Waterproof structure and manufacturing method thereof

A technology of waterproof structure and manufacturing method, applied in snow traps and other directions, can solve the problems of difficult construction, insufficient adhesion, difficulty, etc., and achieve the effect of overcoming difficult construction, strong tensile resistance, and reducing construction difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

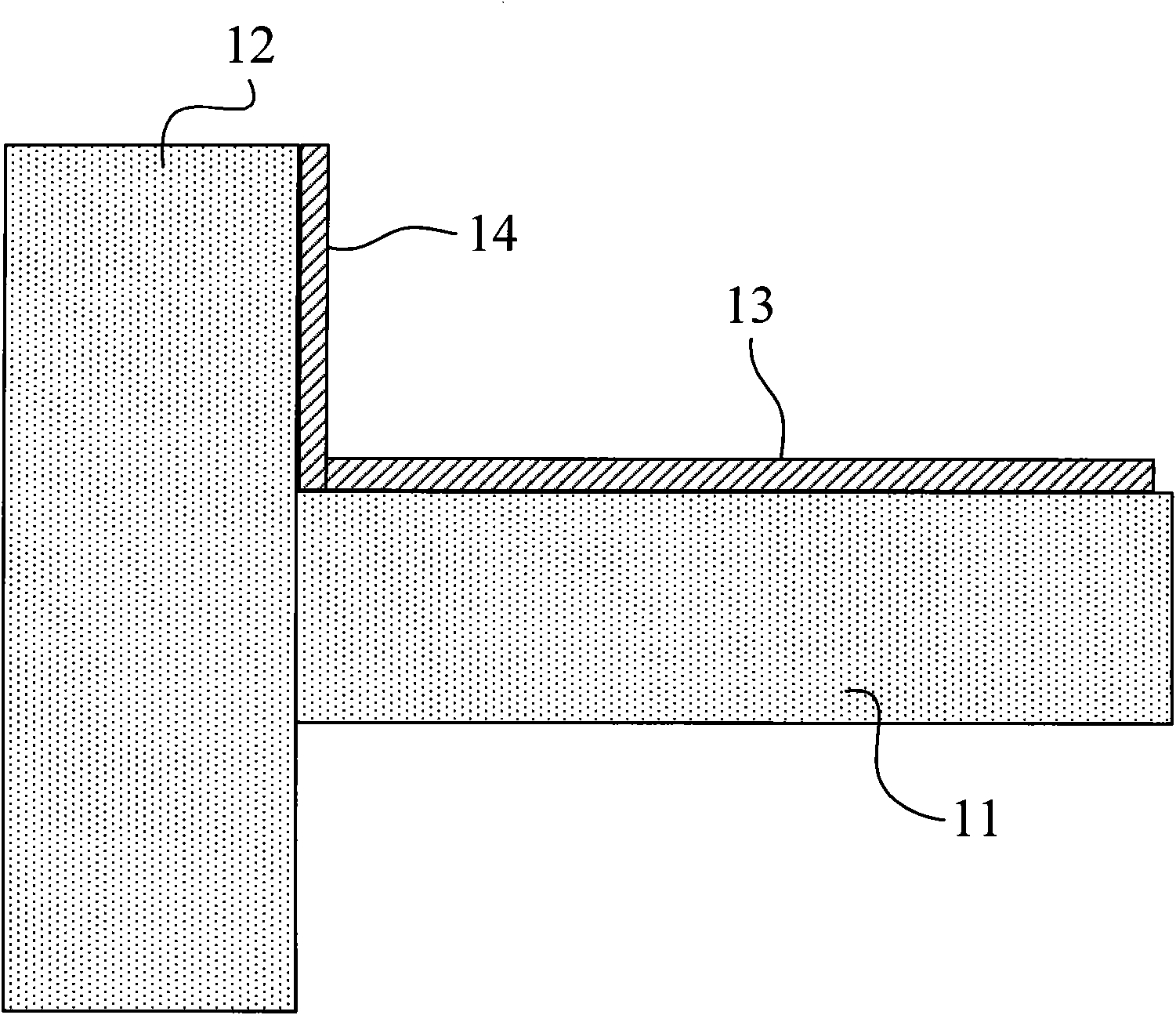

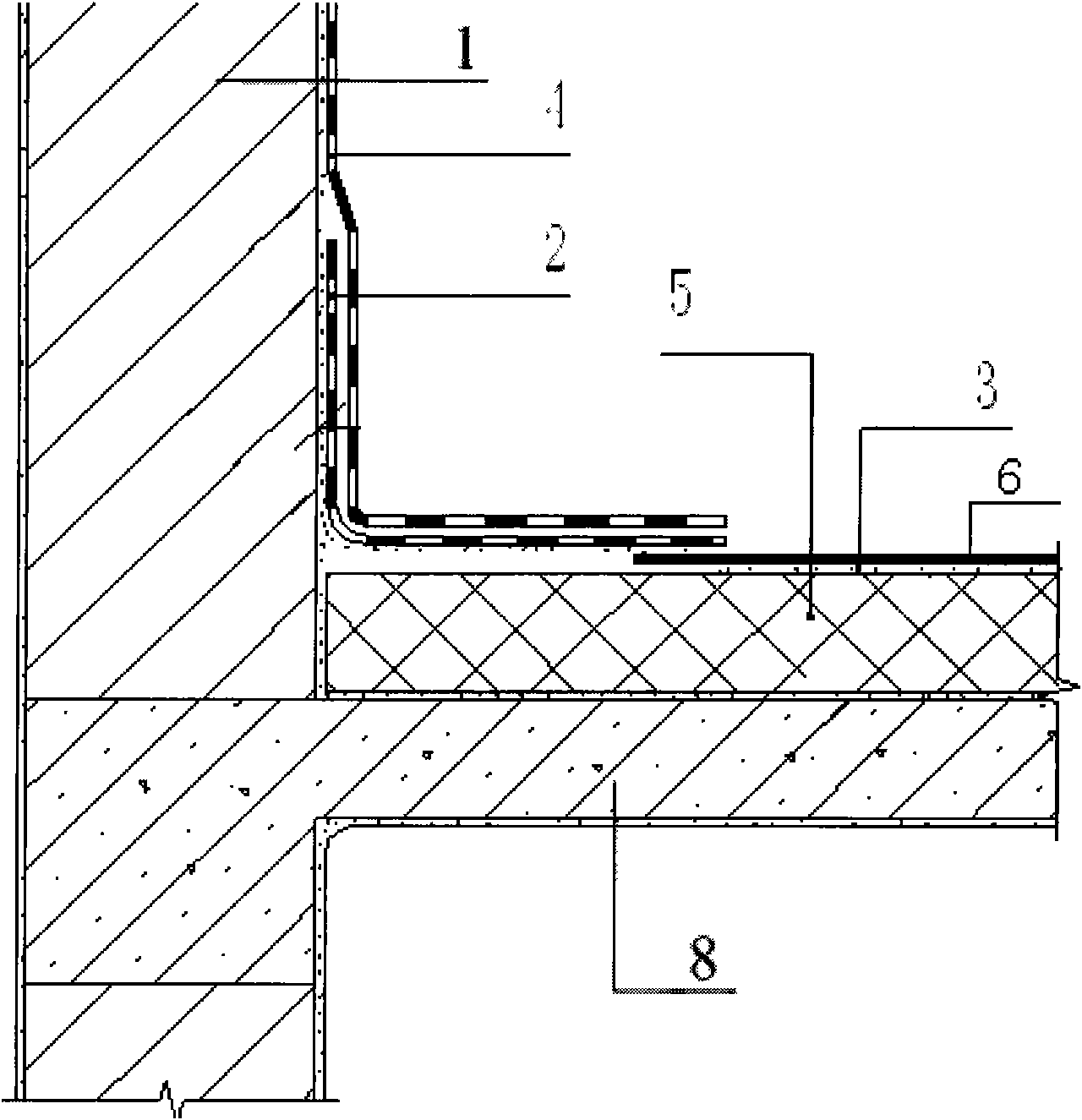

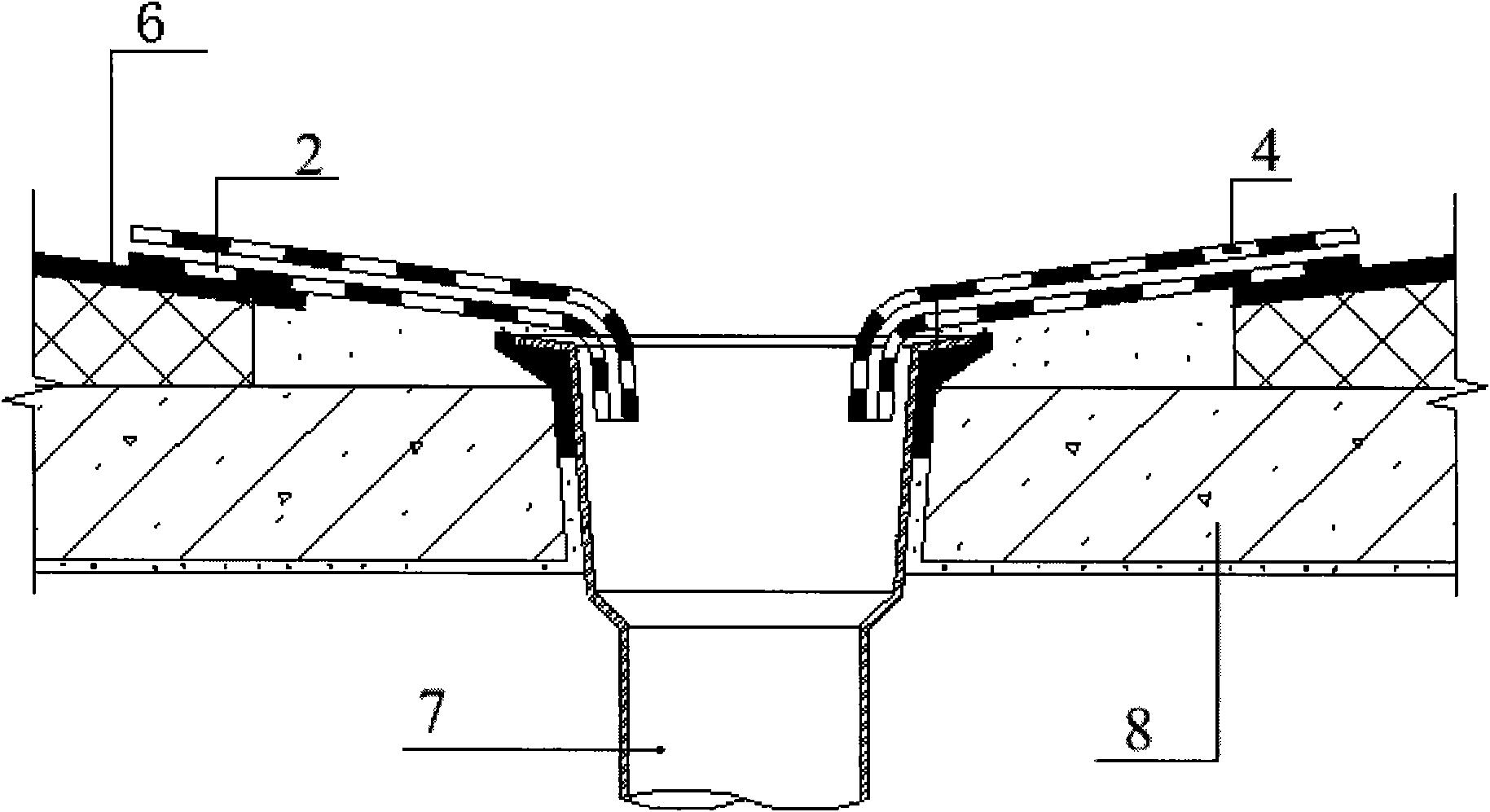

[0027] In order to further explain the technical means and effects that the present invention takes to achieve the intended purpose of the invention, the specific implementation, structure, characteristics and details of the method for waterproofing and waterproofing of roof detail nodes according to the present invention will be described below in conjunction with the accompanying drawings and preferred embodiments. Its effect is described in detail below.

[0028] The roof of the present invention is a concrete roof, a wooden roof, and a metal roof, and they may contain a thermal insulation layer; a parapet, a low wall on a vertical and horizontal plane around the roof. Vertical façades are façade walls that are perpendicular to the horizontal plane and protrude out of the flat roof. Pipes passing through the roof are various pipes that are perpendicular to the horizontal plane and pass through the roof, including chimneys, drain pipes, water pipes, exhaust pipes, and air pi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com