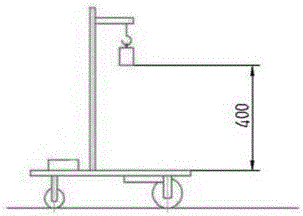

Gear shifting and sliding mechanism for carbon-free cart for traveling up and down hill

A carbon-free car and car technology, applied in toy cars, toy transmission, toys, etc., can solve the problems of increased energy loss, unstable center of gravity of the car, parking on ramps, etc., to avoid the loss of gravitational potential energy, Saving gravitational potential energy and uniform power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

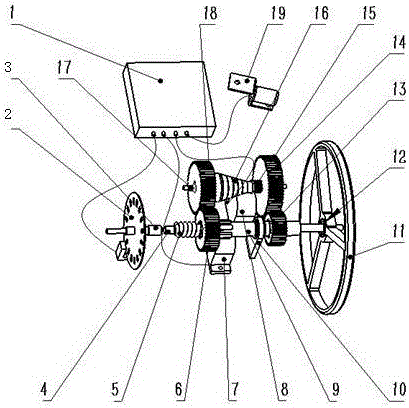

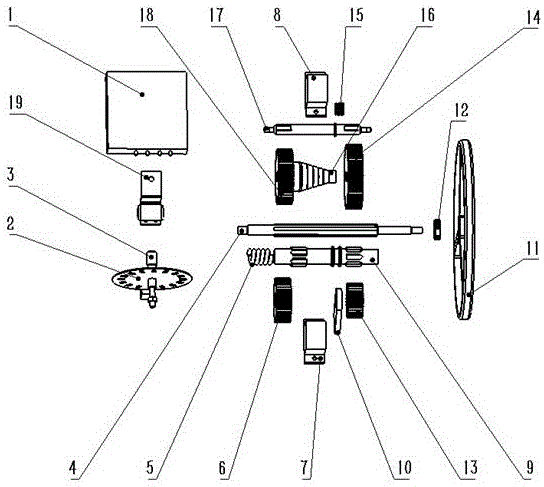

[0033] In order to facilitate the understanding of the present invention, the present invention will be described in more detail below in conjunction with the accompanying drawings and preferred embodiments, but the protection scope of the present invention is not limited to the following specific embodiments.

[0034] Such as figure 2 , image 3 and Figure 4As shown, the shifting and sliding mechanism of a carbonless trolley up and downhill according to the present invention includes a power transmission assembly and an electric control assembly; the power transmission assembly includes a winding shaft 17, a rear driving wheel half shaft 4 and a rear driven wheel half shaft 3 , the rear driving wheel half shaft 4 and the rear driven wheel half shaft 3 are connected in a straight line, a large driving gear 14 is installed at one end of the winding shaft 17, a small driving gear 18 is installed at the other end, and a slotted conical Axle sleeve 16, bobbin 17 is provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com