Hydro-mechanical continuously variable transmission

A transmission, variable technology, applied in transmissions, gear transmissions, fluid transmissions, etc., can solve problems such as low efficiency and insufficient to ensure the effective use of the available power of the engine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

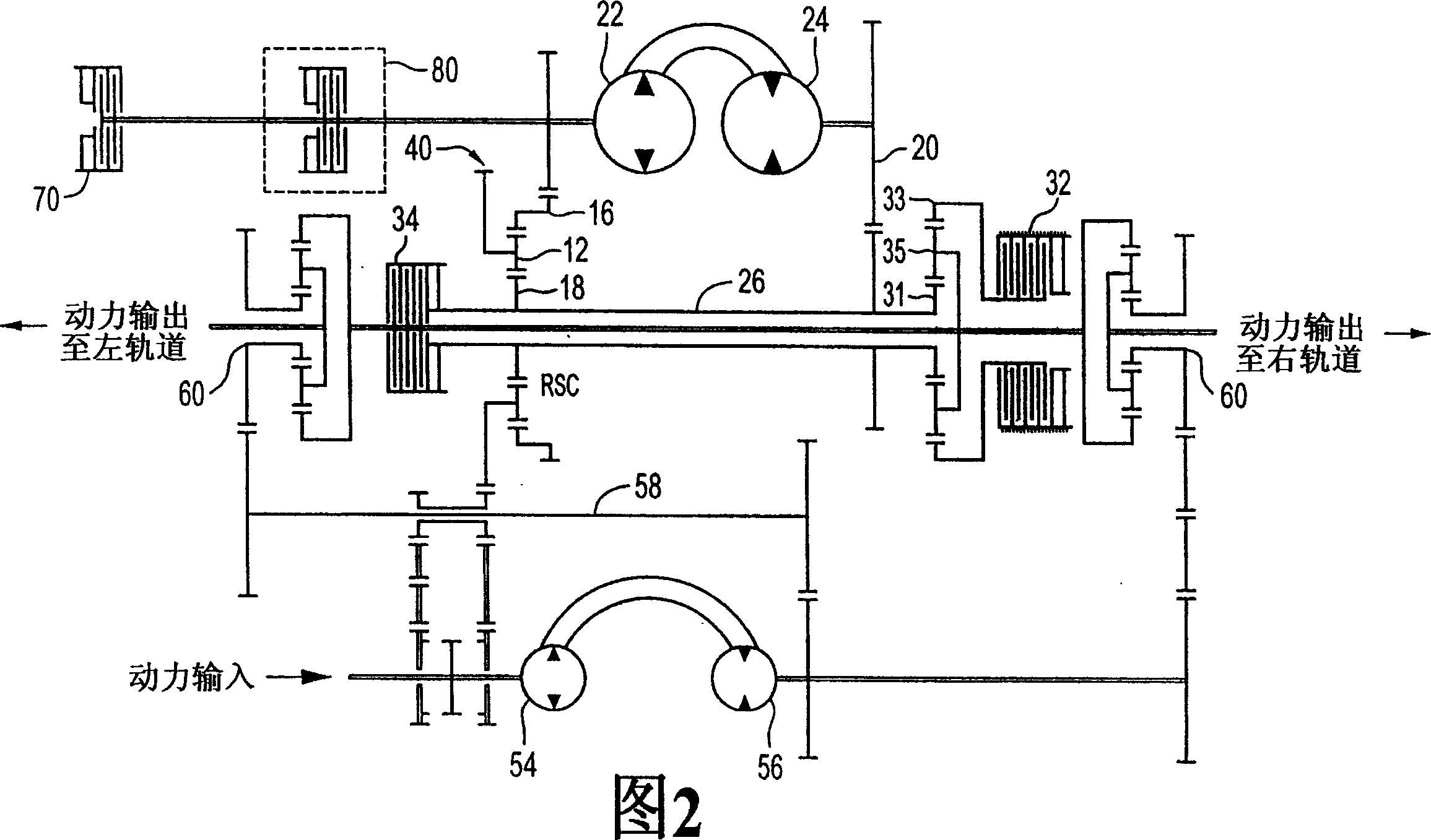

[0029] A hydromechanical continuously variable transmission (HMCVT) is used to split the input power between hydraulic drive branches and parallel mechanical drive branches and recombine the power from each branch into a single output, where the hydraulic drive branch uses hydraulic pumps and Motors, mechanical drive branches using shafts and / or gears.

