Gear-shifting control method for driving intention change during kick-down process

A technology of kickdown and driving intention, applied in the direction of transmission control, components with teeth, belt/chain/gear, etc., can solve the problems of reducing the mass of the transmission, achieve smooth shifting, and improve fuel economy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

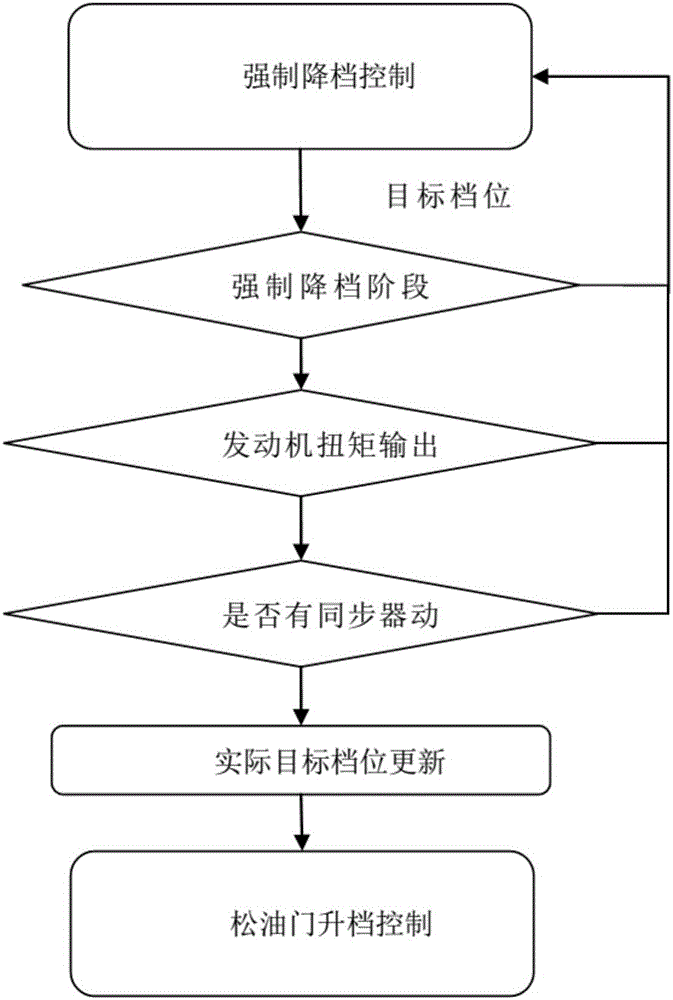

[0032] The method maintains real-time monitoring of the accelerator pedal when the transmission starts the process of kicking down, and when the accelerator pedal is released, judges the driving intention according to the driving state, and adjusts the state of the transmission from kickdown control to Gear recovery or upshift control.

[0033] The kick-down control includes: kick-down odd-numbered gears (1, 3 gears) control and kick-down even-numbered gears (2, 4 gears), wherein:

[0034] Forcibly down odd-numbered gear control, including the following steps:

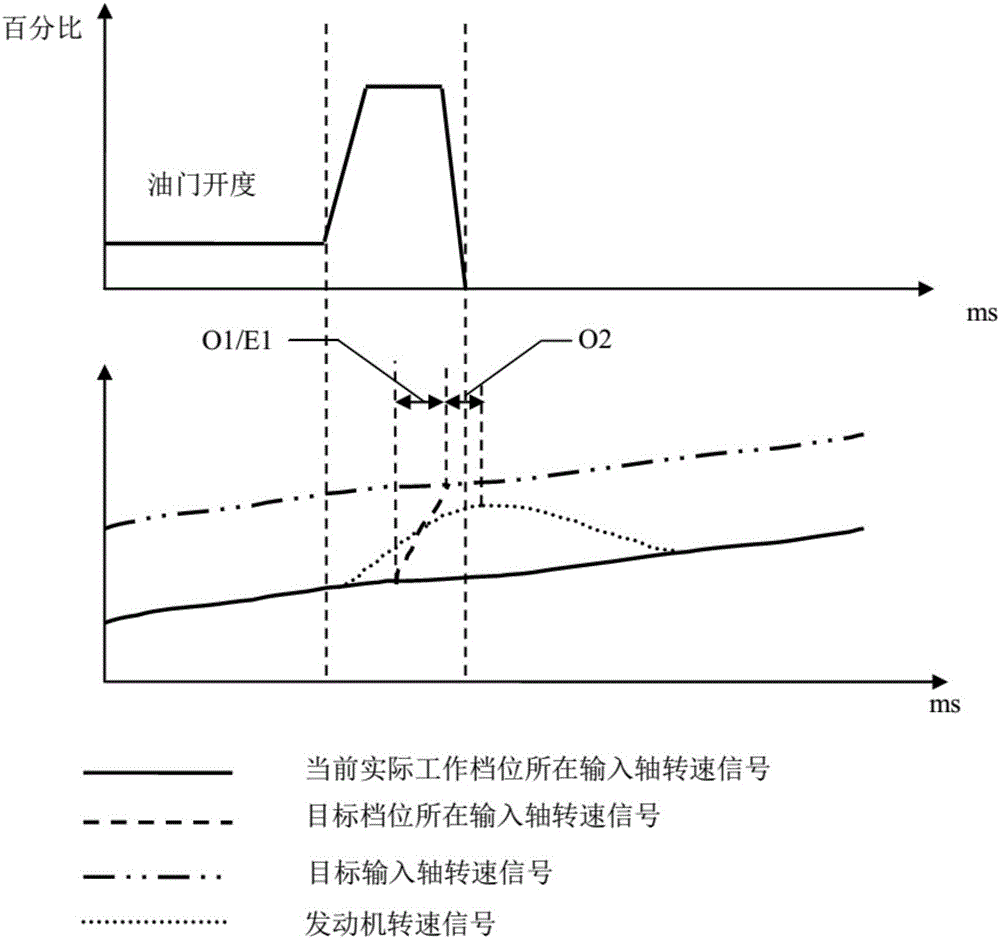

[0035] 1) The target gear synchronizer action stage (O1 stage), while the engine speed is adjusted to the target gear input shaft speed;

[0036] 2) Target gear clutch pre-charge phase (O2 phase), at the same time the engine speed is adjusted to the target gear input shaft speed.

