Novel imported port tractor gearbox wiring harness, and preparation method thereof

A technology for gearboxes and tractors, applied in the field of vehicle parts, can solve the problems of corrosion damage of wiring harnesses, affecting the normal operation of vehicles in the mission life of wiring harnesses, etc., to prevent corrosion damage, improve sealing and corrosion resistance, and prolong mission life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing, technical scheme of the present invention is described in further detail:

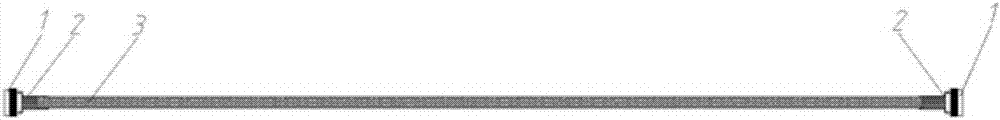

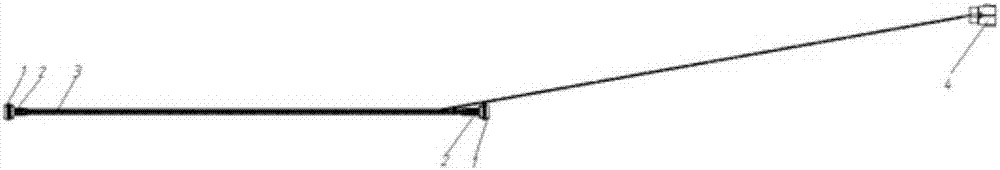

[0026] Such as figure 1 , figure 2 As shown, the new imported port tractor gearbox wire harness provided by the present invention specifically includes a first connector 1, a heat shrinkable tube 2, a wire harness braided wire 3, a second connector 4 and electric wires, specifically as figure 1 As shown, the first connector 1 is connected to both ends of the wire to form a complete circuit, and then the braided wire 3 is wrapped outside the wire. The braided wire used in this embodiment is the imported braided wire of EY-1877. Diameter 0.71mm, this type of braided wire is flexible, high temperature and corrosion resistant. Finally, a thermoplastic tube is provided at the connection between the two ends of the wire and the first connector 1, and the connection is packaged with the thermoplastic tube, so that the external protection of the wire is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com