Butadiene rubber dust cover and preparation method thereof

A technology of cis-butadiene rubber and dust cover, applied in the field of rubber materials, can solve the problems of low tear strength and tensile strength of cis-butadiene rubber, poor processing performance, etc., and achieve good low temperature resistance, dynamic performance, and good mechanical performance. , The effect of good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

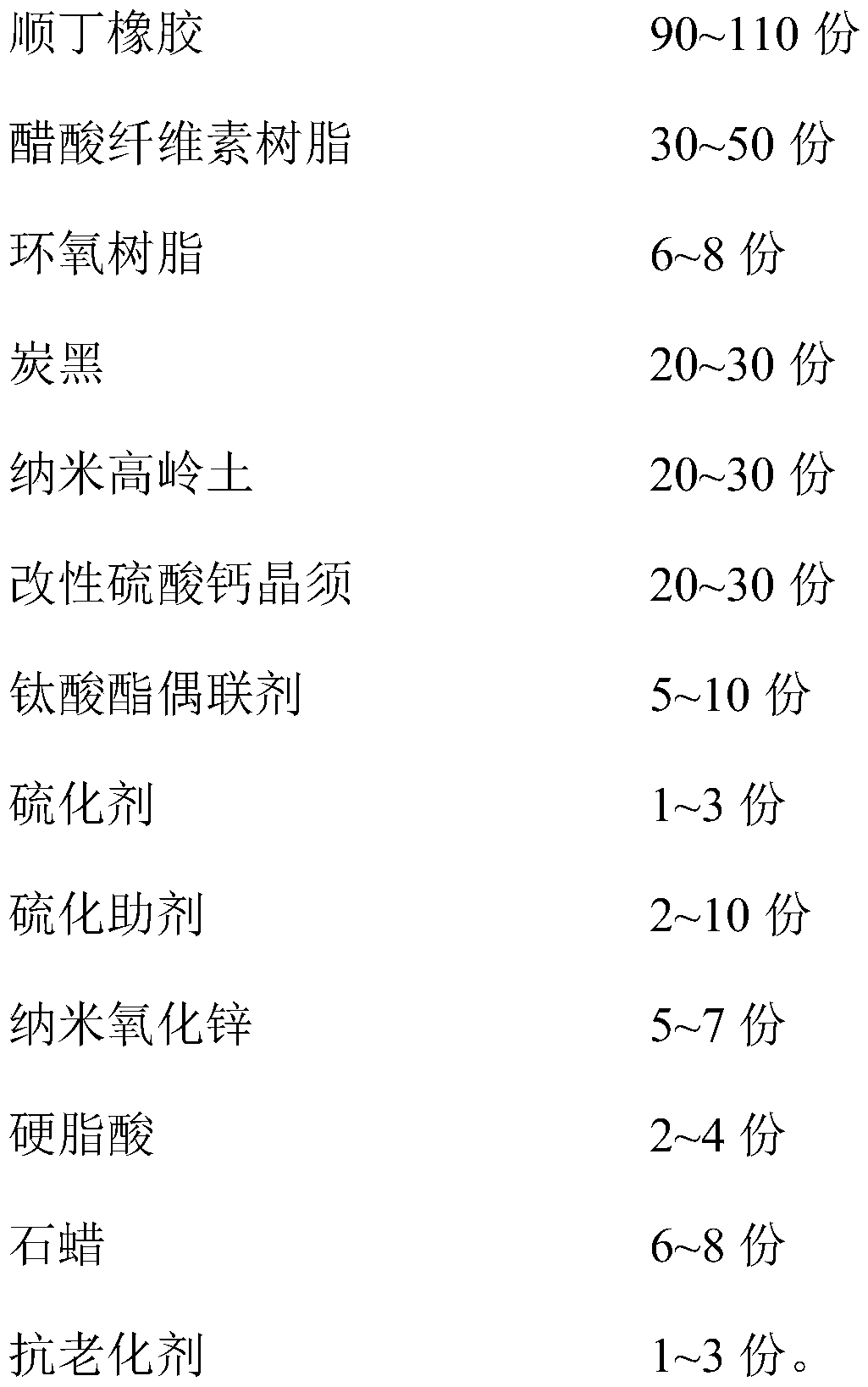

[0031] A butadiene rubber dust cover, comprising the following raw materials in parts by weight:

[0032]

[0033] The weight ratio of carbon black, nano kaolin and modified calcium sulfate whiskers is 1:1:1.

[0034] Curing agents include combinations of t-butyl peroxybenzoate, sulfur and phenolic resins.

[0035] The weight ratio of tert-butyl peroxybenzoate, sulfur and phenolic resin in the vulcanizing agent is 0.3:0.5:0.2.

[0036] The vulcanization aid is a composition of 0.5 parts of hexamethylene diisocyanate, 0.5 parts of zinc chloride and 1 part of 4,4'-bismaleimide.

[0037] The modified calcium sulfate whisker is calcium sulfate whisker modified by aluminate coupling agent.

