Gear shift control device of hybrid power vehicle

一种混合动力车辆、控制装置的技术,应用在混合动力车辆、动力装置、控制装置等方向,能够解决旋转同步费时间、换档所需要的时间加长等问题,达到迅速换档、缩短同步时间的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

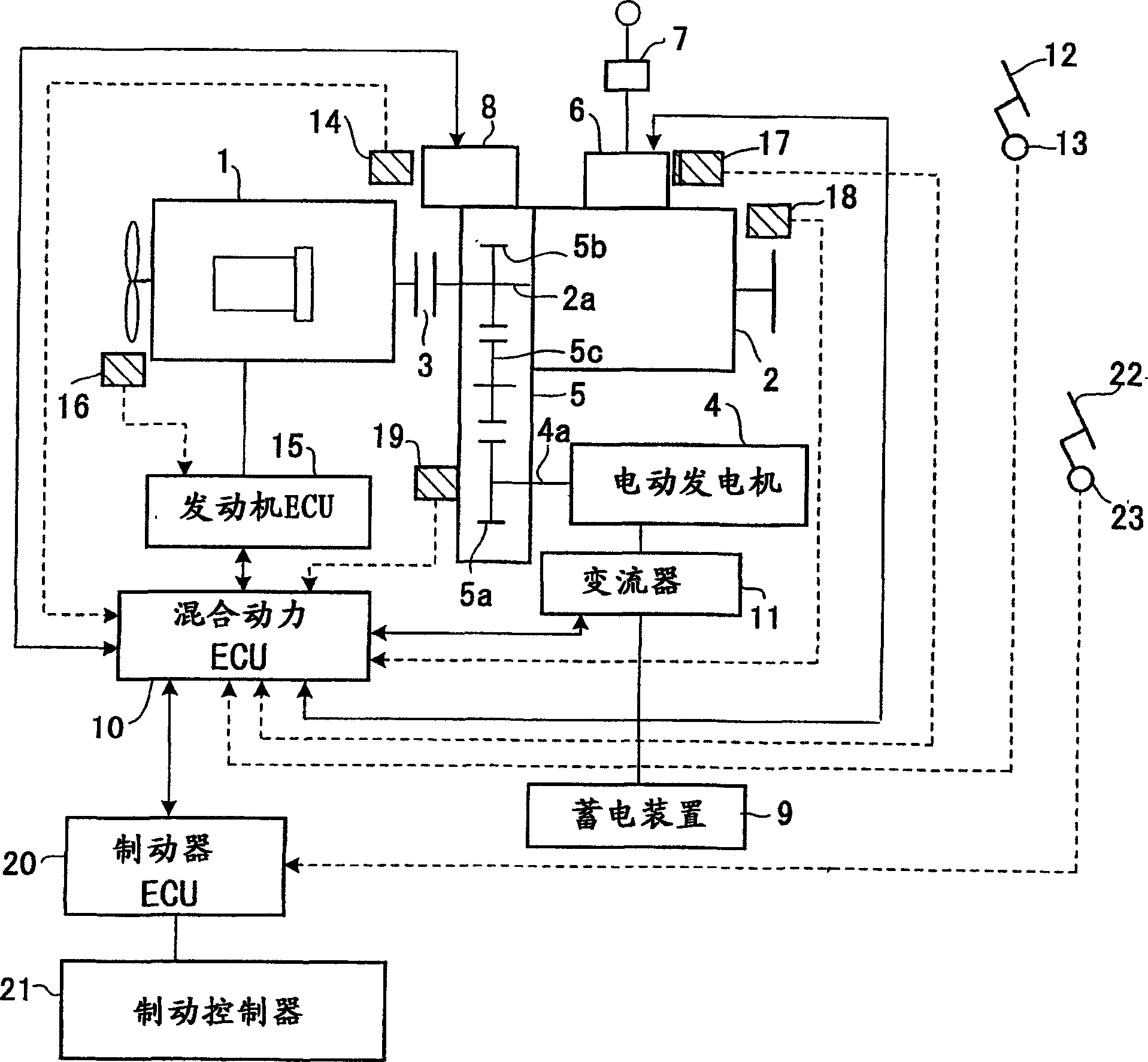

[0012] exist figure 1 Among them, 1 is an engine, 2 is a gear type transmission, and a friction clutch 3 is installed between the output shaft of the engine 1 and the input shaft 2a of the transmission 2 .

[0013] As for the engine 1, a diesel engine or a CNG engine (an engine fueled by compressed natural gas) can be used. 4 is a rotating electric machine (motor generator), which functions as a generator and a motor. The input / output shaft 4a of the rotary electric machine 4 is connected to the input shaft 2a side of the transmission 2 via a rotation transmission mechanism 5 serving as a gearbox.

[0014] The transmission 2 is provided with a control unit 6 for controlling the shifting. Connect the control unit 6 to the shift lever device 7 and the hybrid electronic control unit 10 (hybrid ECU). Command the corresponding gear shift.

[0015] A propeller shaft is connected to the output shaft 2b of the transmission 2 to transmit driving force to the wheels.

[0016] The c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com