Multi-gear transmission and center wheel pawl installation structure used in same

A multi-speed transmission and center wheel technology, which is applied in vehicle gearboxes, multi-gear ratio transmissions, transportation and packaging, etc., can solve the problem that the size of the inner transmission shell cannot be further reduced, it is not conducive to the lightweight of bicycle transmissions, and the size of transmissions can be increased. Weight and other issues, to achieve the effect of reducing transmission space, reducing size, simple and reliable control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

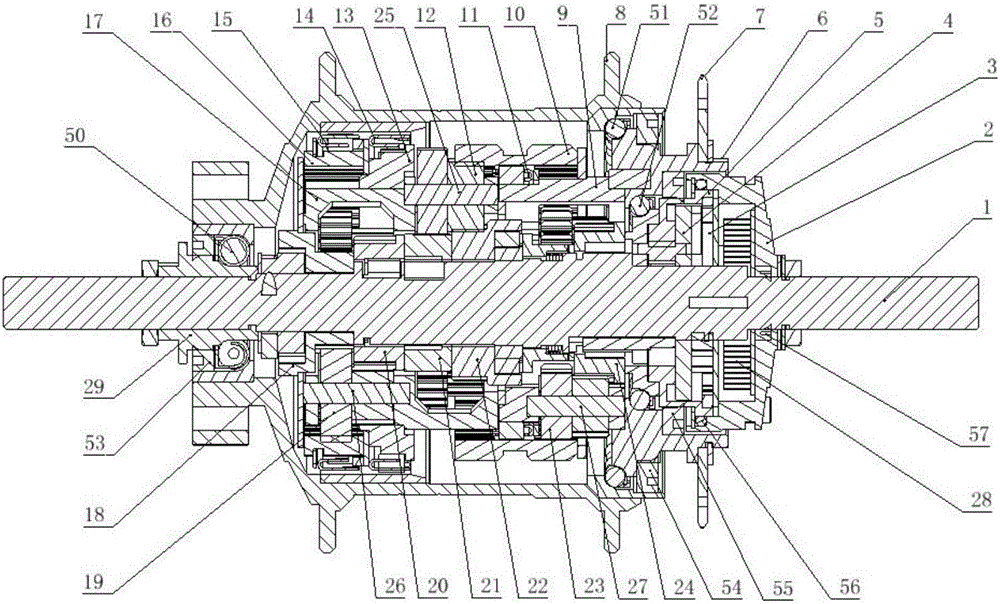

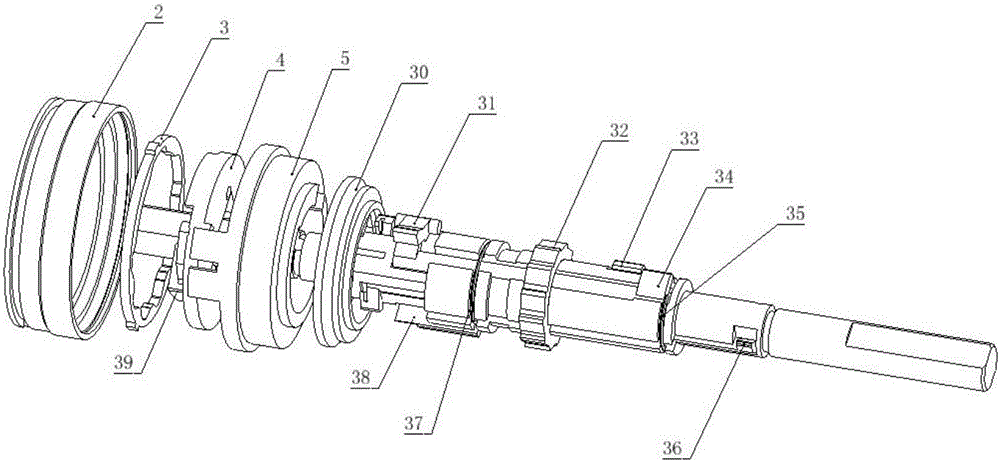

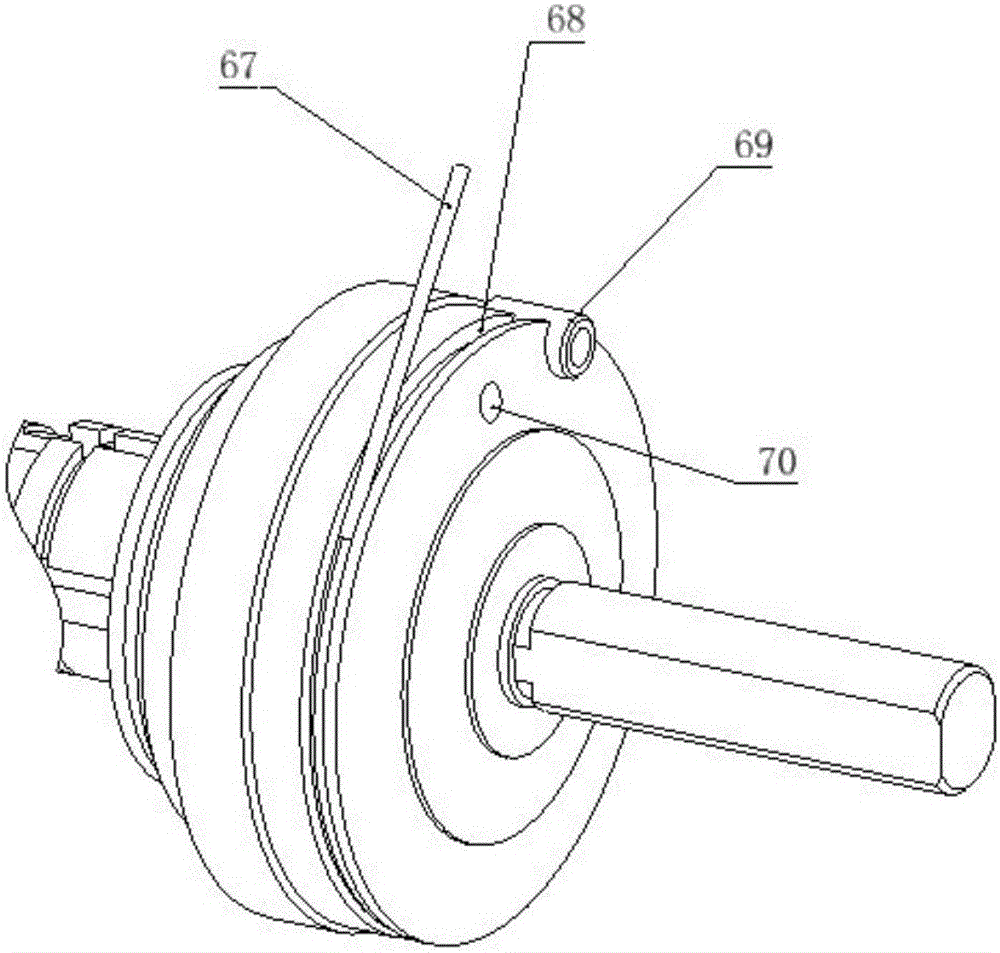

[0041] The present embodiment is described with the ten-speed internal transmission of bicycle, see Figure 1 to Figure 5 , The internal transmission of this embodiment includes a main shaft 1 , a power input assembly, a power transmission assembly, a gear control assembly and an output hub 8 .

[0042] The power input assembly includes a flywheel 7, a flywheel seat 6, and a flywheel retainer. The flywheel 7 is fastened on the flywheel seat 6, and the bicycle power drives the flywheel seat 6 to rotate through the flywheel 7. The power input assembly inputs bicycle power through the flywheel 7 and transmits it to the power transmission assembly through the flywheel seat 6;

[0043] The power transmission assembly of the internal ten-speed transmission consists of three sets of double-row planetary gear trains, including two planetary carriers, three sets of double planetary gears, five sun gears, three one-way clutches, two ring gears, and planetary gear trains The input end is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com