Novel trans-1,4-polyisoprene synthesis method with high monomer conversion rate

A technology of polyisoprene and isoprene, applied in the field of polymer synthesis, can solve the problems of affecting product quality, large stirring power, long reaction time and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

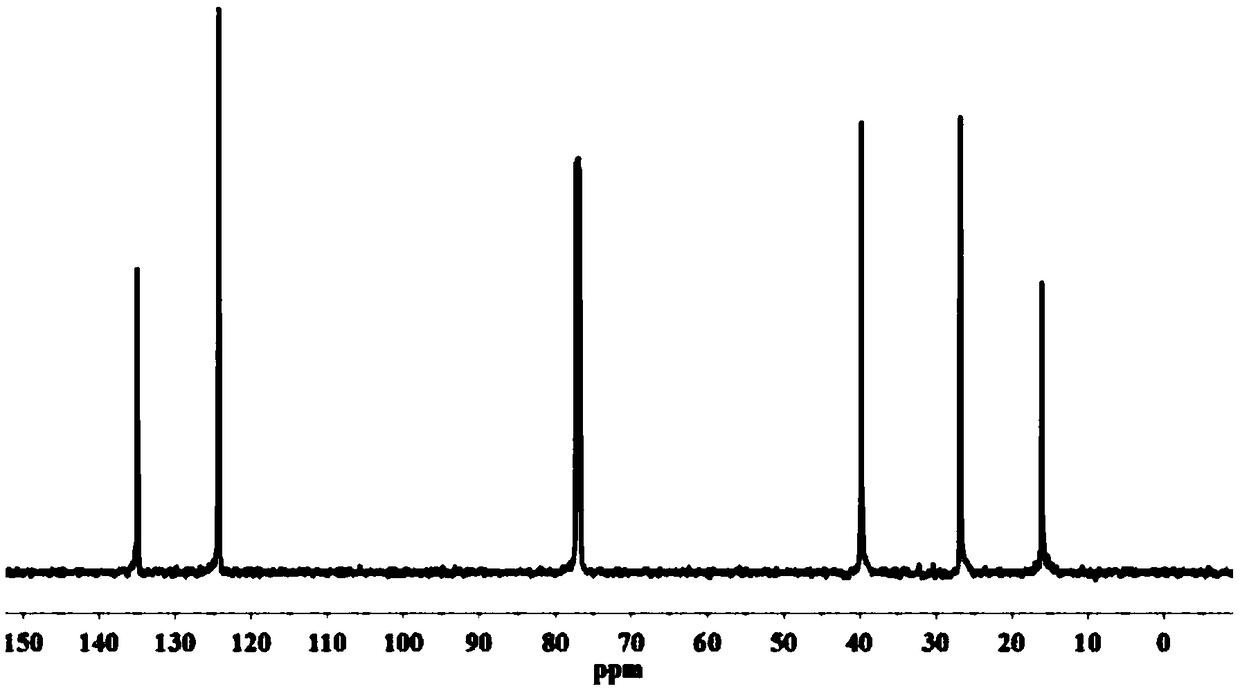

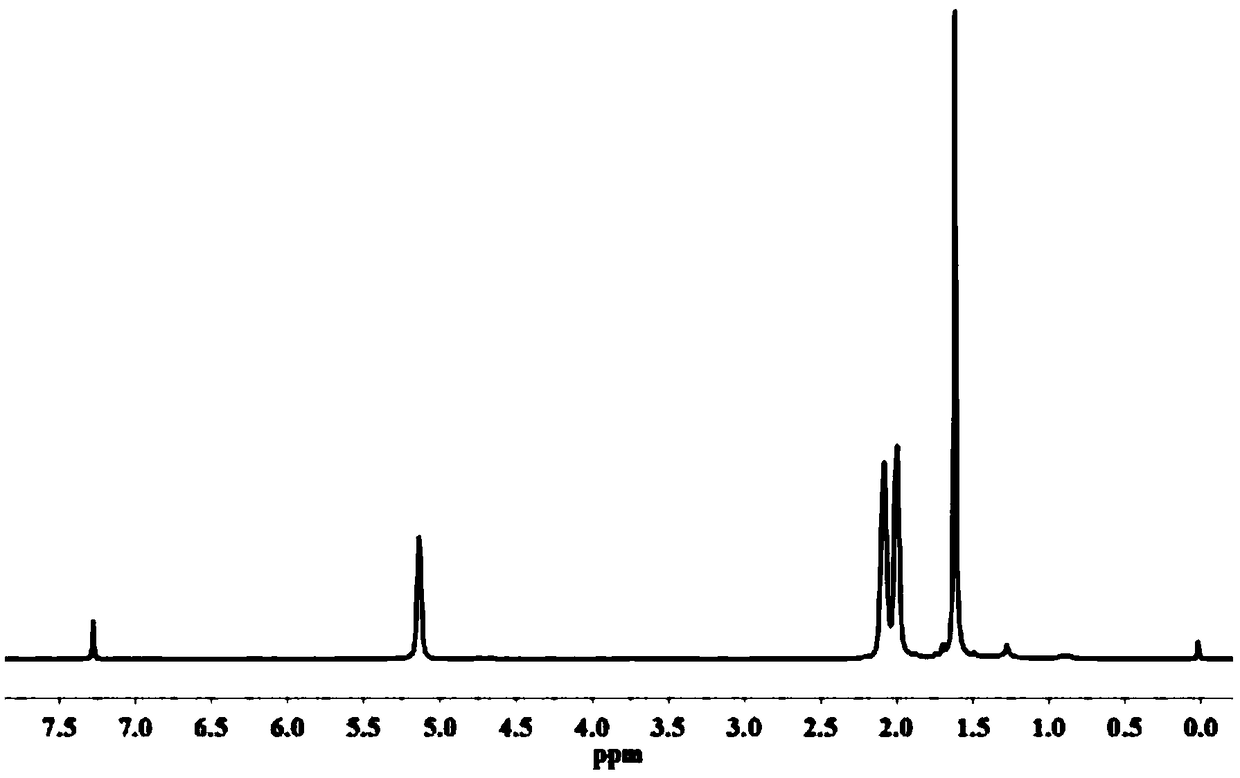

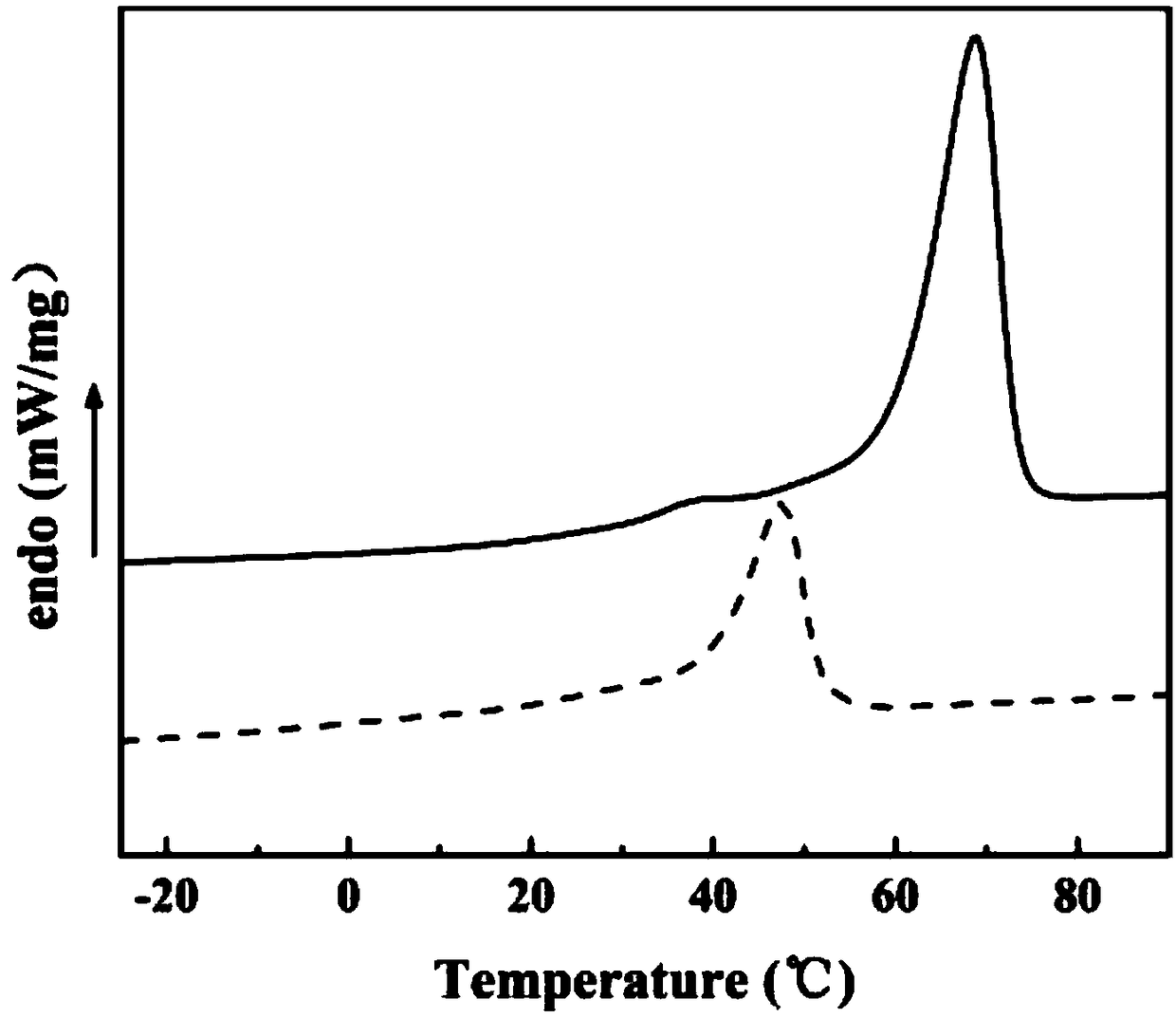

[0027]Bake a clean 30ml polymerization tube at 100°C for 2 hours and replace it with high-purity nitrogen several times. After cooling, add isoprene monomer, n-hexane, triisobutylaluminum and The supported titanium catalyst was pre-polymerized in an ice bath at 0°C with stirring for 30 minutes, then transferred to a water bath at 30°C to continue polymerization for 6 hours, and finally injected an ethanol solution containing anti-aging agent 264 into the polymerization tube to terminate the reaction. The mixture was taken out and washed repeatedly with the