[0037] 3) The clutch where the current actual working gear is located and the clutch where the target gear is located are in the torque i...

Embodiment 2

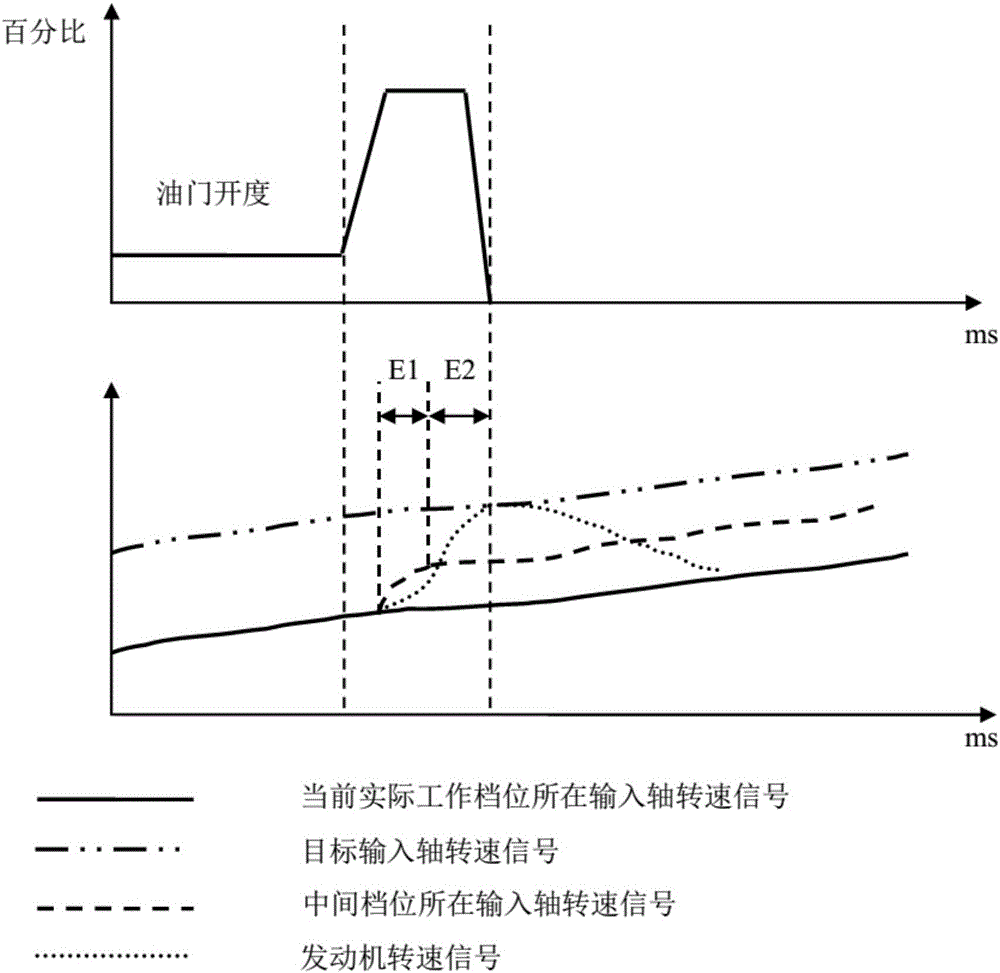

[0059] This embodiment provides a method for updating the target gear to the original working gear before the kickdown due to the change of the driver's intention when interacting with the intermediate gear torque during the even-numbered gear down (2nd, 4th gear). control methods such as image 3 As shown, the specific implementation steps of this embodiment are as follows:

[0060] 1) Real-time monitoring of the status of the synchronizer and clutch, including: whether the target synchronizer is in place, whether the target clutch is pre-charged, engine speed, etc.;

[0061] 2) Even-numbered downshifts need to be transitioned with the aid of the intermediate odd-numbered gears. When the synchronizer of the intermediate gear is engaged and the clutch pre-charge of the intermediate gear is completed, torque interaction is performed between the original gear and the intermediate gear. When the change of the driver’s intention is detected (release the accelerator pedal), the ta...

Embodiment 3

[0066] This embodiment provides an even-numbered gear down (2nd, 4th gear) process, after the target gear synchronizer is engaged, due to the change of the driver's intention, the target gear is updated to the original work before the kick down Gear control methods, such as Figure 4 As shown, the specific implementation steps of this embodiment are as follows:

[0067] 1) Real-time monitoring of the status of the synchronizer and clutch, including: whether the target synchronizer is in place, whether the target clutch is pre-charged, engine speed, etc.;

[0068] 2) In the even-numbered gear down condition, when the middle gear takes over the power transmission, the synchronizer of the target gear is put in place, and then the clutch corresponding to the target gear is precharged, and the change of the driver’s intention is detected (release the accelerator pedal Pedal), at this time, re-judgment and update the target gear, if the predicted target gear is greater than or equa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com