Patents

Literature

57results about How to "Reduce power interruption time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electric motor zero torque control bisynchronous shifting method for hybrid vehicle

InactiveCN101830221AReduce wearImprove acceleration performanceHybrid vehiclesElectric machineryHybrid vehicle

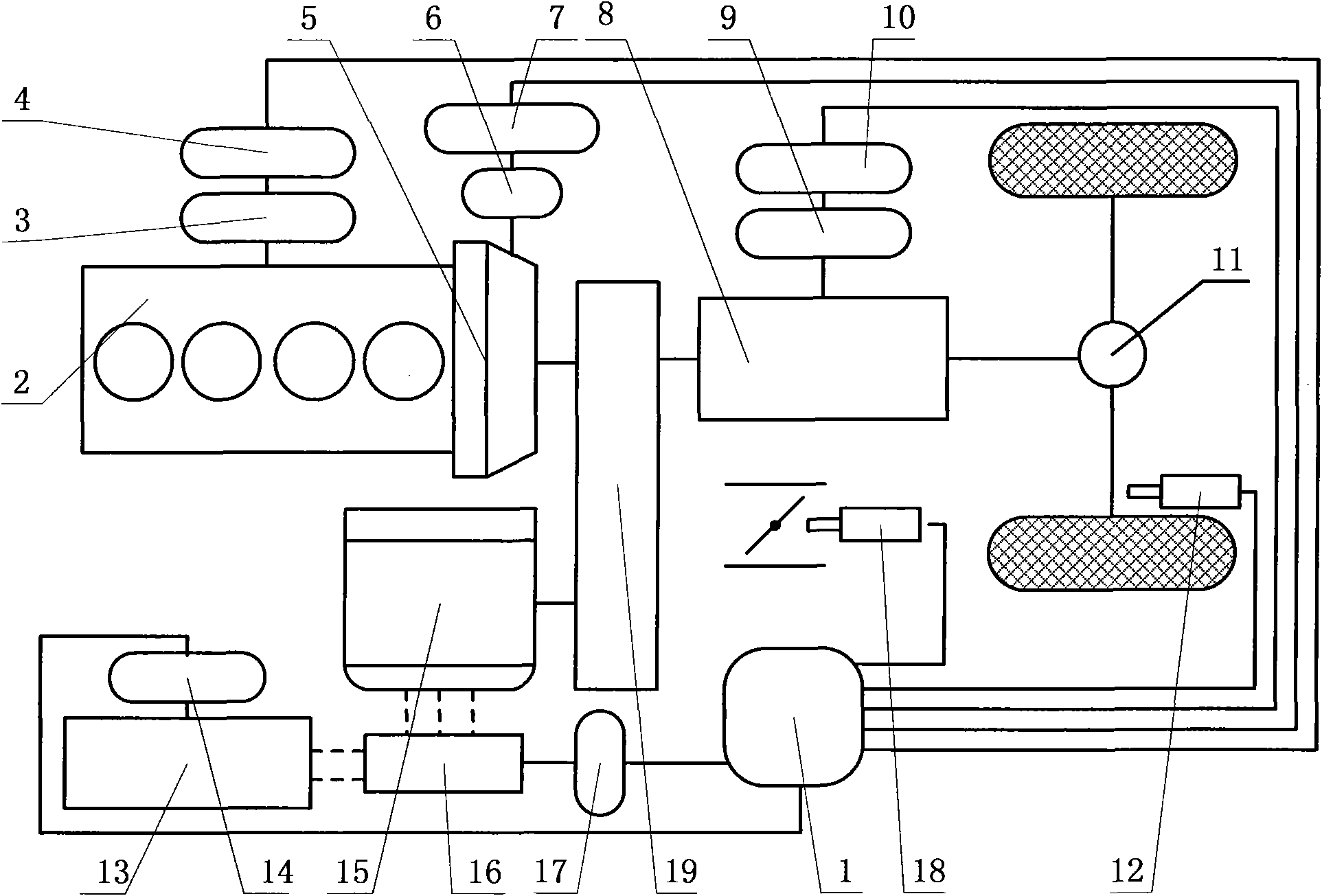

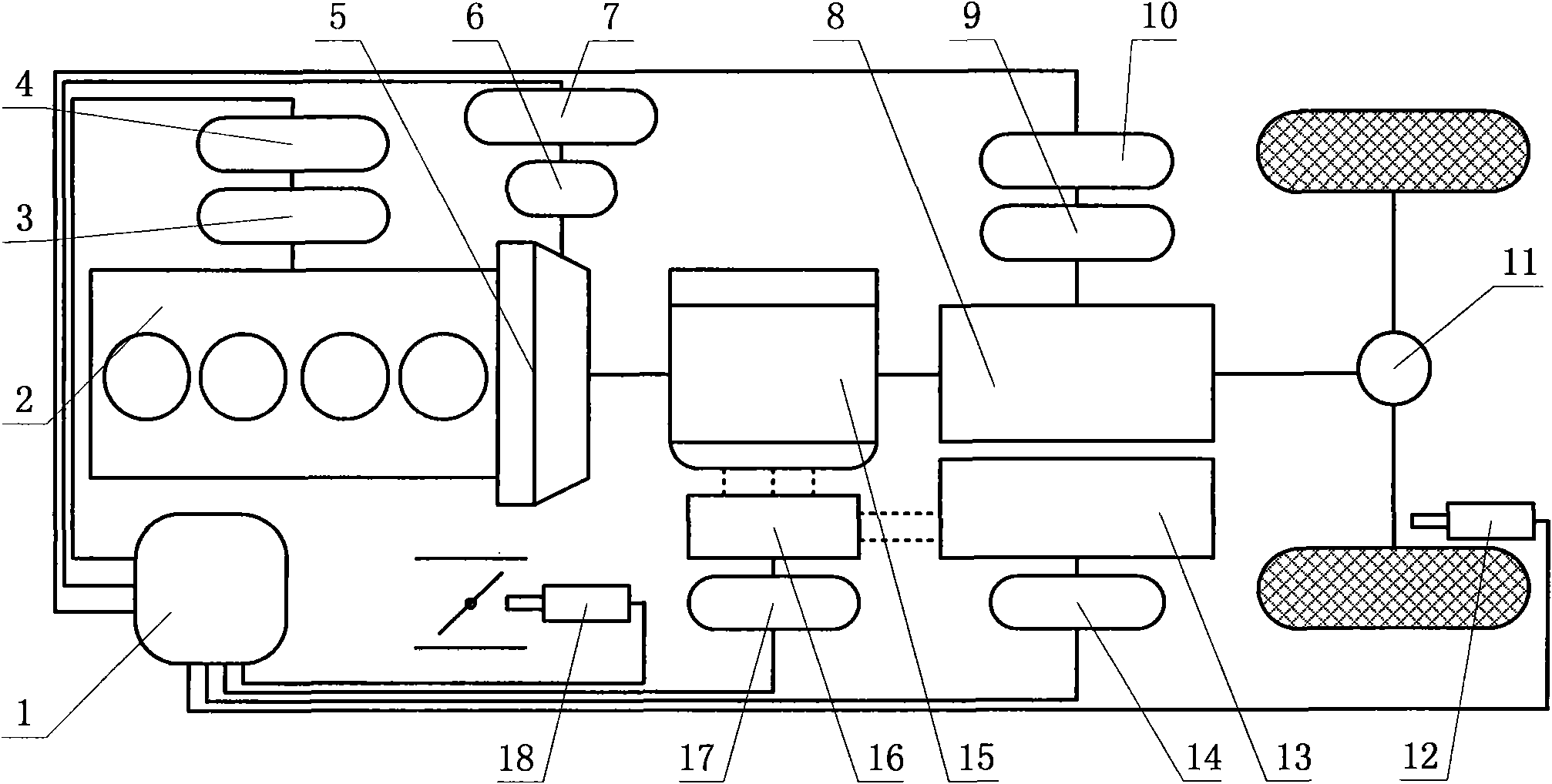

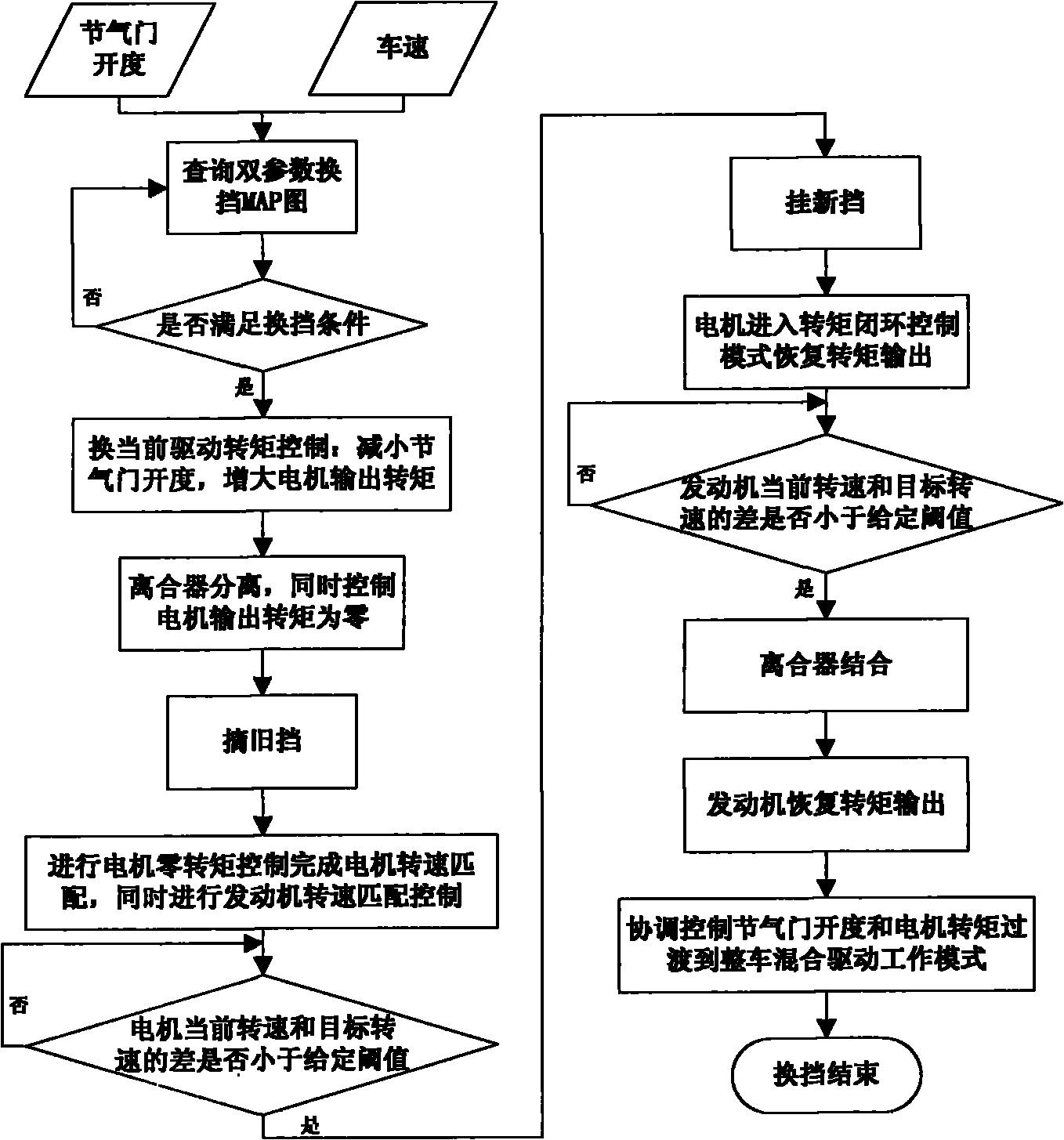

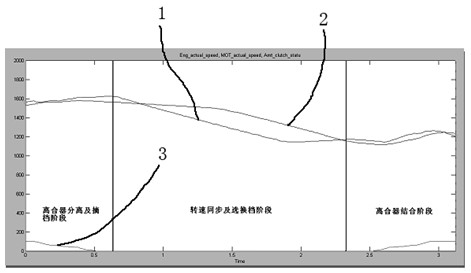

The invention relates to an electric motor zero torque control bisynchronous shifting method for hybrid vehicles, belonging to the technical field of modern transportation. The method is characterized in that vehicle speed ua and throttle valve alpha are monitored to identify shifting points; throttle percentage is reduced and the electric motor torque is increased; when throttle percentage is less than the given threshold value, a clutch is separated and the electric motor torque is controlled to be zero and original shift is restored; engine speed is adjusted to matched target speed ne, meanwhile zero torque control is performed on the electric motor and a zero torque control map, input voltage Uin and input current Iin corresponding to the given inverter matched target speed nm are inquired and the electric motor speed is controlled to reach the matched target speed nm; when the deviation between the electric motor speed nm and the matched target speed nm of the electric motor is less than the given threshold value, a new shift is moved to; electric motor torque output is restored; when the deviation between the engine speed ne and the matched target speed ne is less than the given threshold value, the clutch is combined; finally, engine torque output is restored. The invention has the effects and benefits of reducing shifting impact, shortening power interruption time and improving shifting comfort.

Owner:DALIAN UNIV OF TECH

Control method for improving gear shifting smoothness based on AMT (automated mechanical transmission)

A control method for improving gear shifting smoothness based on an AMT (automated mechanical transmission) is characterized in that torque control and rotating speed control are combined, a gear shifting process is decomposed into a plurality of real-time control stages, rapid gear shifting and effective torque compensation are realized by the aid of rapid response of a motor on the basis of the actual torque and rotating speed feedback of an engine and the motor at the stages, the actual output torque of a transmission system has no long-time large fluctuation as compared with overall needed torque by means of dynamic coordinated control during actual running of a vehicle, and the impact of the whole vehicle is decreased as far as possible, so that gear shifting smoothness and comfortableness are improved.

Owner:CHANGSHA CRRC INTELLIGENT CONTROL & NEW ENERGY TECH CO LTD

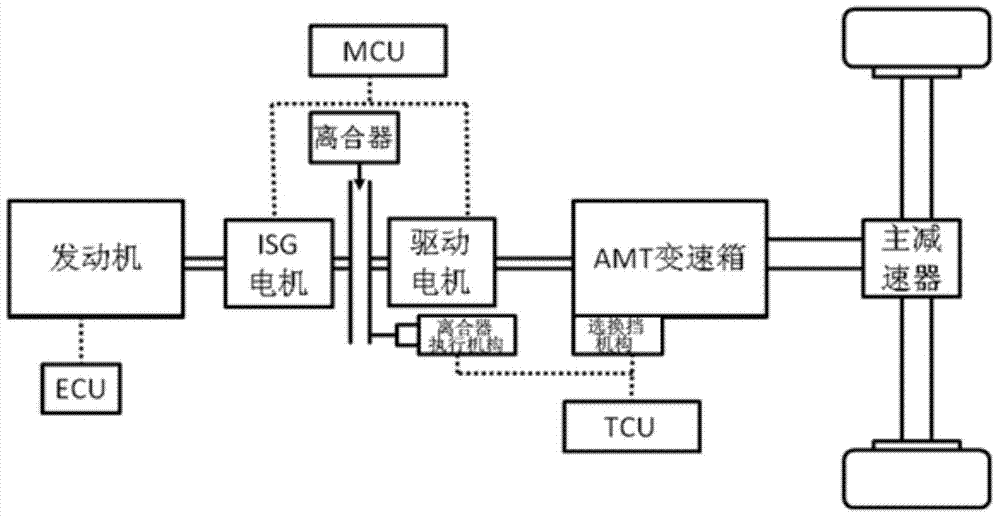

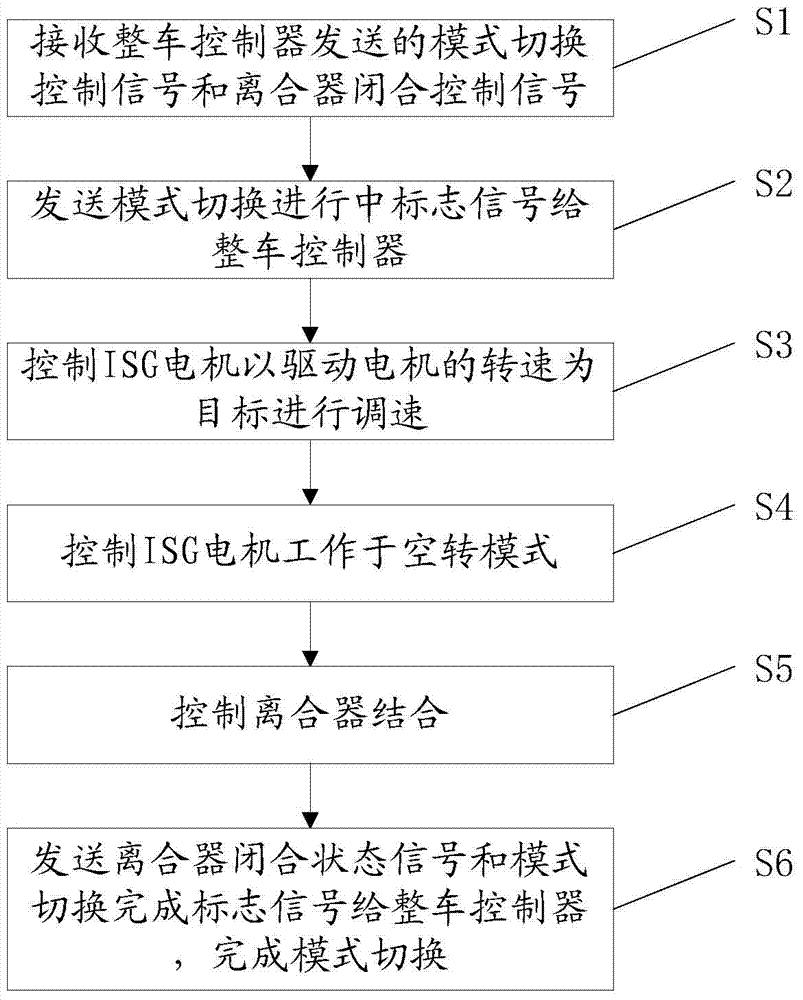

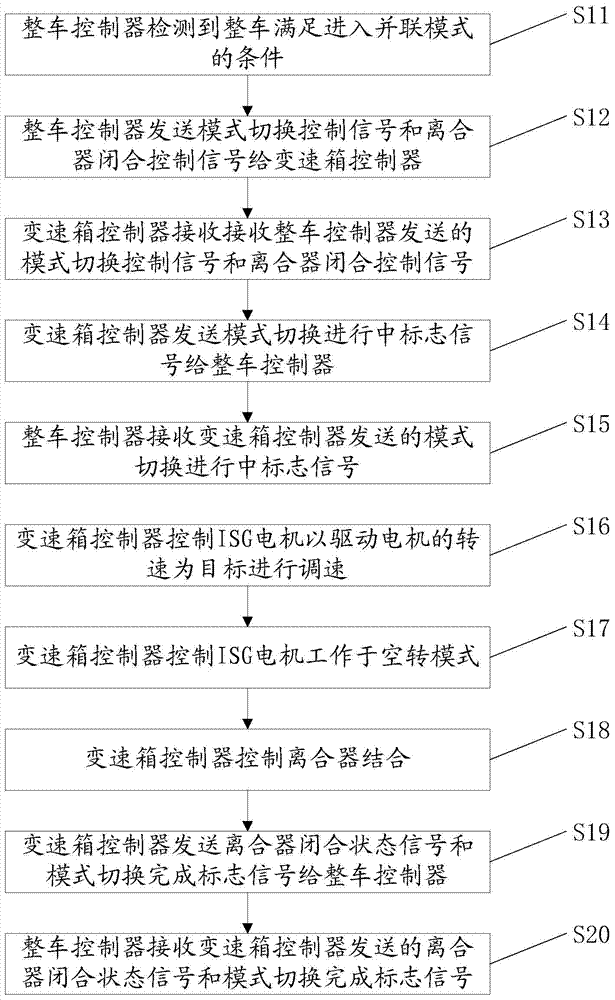

Vehicle working mode switching method and system of hybrid electric vehicle and transmission control unit

ActiveCN104842992AIncrease active speed controlAvoid frustrationHybrid vehiclesControl signalElectric machine

The invention provides a vehicle working mode switching method and a vehicle working mode switching system of a hybrid electric vehicle. The method comprises the steps of receiving a mode switching control signal and a clutch closing control signal sent by a vehicle controller when the vehicle is required to be switched to a parallel mode from a series mode; sending a mode switching in-progress marking signal to the vehicle controller; controlling an ISG motor to work in a rotation speed control mode, and adjusting the speed of the ISG motor by taking the rotation speed of a drive motor as the target; controlling the ISG motor to work in an idle mode; controlling the clutch to be combined; sending a clutch closed state signal to the vehicle controller. The vehicle working mode switching method and the vehicle working mode switching system of the hybrid electric vehicle have the advantages that the technical problems of long interruption time of power and great wear of the clutch in mode switching caused by a fact that rotation speeds of the ISG motor and the drive motor are synchronized through a sliding membrane of the clutch in mode switching of the existing hybrid electric vehicle are solved, and the active speed adjusting process of the ISG motor and the drive motor is added before the clutch is combined, so that the mode switching time is shortened and the smoothness in the process of mode switching is improved.

