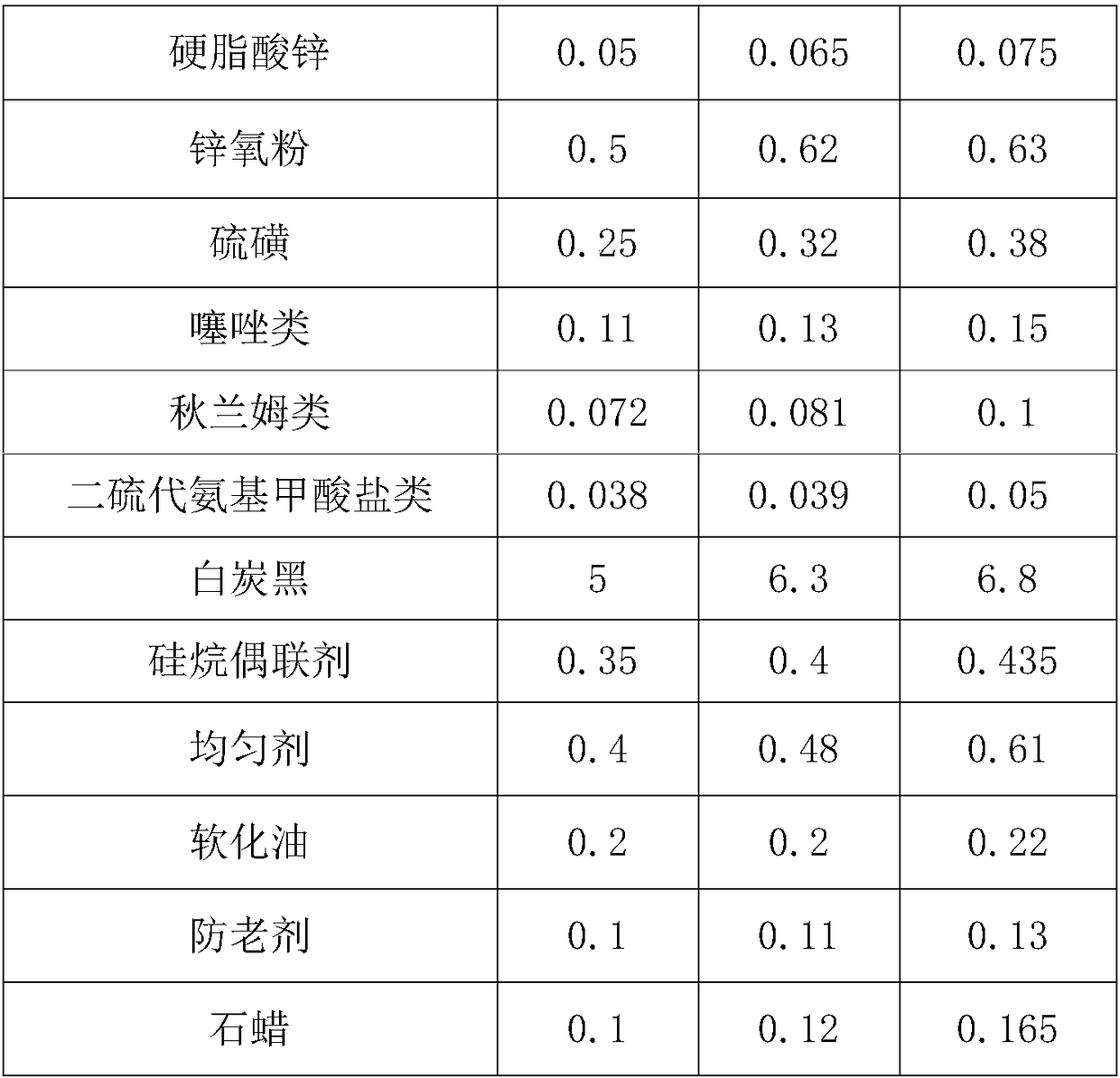

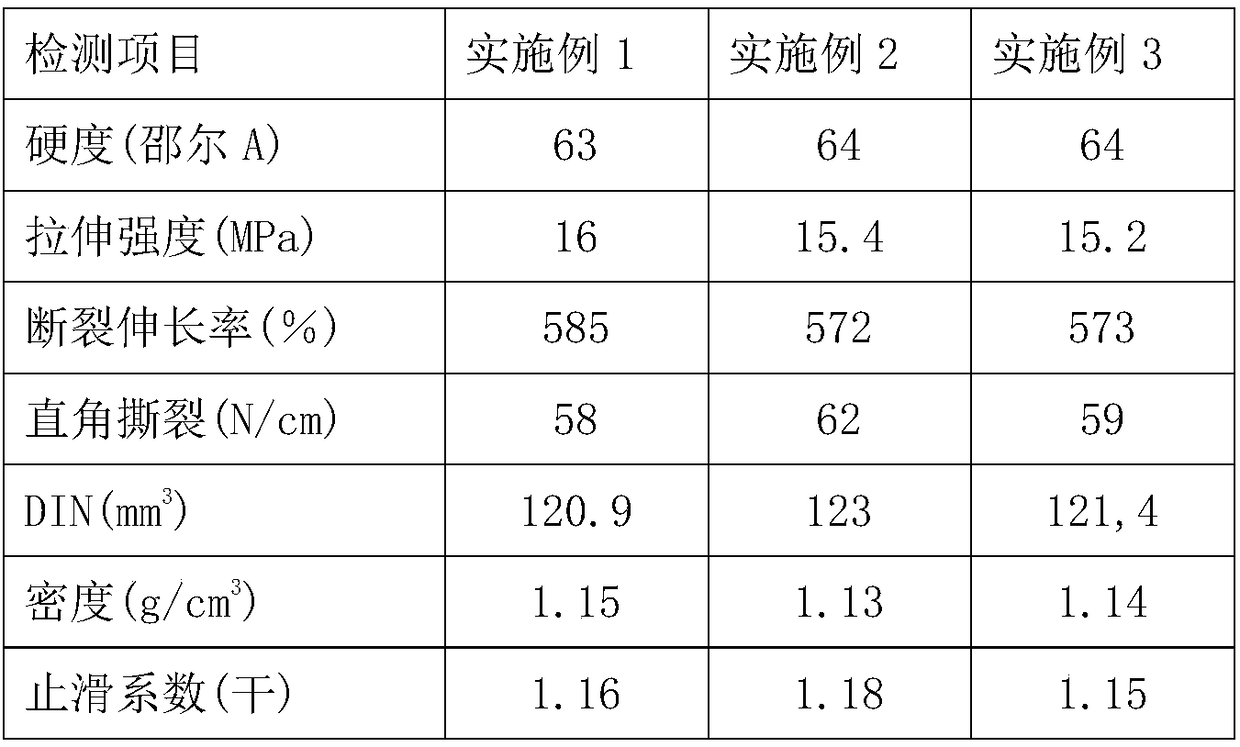

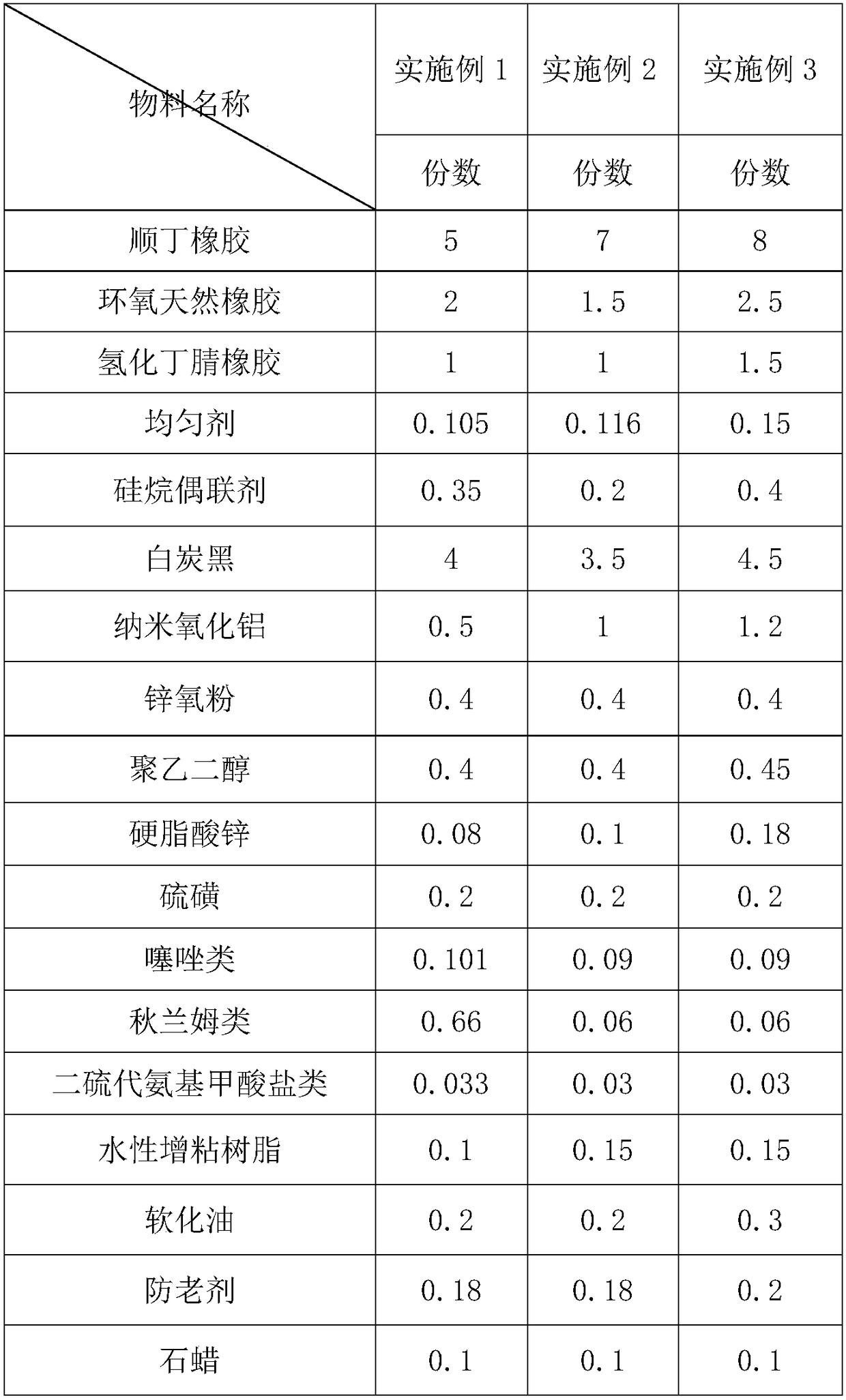

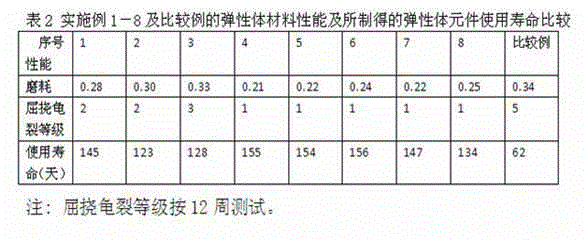

Rubber for sports shoe soles and preparation method thereof

InactiveCN108192163AImprove physical strengthGood vibration damping performanceSolesChemistryButadiene-styrene rubber

The invention discloses rubber for sports shoe soles. The rubber for the sports shoe soles comprises the following components in parts by mass: 30-70 parts of butadiene rubber, 20-40 parts of naturalrubber, 15-30 parts of brominated butyl rubber, 10-20 parts of solution-polymerized styrene-butadiene rubber, 5-10 parts of glass fiber, 2-5 parts of polyethylene glycol, 0.5-2 parts of zinc stearate,2-5 parts of zinc oxide powder, 2.5-4 parts of a vulcanizing agent, 1.5-2.5 parts of an accelerator, 30-50 parts of white carbon black, 3-4.5 parts of a silane coupling agent, 4-7 parts of a homogenizing agent, 2-5 parts of softening oil, 1-3 parts of an anti-aging agent and 0.5-1 part of paraffin. The invention further provides a preparation method of the rubber for the sports shoe soles. Rubbershoe soles for sports shoes, prepared according to the technical scheme adopted by the invention, have many properties such as super wear resistance, good folding resistance and anti-slip performance; the preparation method is simple in production process and is suitable for wide application.