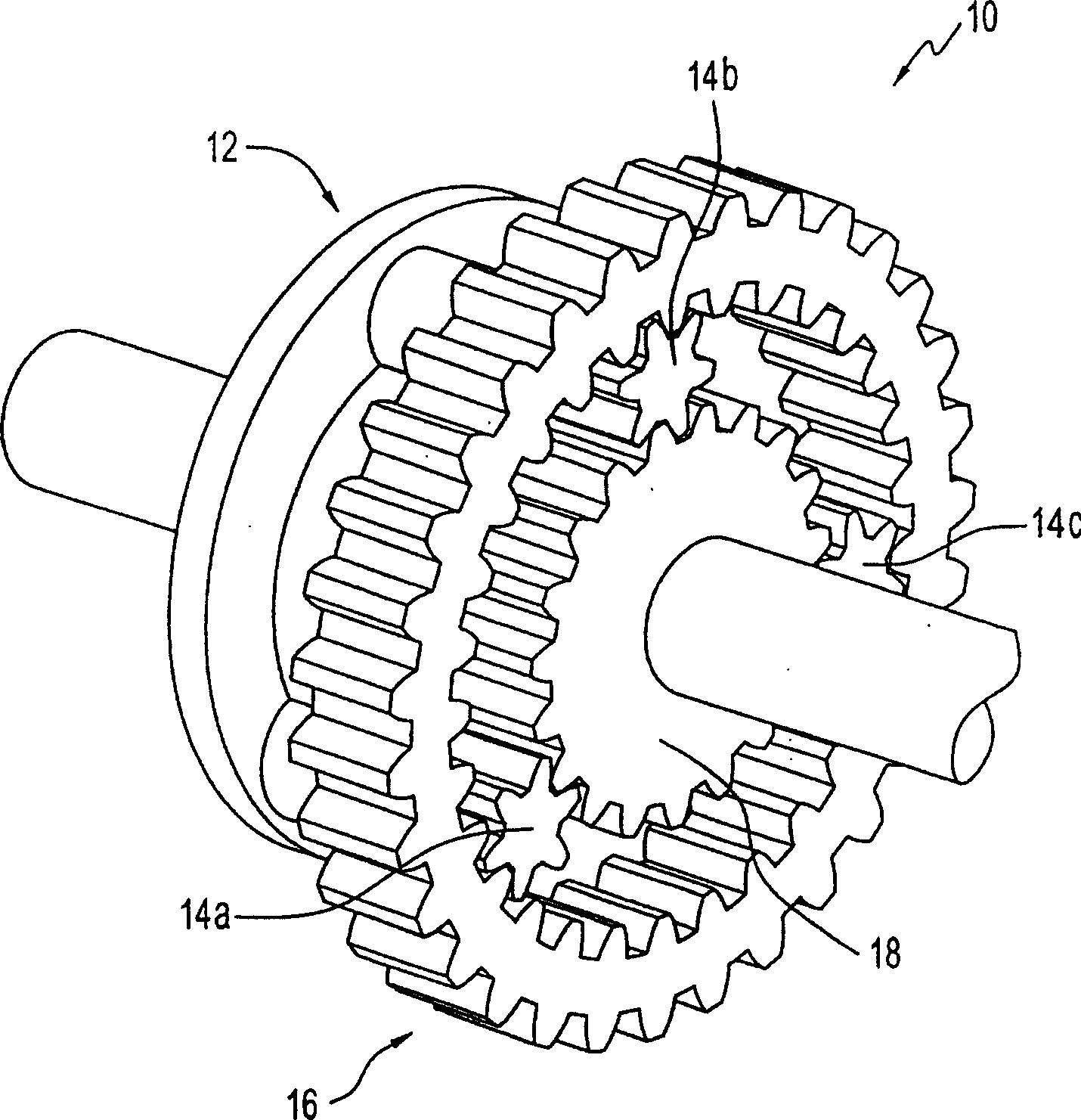

[0030] HMCVT with figure 1 The illustrated planetary gear set 10 is the basis. The planetary gear set 10 includes four parts: a carrier gear 12 ; planetary gears 14 ; a ring gear 16 and a sun gear 18 . The ring gear 16 and the sun gear 18 are connected by planetary gears 14 . The planet gears 14 are also connected to the carrier gear 12 . exist figure 1 In , three planetary gears 14a-c are used, more can be used if desired.

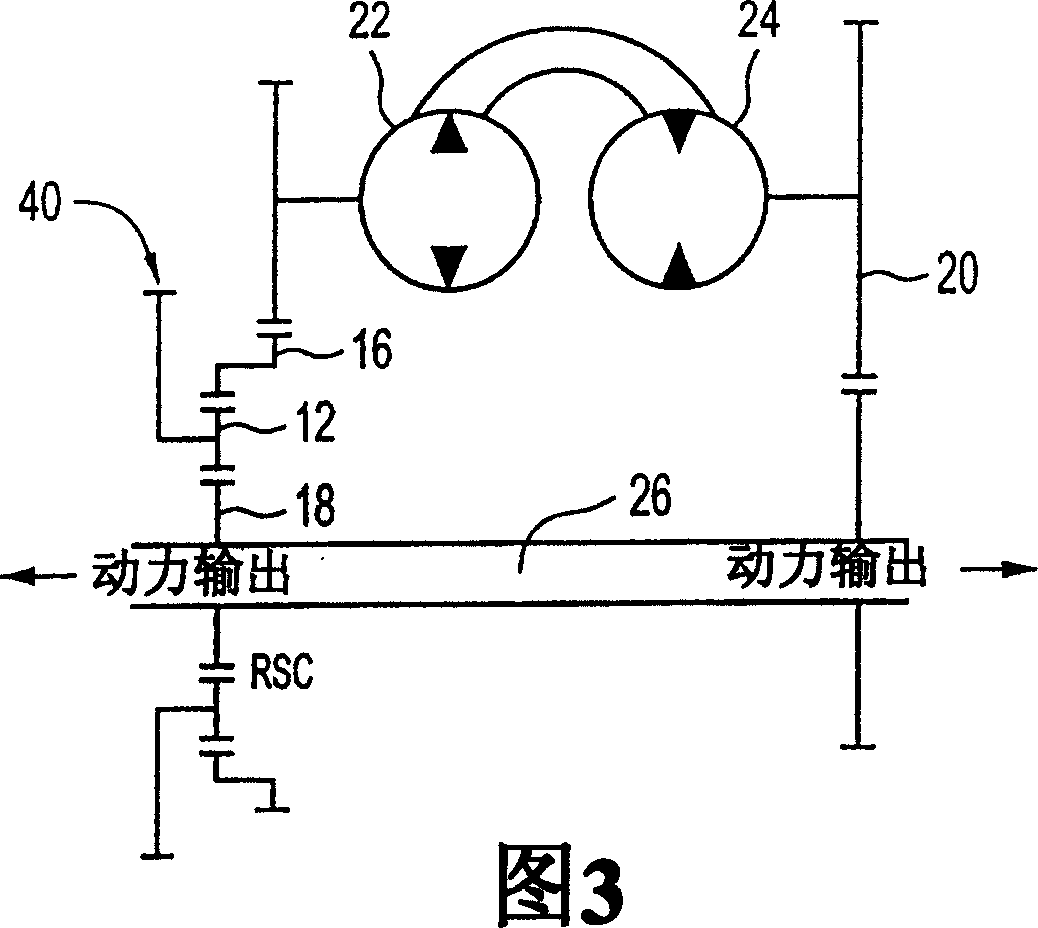

[0031] Planetary gear set 10 is connected to hydraulically driven pump 22 (see FIG. 2 ), main shaft 26 and transmission input 40 . For descriptive purposes, a three-letter code (R=ring gear; S=sun g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com