Owner:BEIQI FOTON MOTOR CO LTD

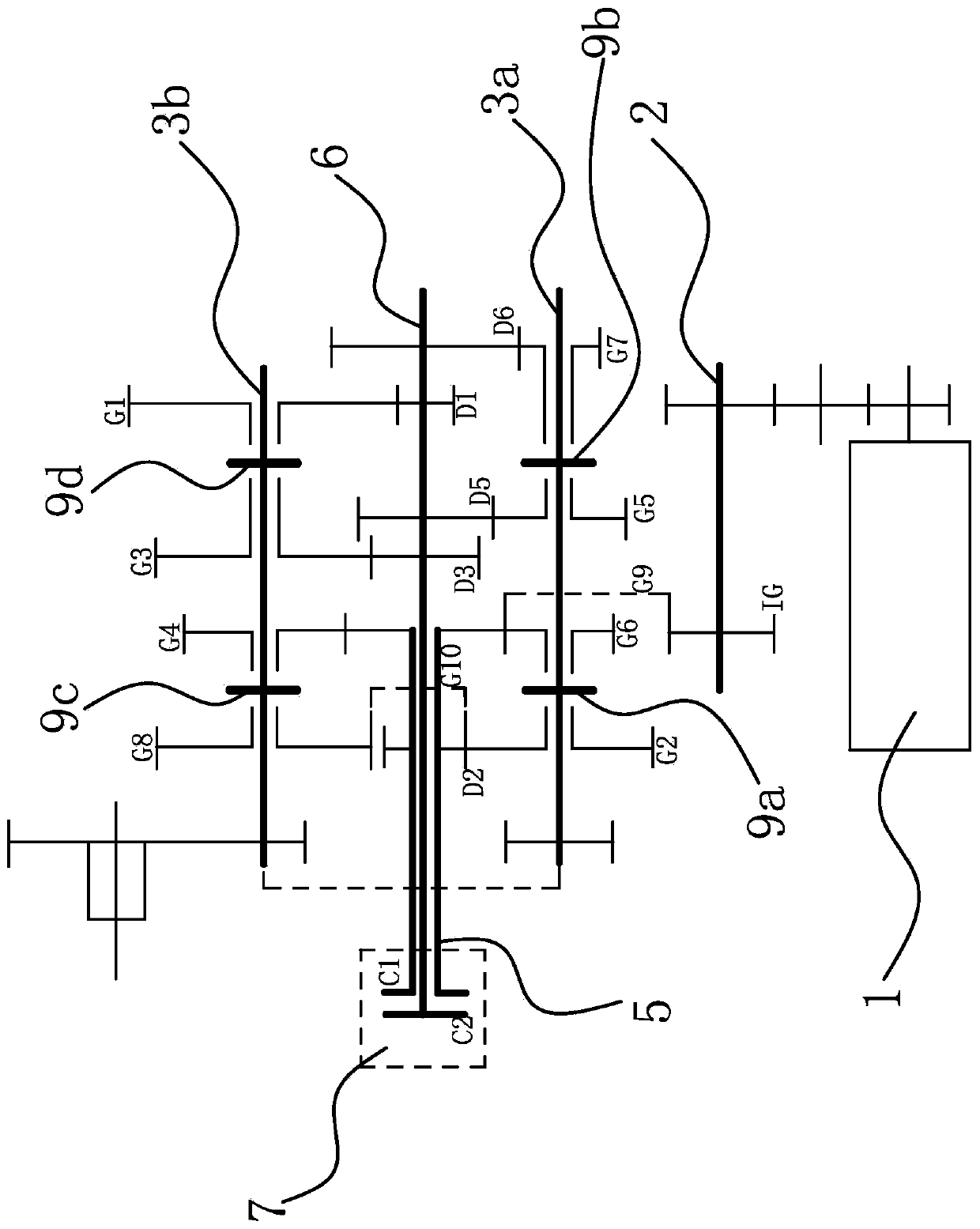

Motor and AMT (automated mechanical transmission) integration-based electric vehicle driving system and driving method

InactiveCN103552448ASmall sizeFlexible and convenient layoutSpeed controllerElectric propulsion mountingBrushless motorsElectric machine

The invention discloses a motor and AMT (automated mechanical transmission) integration-based electric vehicle driving system and a motor and AMT integration-based electric vehicle driving method. The driving system comprises a driving motor, a motor controller, a transmission drive assembly, a gear selection and shifting execution mechanism and a controller for the gear selection and shifting execution mechanism, wherein the transmission drive assembly comprises driving and driven gears of four gears, two splined hubs, two jointing sleeves and an output sensor; the driving motor is a direct current brushless motor; an output shaft of the driving motor is provided with an internal spline; a shell of the driving motor is integrally and directly connected with a transmission case through fine thread screws after being positioned through fixing pins; the output shaft, with the internal spline, of the motor is positioned in the motor; an input shaft of a transmission is directly inserted into the motor to be connected with the output shaft, with the internal spline, of the motor. According to the system, a clutch is eliminated, so that power interruption time during gear shifting is reduced, and the cost is also lowered; the jointing sleeves and the gears of a target gear can be synchronized during gear shifting by actively regulating the speed of the driving motor, and a synchronizer with high requirements on materials is eliminated from the transmission, so that the cost is further lowered.

Owner:张利鹏 +1

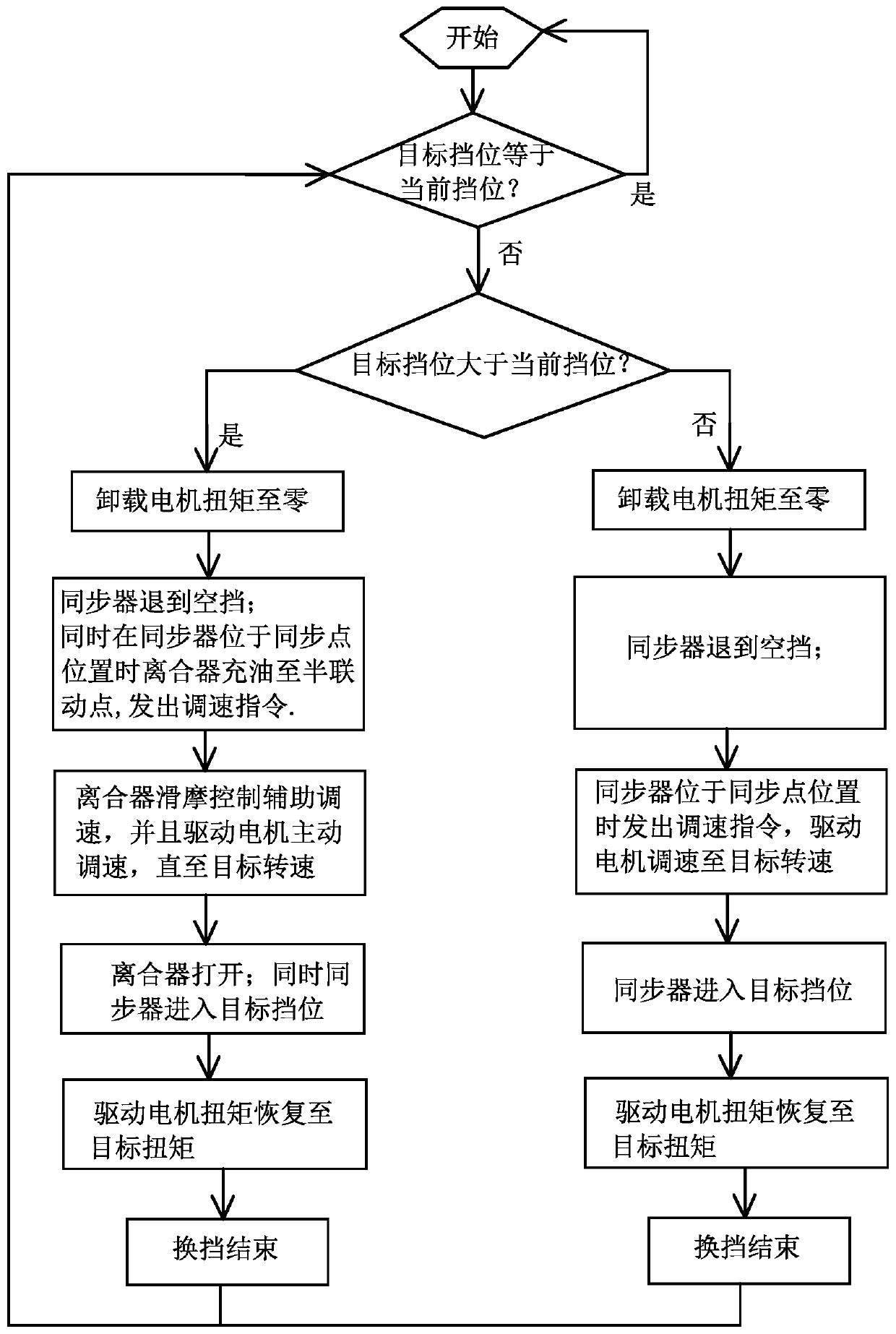

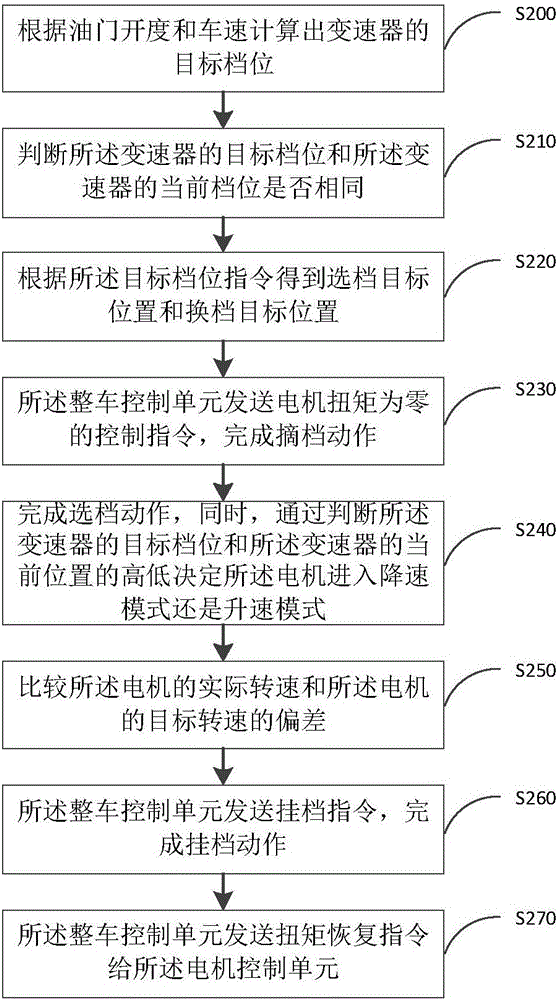

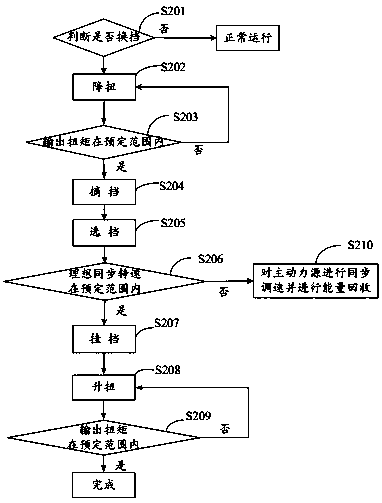

Gear shifting control method and device for pure electric mode of hybrid electric vehicle

The invention provides a gear shifting control method and device for a pure electric mode of a hybrid electric vehicle which belongs to the technical field of vehicles, and solves the problem that inthe prior art, the power interruption time is long during gear shifting. The gear shifting control method for the pure electric mode of the hybrid electric vehicle comprises the steps of when it is judged that a target gear is inconsistent with a current gear according to the real-time working condition information of the vehicle, entering a gear shifting mode; unloading the torque of a driving motor to zero; enabling a synchronizer to be disengaged from the current gear to a neutral gear; when the synchronizer is disengaged to the synchronization point of the current gear, sending out a speedregulation instruction signal through a gearbox controller; using a motor controller to control the driving motor to adjust the speed, and when the rotating speed of the driving motor reaches the target rotating speed, unloading the torque of the driving motor to zero; and enabling the synchronizer to enter the target gear, and recovering the torque of the driving motor to the target torque. Theinvention further provides a gear shifting control device for the pure electric mode of the hybrid electric vehicle. According to the invention, the gear shifting power interruption time in the pure electric driving mode can be shortened.

Owner:ZHEJIANG GEELY AUTOMOBILE RES INST CO LTD +1

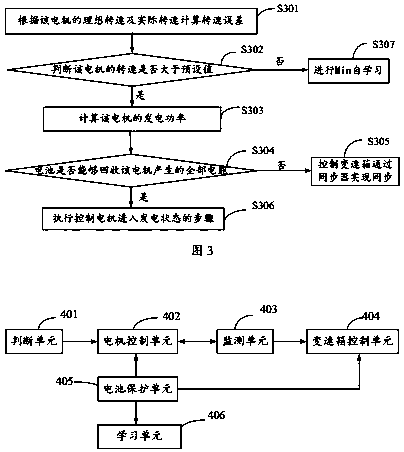

Automatic starting control method of hybrid electric vehicle

ActiveCN110562238ASpeed up the closing processReduce power interruption timeHybrid vehiclesElectric motor startersControl systemElectric machine

The invention discloses an automatic starting control method of a hybrid electric vehicle. The automatic starting control method comprises the following steps: S1, when t is greater than t1 and less than t2, a control system does not receive a brake or accelerator signal, the vehicle is driven by a motor separately; S2, when t is equal to or greater than t2 and equal to or less than t3, a driver steps on the accelerator, the control system controls a clutch to a peristalsis point from the opening state after receiving the accelerator stepping signal, the torque Tc(t) of the clutch is enlargedto pull and start an engine, at the same time, the control system controls the output torque Tm(t) of the motor to increase, the actual torque is Ts (t) and keeps unchanged, and the control system adjusts the revolving speed of the engine to the starting revolving speed vq; and S3, when t is equal to or greater than t3 and equal to or less than t4, the clutch is closed from the peristalsis point,the actual torque Ts(t) of the vehicle keeps unchanged, the control system simultaneously gives out a command for adjusting the revolving speed of the engine to enable the revolving speed growth rateof the engine to be consistent with the growth rate of the vehicle speed. With adoption of the automatic starting control method, the automatic starting control of the engine of the hybrid electric vehicle is finished, and the starting process is steady and fast.