Owner:ANTA CHINA

Rubber composition for manufacturing wrapping cloth V-belt compression layer and preparation method of rubber composition

ActiveCN107177057AExcellent compression fatigue resistanceHeat generation is smallBuilding insulationsVulcanizationPolymer science

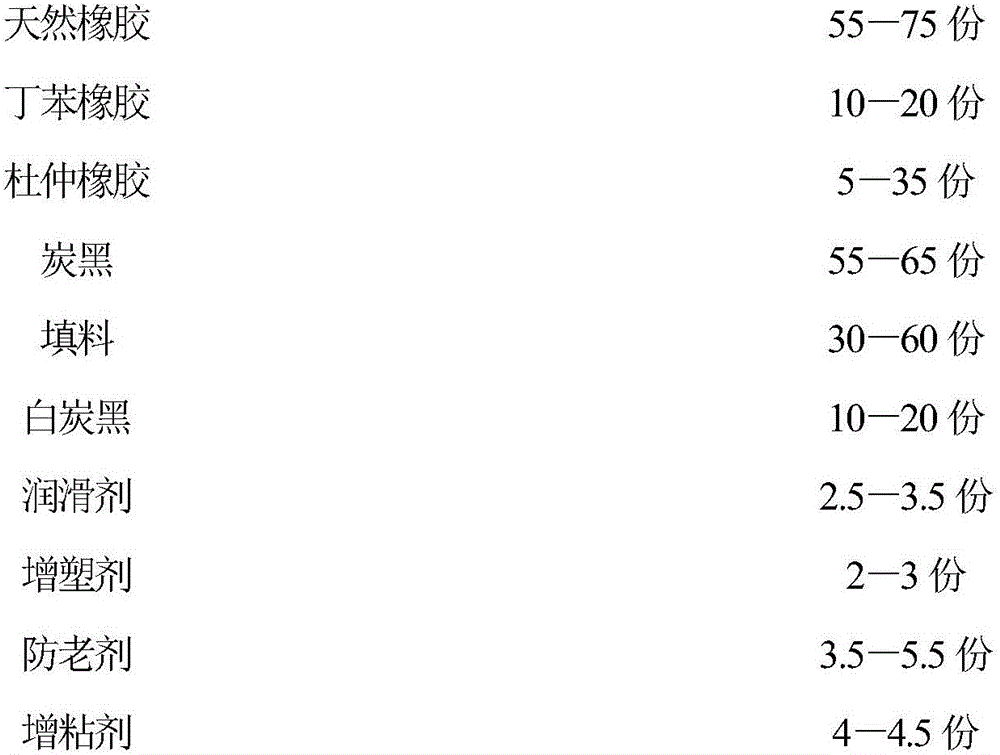

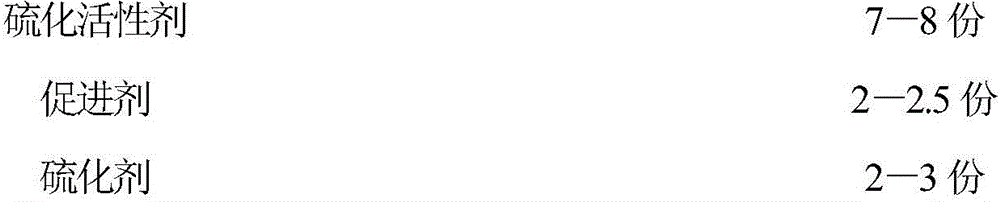

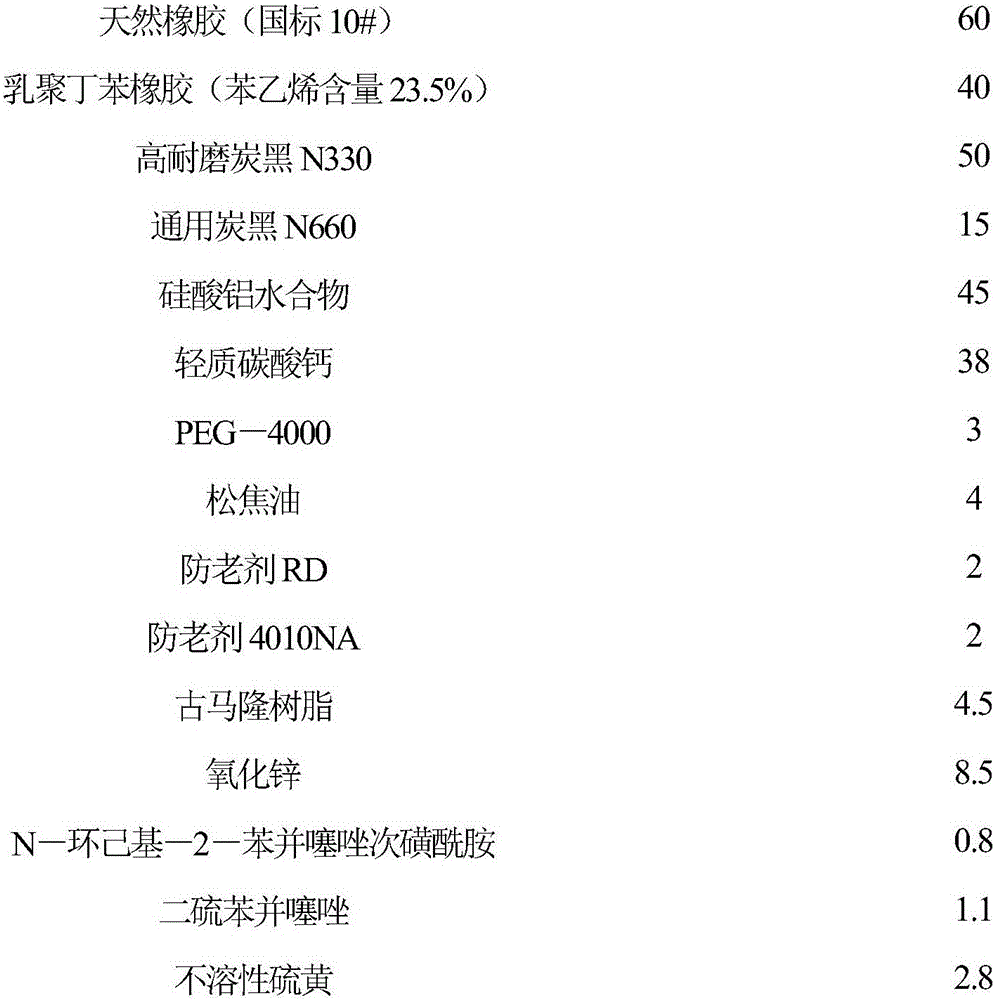

The invention relates to rubber composition for manufacturing a wrapping cloth V-belt compression layer and a preparation method of the rubber composition. The rubber composition is mainly prepared from components as follows: natural rubber, styrene butadiene rubber, eucommia rubber, a vulcanization activator, a lubricant, an antiaging agent, carbon black, white carbon black, pottery clay, calcium carbonate, a plasticizer, a tackifier, an accelerator and a vulcanizing agent. A natural rubber, styrene butadiene rubber and eucommia rubber compound system is adopted in the rubber composition, the flexural fatigue resistance and heat resistance of the rubber composition are improved, besides, carbon black and white carbon black are combined to serve as a reinforcing agent, dynamic heat dissipation is reduced while the support performance of rubber is guaranteed, and the fatigue life of the rubber is prolonged.

Owner:QINGDAO UNIV OF SCI & TECH +1

Automobile shock absorber bushing

The invention relates to the technical field of automobile shock absorbers, and discloses an automobile shock absorber bushing which comprises the following raw materials by weight: 65-75 parts of natural rubber, 25-35 parts of polynorbornene rubber, 10-25 parts of high abrasion furnace black, 45-55 parts of carbon black N660, 1-4 parts of a promoter, 2-8 parts of zinc oxide, 1-6 parts of paraffin wax, 1-5 parts of an antioxidant, 1-5 parts of a dispersing agent, 3-8 parts of aromatic oil, 1-5 parts of a curing agent, 1-5 parts of a plasticizer and 1-5 parts of a coupling agent. Through simultaneous use of the natural rubber and the polynorbornene rubber, the heat resistance of products is excellent, by simultaneous use of the high abrasion furnace black and the carbon black N660, aging resistance and bending fatigue resistance of the rubber reinforcing system are excellent, the service life is longer, compression permanent deformation is small, rubber tensile strength is high, rebound elasticity is excellent, and the compression permanent deformation is small.

Owner:NINGGUO ZHONGCHEN SEALING PARTS

Preparation of dynamically vulcanized thermoplastic elastomer material

InactiveCN101205331AImprove heat resistanceExcellent flex fatigue resistancePolymer scienceVulcanization

The invention relates to a method for preparing a dynamically vulcanized thermoplastic elastomer material, which is characterized in that the dynamically vulcanized thermoplastic elastomer material is made of the following row materials by the percentage in weight: 20 per cent -30 per cent of polypropylenes, 60 per cent -70 per cent of nitrile rubbers, 0.1 per cent -0.5 per cent of curing agents, 0.5 per cent -1 per cent of vulcanization auxiliaries, 0.1 per cent -1 per cent of antioxidants, 0.1 per cent -1 per cent of lubricant and 5 per cent -15 per cent of compatibilizers. The preparation method comprises the following steps: the raw materials are scaled and taken according to a weight proportion; all the materials are put into a high mixing machine to be mixed for 2-5 minutes; the materials are taken out; the mixed materials are put into a screw compressor for extruding granulations. The rotating speed of the screw compressor is 180-600r / m and temperature is 150-180 DEG C. The invention has the advantages that the polypropylene / nitrile rubber dynamically vulcanized thermoplastic elastomer material by adopting the novel compatibilizer cooperated with the advanced formulation design and equipment combination, can be used on the occasion where the oil resistance is required and is used for partially replacing the nitrile rubber.

Owner:SHANGHAI SUNNY

Wear-resistant rubber for sports shoe soles and preparation method thereof

The invention discloses wear-resistant rubber for sports shoe soles. The wear-resistant rubber for the sports shoe soles comprises the following components in parts by mass: 50-80 parts of butadiene rubber, 10-30 parts of epoxy natural rubber, 5-20 parts of hydrogenated butadiene-acrylonitrile rubber, 1-2 parts of a homogenizing agent, 2-5 parts of a silane coupling agent, 25-65 parts of a reinforcing agent, 2-5 parts of zinc oxide powder, 2-5 parts of polyethylene glycol, 0.5-2 parts of zinc stearate, 1.5-2 parts of a vulcanizing agent, 1.6-2.1 parts of an accelerator, 0.5-2 parts of a tackifier, 2-5 parts of a softening oil, 1-3 parts of an anti-aging agent and 0.5-1 part of paraffin. The invention further provides a preparation method of the wear-resistant rubber for the sports shoe soles. Wear-resistant rubber shoe soles for the sports shoe soles, prepared according to the technical scheme adopted by the invention, have super wear resistance which is incomparable with that of ordinary rubber soles, and have many properties such as good weather resistance and folding resistance; the preparation method is simple in production process and is suitable for wide application.

Owner:ANTA CHINA

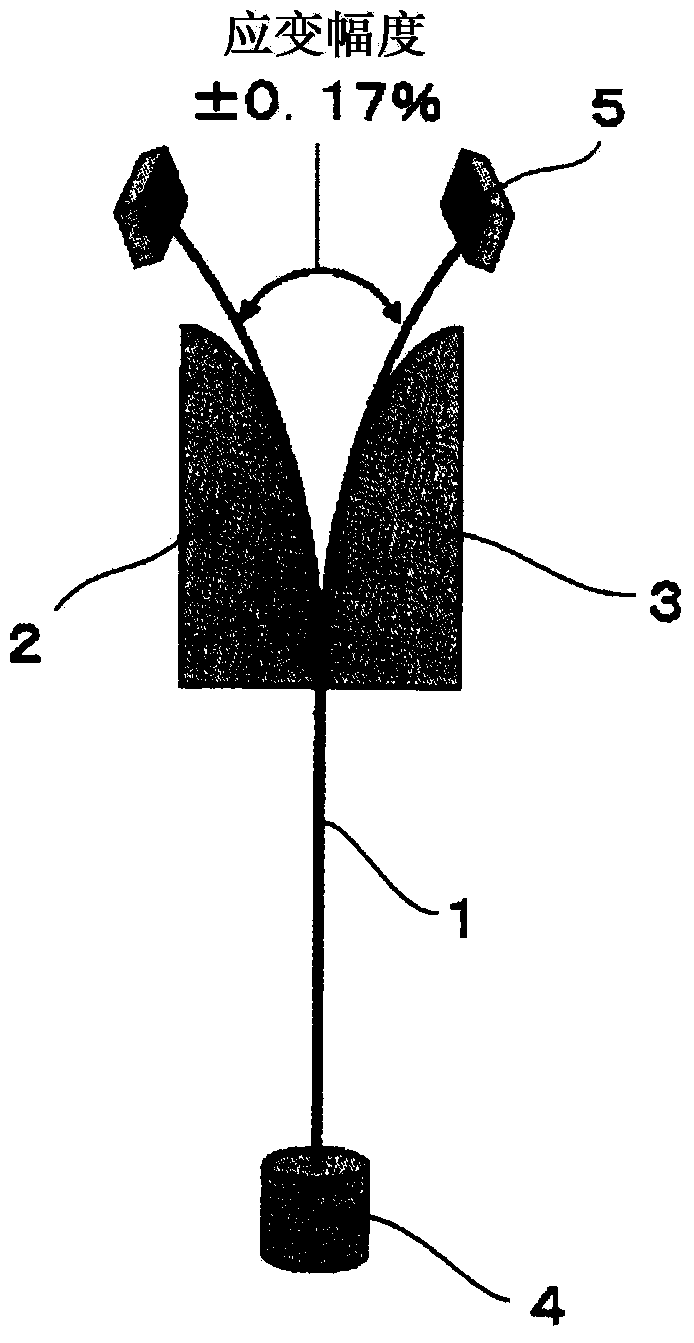

Anti-fatigue thermoplastic elastomer and preparation method of plum coupling element

The invention relates to an anti-fatigue thermoplastic elastomer and a preparation method of a plum coupling element. The anti-fatigue thermoplastic elastomer is prepared from the following raw materials in parts by weight: 100 parts of a polyester elastomer, 10-30 parts of a thermoplastic elastomer, 2-5 parts of a wear-resistant agent, 0.3-0.5 part of a hindered phenolic antioxidant, 0.2-0.5 part of a phosphite antioxidant and 0.5-1.0 part of a lubricating agent. The invention also discloses the preparation method of the plum coupling element by applying the anti-fatigue thermoplastic elastomer. According to the invention, a novel elastomer material is used for replacing a polyurethane material, the disadvantages of internal heating and self-warming of the polyurethane material are overcome, the anti-fatigue property of the elastomer element is improved, and thus the service life of the elastomer element is prolonged. Compared with the existing thermoplastic polyurethane (TPU) elastomer element, the flex fatigue-resistance is significantly increased, and the service life is prolonged by 2-3 times.

