Quick gear-shift control method and control system for electric vehicle gearbox

A technology for electric vehicles and control methods, which is applied in the direction of transmission control, components with teeth, belts/chains/gears, etc., and can solve the problems of long speed difference and slow shifting speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The following description is an example only and is not intended to limit the invention, its application or uses. It should be understood that corresponding reference numerals will be used in the drawings to denote similar elements, and the present invention will be further described below with reference to the drawings.

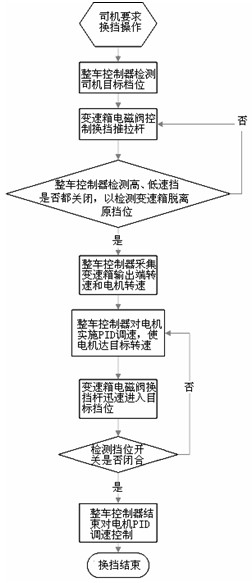

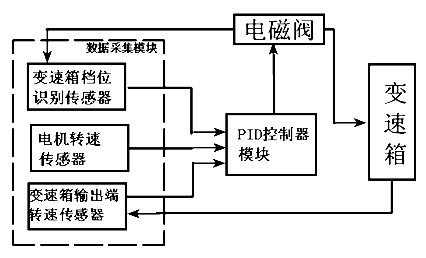

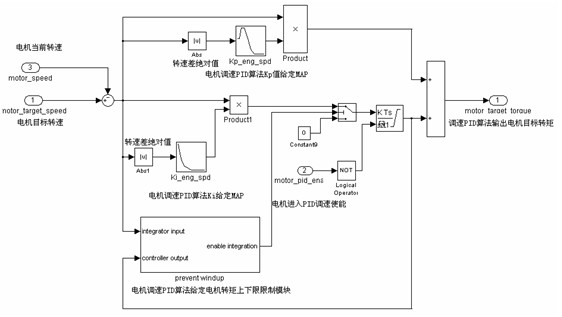

[0014] A quick shift control method for an electric vehicle gearbox, including a PID controller module and a data acquisition module. The data and signals are used to quickly adjust the motor speed through the PID controller, so that the master and slave gears of the gearbox can be quickly synchronized to complete the gear shifting operation.

[0015] As a further specific implementation of this embodiment, the data acquisition module includes a gearbox output speed sensor, a motor speed sensor, and a gearbox gear recognition sensor, such as image 3 The speed sensor at the output end of the gearbox shown, the motor speed sensor, and the gearbox gear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com