Owner:海博瑞德(北京)汽车技术有限公司

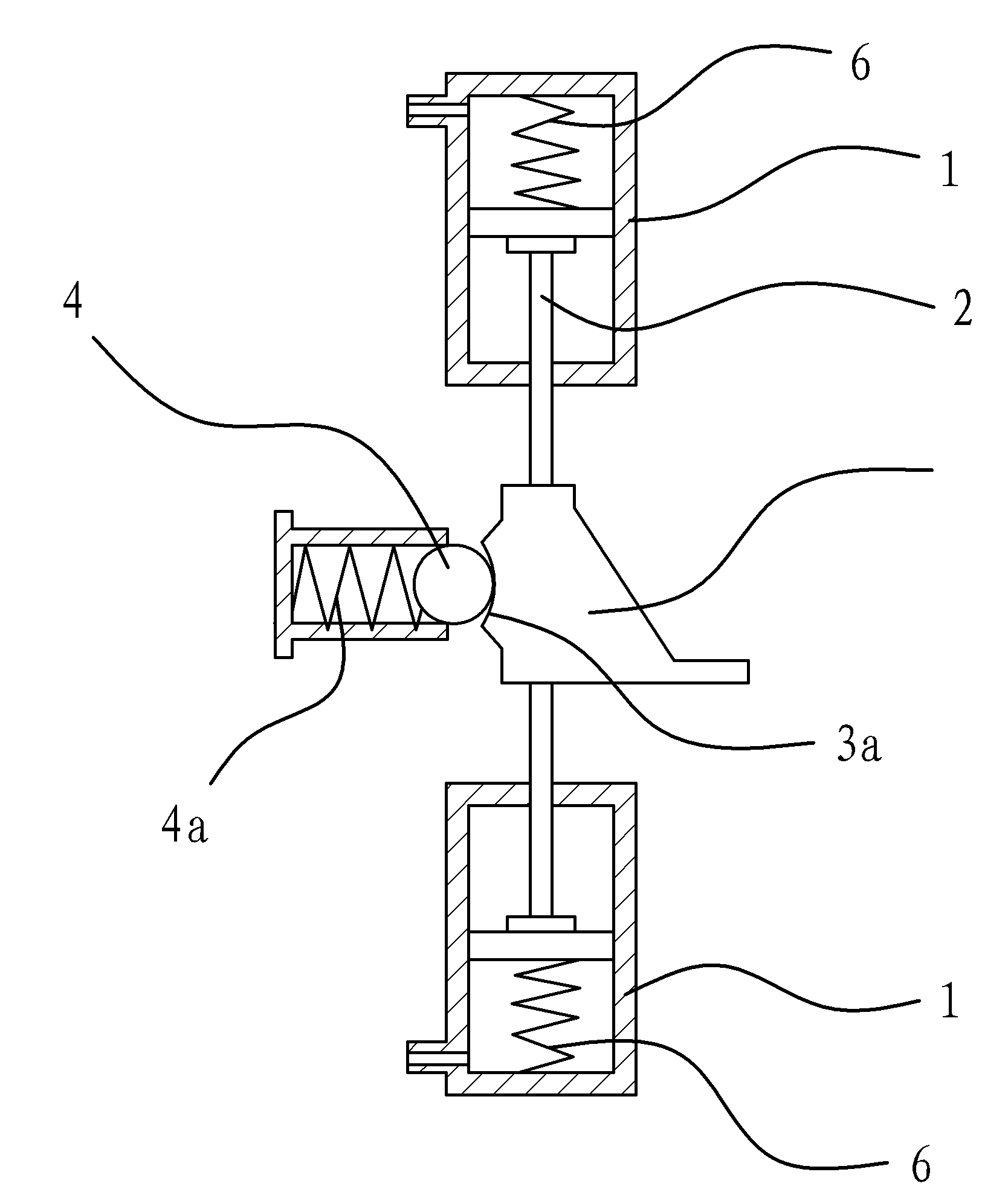

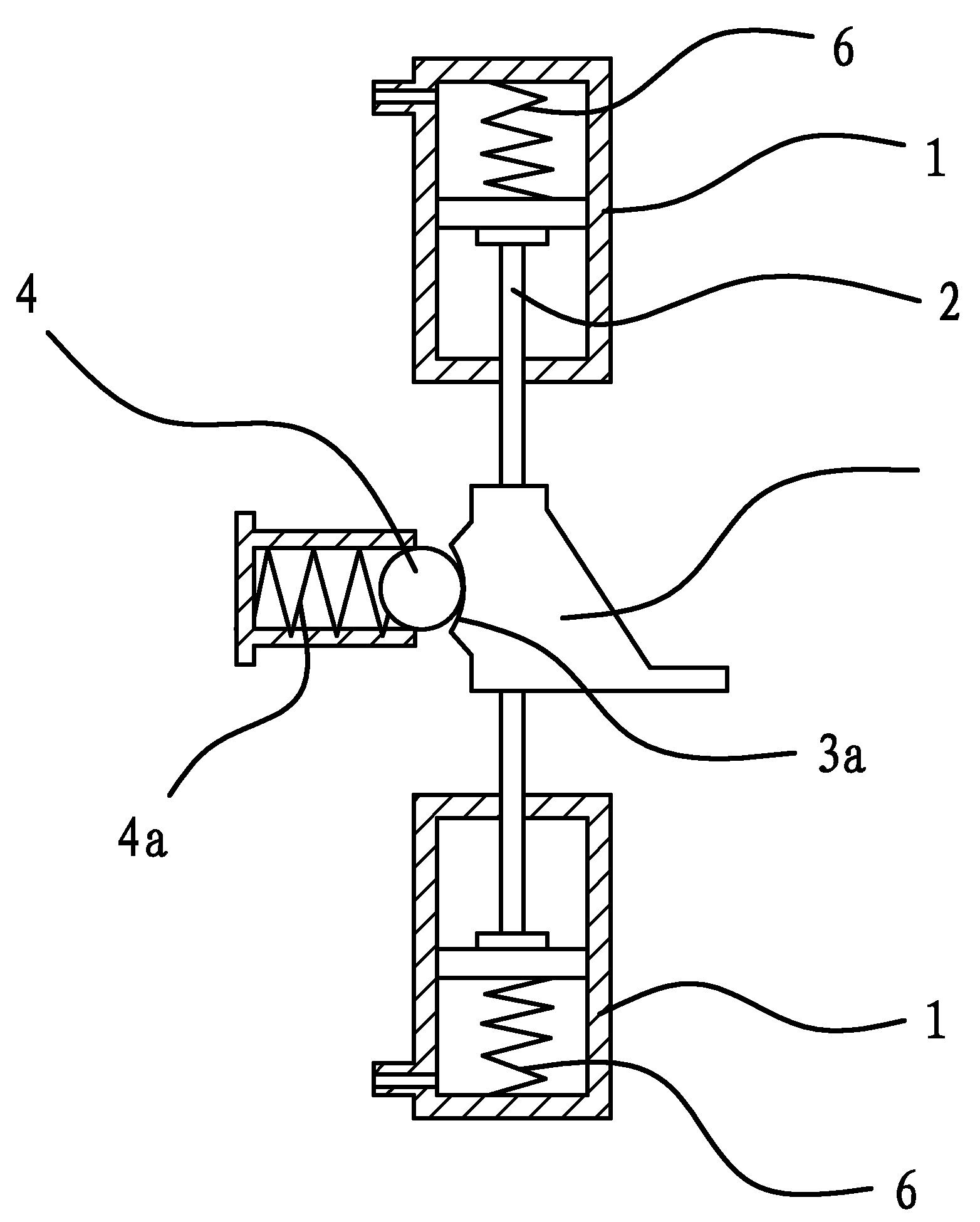

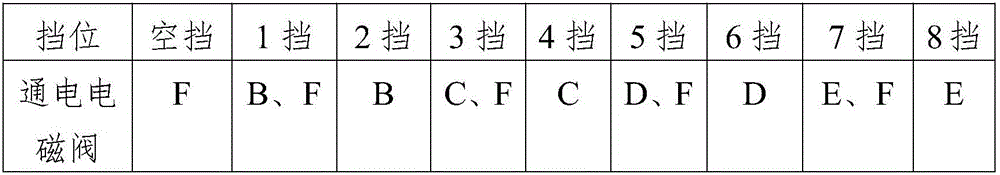

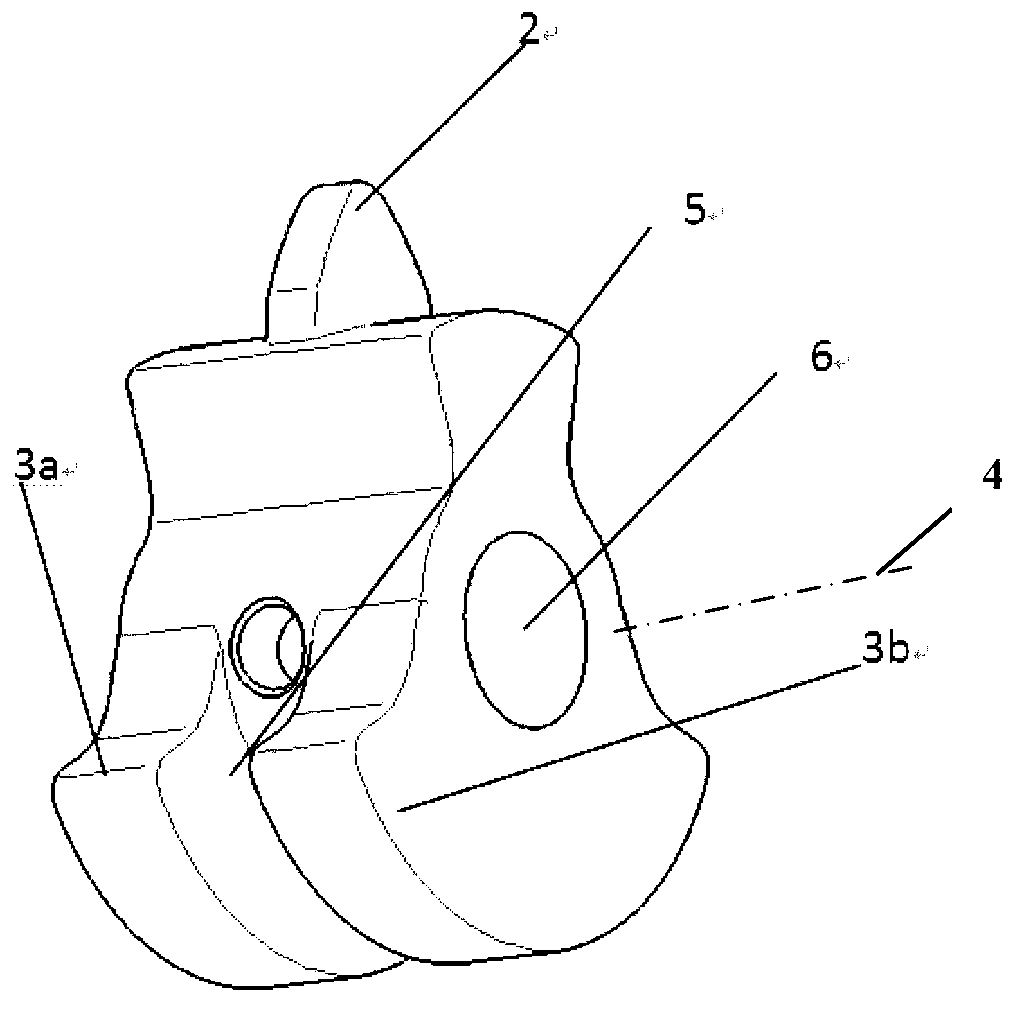

A gear selection actuator of an electronically controlled mechanical automatic transmission

InactiveCN102261461AReduce power interruption timeShift quicklyGearing controlAutomatic transmissionEngineering

The invention provides a gear selection actuator of an electronically controlled mechanical automatic gearbox, which belongs to the field of mechanical technology. It solves the problem that the existing AMT gear selection actuators with 5 gears and lower gears cannot meet the requirements of four gear selection positions. The gear selection actuator of the electronically controlled mechanical automatic transmission is arranged at the shift lever of the automatic transmission, and the mechanism includes several shift parts located between two adjacent shift rods. It is two oil cylinders and a piston rod located between the two oil cylinders. The two ends of the piston rod are respectively located in the above two oil cylinders and there is a shift fork on the piston rod that can toggle the shift rod. The above-mentioned several shift parts and The hydraulic lines are connected. The present invention is a plurality of shifting parts arranged between two adjacent shift levers. Each shifting part is independent and centrally controlled through hydraulic pipelines. There is no gear selection process when shifting gears, which greatly reduces the need for electronically controlled mechanical automatic The power interruption time when the gearbox shifts gears makes the shifting fast and stable.

Owner:ZHEJIANG GEELY AUTOMOBILE RES INST CO LTD +1

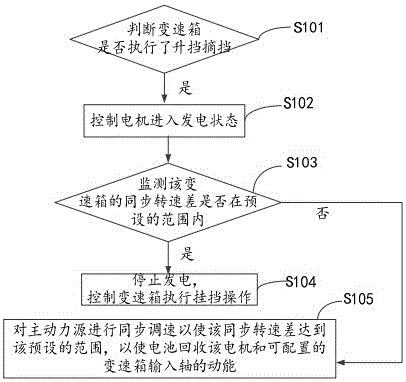

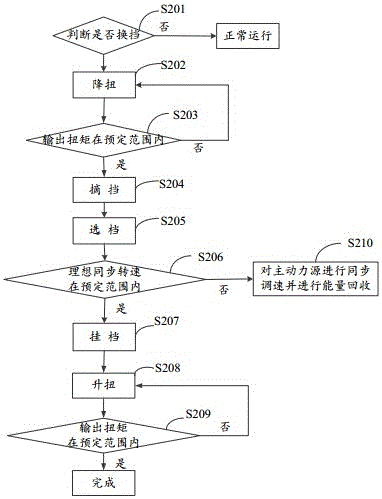

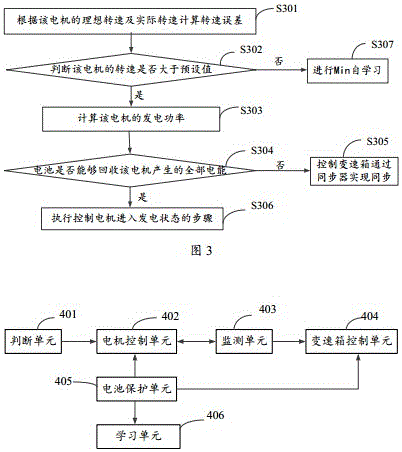

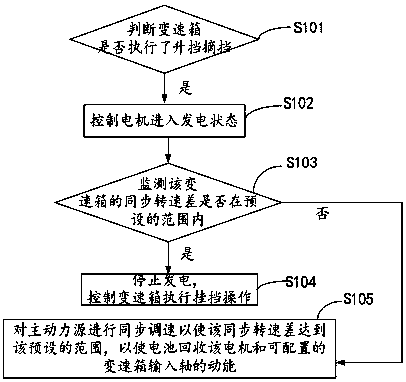

Control method, device and system for automobile energy recovery

The invention discloses a control method, device and system for automobile energy recovery, and belongs to the technical field of automobiles. The method comprises the following processes of judging whether a gearbox completely executes the operations of upshifting and downshifting or not, if yes, controlling a motor to enter an electricity generation state, converting the kinetic energy of the motor and the kinetic energy of the gearbox into electric energy, and storing the electric energy in batteries for standby application; and monitoring whether the synchronous rotational speed difference of the gearbox is in a preset range or not, if yes, stopping electricity generation and controlling the gearbox to execute the operation of putting in gear, else, and performing synchronous speed adjustment on a primary power source so as to enable the synchronous rotational speed difference to reach the preset range and enable the batteries to recover the electric energy produced by the motor, wherein the primary power source is the motor. Through the adoption of the control method, device and system disclosed by the invention, energy produced in the upshifting process of the gearbox is stored and used as the electric energy required for upshifting after the completion of gear shifting, so that the efficiency can be improved, and the energy consumption can be reduced.