Owner:长沙五犇新材料科技有限公司

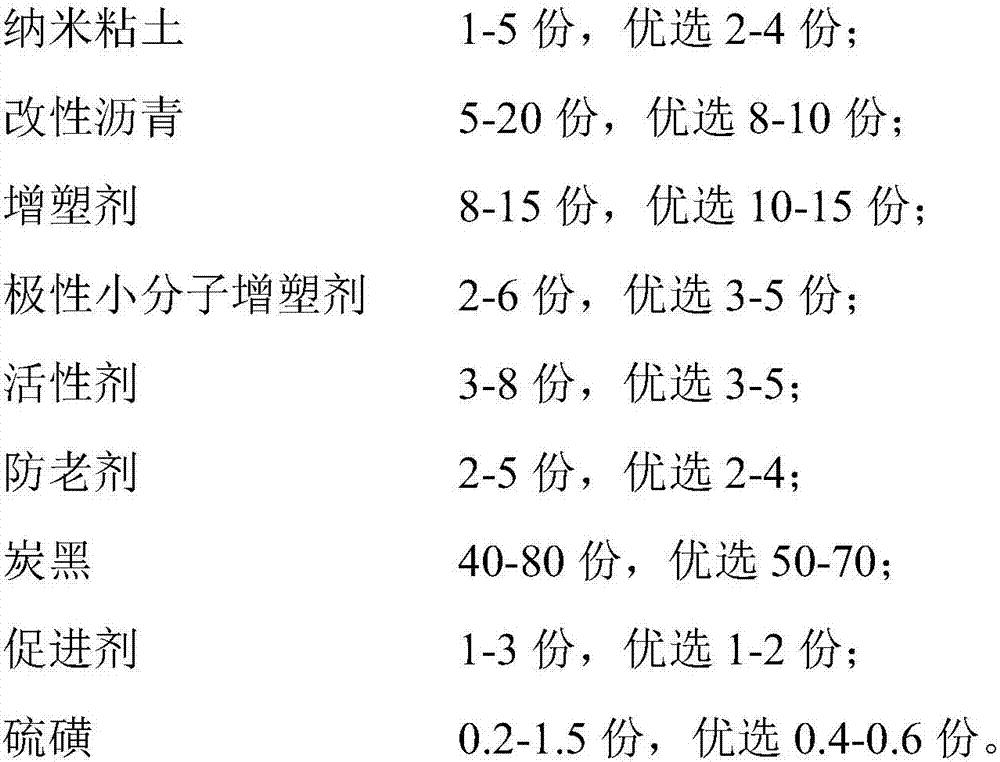

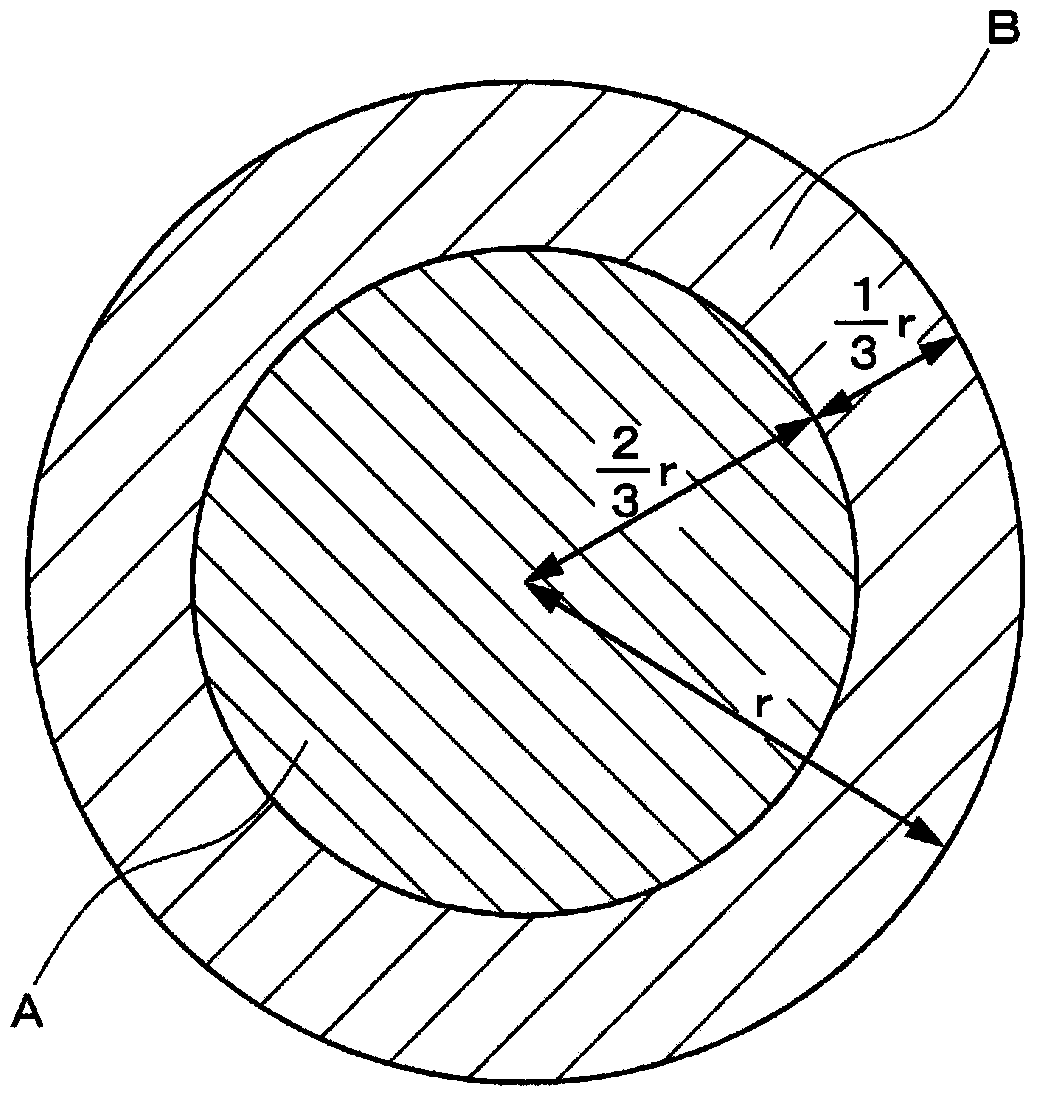

Tyre inner liner composite material and preparation method thereof

ActiveCN107540963AImprove air tightnessGood physical and mechanical propertiesBuilding insulationsPolymer sciencePlasticizer

The present invention relates to a tyre inner liner composite material and a preparation method thereof, and belongs to the field of high-performance all-steel radial tyres. By introducing butadiene-acrylonitrile rubber into the formula of a brominated butyl rubber inner liner, airtightness is greatly raised. A proper compatilizer is selected for compatiblizing modification of BIIR and NBR. Nano-clay is mixed into a dispersion phase. By adding a polar small molecular plasticizer to adjust the rubber compounding, the airtightness, ozone resistance, flexural fatigue resistance and mechanical properties of the material are further improved, and performance requirements of the high-performance radial tyre inner liner can be met. In addition, the invention also has advantages of simple equipment, simple operation, good controllability, low cost and industrialization amplification.

Owner:BEIJING UNIV OF CHEM TECH +1

Method for manufacturing truck tire rubber

The invention relates to a method for manufacturing truck tire rubber. The method comprises the following steps of plasticating, mixing, calendering, vulcanizing, molding and the other steps, wherein in the mixing process, the plasticated rubber is put into a roll gap and evenly wrapped on a front roller, after the rubber is removed, the roller distance is adjusted to be 1.5mm, the rubber is again wrapped on the front roller and a compounding agent is put in the sequence of natural plasticated rubber, an auxiliary material, zinc oxide, carbon black, No.30 engine oil and sulfur, and the auxiliary material can be one of a promoting agent, an anti-aging agent and stearic acid. The tire prepared from the rubber composition disclosed by the invention is environment-friendly and safe and has excellent flexibility resistance and fatigue resistance.

Owner:安徽圣源橡塑科技有限公司

Preparation method for graphene rare earth aluminum alloy high-conductivity material cable

ActiveCN107230508AReduce primary silicon particle sizeImproved resistance to adverse effects caused by corrosionConductive materialApparatus for manufacturing conducting/semi-conducting layersMagnesiumHigh intensity

The invention discloses a preparation method for a graphene rare earth aluminum alloy high-conductivity material cable. Aluminum alloy is obtained by performing smelting on waste aluminum, silicon-calcium alloy, copper-aluminum alloy, zinc-aluminum alloy, magnesium ingot, rare earth aluminum alloy and graphene; and next, heat treatment is performed, and then the graphene rare earth aluminum alloy high-conductivity material cable is obtained by processing. According to the preparation method for the graphene rare earth aluminum alloy high-conductivity material cable provided by the invention, through reasonable setting of the technological parameters and optimization of the graphene structure, the overall performance of the aluminum alloy is improved effectively, so that the obtained graphene rare earth aluminum alloy high-conductivity material cable has the advantages of high intensity, plasticity, conductivity, heat resistance, resistance to fatigue under flexing, and processing performance and the like.

