Wear-resistant rubber for sports shoe soles and preparation method thereof

A wear-resistant rubber and shoe sole technology, applied in the field of materials, can solve the problems of easy aging and loss of elasticity of the sole material, difficult to control the thickness of the sheet, poor elasticity and weather resistance, etc., and achieves excellent oxygen resistance, excellent chemical corrosion resistance, The effect of super anti-slip and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

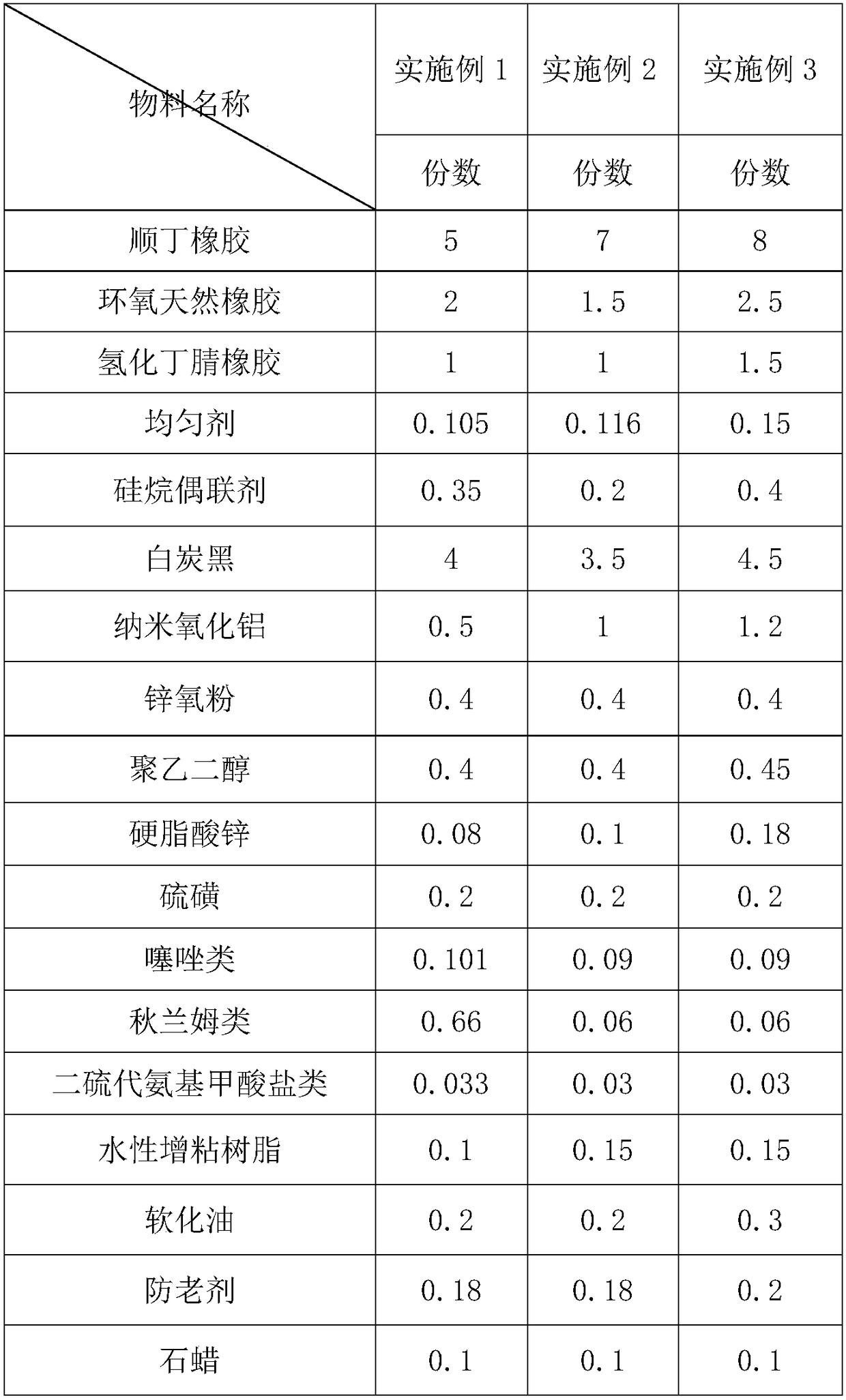

[0030] The present invention simultaneously provides a preparation method of wear-resistant rubber for sports shoe soles, comprising the following steps:

[0031] 1) Weigh the following ingredients in parts by mass: 50-80 parts of butadiene rubber, 10-30 parts of epoxy natural rubber, 5-20 parts of hydrogenated nitrile rubber, 1-2 parts of leveling agent, 2-5 parts of silane coupling agent 20-50 parts of white carbon black, 5-15 parts of nano-alumina, 2-5 parts of zinc oxide powder, 2-5 parts of polyethylene glycol, 0.5-2 parts of zinc stearate, 0.5-2 parts of water-based tackifying resin 2-5 parts of softening oil, 1-3 parts of anti-aging agent, 0.5-1 part of paraffin;

[0032] 2) Pour all the ingredients weighed in step 1) into the internal mixer for mixing, the mixing time is 7-9 minutes, and the temperature is 120-140°C;

[0033] 3) discharging, discharging, and cooling the mixture obtained in step 2);

[0034] 4) Weigh the following components by mass parts: 1.5-2 parts...

Embodiment 2

[0041] In Example 2, the mixing time in step 2) is 7 minutes, and the temperature is 120-140°C; the mixing time in step 5) is 5 minutes, and the temperature is 50-70°C;

Embodiment 3

[0042]In Example 3, the mixing time in step 2) is 8 minutes, and the temperature is 120-140°C; the mixing time in step 5) is 4 minutes, and the temperature is 50-70°C.

[0043] The wear-resistant rubber for sports shoe soles prepared in the above-mentioned Examples 1, 2 and 3 was tested for performance, and compared with the performance of existing products at the same time, the results are shown in Table 2 below.

[0044] Table 2: The performance of embodiment 1-3 and existing wear-resistant rubber for sports shoe soles

[0045] Test items

Example 1

Example 2

Example 3

67

68

67

Tensile strength (MPa)

17

18

17

Elongation at break (%)

737

745

742

Right angle tear (N / cm)

72

69

70

DIN (mm 3 )

33

31

35

Density (g / cm 3 )

1.13

1.14

1.13

Folding resistance (mm)

5.1

5.2

5.2

Hydrolysis resistance

conf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com