Owner:广东戈兰玛汽车系统有限公司

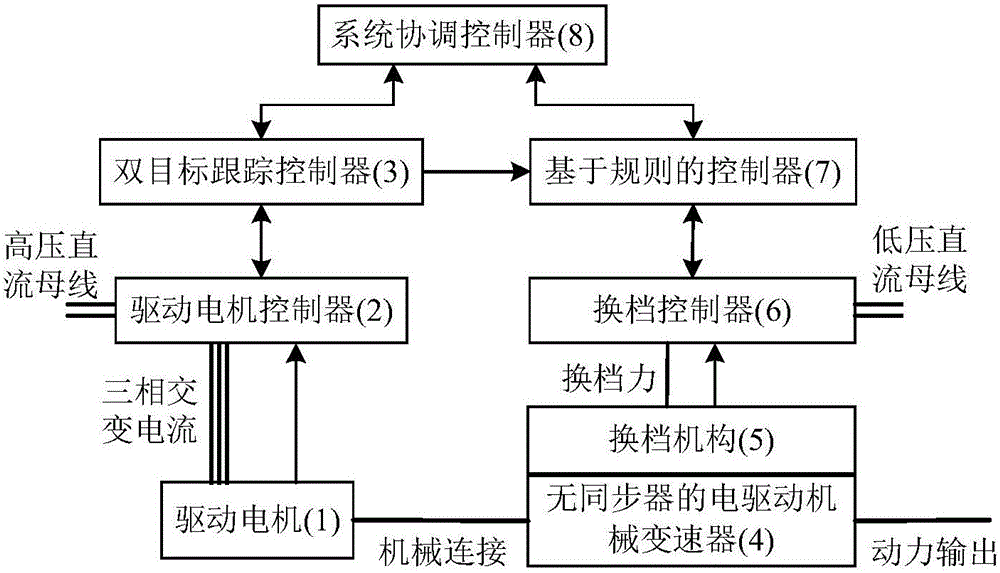

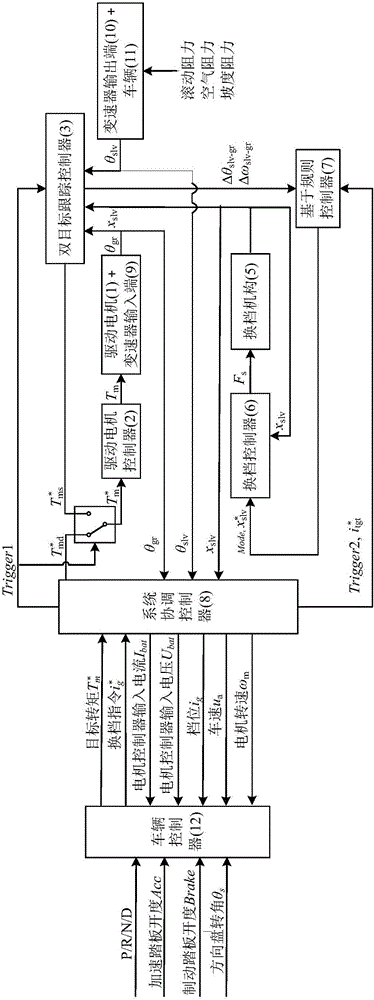

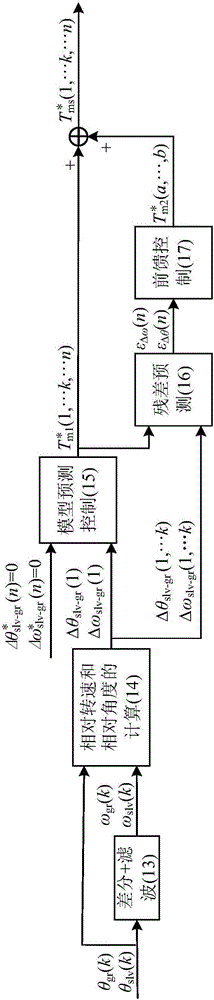

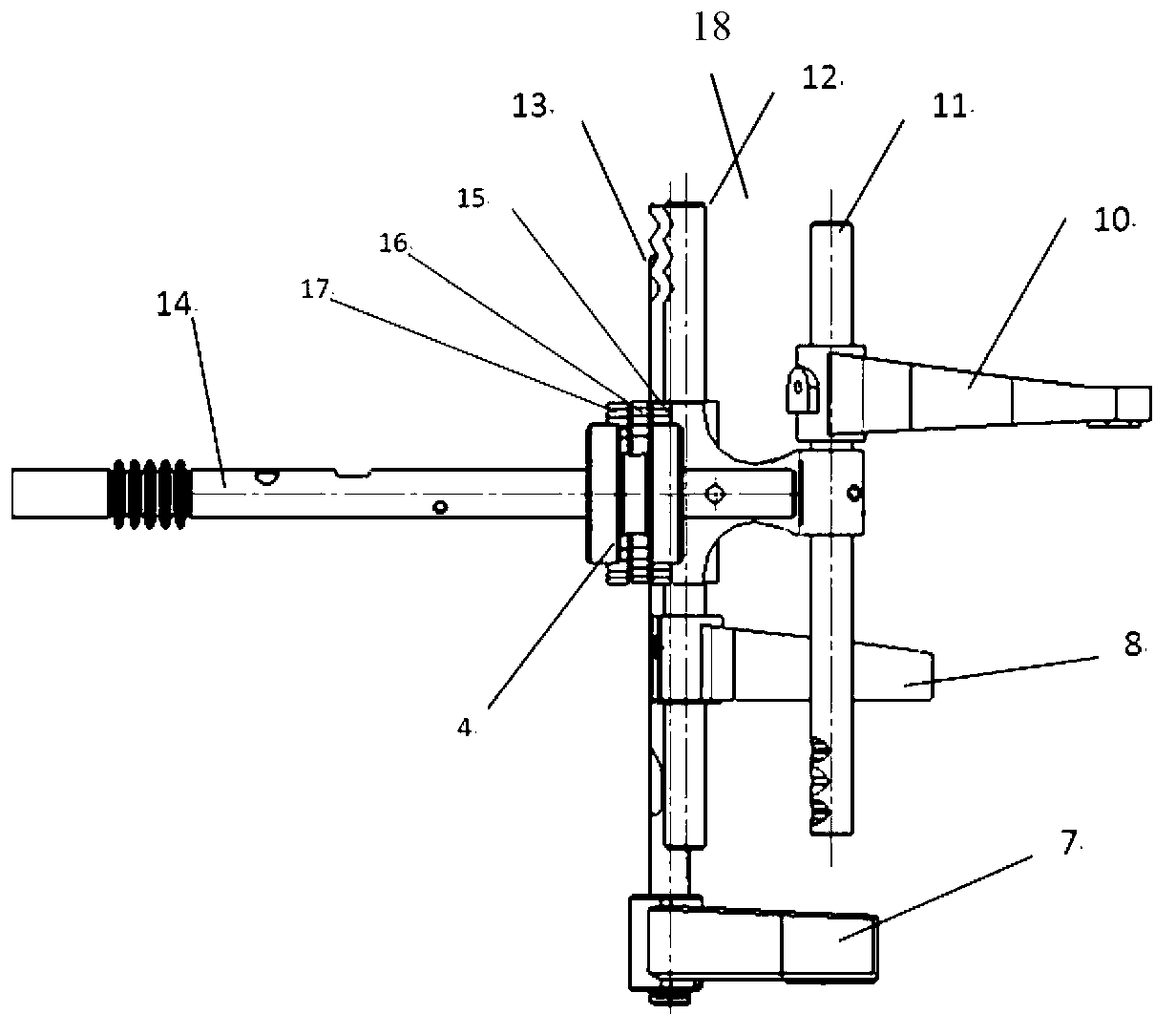

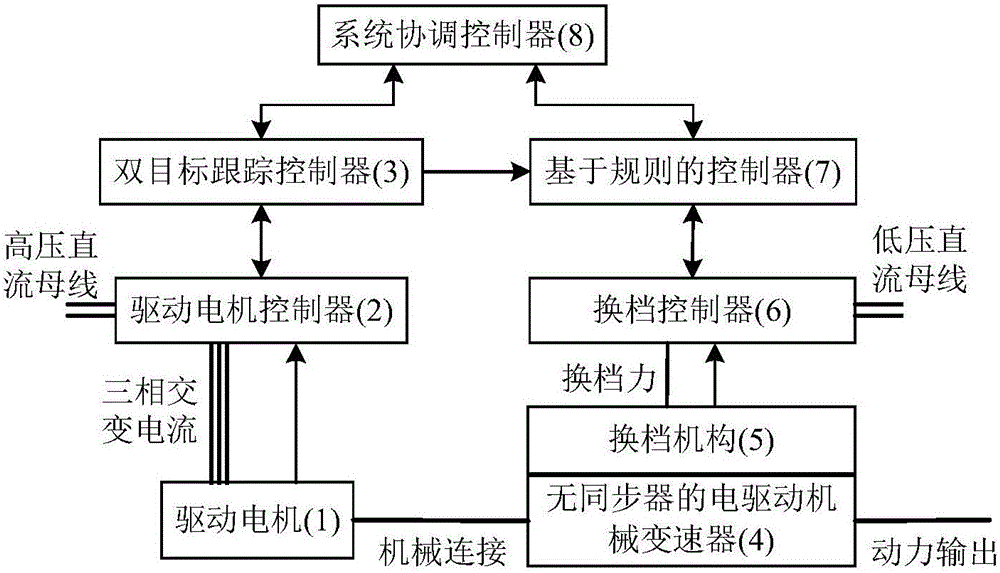

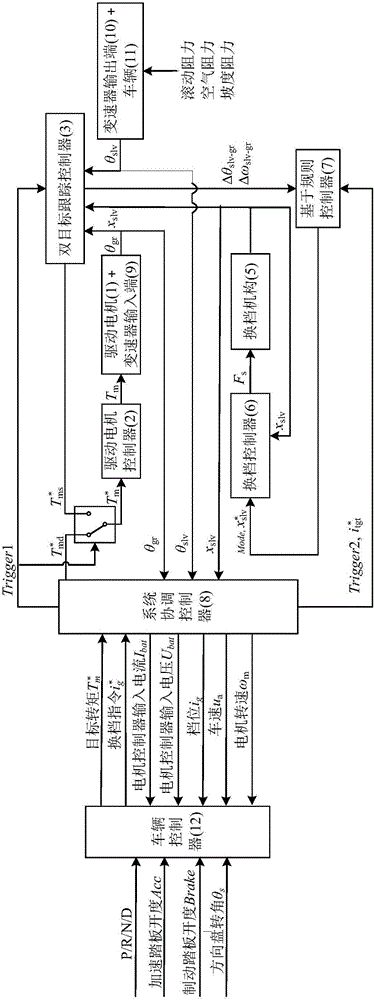

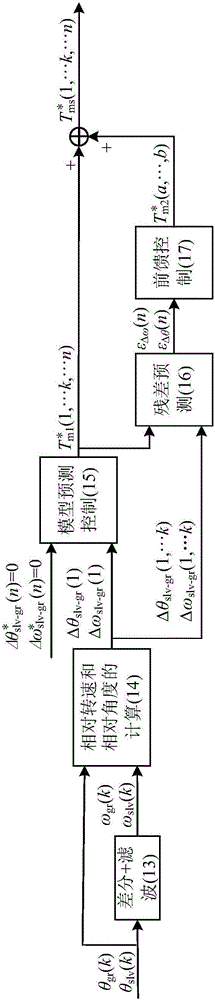

Impact-free gear shift control method and system for electrically driven mechanical transmission without synchronizer

The invention relates to an impact-free gear shift control method and system for an electrically driven mechanical transmission without a synchronizer. The electrically driven mechanical transmission is provided with no synchronizer; a drive motor and the electrically driven mechanical transmission are directly coupled, and a clutch between the drive motor and the electrically driven mechanical transmission is omitted. An automobile controller determines the target gear and sends a gear shift instruction to a system coordinating controller; the system coordinating controller coordinates the working sequence and working mode of a dual target tracking controller and a rule-based controller, so that the drive motor and the electrically driven mechanical transmission are in coordinated fit to achieve gear shift; and by accurately controlling a motor rotor, a target joint gear ring accurately tracks rotation of a joint sleeve in the joint process, the requirements for zero rotation speed difference and zero rotation corner difference are met, and impact-free gear shift control is achieved. The method and system can eliminate collision between the joint sleeve and the joint gear ring in the joint process, then gear shift impact is restrained, and the power failure duration is shortened.

Owner:TSINGHUA UNIV

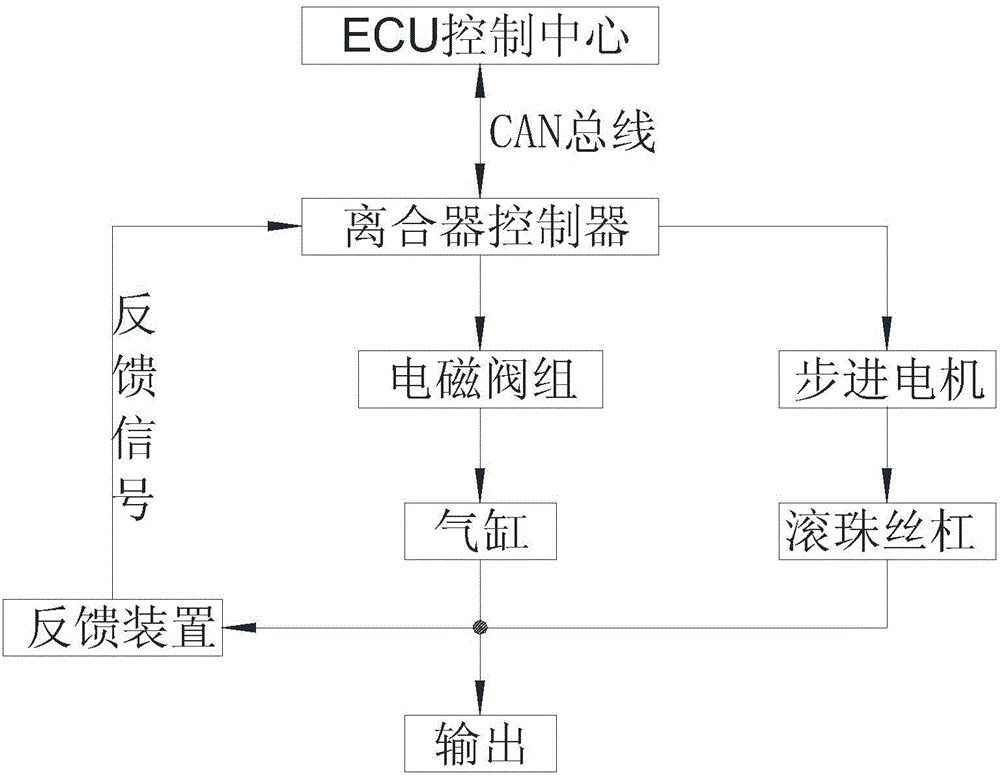

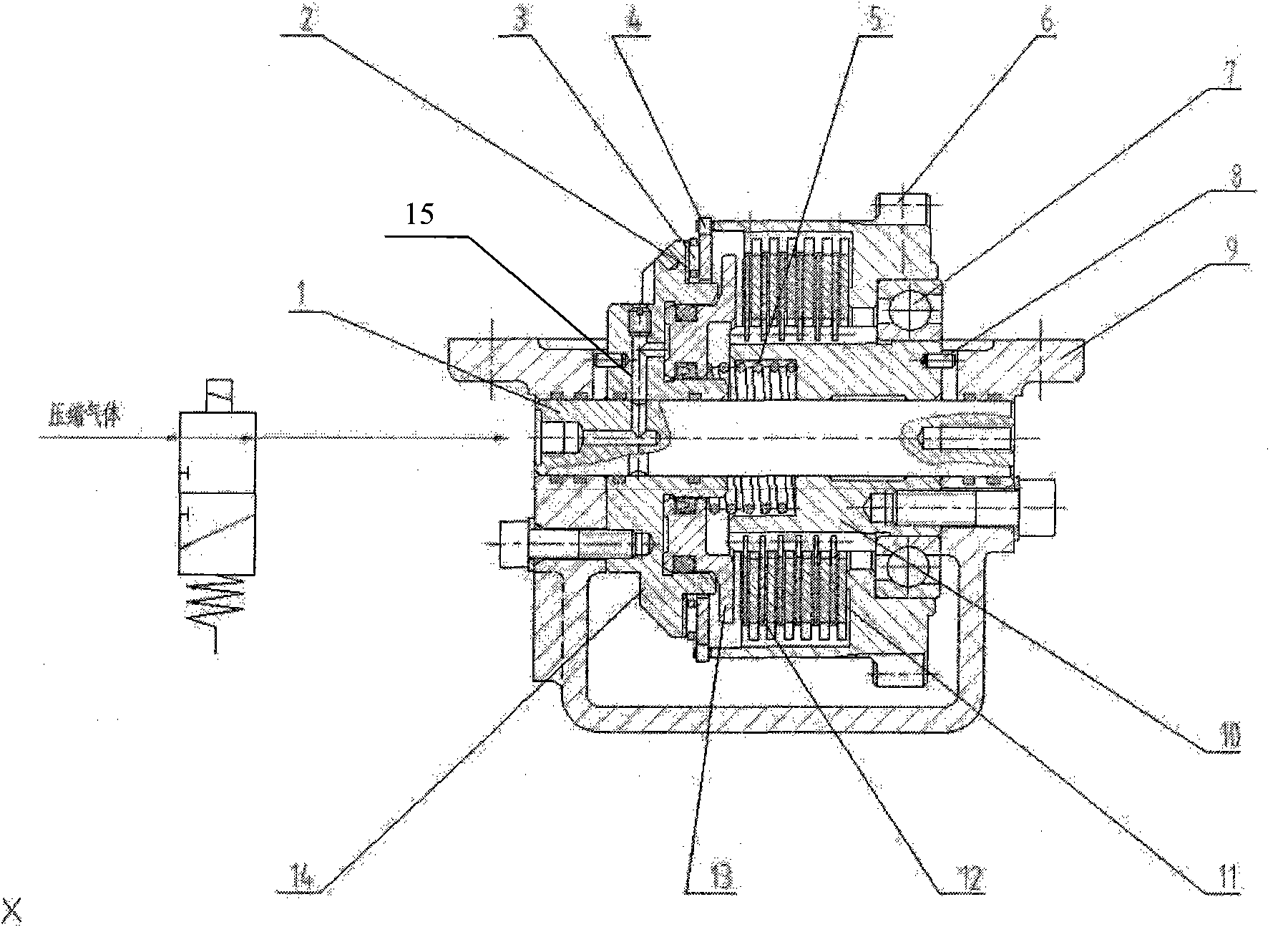

Pneumatic separation-motor positioning clutch control system

The invention discloses a pneumatic separation-motor positioning clutch control system. The system comprises a motor system, a pneumatic system, a pressure sensor, a displacement sensor and a clutch controller. The control system is a parallel closed loop servo system. By the use of accurate positioning characteristics of the motor system, half-linkage position and speed can be accurately controlled during a clutch engaging process. By the use of rapid movement characteristics of a cylinder piston, clutch displacement and engagement speed operations can be rapidly carried out, so that the breaking time of system power can be reduced. The system is simple in whole structure and control process, high in accuracy and stability, rapid in response, high in self-adaptability, simple in manufacturing and assembling technology and low in power consumption, and is environment-friendly.

Owner:DALIAN NATURE MACHINERY ELECTRONICS EQUIP

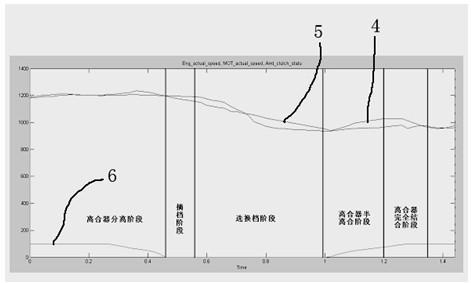

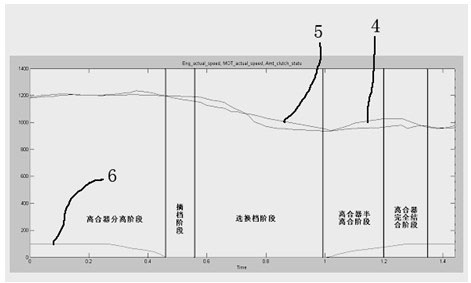

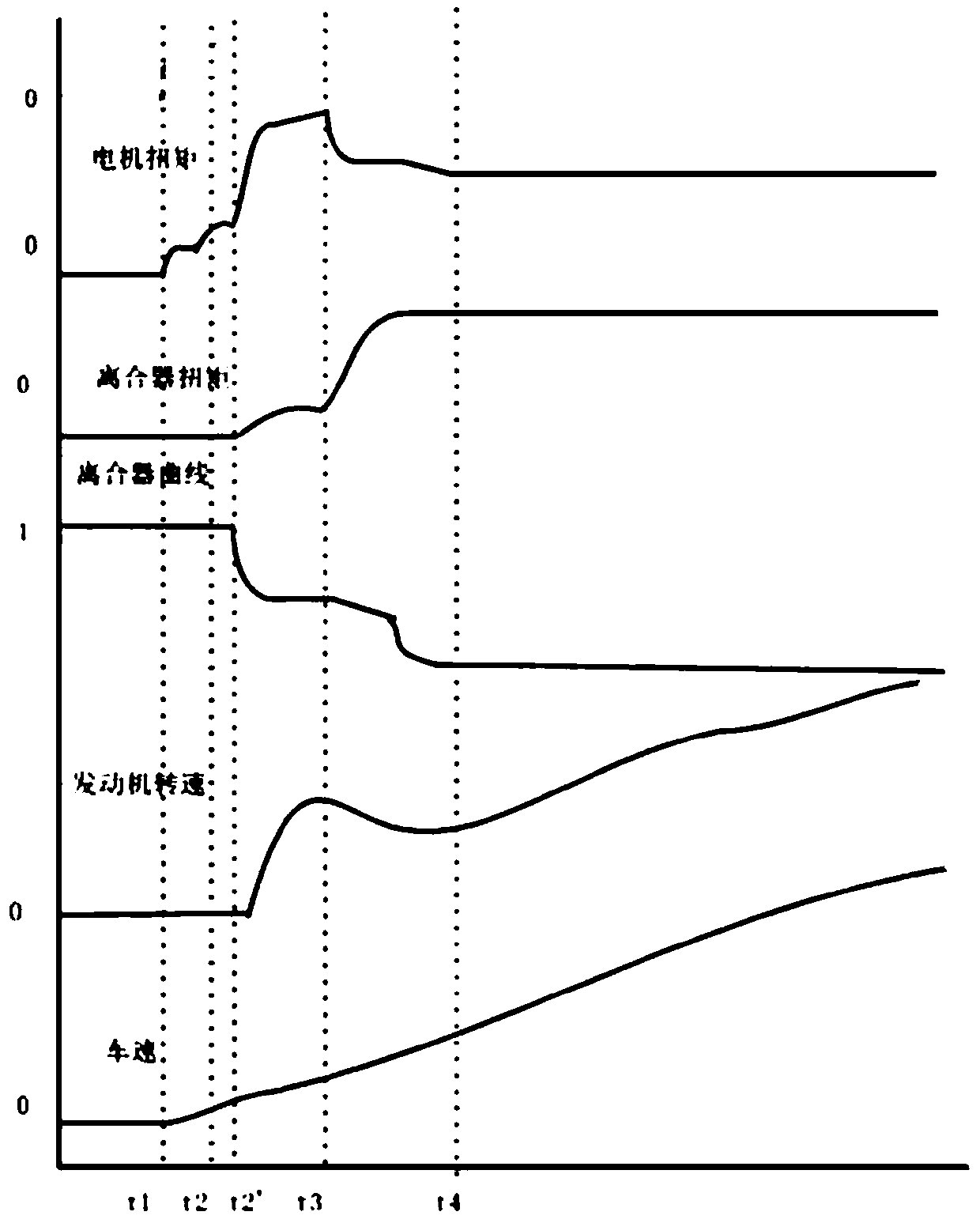

Power interruption compensation control method for a hybrid electric vehicle AMT shifting process