Owner:ANHUI NANYANG NEW MATERIAL TECH CO LTD

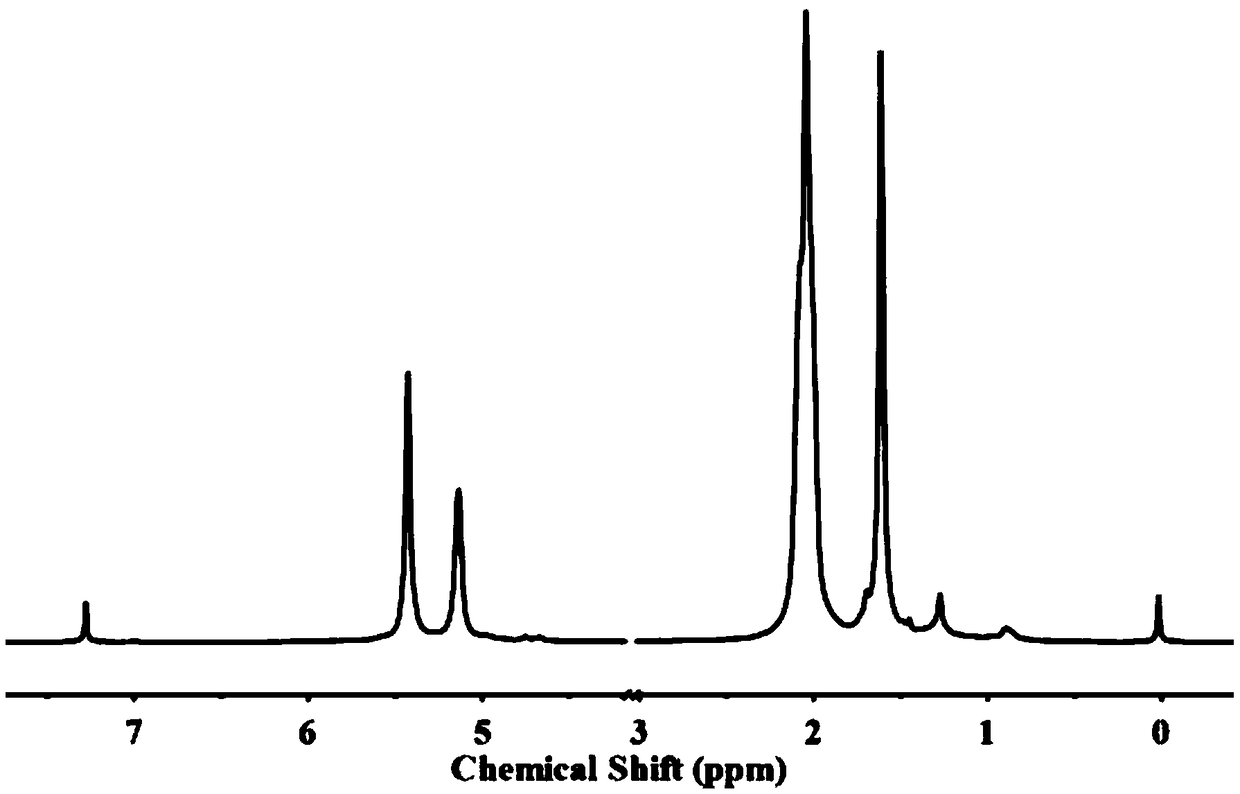

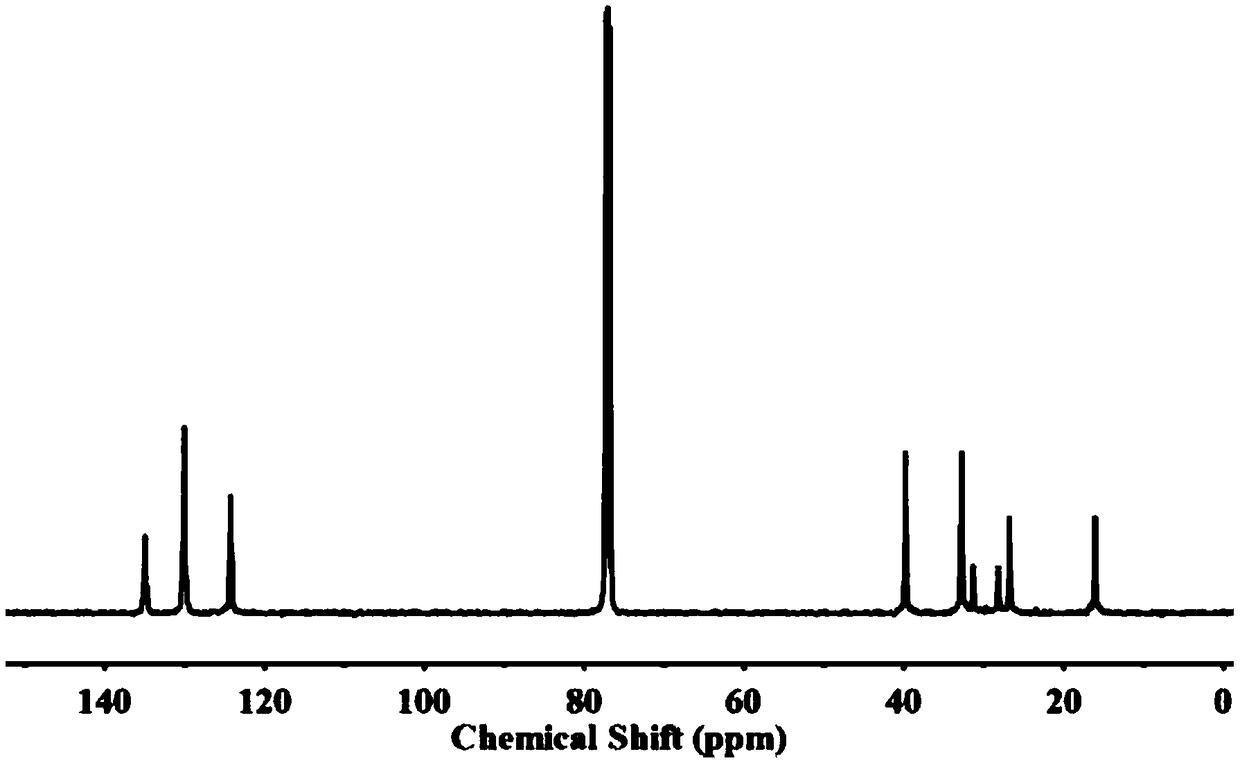

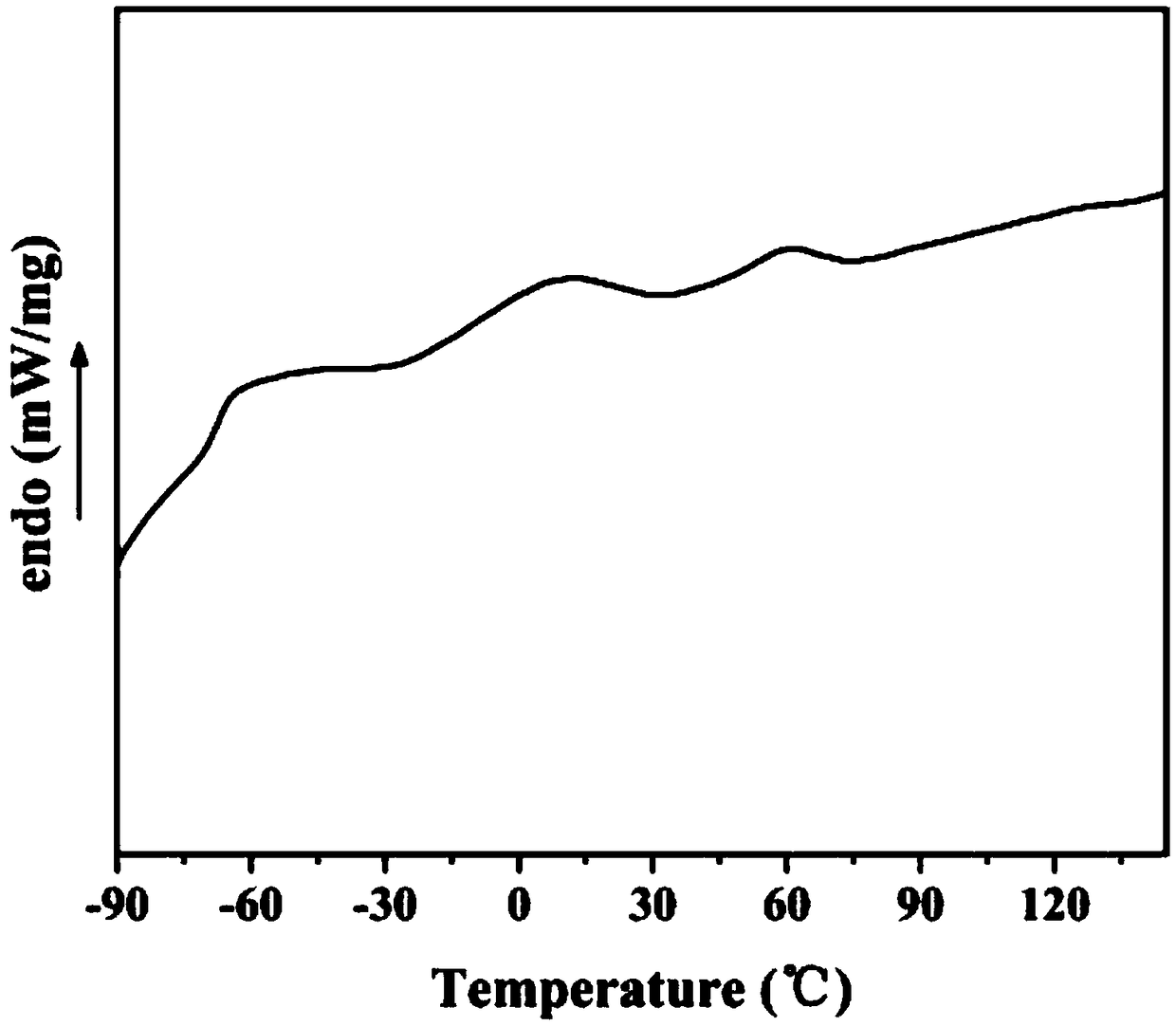

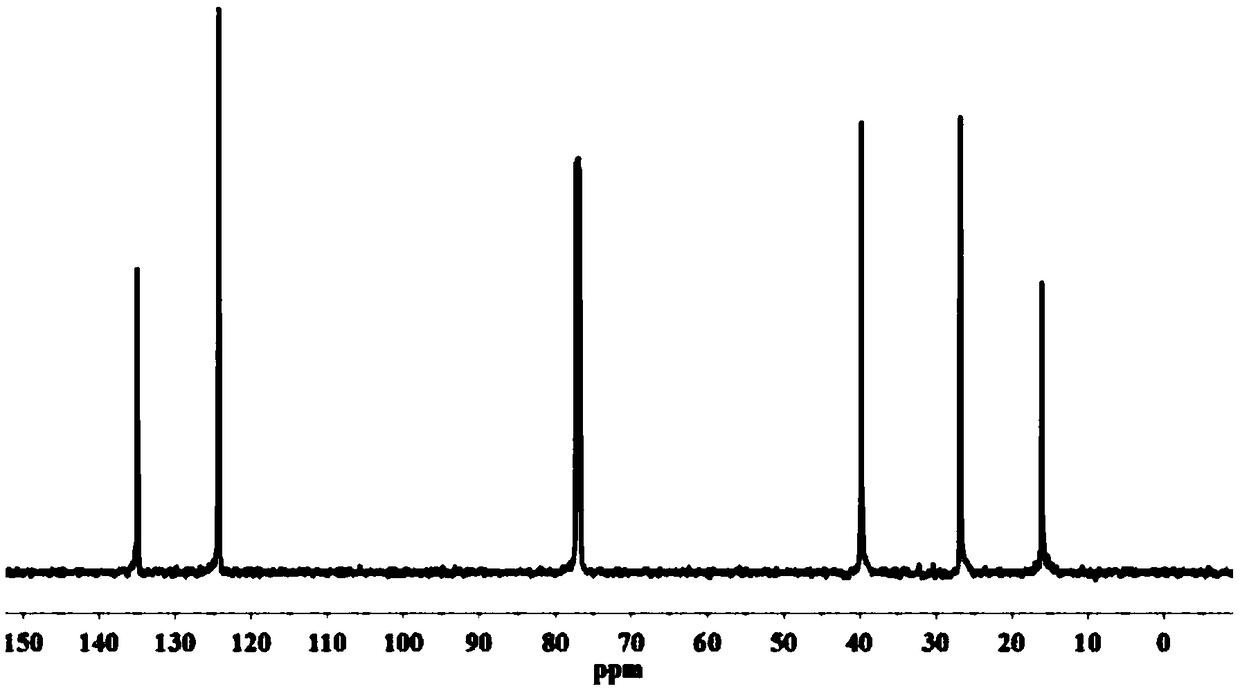

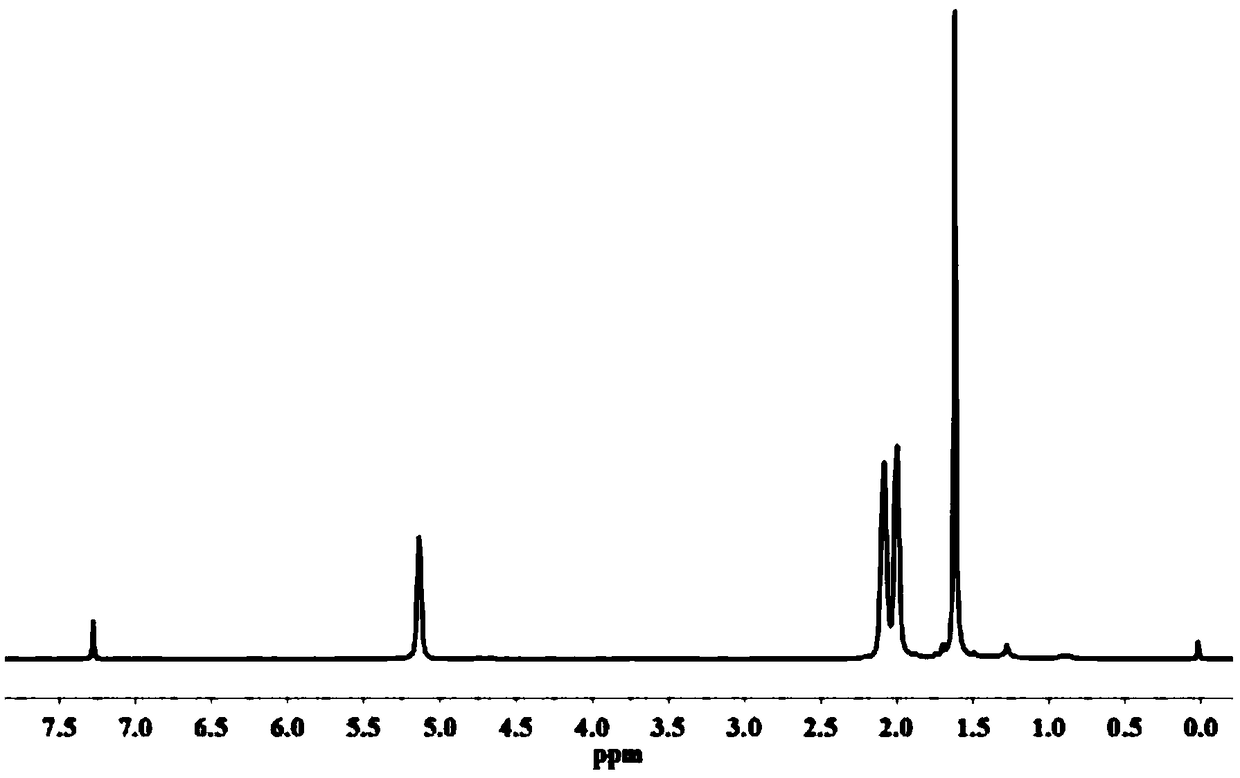

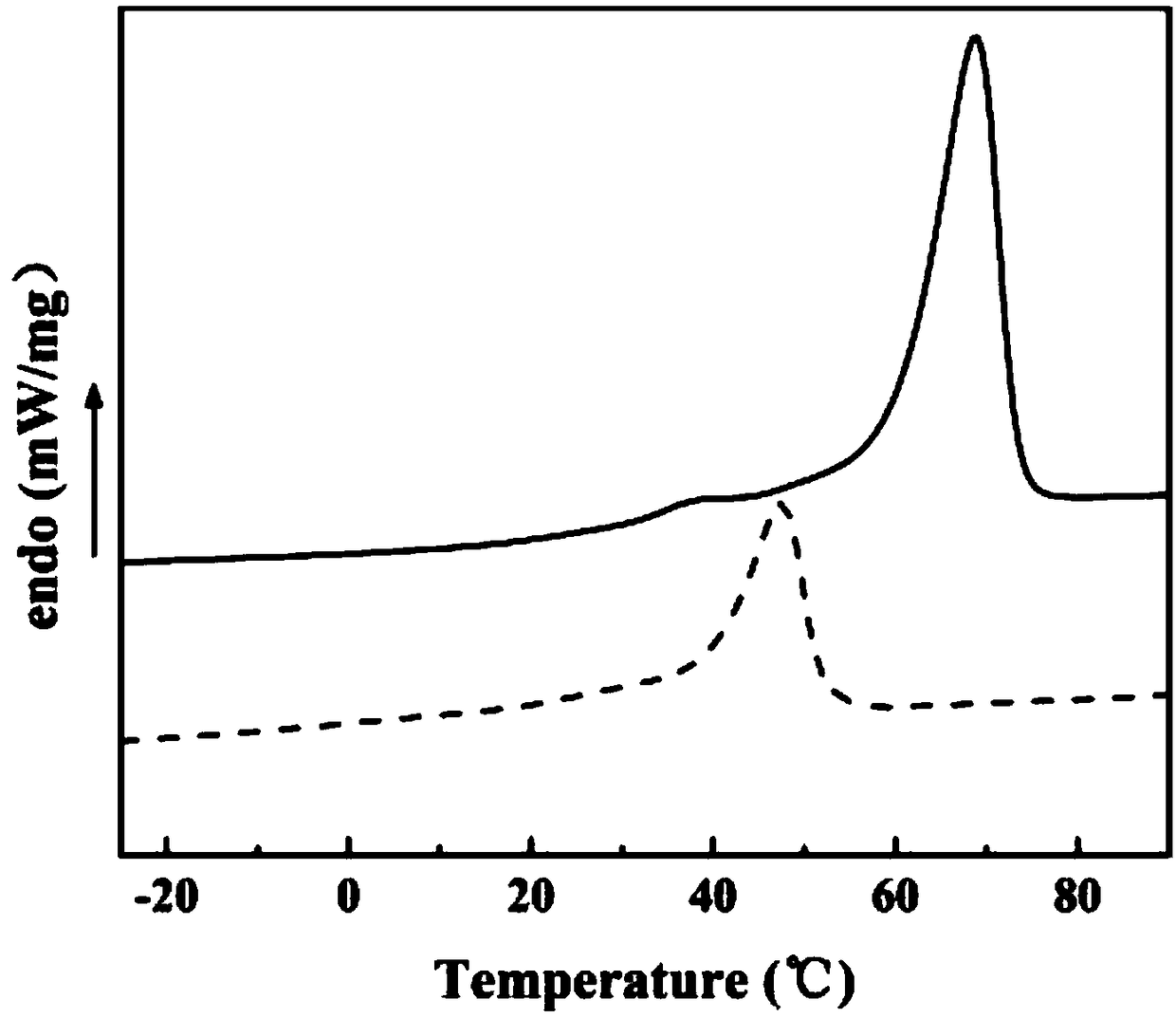

Preparation method of high trans-1,4-isoprene-butadiene copolymer

The invention discloses a preparation method of a high trans-1,4-isoprene-butadiene copolymer. By adopting a solution slurry method, isoprene and butadiene are catalyzed to be polymerized by a supported titanium catalyst and further the high trans-1,4-isoprene-butadiene copolymer is synthesized. The copolymer consists of an isoprene unit with the mole fraction of 42.8 to 89.9 percent and a butadiene unit with the mole fraction of 10.1 to 57.2 percent; the mole contents of trans-1,4-configurations of the isoprene unit and the butadiene unit are both greater than 97 percent. Compared with high trans-1,4-polyisoprene and high trans-1,4-polybutadiene, the copolymer as a novel trans-1,4-polydiolefin has the advantage that processing and blending properties are remarkably improved; meanwhile, the copolymer has excellent dynamic properties such as small rolling resistance, good flexural fatigue resistance and low dynamic heat build-up and provides an ideal sizing material for high-performancegreen tires.

Owner:QINGDAO UNIV OF SCI & TECH

Method for quickly constructing joint of IW steel curtain mesh conveying belt

ActiveCN101975244AThe connection method is simpleFast bondingBelt fasteningsEngineeringUltimate tensile strength

The invention relates to a method for quickly constructing a joint of an IW steel curtain mesh conveying tape. The method comprises the following steps: reserving a raw head on the top of a vulcanized tape, and compositely reinforcing the upper side and the lower side of the raw head with super glue canvas; dissolving the upper raw glue and the lower raw glue with solvent until the raw glue is peeled off and the steel curtain mesh is exposed when the tape head of the tap is adhered, and cutting the weave connecting wire of a steel wire and a steel wire rope, removing weft steel cord, and cutting steel wire ropes into step fingers one by one; laying a lower covering layer raw glue plate and an adhesive layer core raw glue plate under the steel wire ropes in sequence, performing step finger abut on the steel wire ropes at two ends of the tape; filling adhesive core glue in clearance of two adjacent abutted steel wires and clearance between ends; and laying an adhesive layer core glue raw glue plate, an anti-tearing steel core mesh raw glue fabric and an upper covering layer raw glue plate above the steel wires; and vulcanizing after finishing. The method has the advantages of simple jointing method, time and manpower conservation, quick adhering connection speed, no seam, high jointing strength and good flex fatigue resistance.

Owner:WUXI BOTON CONVEYOR SOLUTION CO LTD

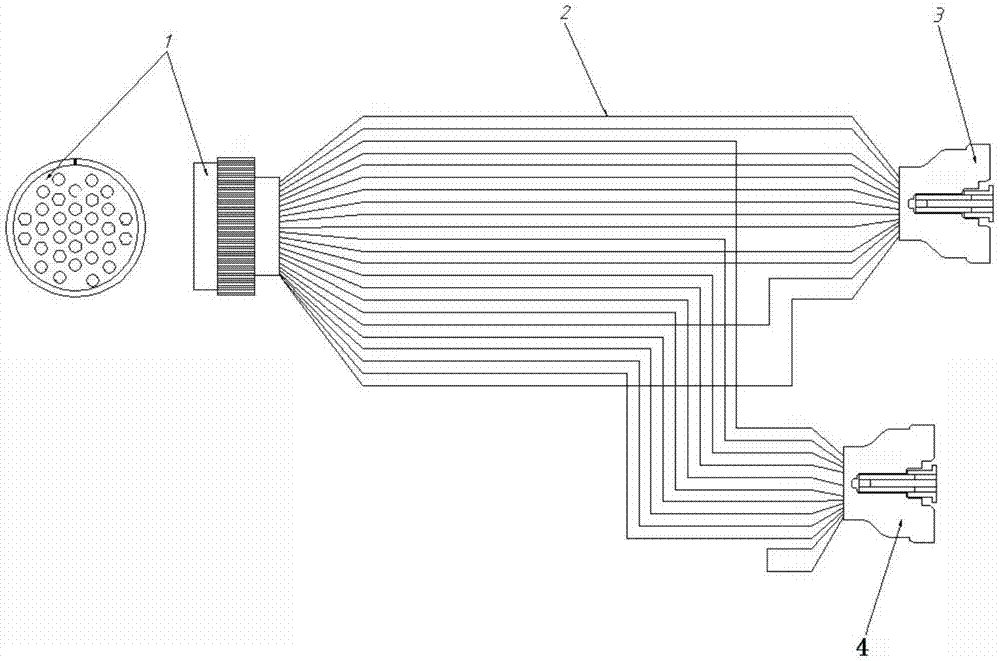

Gearbox controller connection wire harness

PendingCN107221819AShift quicklyAccurate gear shiftCoupling device connectionsVehicle connectorsMicrocomputerGear wheel

