Electromobile power assembly and application thereof

A powertrain, electric vehicle technology, applied in electric vehicles, electric power units, power units, etc., can solve the problems of motor stall and burnout, vehicle power failure, running failure, etc., to improve ride comfort and reliability, Efficient operation of the motor and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

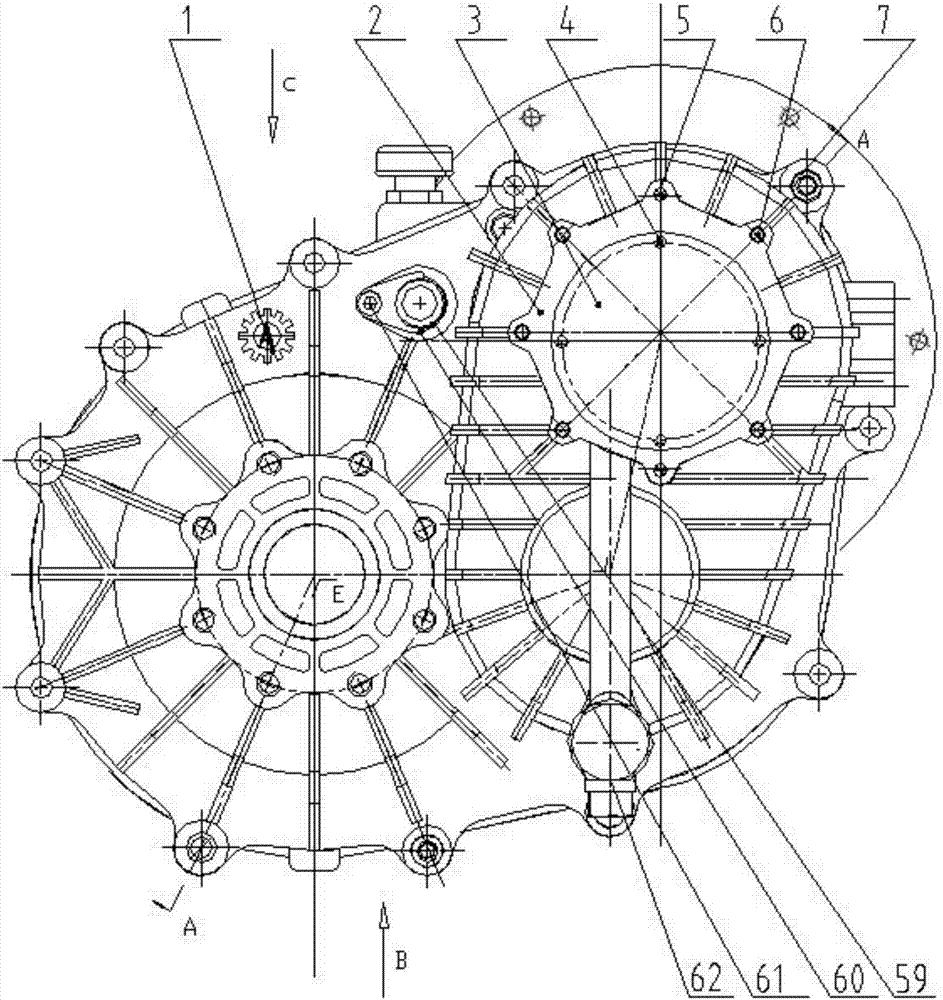

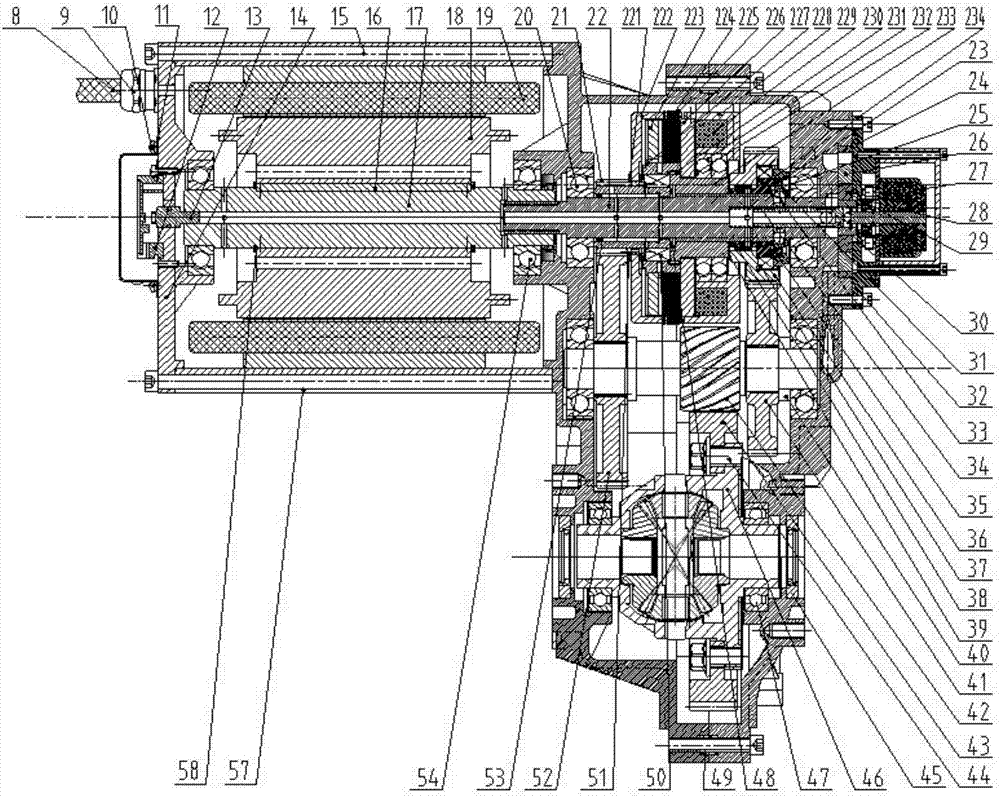

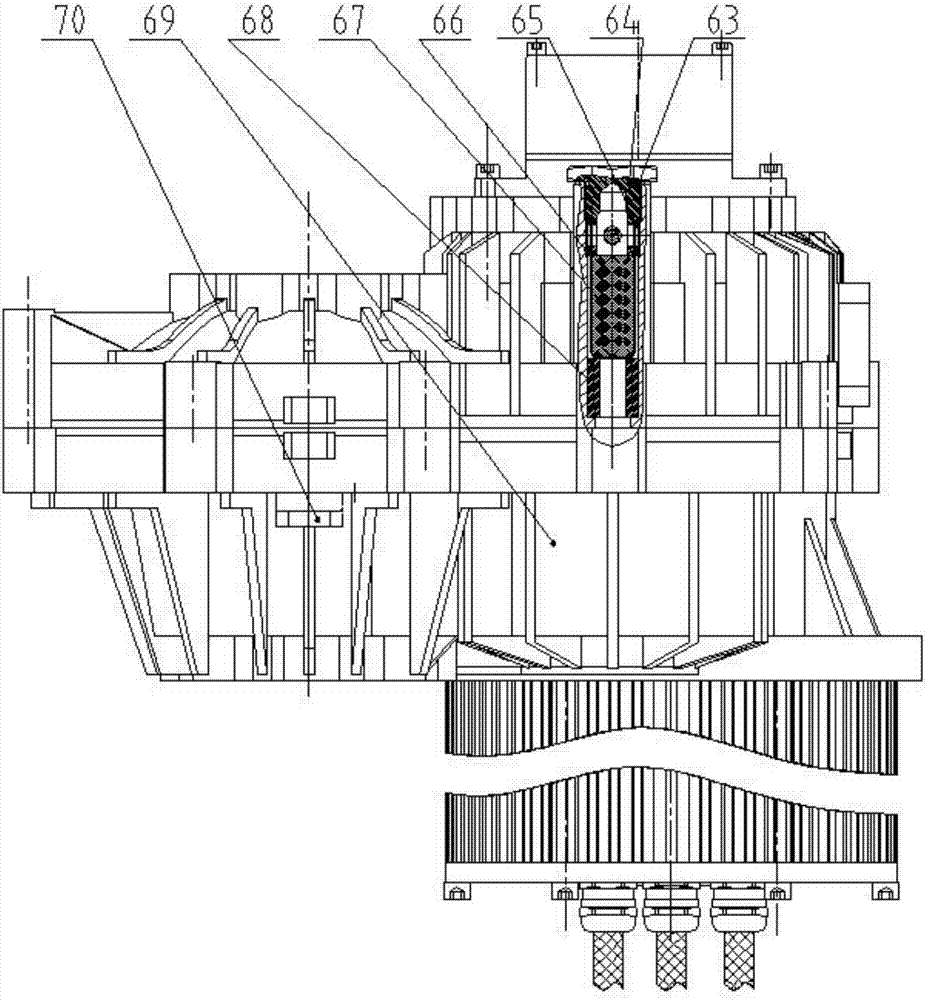

[0027] Such as Figure 1 to Figure 4 As shown, this embodiment provides an electric vehicle powertrain, including an integrated driving motor, transmission, clutch, differential and oil pump; specifically, the motor sensor 12 is connected with the motor end cover 14, and the sensor dust cover 11 corresponds to the threaded hole provided on the motor end cover 14 and is fixedly connected with the bolt 10, the sensor induction shaft 13 is provided with an interference fit with the motor shaft 17; the motor shaft 17 is concentrically matched with the motor rotor 18 and fixed with a flat key 16, The motor shaft collar 58 is installed in the annular groove that the motor shaft 17 is provided with, the inner diameter of the motor bearing 54 is connected with the journal that the motor shaft 17 is provided with for interference fit, and the outer diameter is provided with the motor end cover 14 and the transmission upper housing 69. The hole fits; the motor stator 19 is connected wit...

Embodiment 2

[0032] A kind of working method of electric vehicle power assembly as described in embodiment 1, its specific work process is as follows:

[0033] The motor sensor and speed sensor collect the motor shaft position and output speed, and send the collected data information such as motor power and motor speed to the vehicle controller, and the vehicle controller decides whether to work in first gear or second gear according to the built-in program Operation; when it is the first gear, the vehicle controller energizes the electromagnet 27 to force the second gear driving gear 36 to be in the neutral state, and the power is output from the transmission input shaft 22, the one-way clutch 50, and the first gear driving gear 21; When being the second gear, the electromagnet 27 is powered off, and the power is output through the transmission input shaft 22, the star wheel 234, the second gear driving gear 36, and now the first gear driving gear 21 is idling under the effect of the one-w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com