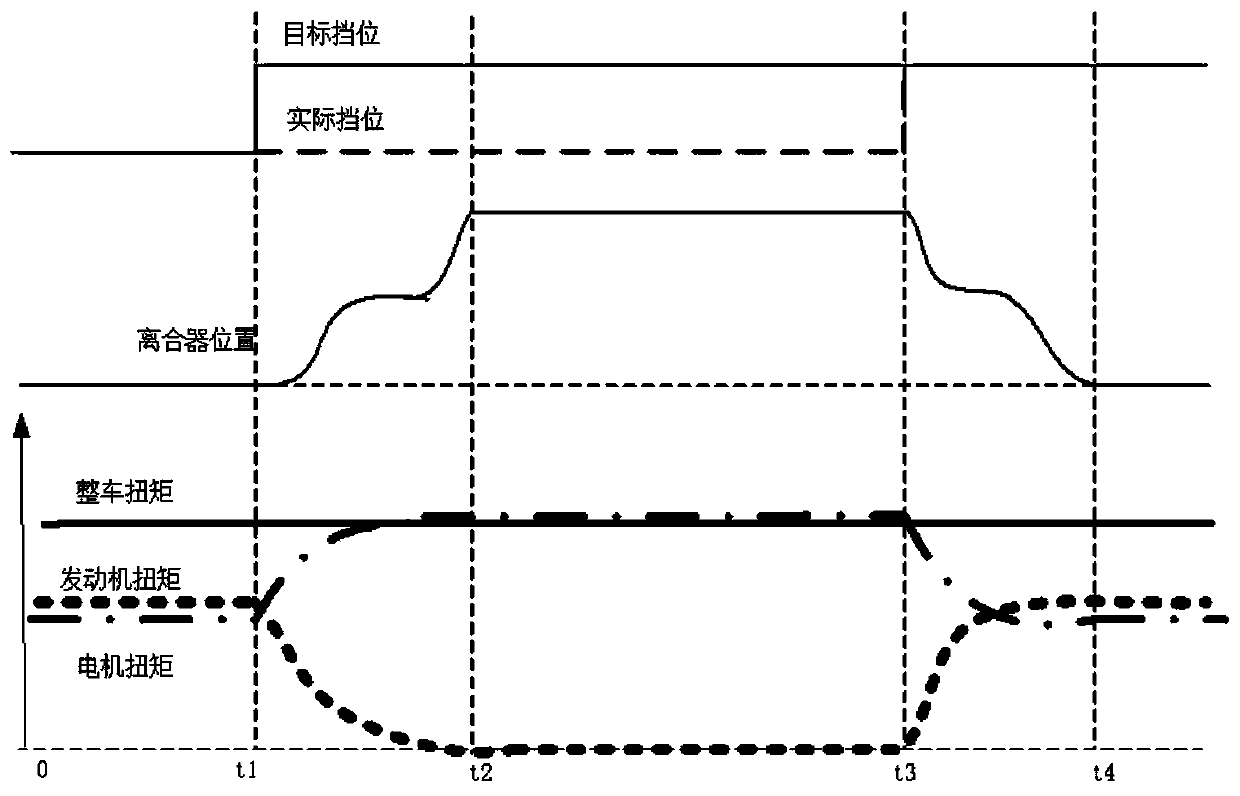

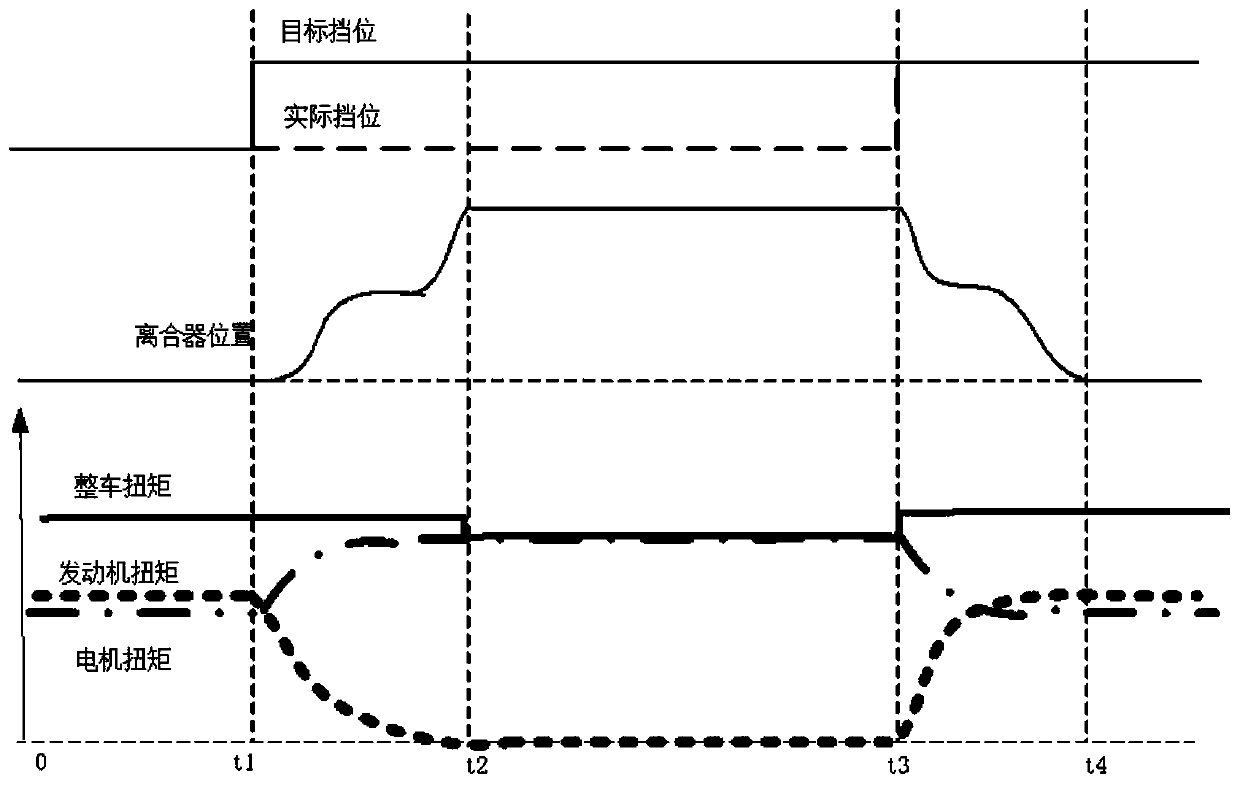

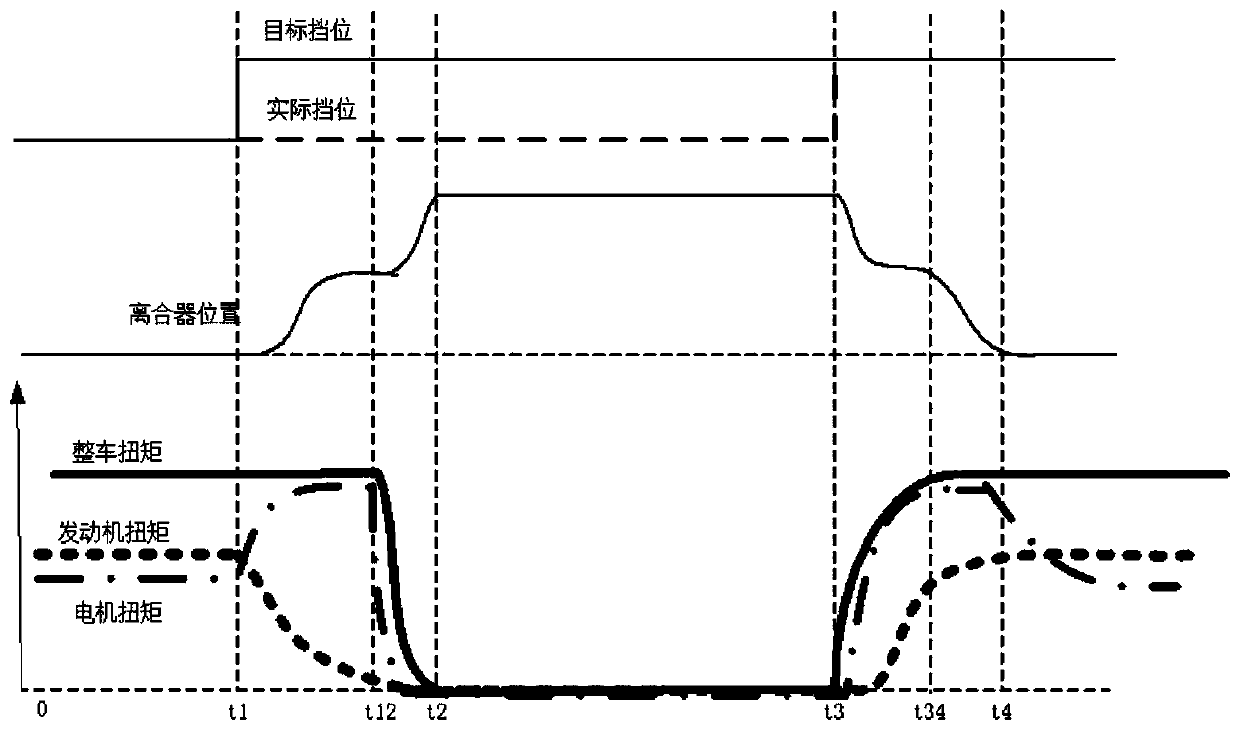

ActiveCN110171425ARealize the power compensation effectGuaranteed continuityHybrid vehiclesClutchElectric vehicle

The invention discloses a power interruption compensation control method for a hybrid electric vehicle AMT shifting process. The power interruption compensation control method comprises the followingsteps that S1, the engine output torque at any moment t is T<ecu_act>(t), the motor output torque is T<mot_act>(t), the vehicle torque is T<req_car>(t), and T<req_car>(t) = T<ecu_act>(t) + T<mot_act>(t); during t1-t2, a clutch is opened from closed, T<ecu_act>(t) is reduced, T<ecu_act>(t1) = a, T<mot_act>(t1) = b, T<req_car>(t1) = c, T<ecu_act>(t2) = 0, T<mot_act>(t2) = T<req_car>(t2), and a, b and c are engine required torque, motor required torque and vehicle required torque separately when throttle / brake signals remain unchanged; S2, during t2-t3, the clutch remains open and a gear is shifted, and T<mot_act>(t) = T<req_car>(t); and S3, during t3-t4, the clutch is closed from open, T<ecu_act>(t) is increased, T<ecu_act>(t4) = a, T<mot_act>(t4) = b, and T<req_car>(t4) = c. According to the power interruption compensation control method for the hybrid electric vehicle AMT shifting process, the interruption time of power in the vehicle shifting process is eliminated or shortened, and riding comfort of passengers is improved.

Owner:海博瑞德(北京)汽车技术有限公司

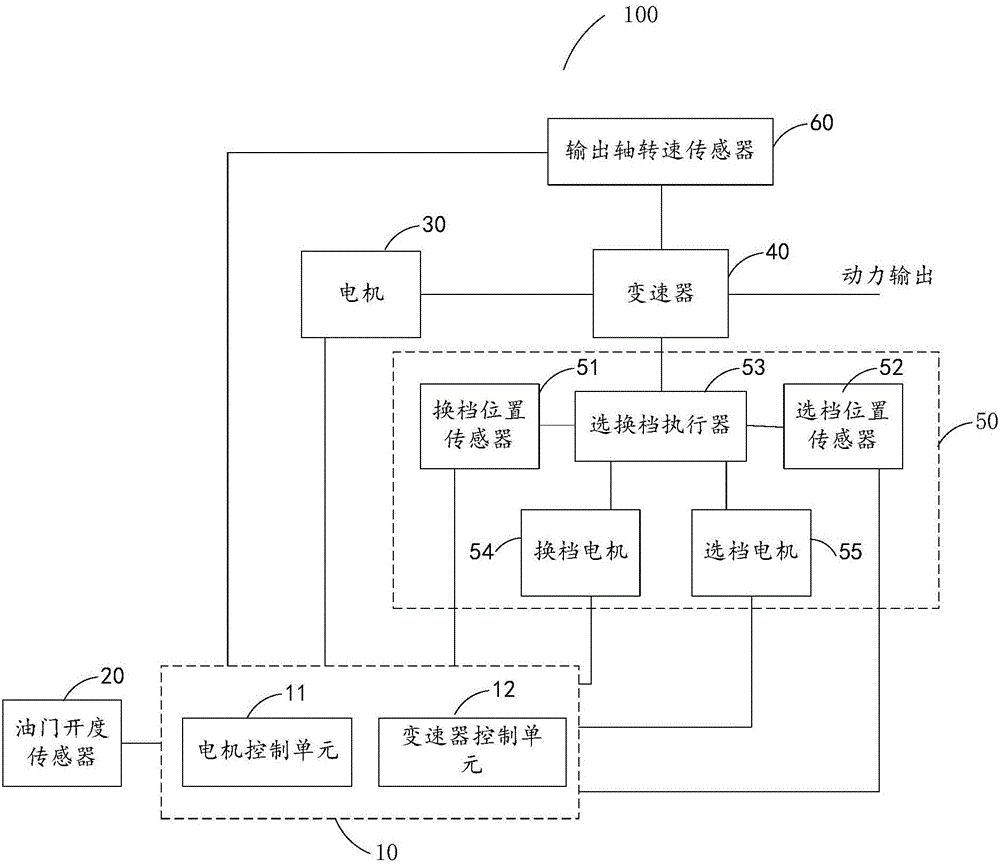

Power motor auxiliary gear-shifting control system and control method thereof

PendingCN106740856AExtended service lifeSmall shift shockDriver input parametersControl systemElectric machine

The invention discloses a power motor auxiliary gear-shifting control system and a control method thereof. The power motor auxiliary gear-shifting control system comprises a vehicle control unit, a throttle opening sensor, a motor, a transmission, a gear-selecting and gear-shifting execution device and an output shaft speed sensor, wherein the throttle opening sensor is connected with the vehicle control unit to transmit throttle opening information to the vehicle control unit, the motor is connected with the vehicle control unit and reaches a target speed according to the instruction action of the vehicle control unit after the vehicle control unit receives the throttle opening information, the gear-selecting and gear-shifting execution device is respectively connected with the vehicle control unit and the transmission and indicates gear-selecting and gear-shifting action of the transmission according to the instruction of the vehicle control unit, and the output shaft speed sensor is connected with the vehicle control unit to feed back acquired transmission output shaft speed information to the vehicle control unit. According to the power motor auxiliary gear-shifting control system and the control method thereof, gear-shifting quality can be improved, and the service life of the transmission is prolonged.

Owner:洁蓝德新能源科技有限公司

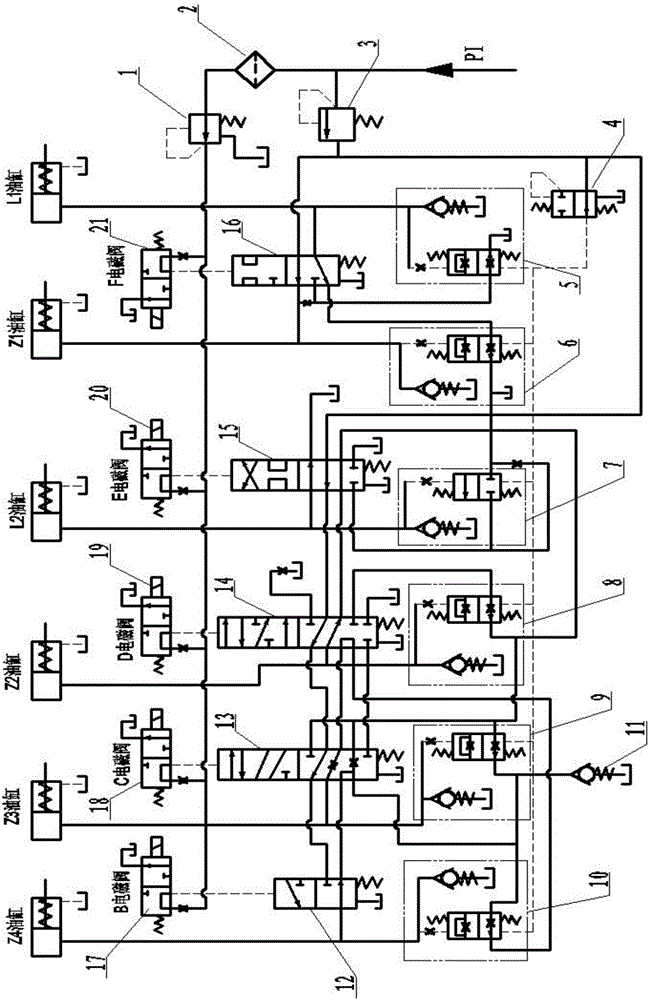

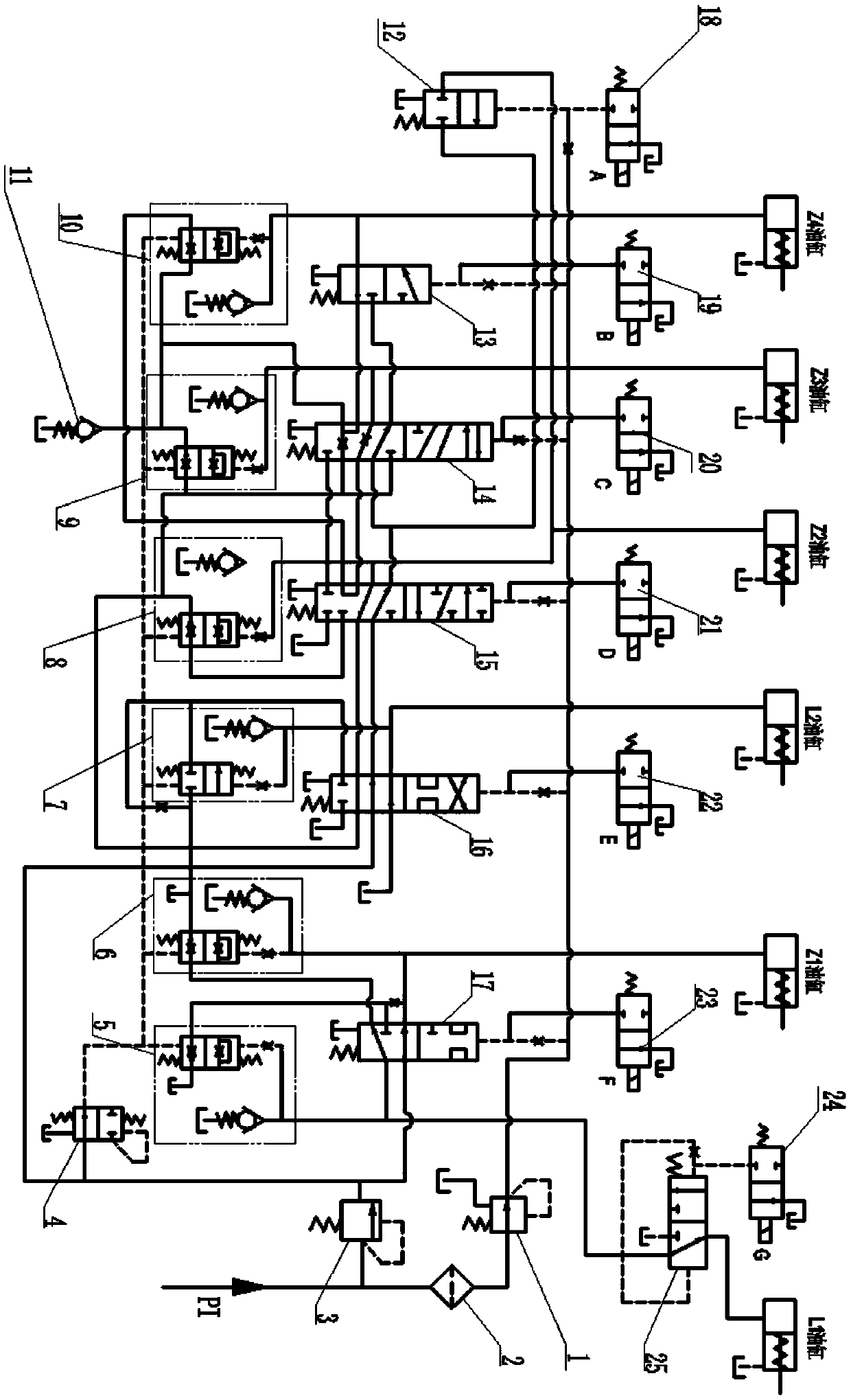

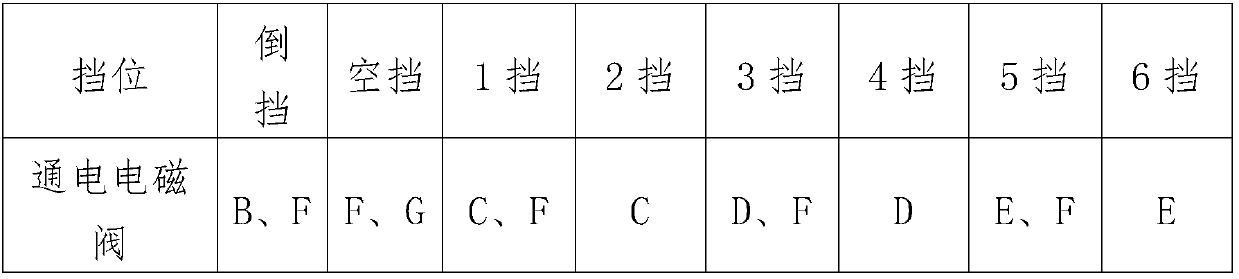

Multi-plate wet clutch oil pressure control system of hydrodynamic transmission

InactiveCN106523690ALess distracting factorsReduce power interruption timeServomotor componentsServomotorsControl systemSolenoid valve