The invention provides a gearbox controller connection wire harness, which comprises a main control wire harness and an auxiliary control wire harness, wherein the main control wire harness comprises a first connector and a second connector connected onto the controller end, and a fourth connector connected onto the gearbox end; the main control wire harness is connected with the main control end of the controller and the gear of the gearbox; the main control wire control part is in charge of gearbox rotation speed control, and instruction signals for speed change sent by the gearbox controller are transmitted to the gearbox through the wire harness; and the auxiliary control wire harness comprises a third connector connected onto the connector end and a fifth connector connected onto the gearbox end and is connected onto the tail end of the gearbox for parameter correction. A connection hub is provided for the gearbox controller and the gearbox, a microcomputer and an execution element are tightly connected through the wire harness, two groups of wires are divided for control and parameter correction, and a tractor can work more stably and the efficiency is higher.

Owner:江苏吉恩利电子科技有限公司

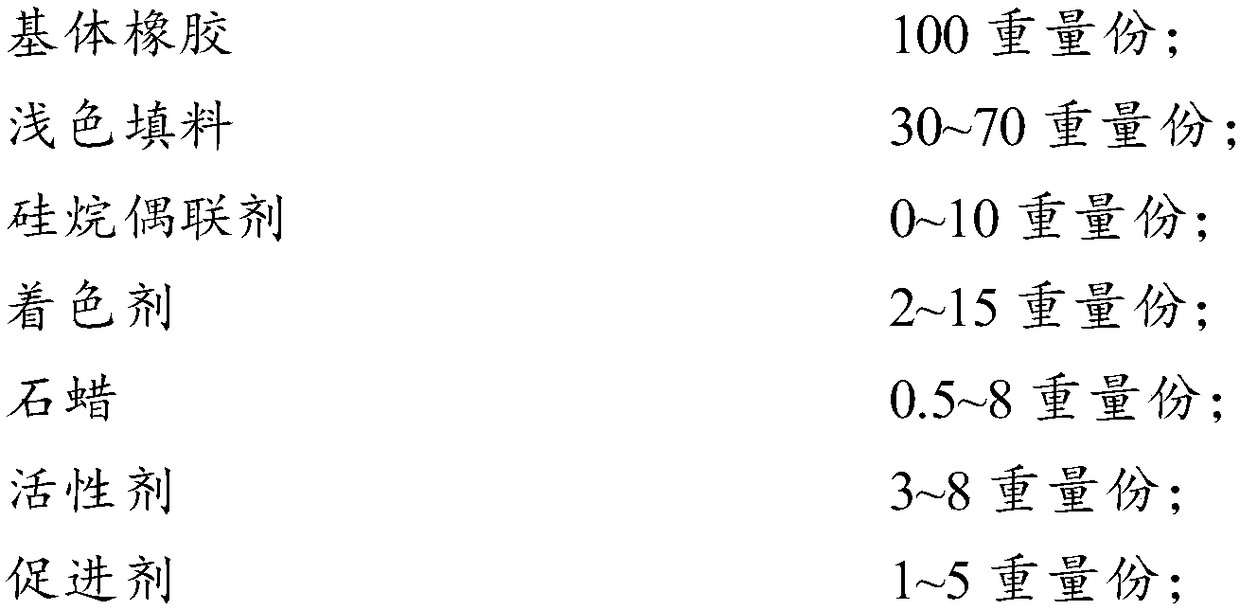

Rubber composition used for base rubber and tire side walls

The invention provides a rubber composition used for tire side walls. The rubber composition comprises the following components in parts by weight: 100 parts of base rubber, 30 to 70 parts of a lightcolor filler, 0 to 10 parts of a silane coupling agent, 2 to 15 parts of a coloring agent, 0.5 to 8 parts of paraffin, 3 to 8 parts of an activating agent, 1 to 5 parts of an accelerant and 0.5 to 3 parts of a vulcanizing agent; the 100 parts of base rubber comprises 30 to 60 parts of natural rubber and butadiene rubber and 40 to 70 parts of halogenated butyl rubber and EPDM rubber in parts by weight; and the weight of natural rubber is greater than or equal to 50% of the total quantity of natural rubber and butadiene rubber. Compared with the prior art, no chemical anti-aging agent is added into the rubber composition provided by the invention, just through balance selectivity of the base rubber and the light color filler, the obtained colored rubber composition has excellent ozone agingresistance, flexing fatigue resistance and processability, and the appearance is colorful and the color is unlikely to change.

Owner:GUANGZHOU FENGLI RUBBER TIRE

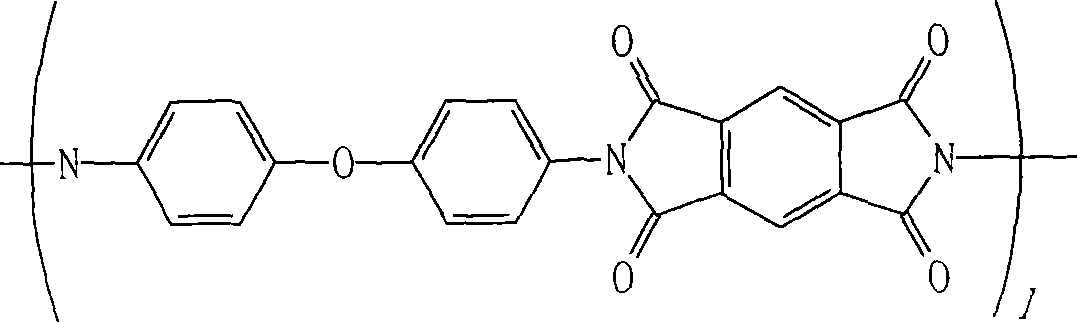

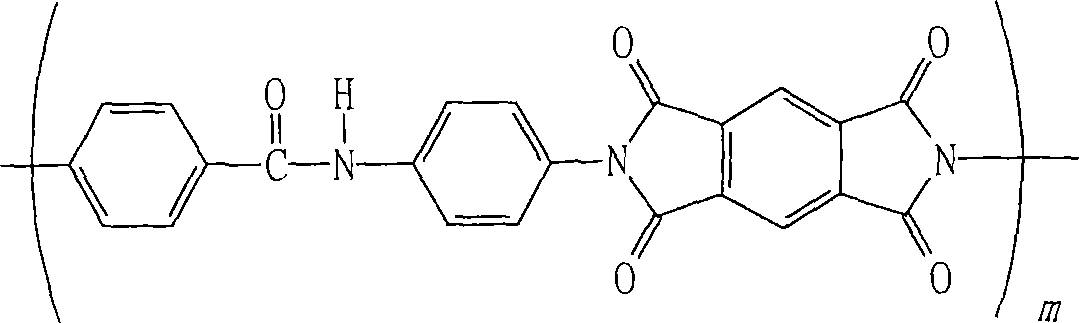

Flexible copper-polyimide laminate and manufacturing method thereof

InactiveCN101010191ANo curlGood dimensional stabilitySynthetic resin layered productsPrinted circuit aspectsFolding endurancePolymer science

The present invention provides a flexible copper-polyimide laminate including a linear random block polyimide layer formed on the at least one side thereof, the linear random block polyimide layer comprising 0.25 to 90.25 mol.% of a repeating unit l represented by the formula 1, 0.25 to 90.25 mol.% of a repeating unit m represented by the formula 2, 0.25 to 90.25 mol.% of a repeating unit n represented by the formula 3, and 0.25 to 90.25 mol.% of a repeating unit o represented by the formula 4. The flexible copper-polyimide laminate having a polyimide layer is free from curls and excellent in dimensional stability, tensile property, folding endurance and resistance to flexural fatigue with low moisture content.

