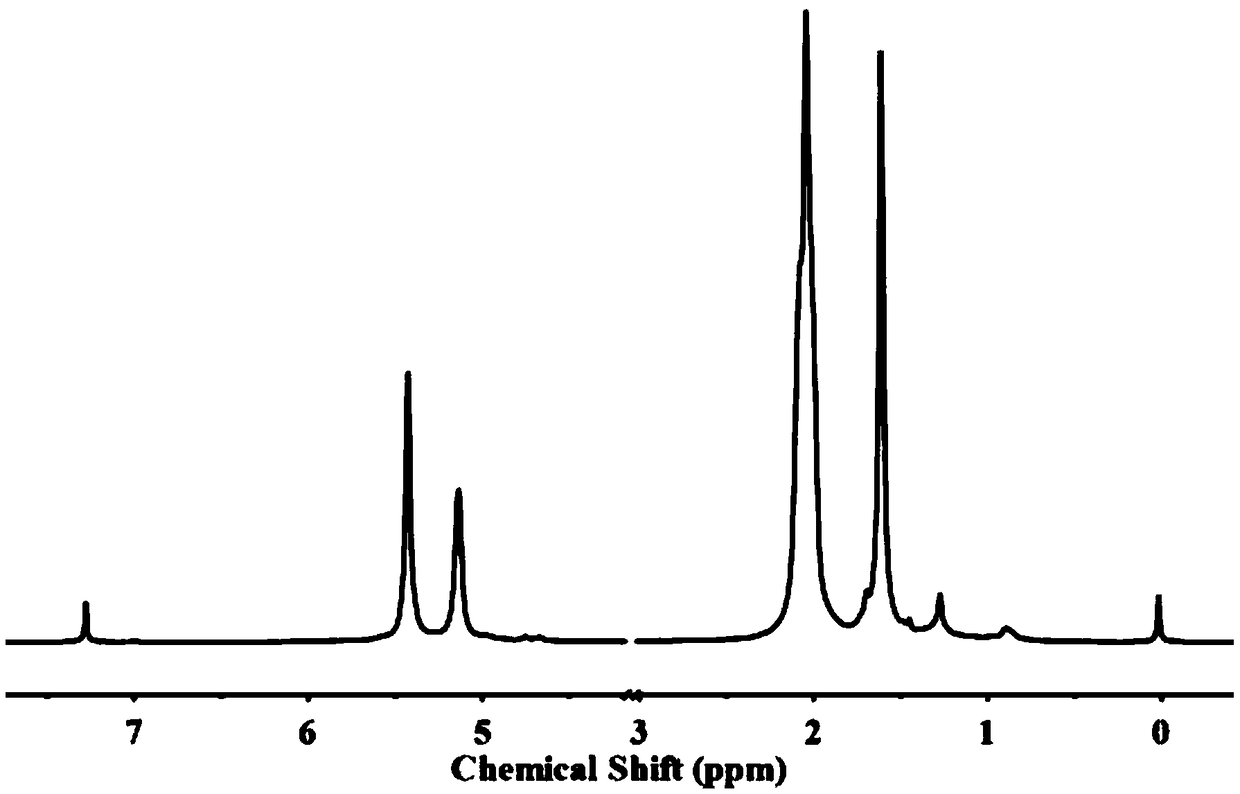

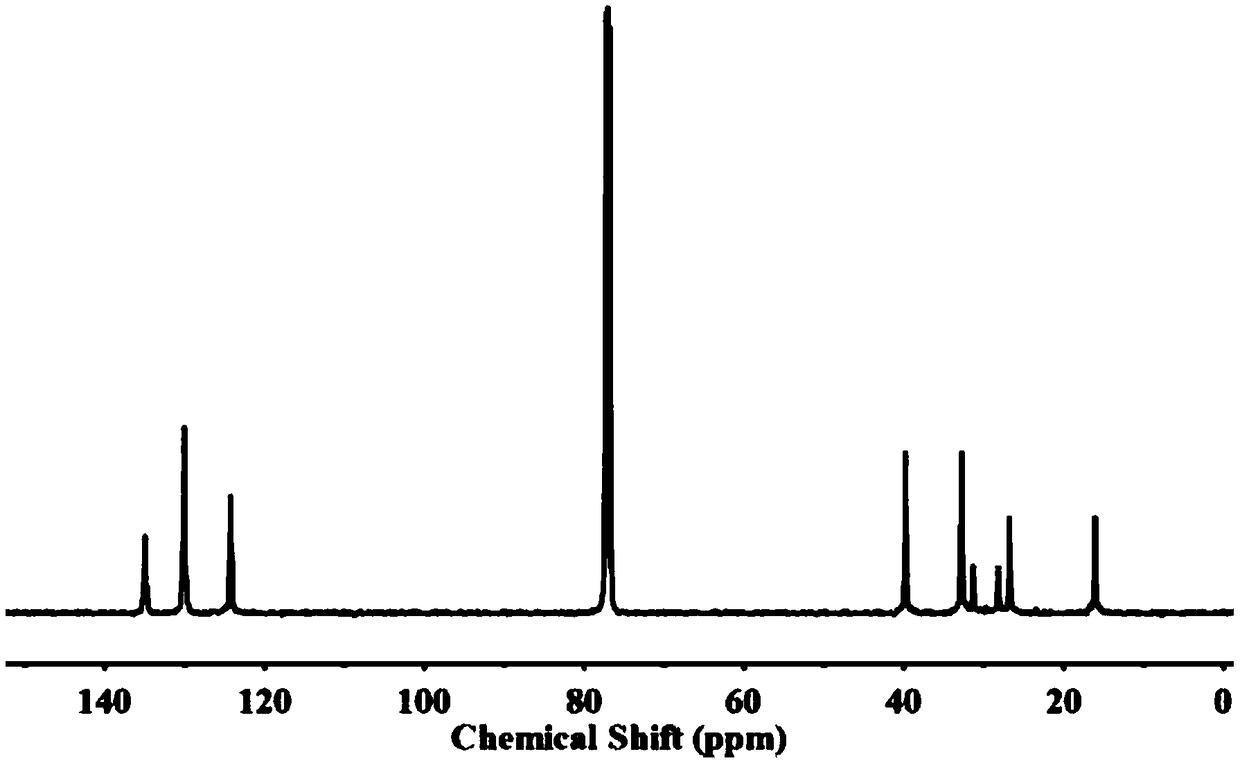

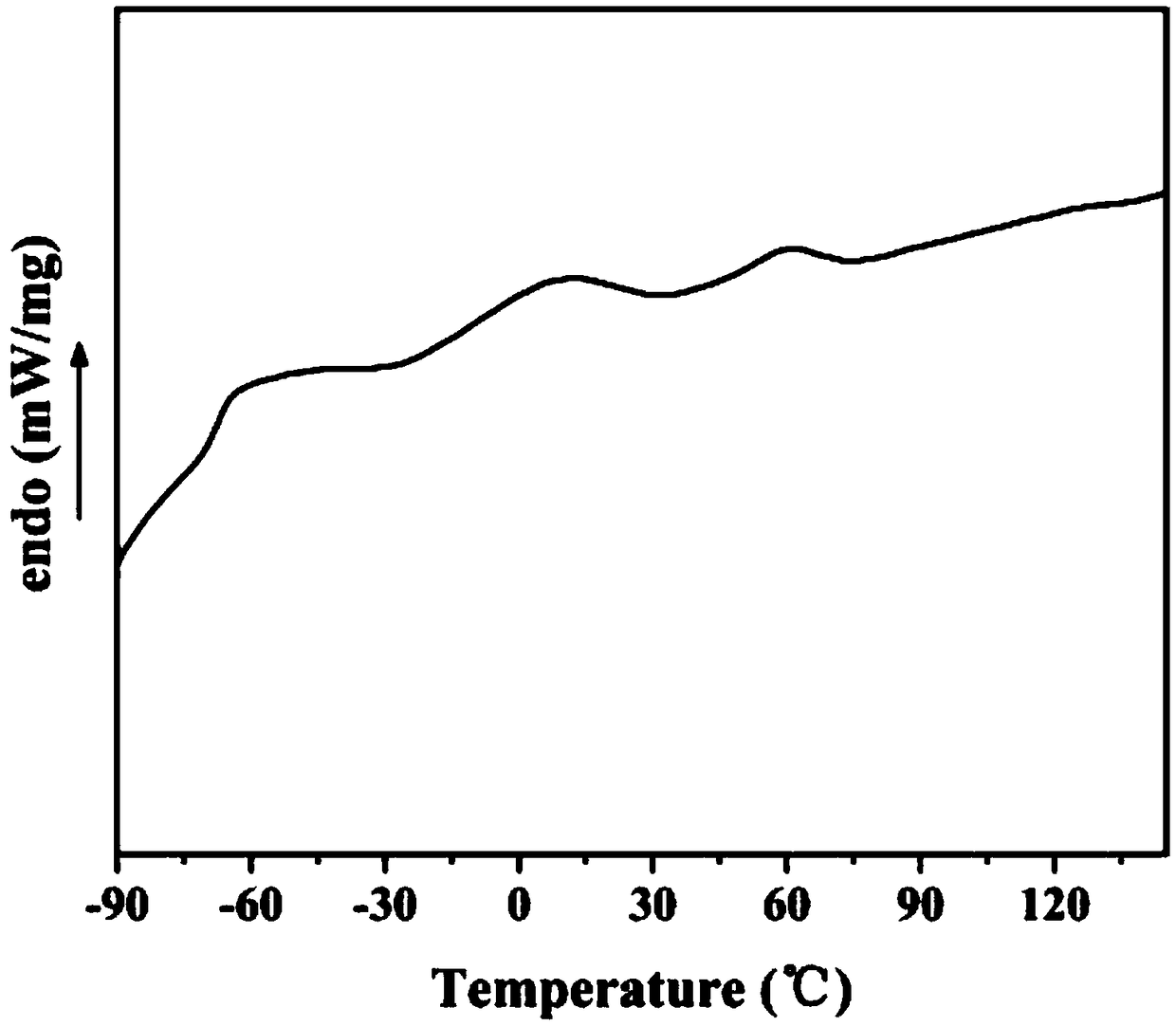

Preparation method of high trans-1,4-isoprene-butadiene copolymer

A technology of isoprene and copolymer, applied in the field of polymer synthesis, can solve the problems of discharge, difficult to dissipate heat, difficult materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Clean the 30mL polymerization tube, dry it, evacuate it and replace it with high-purity nitrogen several times to ensure that the polymerization tube is free of water and oxygen. After the polymerization tube is cooled to room temperature, isoprene, butadiene, n-hexane, organic aluminum and supported titanium catalyst are added in sequence, wherein the feed ratio of butadiene to isoprene is 5:95 (molar ratio), Al / Ti=50 (molar ratio), Ti / Ip=3×10 -4 (molar ratio), the monomer concentration is 4mol / L, pre-polymerized in an ice bath at 0°C for 30min, then transferred to a water bath at 60°C to continue polymerization for 6h, and finally terminated with an ethanol solution containing anti-aging agent 264 (1% by mass) Reaction, the product is taken out and washed repeatedly with ethanol solution, and the copolymerized product is obtained after vacuum drying.

Embodiment 2

[0034] Example 2 adopts the same experimental procedure as that of Example 1, except that the feed ratio of butadiene and isoprene is set at 10:90 (molar ratio).

Embodiment 3

[0036] Example 3 adopts the same experimental procedure as that of Example 1, except that the feed ratio of butadiene and isoprene is set at 15:85 (molar ratio).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com