The invention discloses a multi-plate wet clutch oil pressure control system of a hydrodynamic transmission. The multi-plate wet clutch oil pressure control system comprises a main oil way, wherein the downstream of the main oil way is divided into a servo oil way and a working oil way, the servo oil way comprises an electromagnetic pressure regulating valve, five electromagnetic valves and five reversing slide valves which are connected in series in sequence, and the working oil way comprises a priority valve, a buffer pressure regulating valve, six buffer valves and six clutch cylinders which are connected in series in sequence. According to the multi-plate wet clutch oil pressure control system, a plurality of electromagnetic valves, shift valves and buffer valves are used for performing process control over the oil pressure of a clutch, a gear locking function is added, gear shifting protection is performed by hardware, interference factors are less, and the power interruption time during gear shifting is reduced as far as possible.

Owner:贵州凯星液力传动机械有限公司

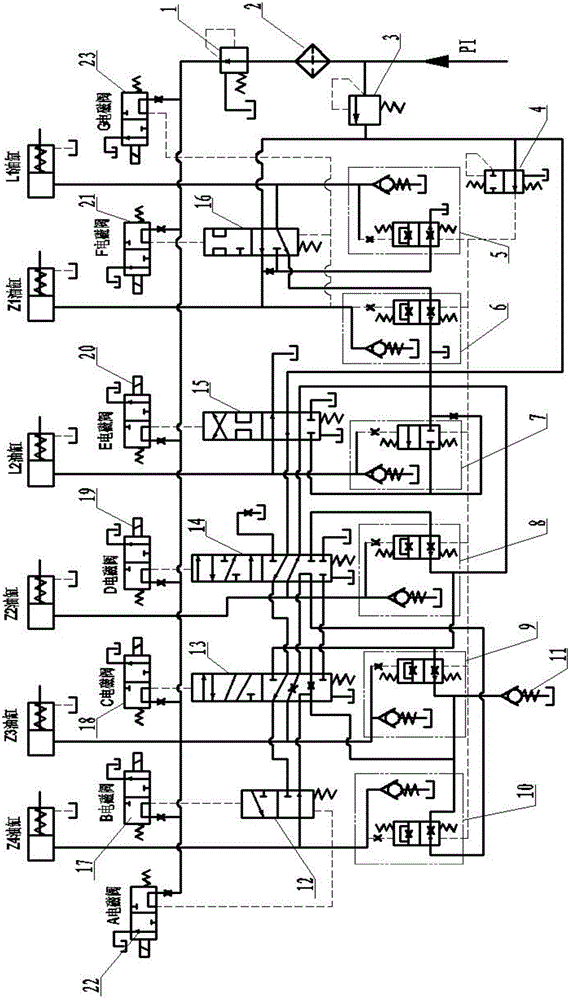

Clutch oil pressure control system for hydrodynamic transmission

InactiveCN109595271ASave assembly spaceAdd neutral brake functionClutchesServomotorsControl systemInterference factor

The invention provides a clutch oil pressure control system for a hydrodynamic transmission. The clutch oil pressure control system for the hydrodynamic transmission comprises a working system oil pressure channel PI. According to the clutch oil pressure control system for the hydrodynamic transmission, process control is carried out on a clutch oil pressure by virtue of a plurality of electromagnetic valves, reversing slide valves and buffer valves, and a neutral-position brake function is added; and the oil pressure control system carries out gearshift protection and neutral-position brake through the on-off of the electromagnetic valves, and is few in interference factors, and a power interruption time during gearshift is reduced as much as possible, so that the overall assembly space is reduced.

Owner:贵州凯星液力传动机械有限公司

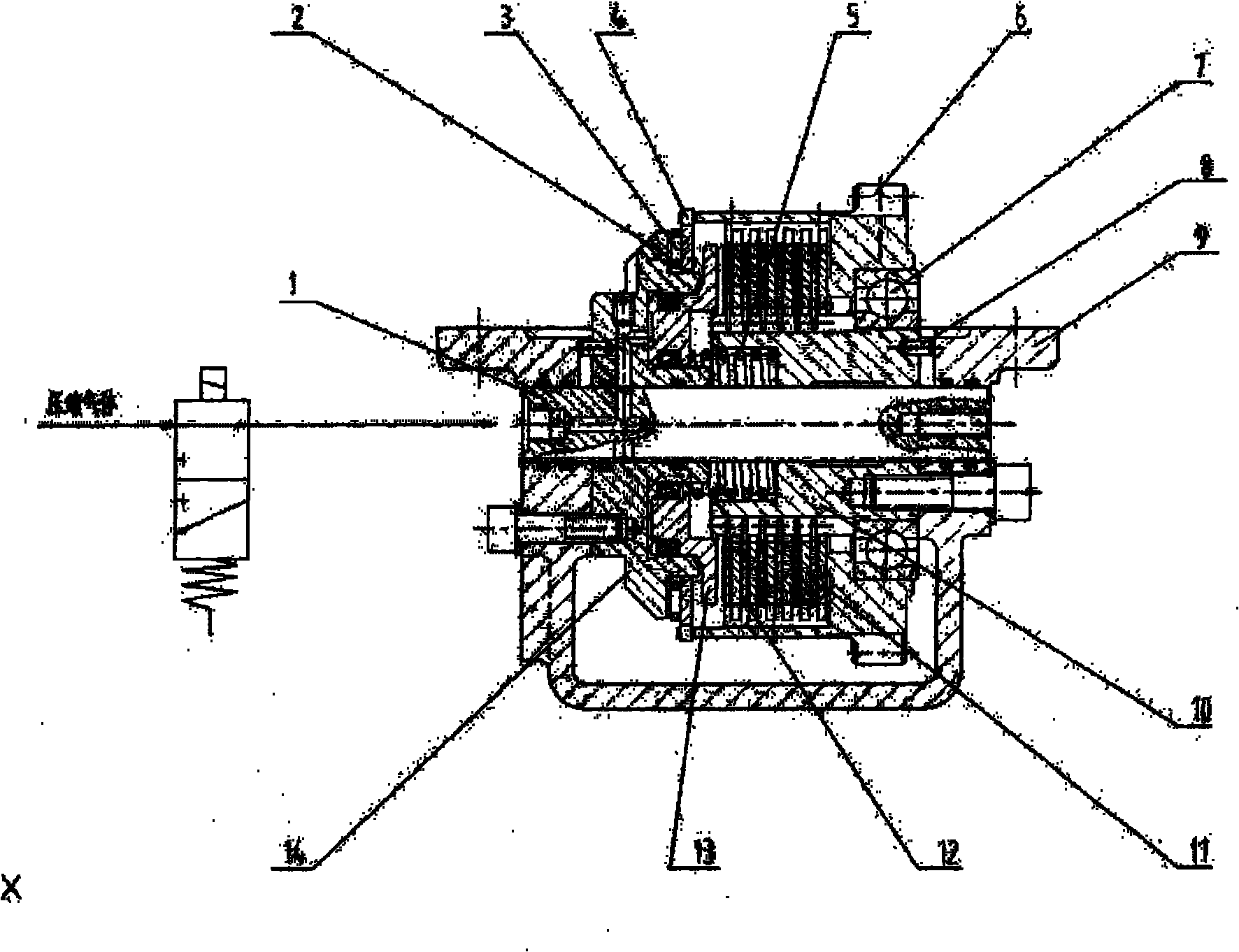

Pneumatic speed changer brake

InactiveCN101813143AReduce power lossEliminate frustrationAxially engaging brakesBrake actuating mechanismsReciprocating motionEngineering

The invention provides a pneumatic speed changer brake, which comprises a shaft, a spring, a gear, a spline shaft, a steel sheet, a friction plate, a piston, a cylinder and an air path. The piston which does reciprocating motion along the shaft and the spline shaft sleeved on the shaft are arranged in the cylinder; the spring is arranged between the piston and the spline shaft; the steel sheet and the friction plate are arranged on the two sides of the spline shaft; the steel sheet is connected with the gear through the spline shaft; the friction plate is connected with the spline shaft through a spline; and the air path is arranged at the end of the shaft and connected with the piston and the cylinder. When the speed changer is shifted up, the brake can quickly reduce the rotation speed of the shaft and related parts of the speed changer, shorten the synchronization time and improve the gear shift performance.

Owner:SHAANXI FAST GEAR CO

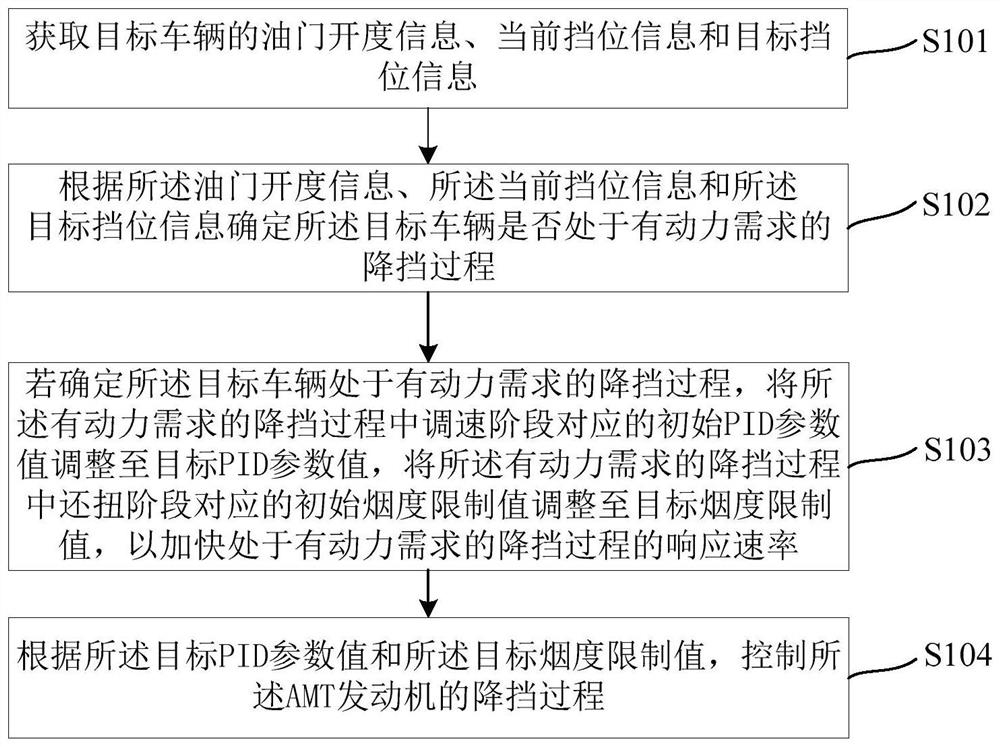

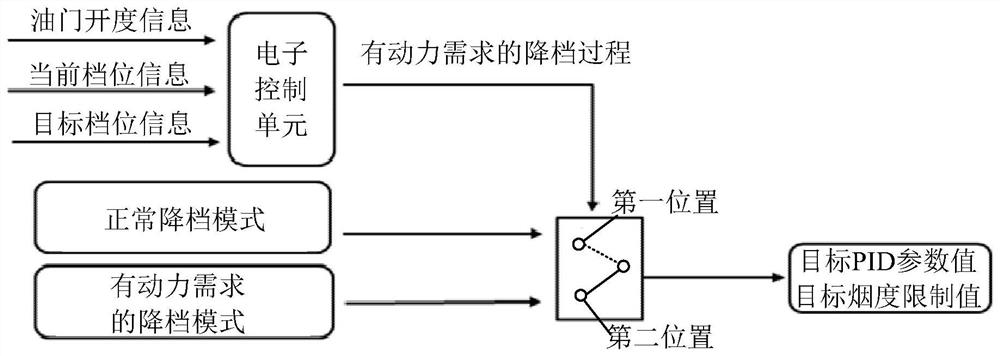

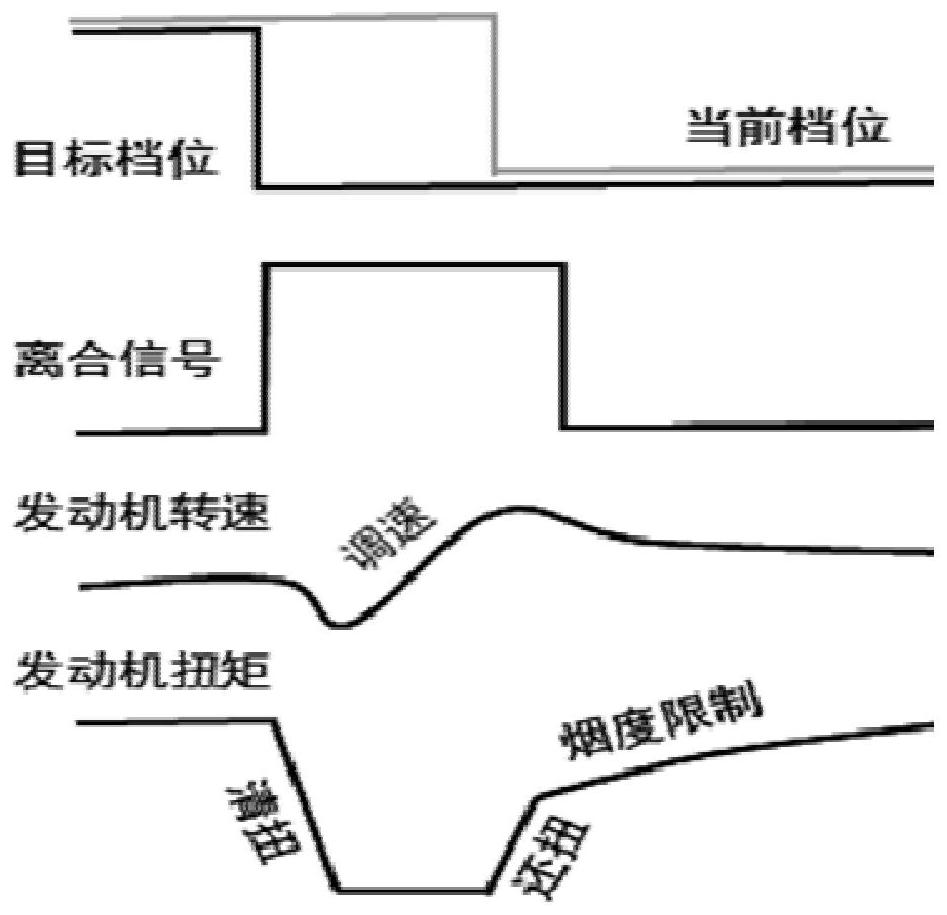

Gear shifting control method and device for AMT engine

ActiveCN114251446AImprove response rateReduce power interruption timeInternal combustion piston enginesGearing controlOvertakingControl theory

The invention discloses a gear shifting control method and device for an AMT engine. The gear shifting control method comprises the steps that accelerator opening degree information, current gear information and target gear information of a target vehicle are obtained; according to the accelerator opening degree information, the current gear information and the target gear information, whether the target vehicle is in the downshift process with the power requirement or not is determined; if it is determined that the target vehicle is in the downshift process with the power demand, the initial PID parameter value corresponding to the speed regulation stage in the downshift process with the power demand is adjusted to the target PID parameter value, and the initial smoke intensity limit value corresponding to the torque returning stage in the downshift process with the power demand is adjusted to the target smoke intensity limit value; the response rate of the downshift process with the power requirement is increased; and according to the target PID parameter value and the target smoke intensity limit value, the downshift process of the AMT engine is controlled. According to the scheme, the response rate of the downshift process with the power requirement is increased, and the dynamic property and safety of the target vehicle during heavy-load climbing or rapid overtaking are guaranteed.