Owner:KOLON IND INC

Novel trans-1,4-polyisoprene synthesis method with high monomer conversion rate

InactiveCN108690156AExcellent flex fatigue resistanceImprove distributionPolymer scienceSynthesis methods

The invention relates to a preparation method of trans-1,4-polyisoprene (TPI). A supported titanium catalyst is used to catalyze polyisoprene polymerization, and a solution-slurry method is adopted tosynthesize powdery or block shaped trans-1,4-polyisoprene (TPI). The catalysis efficiency and monomer conversion rate are high, and the method has reached the industrialization standards. The synthesized TPI has the advantages of high hardness and excellent dynamic properties and can be easily crystallized at a room temperature. TPI has a wide application range. In a zero crosslinking phase, TPIis a thermoplastic material and is used as a medical material; in a low crosslinking phase, TPI is a thermo-elastic material and is used as a shape memory material; and when the crosslinking density exceeds a certain value, TPI becomes a rubber type high elasticity material. At present, TPI has great advantages in fields of green tires and medium-high temperature damping materials, and has a greatapplication value.

Owner:QINGDAO UNIV OF SCI & TECH

High-elasticity and high-durability regenerated rubber seal ring and preparation method thereof

The invention discloses a high-elasticity and high-durability regenerated rubber seal ring. The high-elasticity and high-durability regenerated rubber seal ring is prepared from raw materials in parts by weight as follows: 60-80 parts of regenerated rubber, 5-10 parts of ethylene-propylene-diene monomer rubber, 10-25 parts of diatomite, 5-10 parts of carbon nanofibers, 4-6 parts of rosin, 2-4 parts of butyl acrylate, 0.5-1 part of 2,6-di-tert-butyl-4-methylphenol, 1-2 parts of sulfur, 0.1-0.2 parts of potassium persulfate, 0.1-0.2 parts of sodium dodecyl sulfate, 1-2 parts of diacetyl tartaric acid ester of mono(di)glycerides, 1-2 parts of zinc stearate, 2-4 parts of palm oil and 5-10 parts of a compound aid. The regenerated rubber seal ring has an excellent mechanical property and use performance, good sealing performance and high overall performance, has high elasticity and durability, excellent flexing fatigue resistance and good elastic resilience and is long in service life and applicable to various mechanical devices.