[0038] A preparation method for butadiene rubber dust cover, comprising the following steps:

[0039] (1) modifying the nano kaolin and carbon black with a titanate coupling agent to obtain a modified reinforcing agent;

[0040] (2) Butadiene rubber, cellulose acetate resin, nano-zinc ox...

Embodiment 2

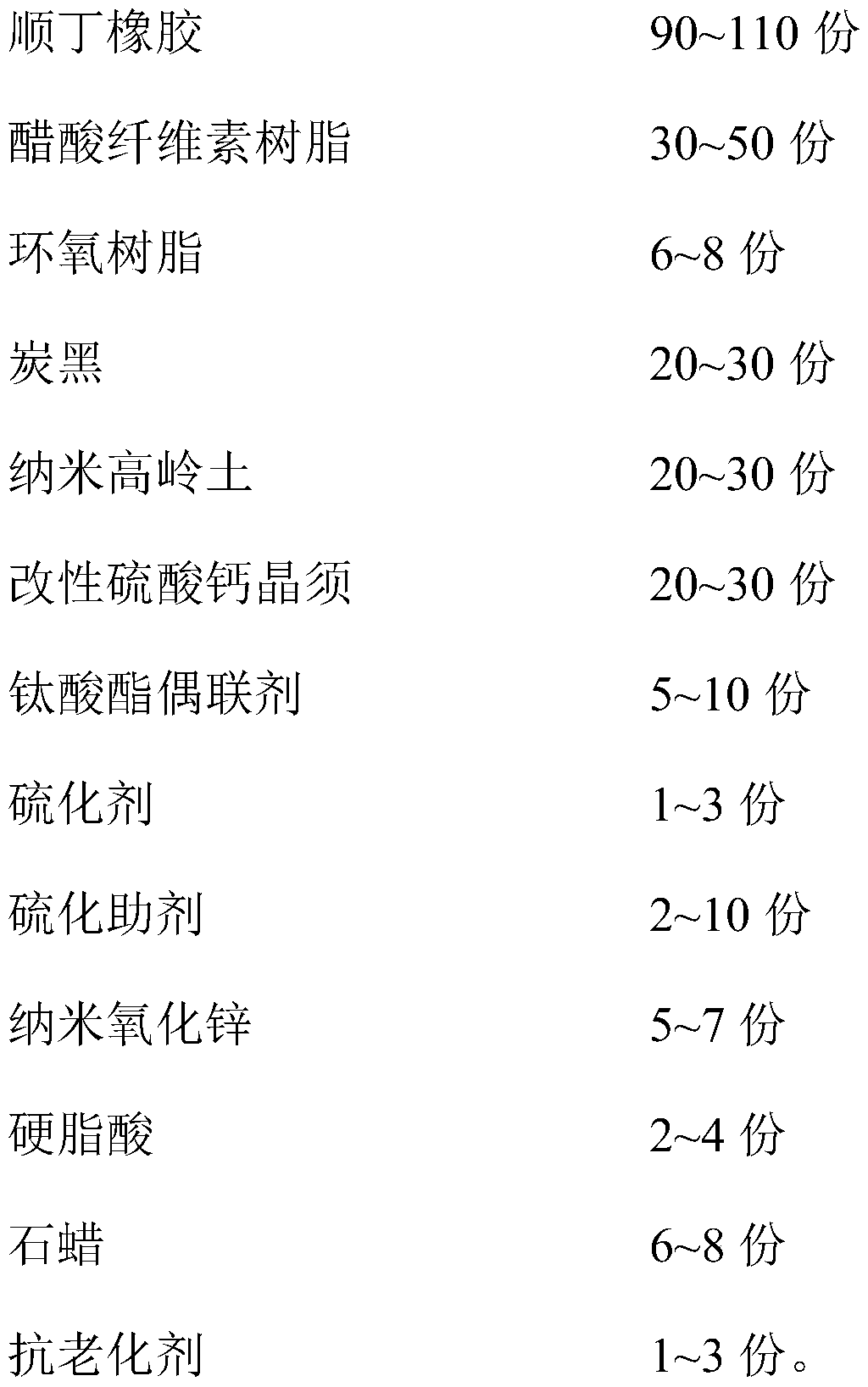

[0045] A butadiene rubber dust cover, comprising the following raw materials in parts by weight:

[0046]

[0047]

[0048] The weight ratio of carbon black, nano kaolin and modified calcium sulfate whiskers is 1:1:1.

[0049] Curing agents include combinations of t-butyl peroxybenzoate, sulfur and phenolic resins.

[0050] The weight ratio of tert-butyl peroxybenzoate, sulfur and phenolic resin in the vulcanizing agent is 1:1:1.

[0051] The vulcanization aid is a combination of 3 parts of 2,4-toluene diisocyanate, 3 parts of magnesium chloride and 4 parts of 4,4'-bismaleimide.

[0052] The modified calcium sulfate whisker is a titanate coupling agent modified calcium sulfate whisker.

[0053] A preparation method for butadiene rubber dust cover, comprising the following steps:

[0054] (1) modifying the nano kaolin and carbon black with a titanate coupling agent to obtain a modified reinforcing agent;

[0055] (2) Butadiene rubber, cellulose acetate resin, nano-zin...

