Anti-fatigue thermoplastic elastomer and preparation method of plum coupling element

A thermoplastic elastomer, anti-fatigue technology, applied in the field of preparation of anti-deflection fatigue thermoplastic elastomer and plum blossom coupling elastomer, can solve the problem of complicated replacement of elastic components of couplings, personal safety of operators, manual pouring Process instability and other problems, to achieve the effect of ensuring long-term normal operation, reducing equipment maintenance costs, and overcoming internal heat self-heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

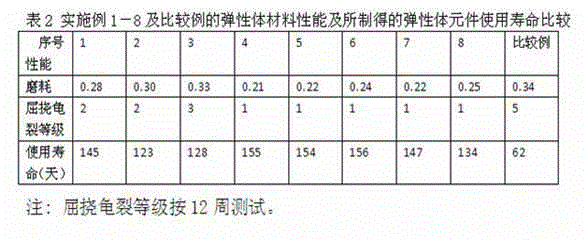

[0023] The present invention will be described in further detail below in conjunction with specific examples.

[0024] 1. Embodiment

[0025] The anti-fatigue thermoplastic elastomer of the present embodiment is compounded according to the proportions in Table 1 with 100 parts of TPEE, TPAE, PTFE, antioxidant and lubricant EBS.

[0026] The preparation method of the plum blossom coupling element of the present embodiment comprises the following steps:

[0027] (1) Preparation of wear-resistant and anti-fatigue elastomer element materials: Add the raw materials listed in Table 1 into a high-speed mixer and mix them (mixing speed is 450rpm), and continuously add them into a twin-screw extruder for blending and granulation to obtain Wear-resistant and anti-fatigue elastomer materials;

[0028] The extrusion process: extrusion temperature: 240°C, extruder vacuum: -0.06MPa, screw speed: 350rpm;

[0029] (2) Molding and processing of wear-resistant and anti-fatigue elastic elemen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com