Owner:WEICHAI POWER CO LTD

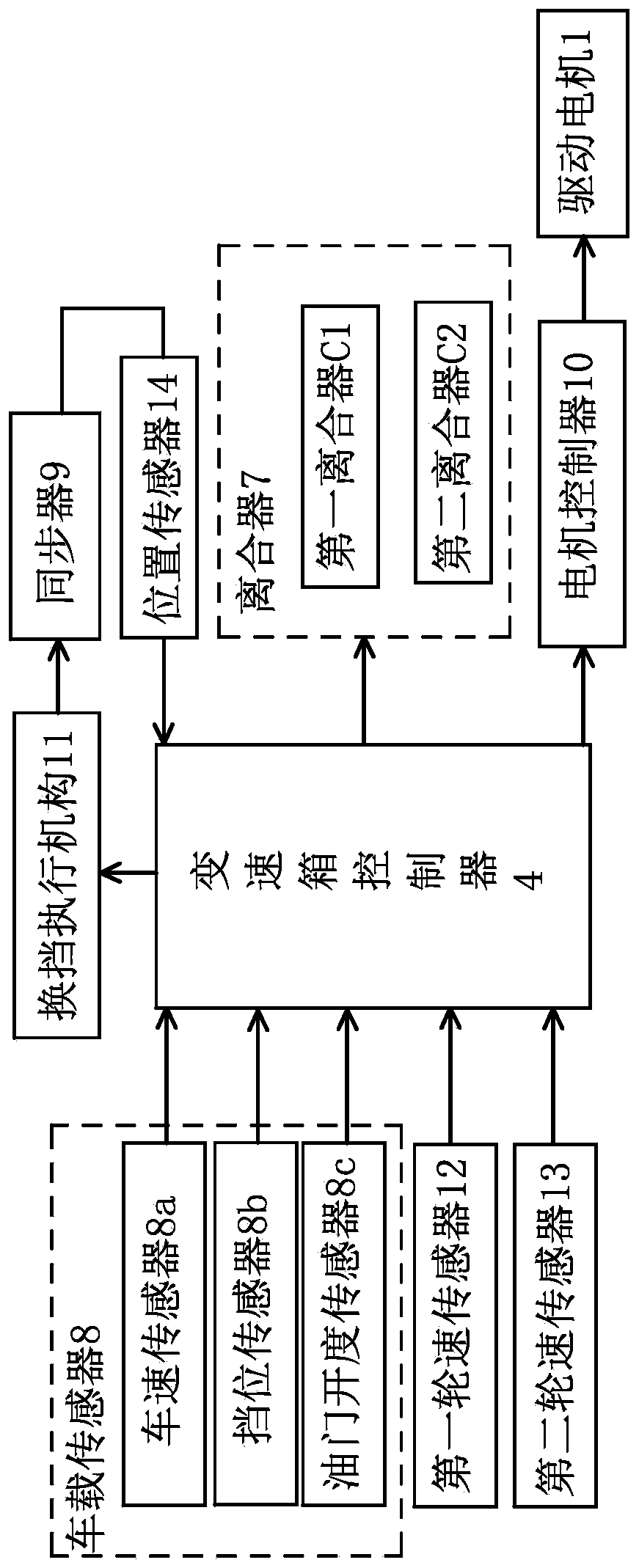

Control method and device for gear shift of hybrid power system, and vehicle-mounted device

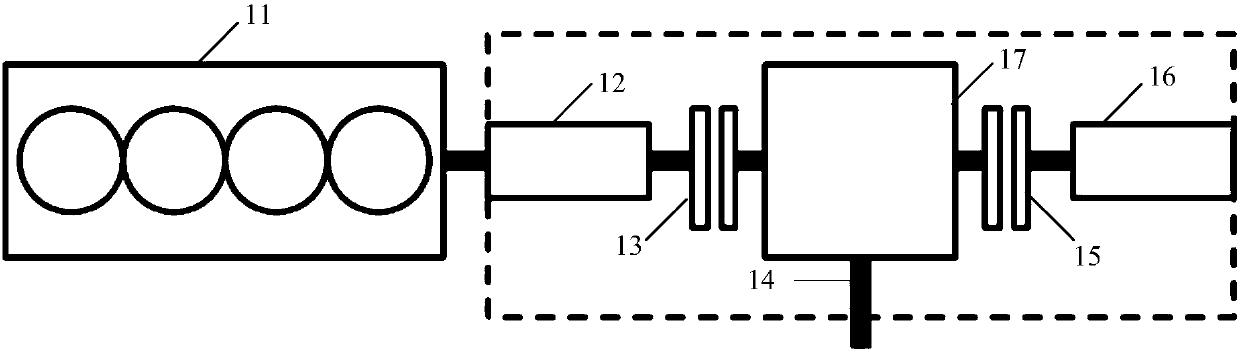

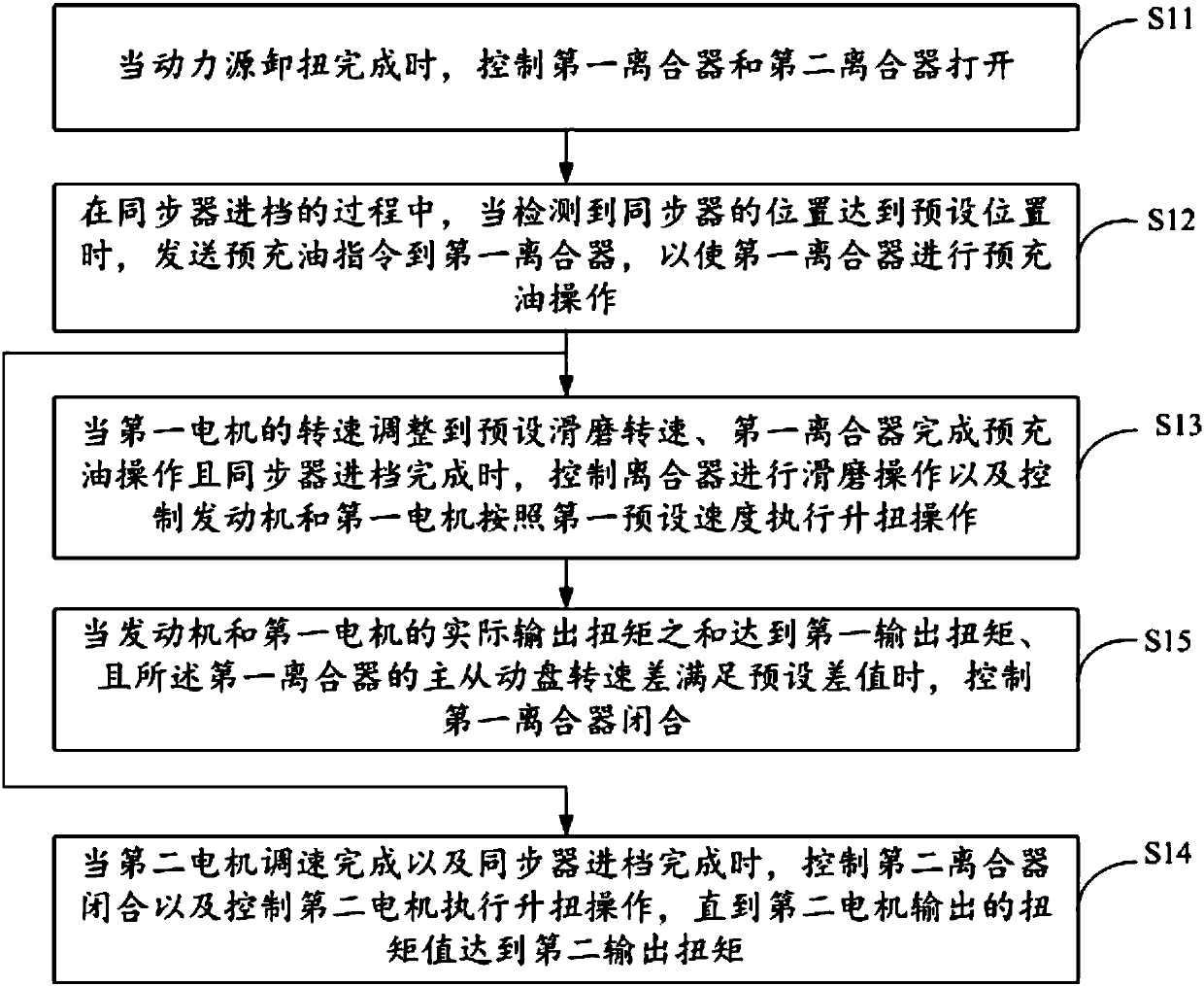

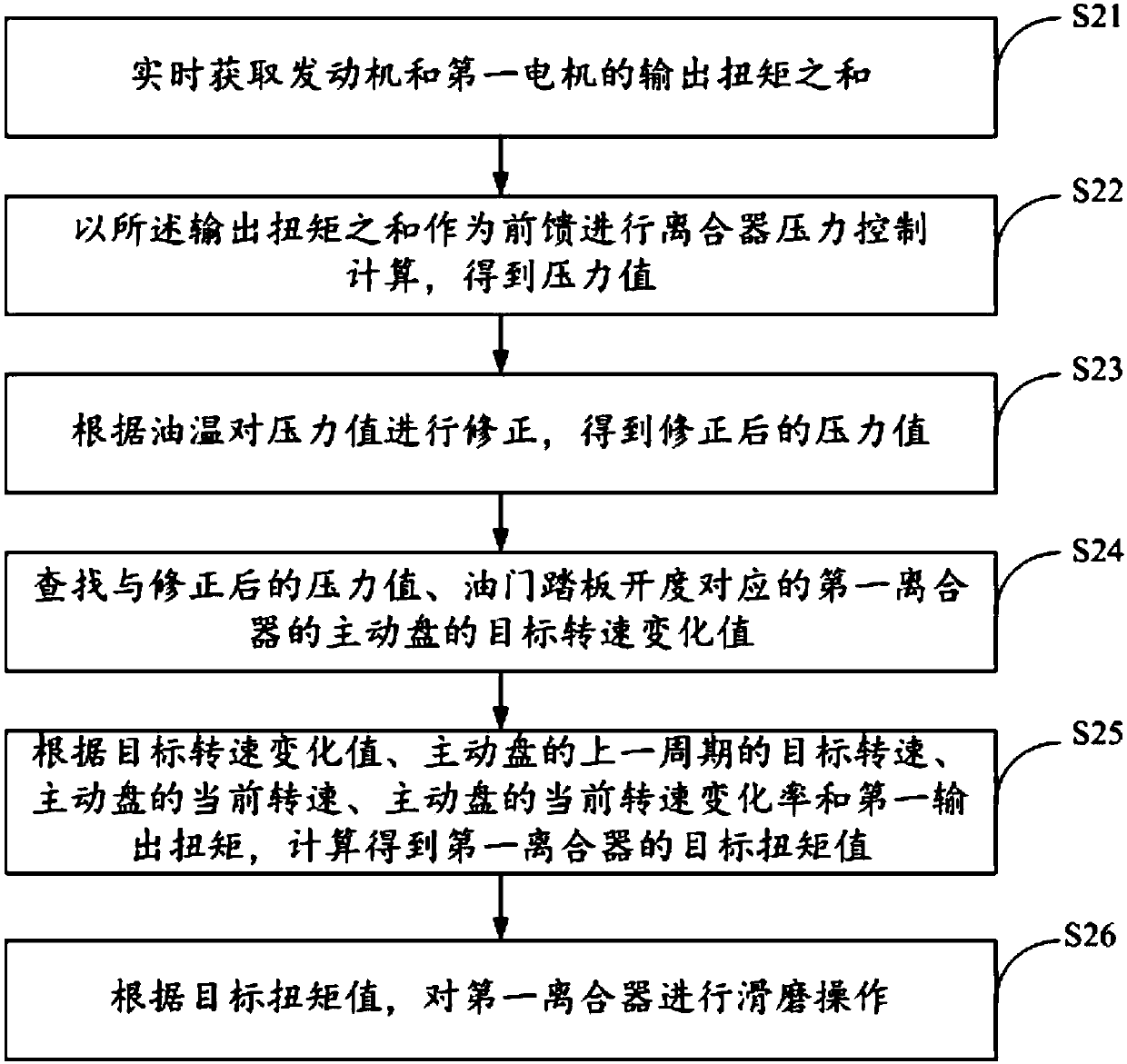

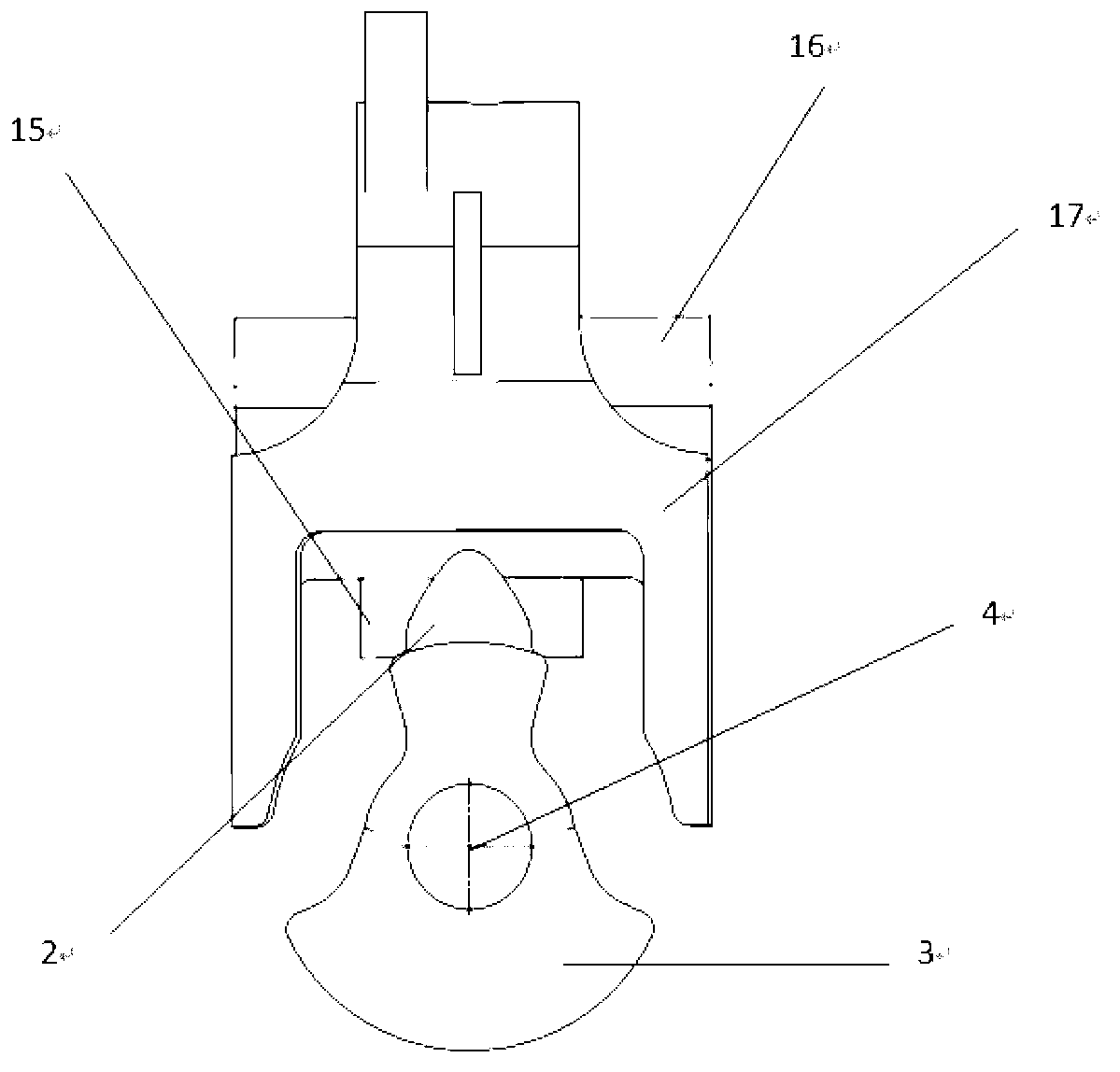

ActiveCN109703545AImprove experienceReduce power interruption timeHybrid vehiclesElectric machineEngineering

The invention provides a control method and device for gear shift of a hybrid power system, and a vehicle-mounted device. Before a synchronizer moves up a gear and a first clutch is closed, an engineand a first motor are controlled to conduct lifting and twisting and sliding friction of the clutch based on a first preset speed. At that time, power can be output, and power-interrupting time can bereduced, and user experience can be improved.

Owner:SAIC MOTOR

Shift control mechanism of transmission

InactiveCN103062385AImplement Shift InterlockDoes not affect the push-in functionGearing controlService efficiencyCam

The invention relates to a shift control mechanism of a transmission. The shift control mechanism comprises a first shift lever, a second shift lever, a third shift lever and a fourth shift lever, wherein a first shift fork and a first shift drive fork are matched on the upper portion of the first shift lever, a second shift fork and a second shift drive fork are matched on the lower portion of the second shift lever, the lower portions of the third shift lever and the fourth shift lever are matched with a third shift drive fork respectively, and a third shift fork is matched on the upper portion of the fourth shift lever. The shift control mechanism is characterized in that a shift block is composed of a shift finger and a shift cam, a mounting hole is arranged at the center of the shift cam, a shift shaft is perpendicular to the fourth shift lever and matched with the mounting hole on the shift cam, and the shift finger is positioned between inner sides of the first shift fork, the second shift fork and the third shift fork. The shift control mechanism is simple in structure, and capable of achieving shift interlocking and gear selection before dislocating, reducing shift time, and improving safety and service efficiency of the transmission.

Owner:CHONGQING TSINGSHAN IND

Control method and system for shockless shifting of electric drive mechanical transmission without synchronizer

The invention relates to an impact-free gear shift control method and system for an electrically driven mechanical transmission without a synchronizer. The electrically driven mechanical transmission is provided with no synchronizer; a drive motor and the electrically driven mechanical transmission are directly coupled, and a clutch between the drive motor and the electrically driven mechanical transmission is omitted. An automobile controller determines the target gear and sends a gear shift instruction to a system coordinating controller; the system coordinating controller coordinates the working sequence and working mode of a dual target tracking controller and a rule-based controller, so that the drive motor and the electrically driven mechanical transmission are in coordinated fit to achieve gear shift; and by accurately controlling a motor rotor, a target joint gear ring accurately tracks rotation of a joint sleeve in the joint process, the requirements for zero rotation speed difference and zero rotation corner difference are met, and impact-free gear shift control is achieved. The method and system can eliminate collision between the joint sleeve and the joint gear ring in the joint process, then gear shift impact is restrained, and the power failure duration is shortened.

Owner:TSINGHUA UNIV

A control method, device and system for vehicle energy recovery

The invention discloses a control method, device and system for automobile energy recovery, and belongs to the technical field of automobiles. The method comprises the following processes of judging whether a gearbox completely executes the operations of upshifting and downshifting or not, if yes, controlling a motor to enter an electricity generation state, converting the kinetic energy of the motor and the kinetic energy of the gearbox into electric energy, and storing the electric energy in batteries for standby application; and monitoring whether the synchronous rotational speed difference of the gearbox is in a preset range or not, if yes, stopping electricity generation and controlling the gearbox to execute the operation of putting in gear, else, and performing synchronous speed adjustment on a primary power source so as to enable the synchronous rotational speed difference to reach the preset range and enable the batteries to recover the electric energy produced by the motor, wherein the primary power source is the motor. Through the adoption of the control method, device and system disclosed by the invention, energy produced in the upshifting process of the gearbox is stored and used as the electric energy required for upshifting after the completion of gear shifting, so that the efficiency can be improved, and the energy consumption can be reduced.