Embodiment 3

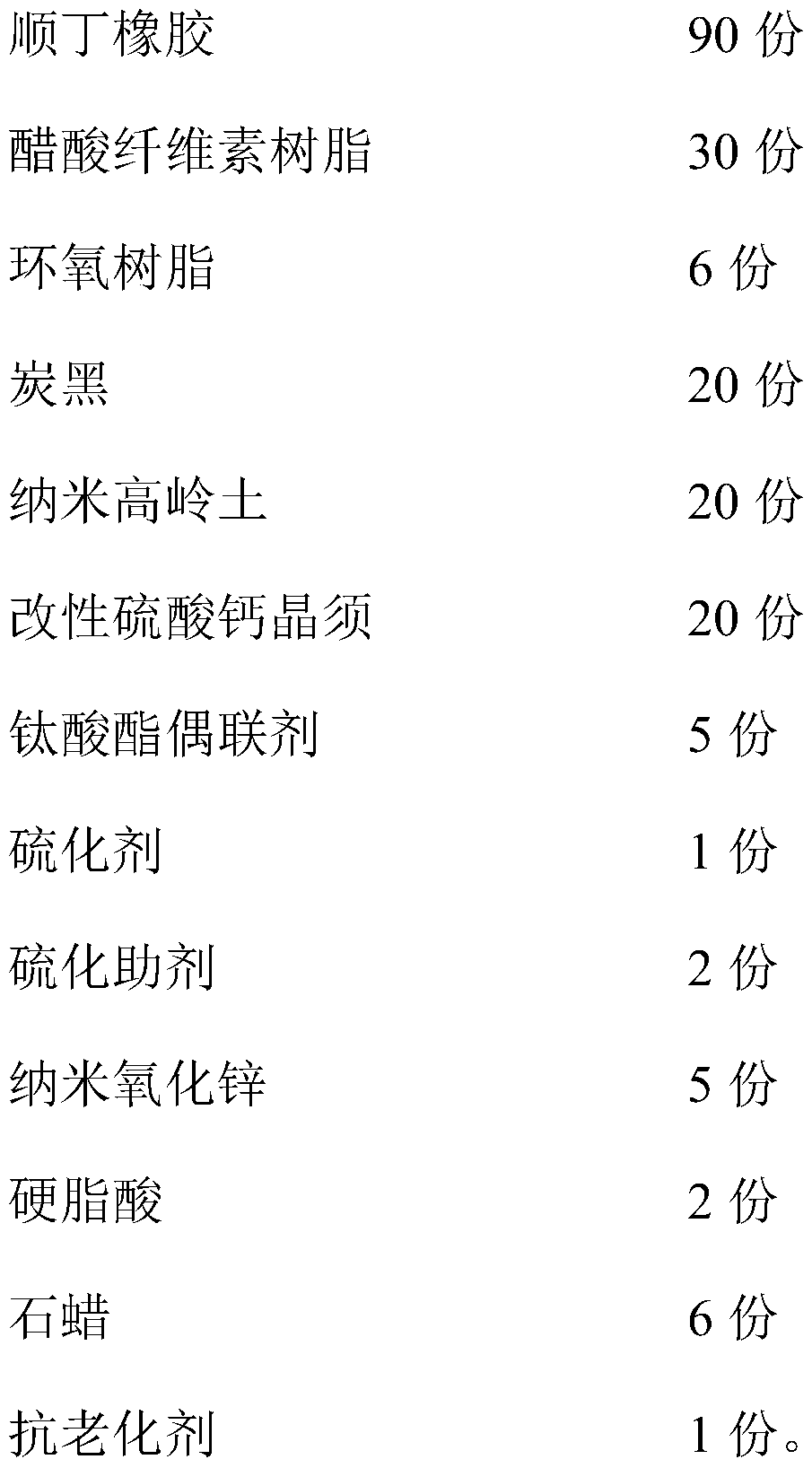

[0060] A butadiene rubber dust cover, comprising the following raw materials in parts by weight:

[0061]

[0062]

[0063] The weight ratio of carbon black, nano kaolin and modified calcium sulfate whiskers is 1:1:1.

[0064] Curing agents include combinations of t-butyl peroxybenzoate, sulfur and phenolic resins.

[0065] The weight ratio of tert-butyl peroxybenzoate, sulfur and phenolic resin in the vulcanizing agent is 0.6:0.8:0.6.

[0066] The vulcanization aid is a combination of 2 parts of 2,6-toluene diisocyanate, 2 parts of ferric chloride and 2 parts of 4,4'-bismaleimide.

[0067] The modified calcium sulfate whisker is an aluminum-titanium coupling agent modified calcium sulfate whisker.

[0068] A preparation method for butadiene rubber dust cover, comprising the following steps:

[0069] (1) modifying the nano kaolin and carbon black with a titanate coupling agent to obtain a modified reinforcing agent;

[0070] (2) Butadiene rubber, cellulose acetate re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com