Green and environmental-friendly waste rubber powder house wall material

A technology of green environmental protection and wall materials, which is applied in the field of green environmental protection waste rubber powder house wall materials, can solve environmental pollution and other problems, and achieve the effects of solving poor air permeability, reducing pollution, and good flex fatigue resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

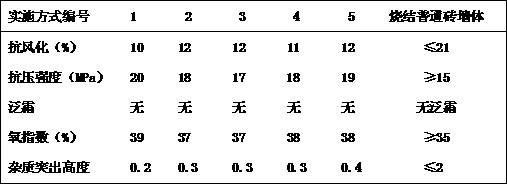

Examples

Embodiment 1

[0019] The technical solution adopted by the present invention is: a waste rubber powder house wall material, characterized in that it is made of 100 parts of waste rubber powder and 52 parts of compounding agent according to the mass ratio; wherein the compounding agent is made of fly ash, silicon Alginate earth, basalt fiber, di-tert-butyl peroxide, tetraethylthiuram disulfide, activated zinc oxide, magnesium hydroxide, nano-montmorillonite, styrenated phenol, 2,4-dinitrophenol by mass The ratio is 10:6:8:6:14:1:2:1:3:1. The preparation includes the following steps: firstly, the waste rubber powder is masticated for 10 minutes on an open mill with a roller temperature of 55°C and a roller distance of 1 mm to obtain a plasticized rubber; then, 52 parts of fly ash and the like are added to the plasticized rubber agent, adjust the roller temperature to 65°C and the roller pitch to 4 mm, knead for 20 minutes to make a mixed rubber, and finally cure it at a temperature of 160°C a...

Embodiment 2

[0020] The processing method of embodiment 2 to embodiment 5 is identical with embodiment 1, and raw material composition is as follows respectively:

Embodiment 2

[0022] The number of parts of the waste rubber powder is constant, and the number of parts of the rubber compounding agent is changed to 54 parts; wherein the compounding agent consists of fly ash, diatomaceous earth, basalt fiber, di-tert-butyl peroxide, tetraethylthiuram disulfide , active zinc oxide, magnesium hydroxide, nano-montmorillonite, styrenated phenol, and 2,4-dinitrophenol in a mass ratio of 10:6:8:7:15:1:2:1:3:1 composition.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com