Owner:安徽创奇乐智能游乐设备有限公司

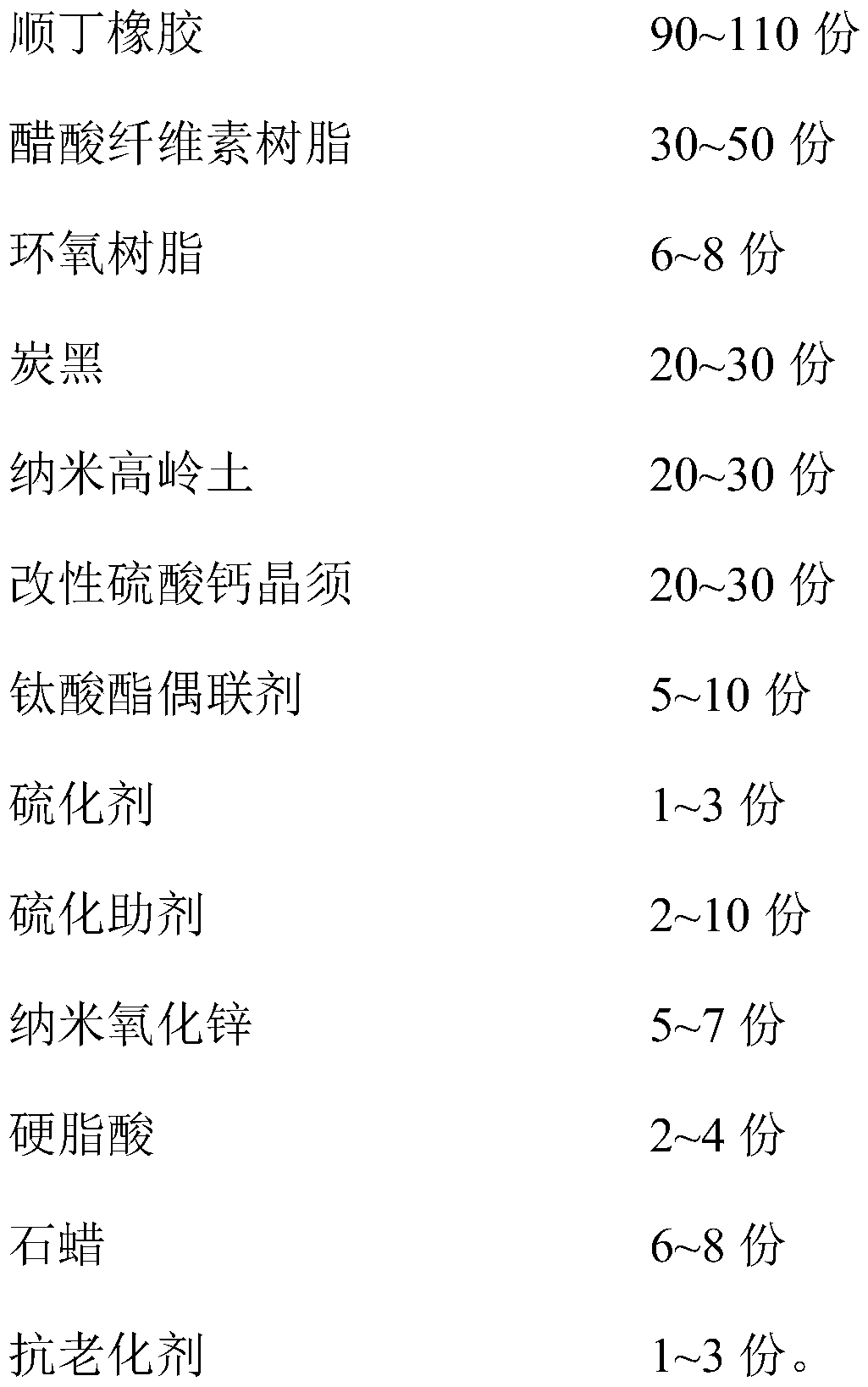

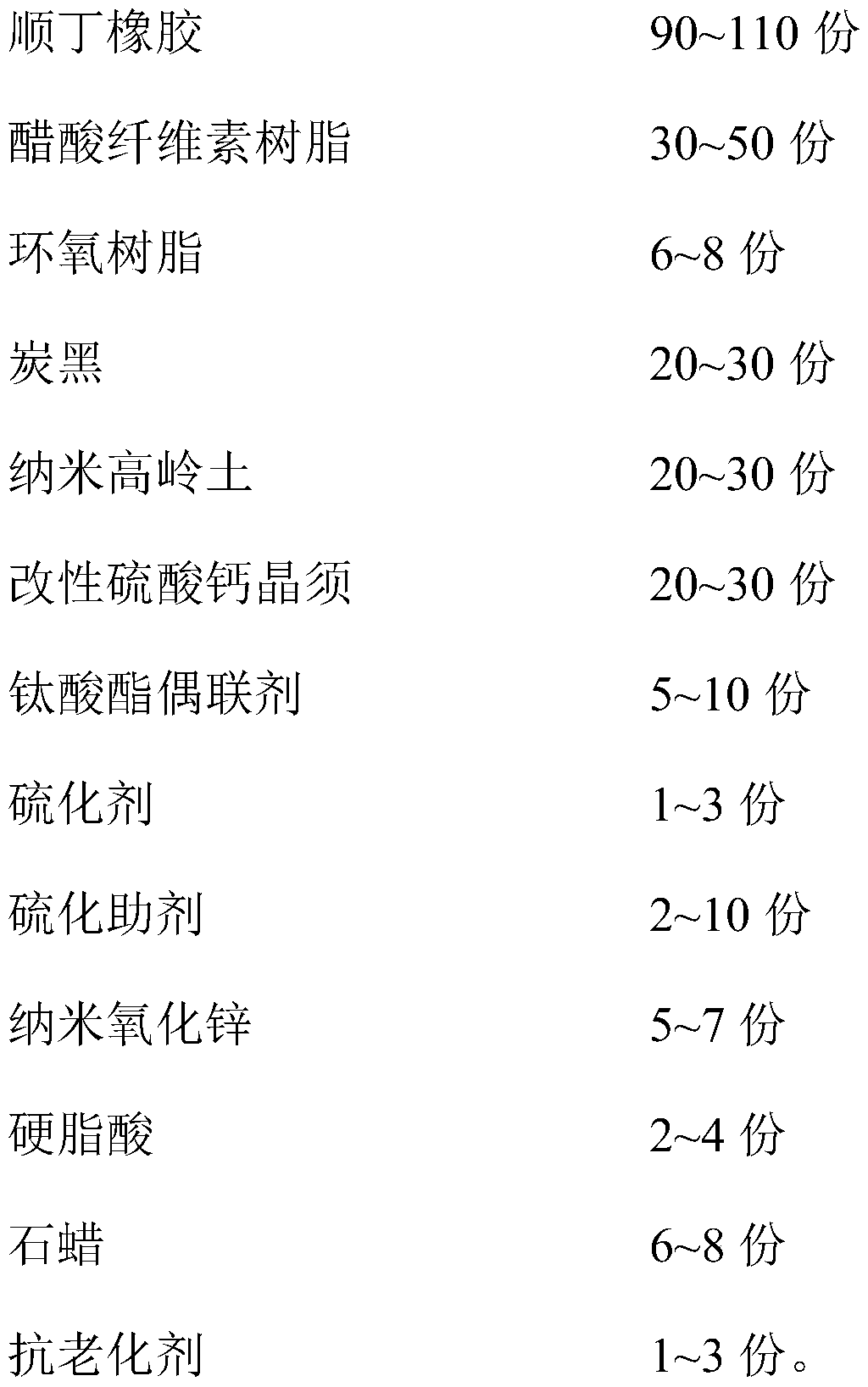

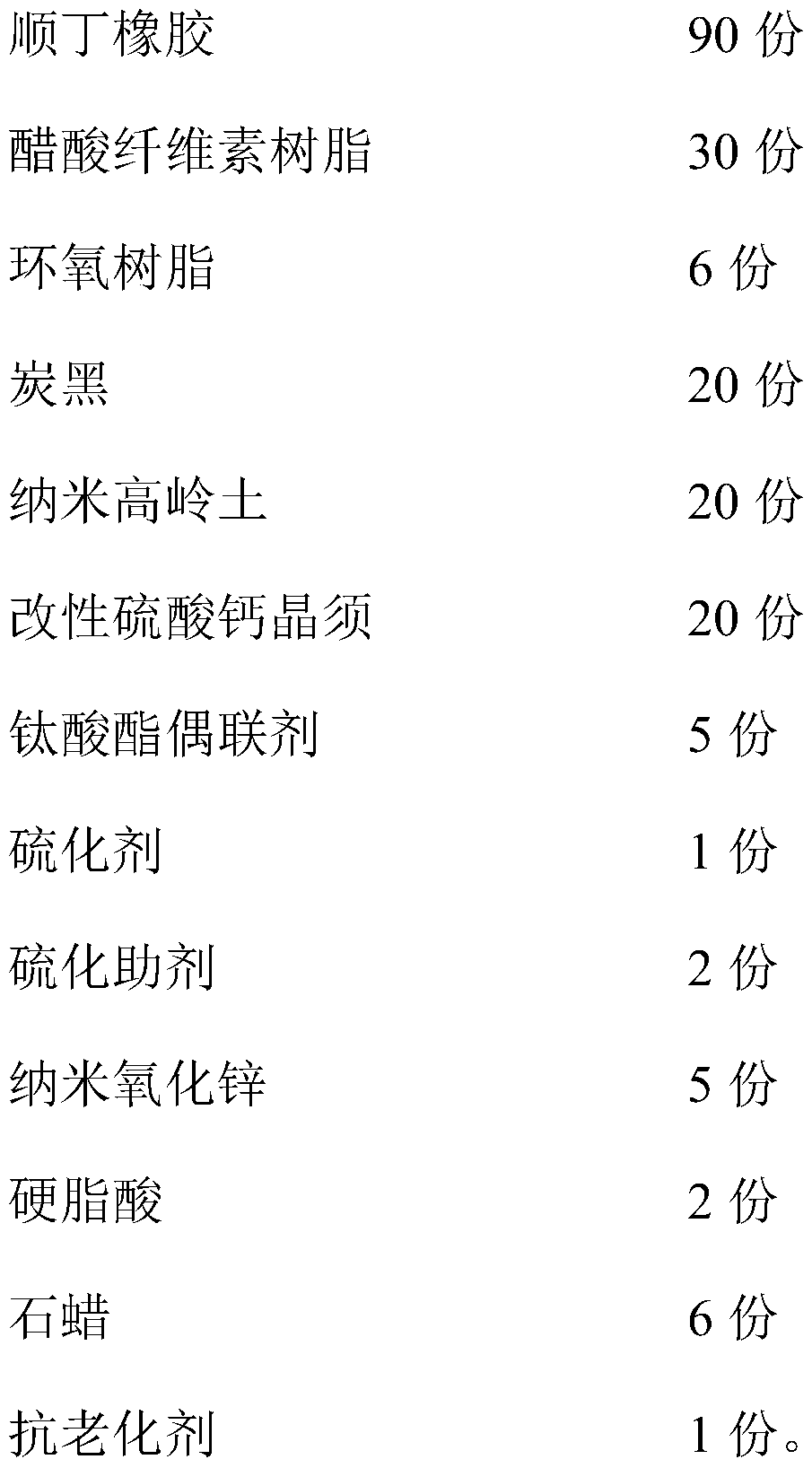

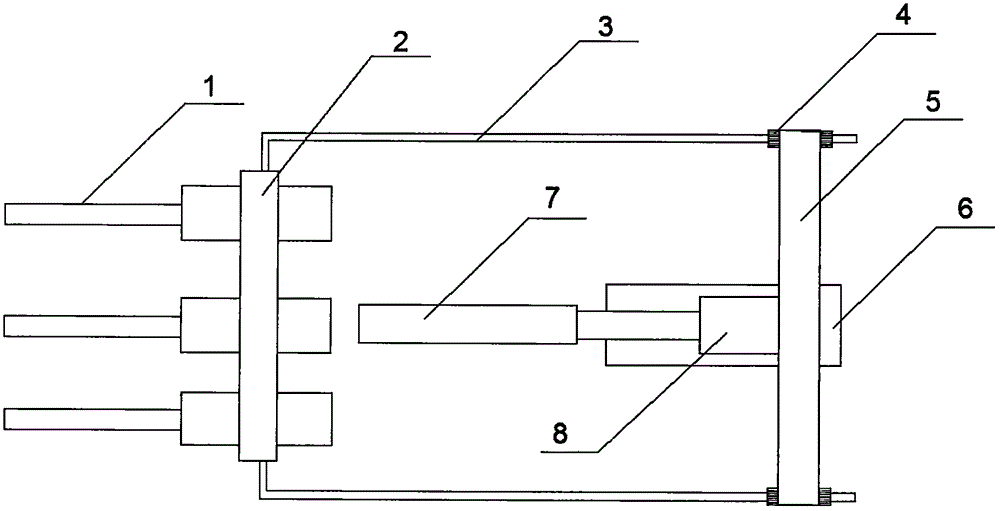

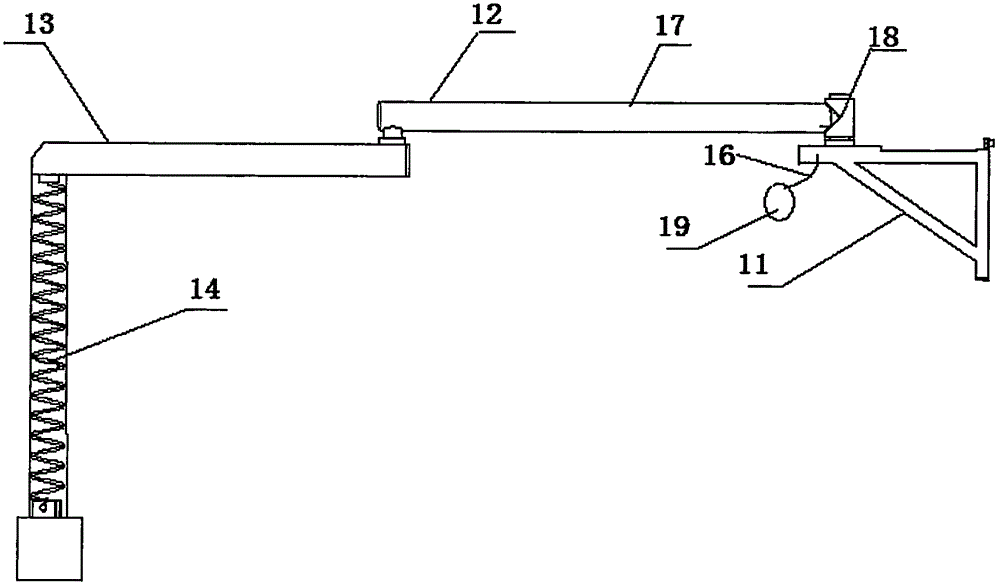

Butadiene rubber dust cover and preparation method thereof

The invention relates to the technical field of rubber materials, and discloses a butadiene rubber dust cover. The butadiene rubber dust cover comprises the following components: 90-110 parts of butadiene rubber, 30-50 parts of cellulose acetate resin, 6-8 parts of epoxy resin, 15-20 parts of carbon black, 15-20 parts of nano kaolin, 15-20 parts of modified calcium sulfate whiskers, 5-10 parts ofa titanate coupling agent, 1-3 parts of a vulcanizing agent, 2-10 parts of a vulcanizing aid, 5-7 parts of nano zinc oxide, 2-4 parts of stearic acid, 6-8 parts of paraffin and 1-3 parts of an anti-aging agent. The invention also discloses a preparation method thereof. According to the butadiene rubber dust cover prepared by the invention, butadiene rubber is used as a raw material; compared withthe prior art, the dust cover has the advantages that other rubber materials do not need to be doped, the processability of the dust cover is improved through vulcanization of tert-butyl peroxybenzoate, sulfur and phenolic resin under the action of cellulose acetate resin, epoxy resin, carbon black, nano kaolin and modified calcium sulfate whiskers, and the obtained dust cover is good in mechanical property and high in tearing strength.

Owner:ZHEJIANG SHITAI IND CO LTD

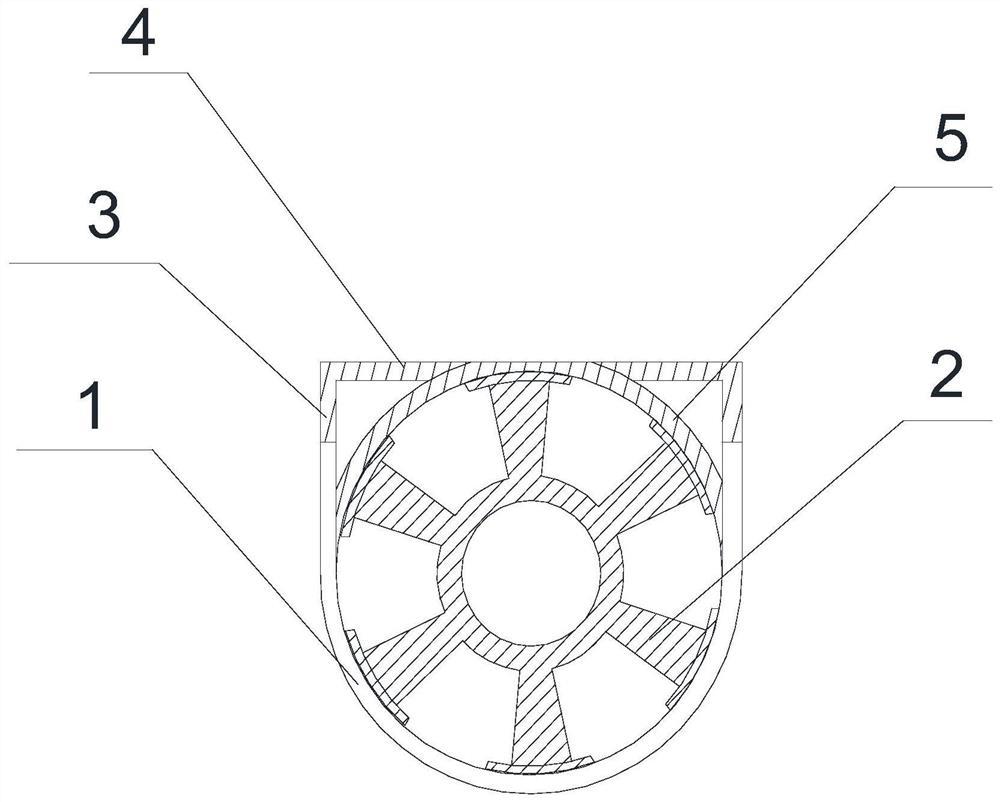

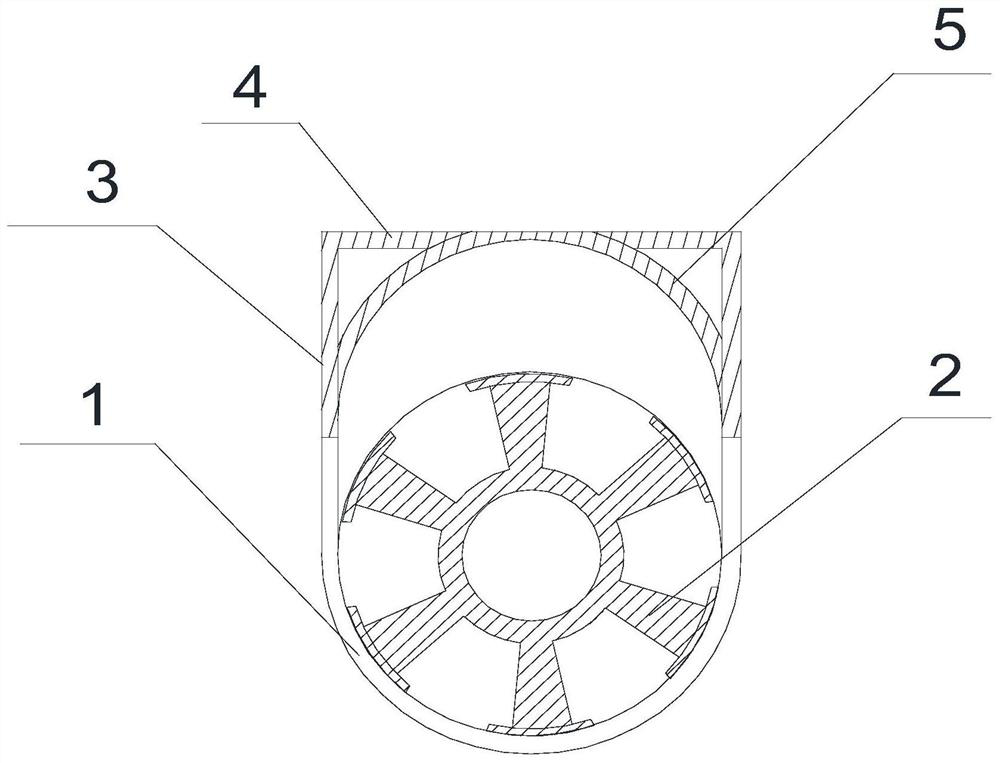

Multifunctional mechanical arm

ActiveCN105666487AAchieve multi-functionExtended service lifeProgramme-controlled manipulatorCouplingEngineering

The invention relates to the technical field of industrial machines, in particular to a multifunctional mechanical arm. The multifunctional mechanical arm comprises a mechanical arm body and further comprises a plurality of work heads and a coupling device matched with the work heads. The mechanical arm body outputs power to the work heads through the coupling device, and the work heads are telescopically mounted on a mounting rack. The coupling device comprises a fixed barrel arranged at one end of the mechanical arm body, an air pump arranged in the fixed barrel and a coupler with one end connected to the air pump, and the other end of the coupler is matched with the work heads. According to the technical scheme, the multifunctional mechanical arm has the following beneficial effects that the structure is simple, the technology is reasonable, and use is convenient; the mechanical arm body is connected with the work heads with different functions through displacement of the coupler, and multiple functions of the mechanical arm are achieved; and an elastic element of the coupler is long in service life, excellent weather fastness, bending fatigue resistance, fire resistance and corrosion resistance are achieved, and therefore use is facilitated, and the service life of the mechanical arm is prolonged.

Owner:苏州云雀机器人科技有限公司

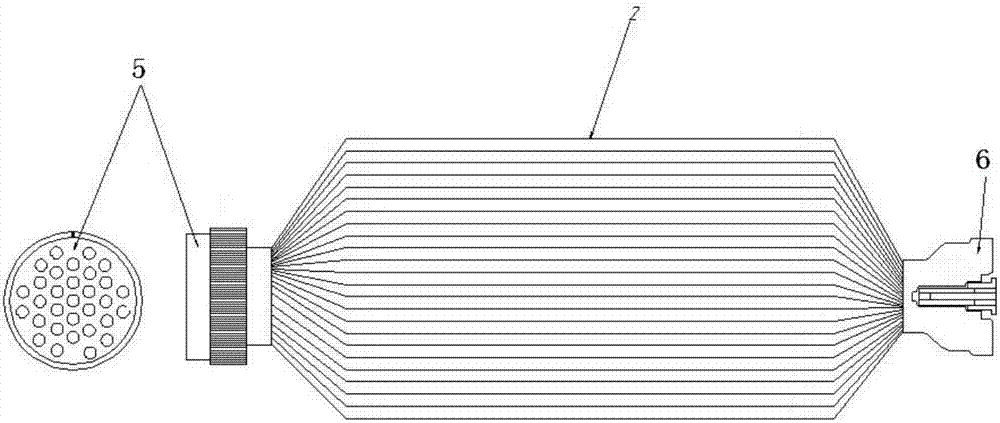

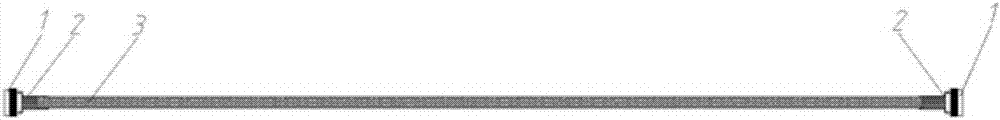

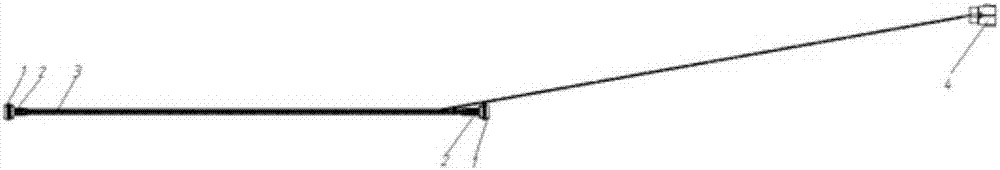

Novel imported port tractor gearbox wiring harness, and preparation method thereof