above-mentioned ethanol solution to obtain a non-adhesive powdery granular polymer, which was dried in a vacuum oven at 40°C to constant weight. According to the quality of product, calculate catalyst efficiency to be 2824.1g / gTi, monomer conversion rate is 59.7%; According to 1 According to the H-NMR spectrum, the calculated trans-1,4-configuration content of the product is 98.2%, the cis-1,4-configuration content is 1.3%, ...

Embodiment 2

[0029] Bake a clean 1000ml three-neck flask at 100°C for 2 hours and replace it with high-purity nitrogen several times. After cooling, in a dry nitrogen atmosphere, first add n-hexane, triisobutylaluminum and supported titanium catalyst in sequence, and then inject A small amount of isoprene, inject the remaining isoprene after a period of time, pre-polymerize for 30 minutes under ice bath and stirring conditions at 0°C, then transfer to a water bath at 30°C to continue polymerization for 6 hours, and finally inject into a three-necked flask containing Ethanol solution of anti-aging agent 264 to terminate the reaction. The mixture was taken out and washed repeatedly with the above-mentioned ethanol solution to obtain a non-adhesive powdery granular polymer, which was dried in a vacuum oven at 40°C to constant weight. According to the quality of product, calculate catalyst efficiency to be 3094.4g / gTi, monomer conversion rate is 65.3%; According to 1 According to the H-NMR sp...

Embodiment 3

[0031] The polymerization method is the same as that of Example 1, except that the polymer is polymerized in a water bath at 60° C., and after post-treatment, a block polymer is obtained. According to the quality of product, calculate catalyst efficiency to be 2851.1g / gTi, monomer conversion rate is 60.2%; According to 1 According to the H-NMR spectrum, the calculated trans-1,4-configuration content of the product is 98.3%, the cis-1,4-configuration content is 1.0%, and the 3,4-configuration content is 0.7%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com