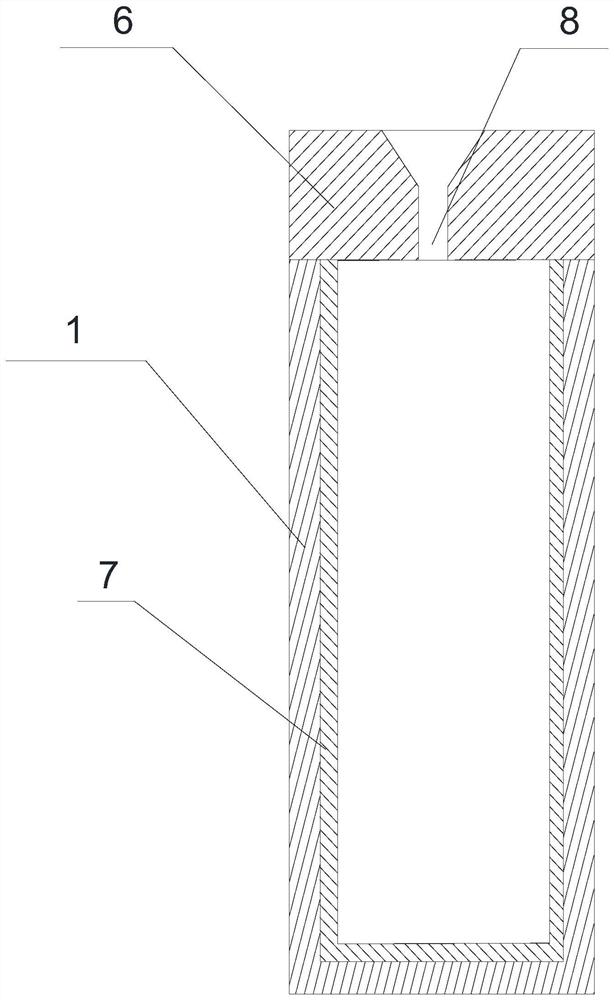

PendingCN107317203AImprove moisture resistanceGood weather resistanceCoupling device connectionsInsulated cablesYarnThermoplastic elastomer

The invention relates to a novel imported port tractor gearbox wiring harness, and a preparation method thereof. The wiring harness comprises first connectors (1), heat-shrinkable tubes (2), wiring harness woven yarns (3), and a wire, wherein the first connectors (1) are connected to the two ends of the wire, so that a complete circuit is formed; the outside of the wire is circumferentially wrapped by the woven yarns (3); and the heat-shrinkable tubes (2) are arranged at the joints between the two ends of the wire and the first connectors. The imported wiring harness woven yarns are used for weaving of the wiring harness and are thermoplastic elastomer (TPE) coated yarns; compared with ordinary vinyl coating, thermoplastic coating can bear higher temperatures and is less susceptible to solvents; and the woven yarns achieve excellent moisture-resistant and weather-resistance performances, extremely high abrasion resistance and flexing fatigue resistance, high chemical substance and oil resistances, and extremely high stability at low temperatures.

Owner:江苏吉恩利电子科技有限公司

Prepn of polyether-type polyurethane as shoe sole material

InactiveCN1189499CImprove low temperature toughnessExcellent flex fatigue resistanceSolesShoe industryPolyurethane elastomer

the present invention is preparation process of polyether-type polyurethane as shoe sole material. Polyether polyol with high activity and low unsaturation degree is synthesized with water as foaming agent and bimetal cyanide as catalyst; and isocyanate capped modified semi-prepolymer is prepared with small molecule modifier containing active hydrogen. The modified semi-prepolymer and the Polyether polyol are further produced into the porous polyurethane elastomer through mixing, casting, foaming and demolding. The material has high tensile strength, tearing strength, elongation and permanent deformation performance, and rather high low temperature embrtittlement and bending performance, and can meet the requirement as shoe material.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Aluminum-based composite conducting bar for motor remanufacturing as well as preparation method and application of aluminum-based composite conducting bar

ActiveCN113839524AImprove conductivityGood fluidityConductive materialElectric machinesElectric machineGraphite

The invention discloses an aluminum-based composite conducting bar for motor remanufacturing and a preparation method and application of the aluminum-based composite conducting bar for motor remanufacturing. The method comprises the steps of preparing graphene aluminum-based composite liquid, wherein the graphene aluminum-based composite liquid comprises graphene, a rare earth material, a boron element and a rhenium element; coating the groove wall of a rotor core with an insulating layer; and preheating the rotor iron core, and casting the graphene aluminum-based composite liquid into a groove of the rotor iron core after preheating to obtain the aluminum-based composite conducting bar. The conducting bar provided by the invention has high conductivity, high thermal conductivity and better toughness, can further improve the efficiency of the motor, and is more favorable for being used in the field of motor remanufacturing.

Owner:内蒙古靓固科技有限责任公司

High-flexing low-smoke halogen-free antiflaming sheathing material of elevator cable, preparation method and application

ActiveCN106589512AIncreased tensile strength and elongation at breakGood flex fatigue resistancePlastic/resin/waxes insulatorsSilane couplingPolyolefin

The invention relates to a high-flexing low-smoke halogen-free antiflaming sheathing material of an elevator cable, and a preparation method and application thereof. The sheathing material is prepared through the following steps that (1), a vulcanizing agent is dissolved into a silane coupling agent, and a silane coupling agent solution containing the vulcanizing agent is obtained; (2), polyolefin elastomer resin and acrylic ester rubber are mixed to obtain a mixture; (3), the silane coupling agent containing the vulcanizing agent is adsorbed in the mixture obtained in the step (2), and then a mixed material is obtained; and (4), an inorganic flame retardant, an antioxidant and the mixing material obtained in the step (3) are put into an internal mixer together, mixing is conducted for five to ten minutes at the temperature of 120-140 DEG C, then a catalyst is added, banburying is conducted for one to three minutes at the temperature of 120-140 DEG C, and the high-flexing low-smoke halogen-free antiflaming sheathing material is obtained. According to the high-flexing low-smoke halogen-free antiflaming sheathing material of the elevator cable, the preparation method and the application, the sheathing material is high in tensile strength and breaking elongation rate and good in flex fatigue resistant property; the formula and technological operation are easy, and cost is low.

Owner:上海高分子功能材料研究所

Aluminum alloy conductor

ActiveCN103492597AHigh and moderate yield strengthEasy to handleSingle bars/rods/wires/strips conductorsConductive materialElectrical conductorAluminium alloy

Owner:FURUKAWA ELECTRIC CO LTD +1

A kind of trans-1,4-structure butadiene-isoprene copolymer rubber and its preparation method

A trans-1, 4-structured butadiene-isoprene copolymer rubber and a preparation method thereof. A Ziegler-Natta catalytic system containing MgCl2 loaded titanium and an organic aluminium compound is used to catalyze butadiene and isoprene for copolymerization synthesis of the butadiene-isoprene copolymer with trans 1, 4-structure greater than 90%; and the copolymer rubber comprises, by molar fraction, 20-99.5% of an isoprene unit and 0.5-80% of a butadiene unit. One preparation method of the trans copolymer rubber is by maintaining a feeding ratio of butadiene to isoprene, and catalyzing butadiene and isoprene for copolymerization synthesis of trans copolymer rubber with gradient composition at 0-90 DEG C. A second preparation method of the trans copolymer rubber is by maintaining the concentration of butadiene in reaction materials, and catalyzing butadiene and isoprene for copolymerization synthesis of trans copolymer rubber with relatively uniform composition at 0-90 DEG C. The trans copolymer rubber has characteristics of low heat, good abrasion resistance and excellent flex and fatigue resistant performance, and is suitable rubber products for dynamic usage.

Owner:QINGDAO UNIV OF SCI & TECH +1

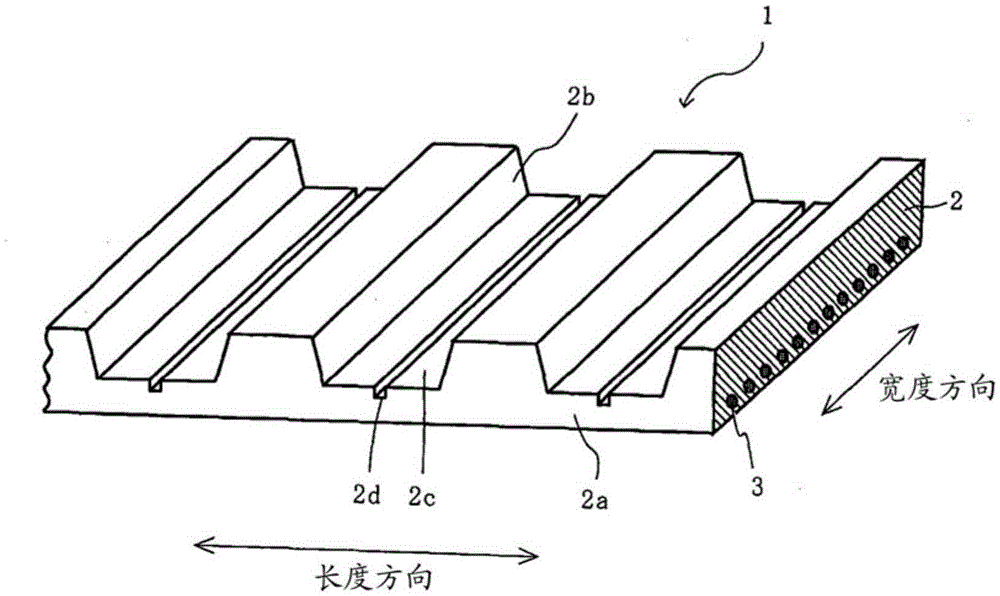

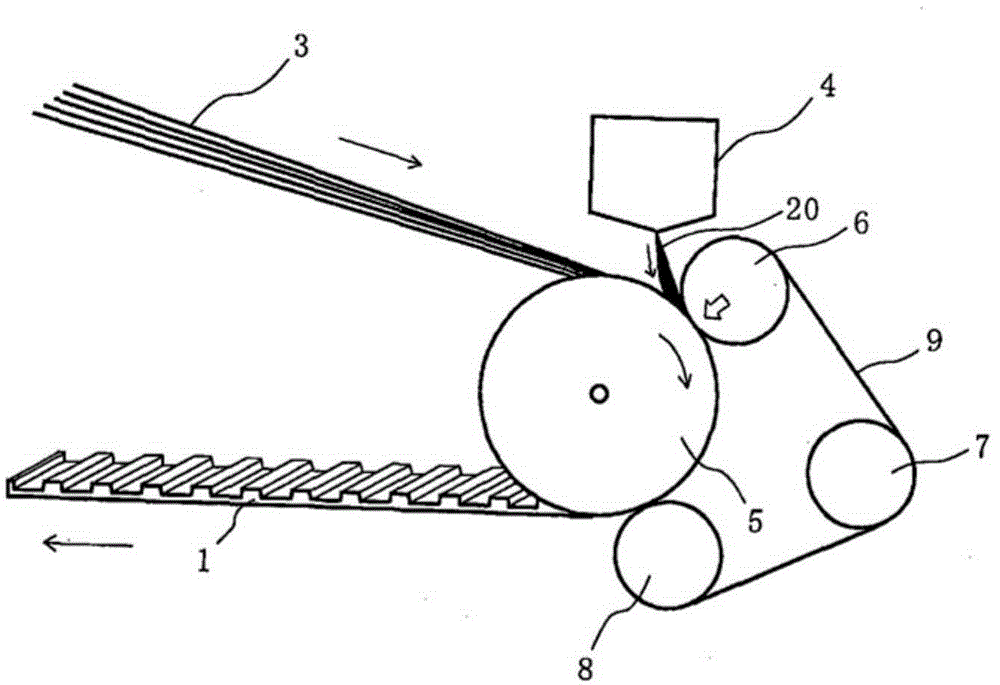

toothed belt

InactiveCN103534511BNot easy to wearNot easy to damageDriving beltsThermoplastic elastomerThermoplastic polyurethane

The present invention provides a toothed belt characterized in that all or part of the belt body is made of modified ethylene-propylene-diene copolymerized with thermoplastic polyurethane (A) and modified with unsaturated carboxylic acid or its derivatives. The thermoplastic elastomer alloy of rubber (B) is formed. The weight ratio [(B) / (A)] of the modified ethylene-propylene-diene copolymer rubber (B) modified with an unsaturated carboxylic acid or its derivatives to the thermoplastic polyurethane (A) is preferably 0.1 / 99.9~30 / 70. According to the toothed belt of the present invention, even if it is used under a high load for a long period of time, abrasion, scratches, cracks, breakage, etc. are hardly generated on the belt main body, and the durability is extremely excellent.

Owner:NITTA CORP +1

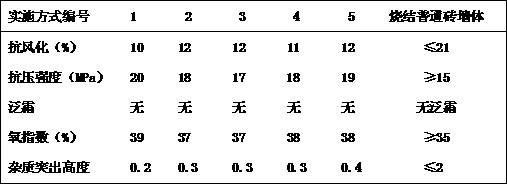

Green and environmental-friendly waste rubber powder house wall material

The invention discloses a green and environmental-friendly waste rubber powder house wall material and solves the technical problems that traditional wall materials are low in strength, not resistantto aging, poor in flame retardance and the like. The material is prepared from 100 parts of waste rubber powder and 52 parts of a compounding agent in the mass ratio. The compounding agent comprises fly ash, diatomite, basalt fiber, di-tert-butyl peroxide, tetraethylthiuram disulfide, activated zinc oxide, magnesium hydroxide, nano-montmorillonite, styrenated phenol and 2,4-dinitrophenol in the mass ratio being 10:6:8:6:14:1:2:1:3:1. The material is processed with a casting molding process. The waste rubber powder house wall material has the weather-resisting degree not larger than 12%, compressive strength larger than 17 MPa, no scumming, oxygen index reaching 37% or above and impurity protruding height not larger than 0.4 and can be used as a house wall material.

Owner:QIQIHAR UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com