Owner:广东戈兰玛汽车系统有限公司

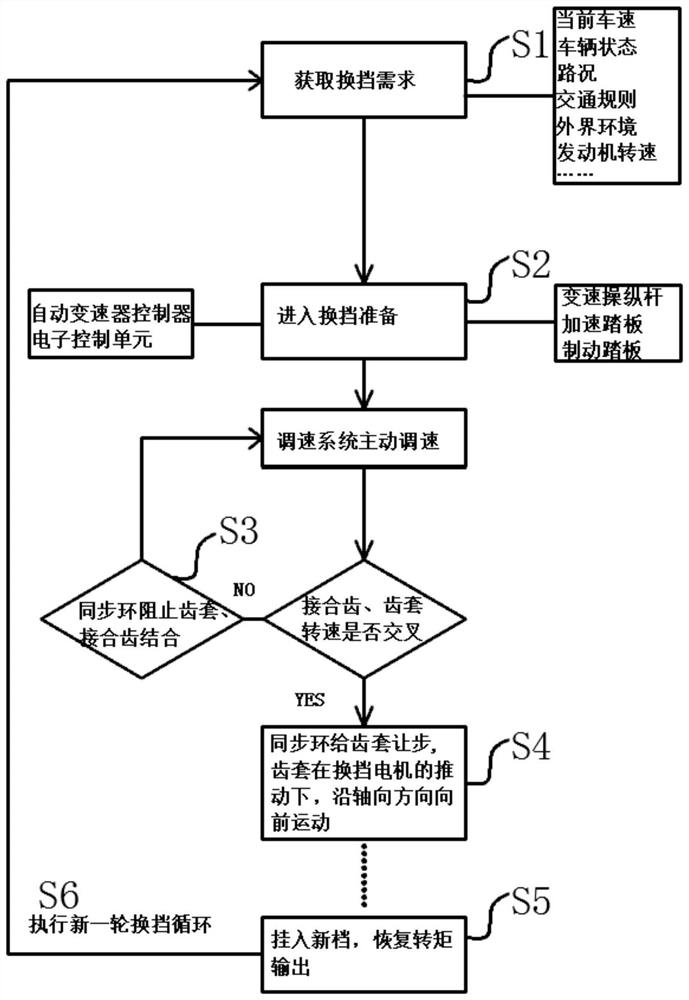

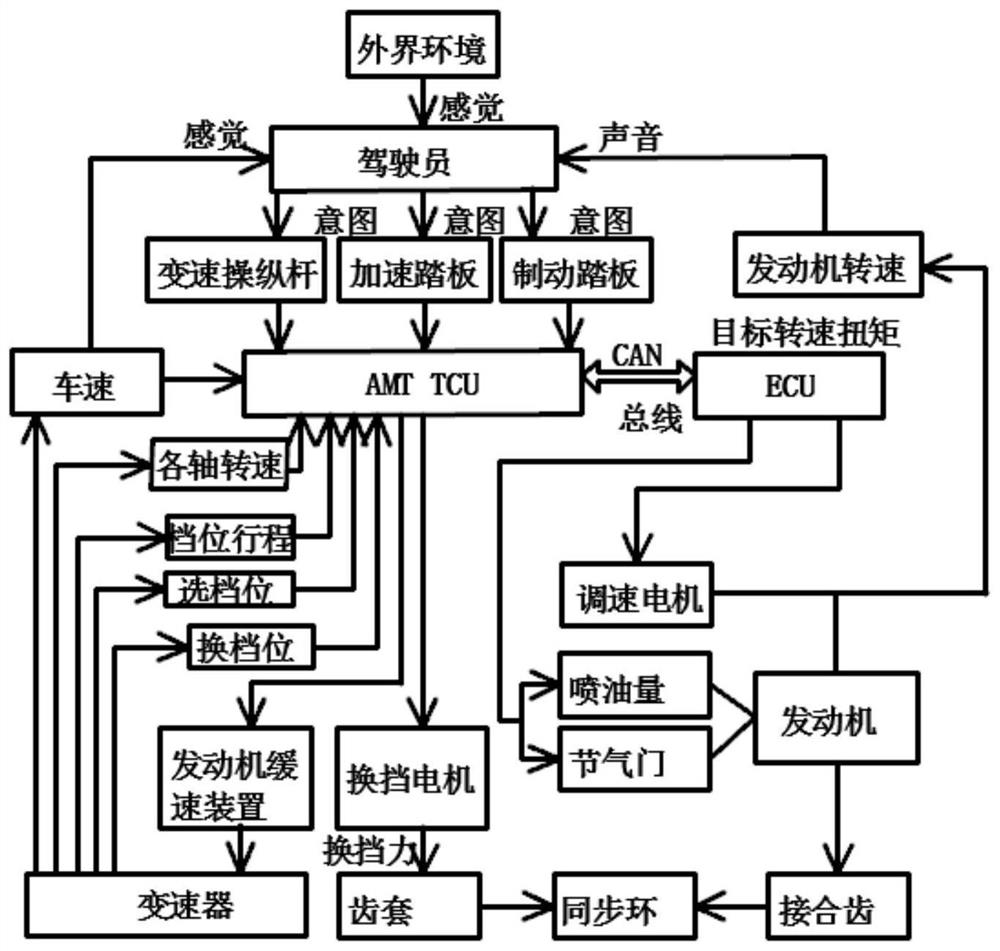

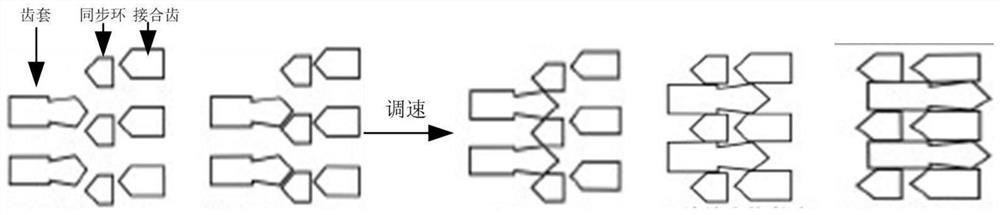

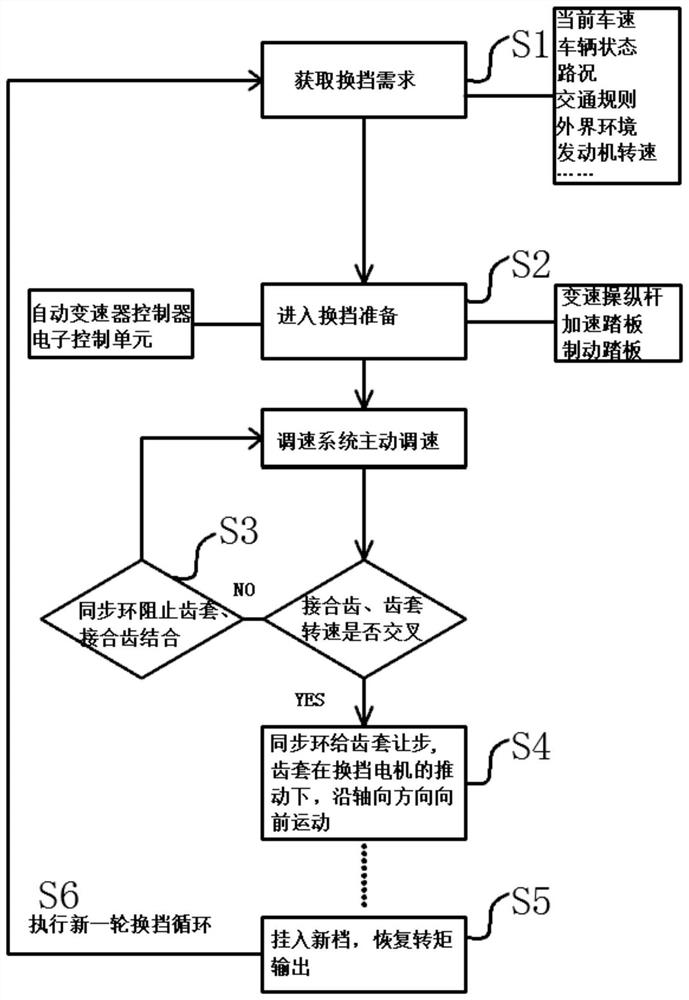

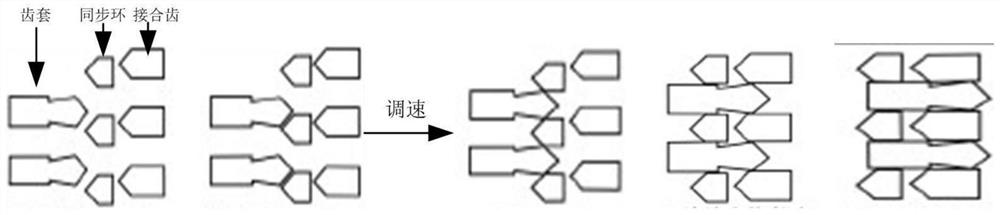

Clutch-free synchronous gear shifting control method and system of hybrid power system

The invention discloses a clutch-free synchronous gear shifting control method and system of a hybrid power system. The method comprises the following steps: S1, obtaining gear shifting requirements,S2, entering shift preparation, S3, when the rotating speeds are different, protecting a synchronous ring, under the action of a gear shifting motor, allowing a gear sleeve to move forwards, wherein when the gear sleeve makes contact with the synchronous ring, due to the fact that the rotating speed w1 of joint teeth is different from the rotating speed w2 of the gear sleeve, the synchronous ringbears friction torque of the joint teeth and shifting ring torque of the gear sleeve, the friction torque is larger than the shifting ring torque, and the gear sleeve cannot drive the synchronous ringto move and cannot penetrate through the synchronous ring to be combined with the joint teeth; S4, performing gear shifting after speed regulation; S5, engaging a new gear, recovering torque output,and S6, executing a new gear shifting cycle. The clutch-free synchronous gear shifting control system of the hybrid power system comprises an execution unit, an automatic transmission controller, a gear shifting motor, the hybrid power system and the synchronous ring, a clutch is prevented from being adopted during gear shifting, the cost is reduced, and the power interruption time is shortened.

Owner:江苏新能源汽车研究院有限公司

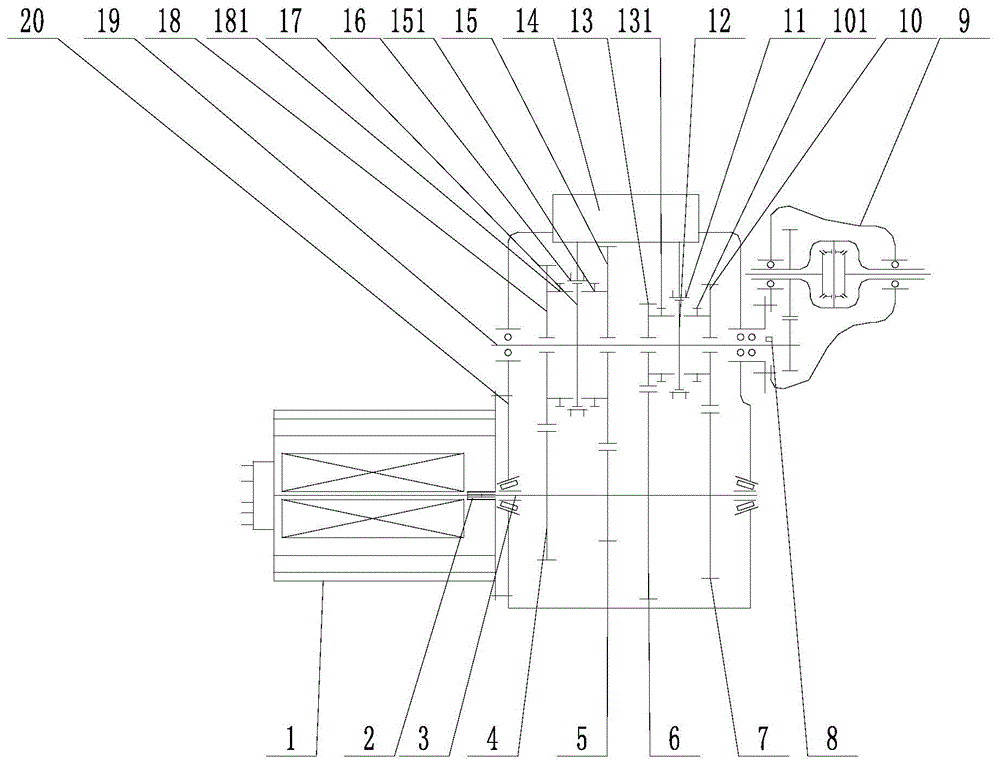

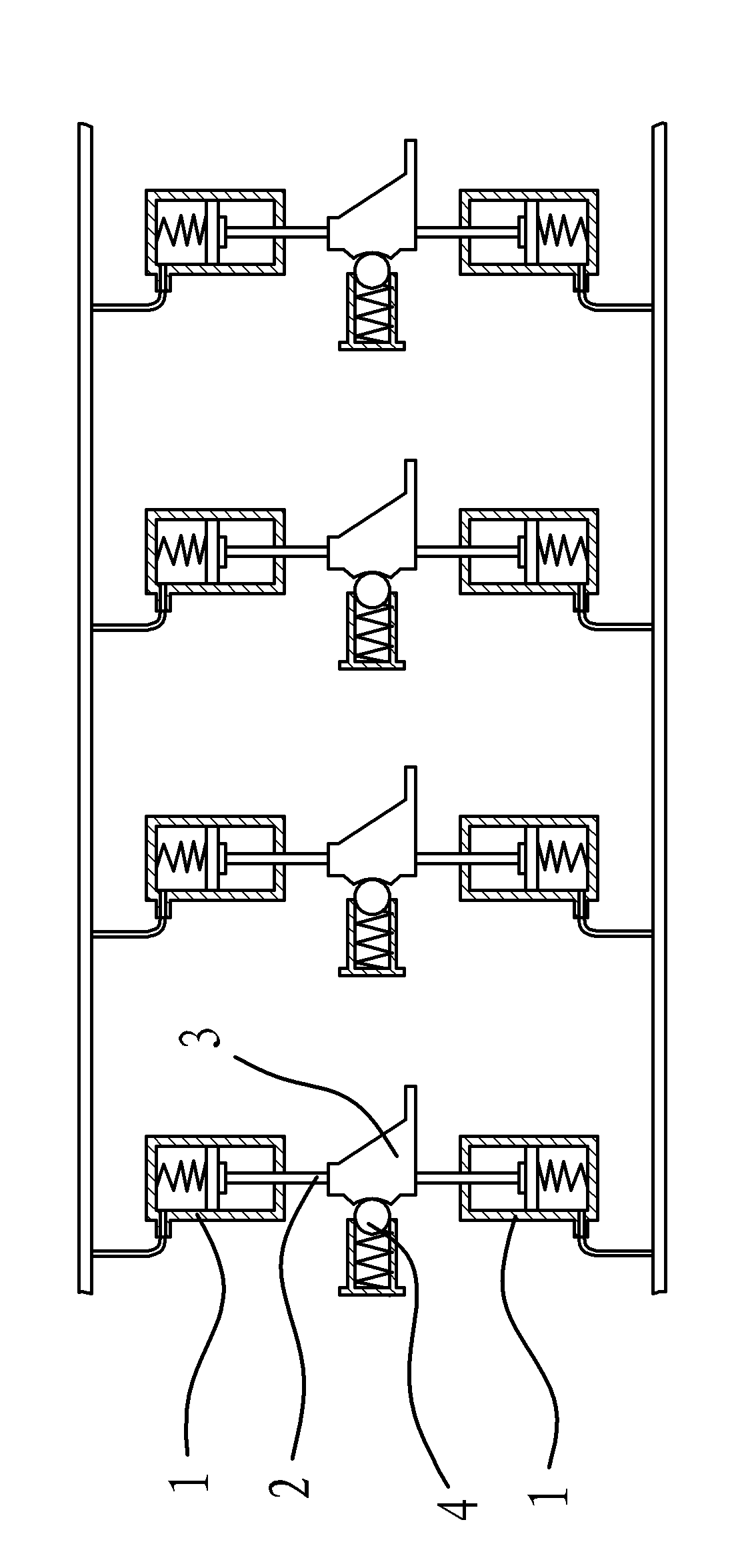

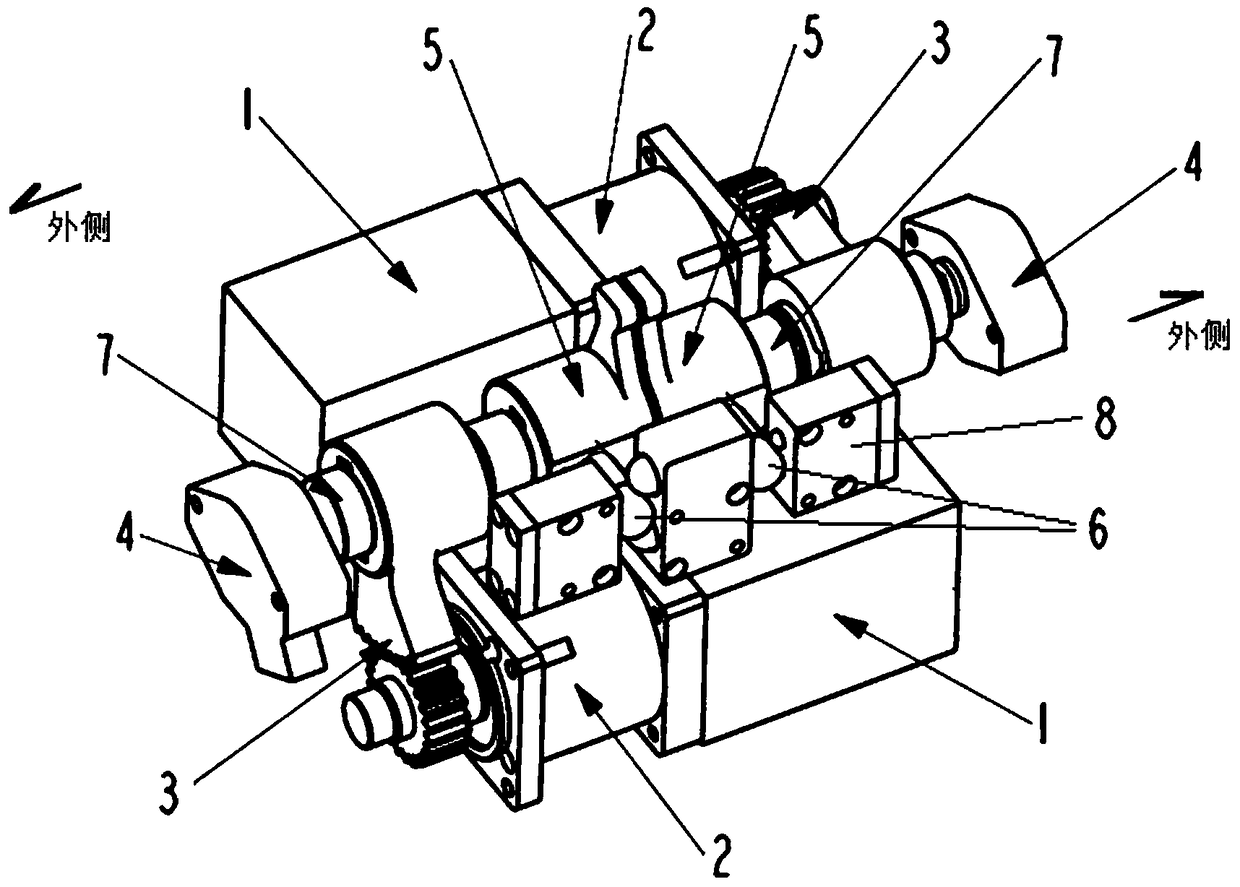

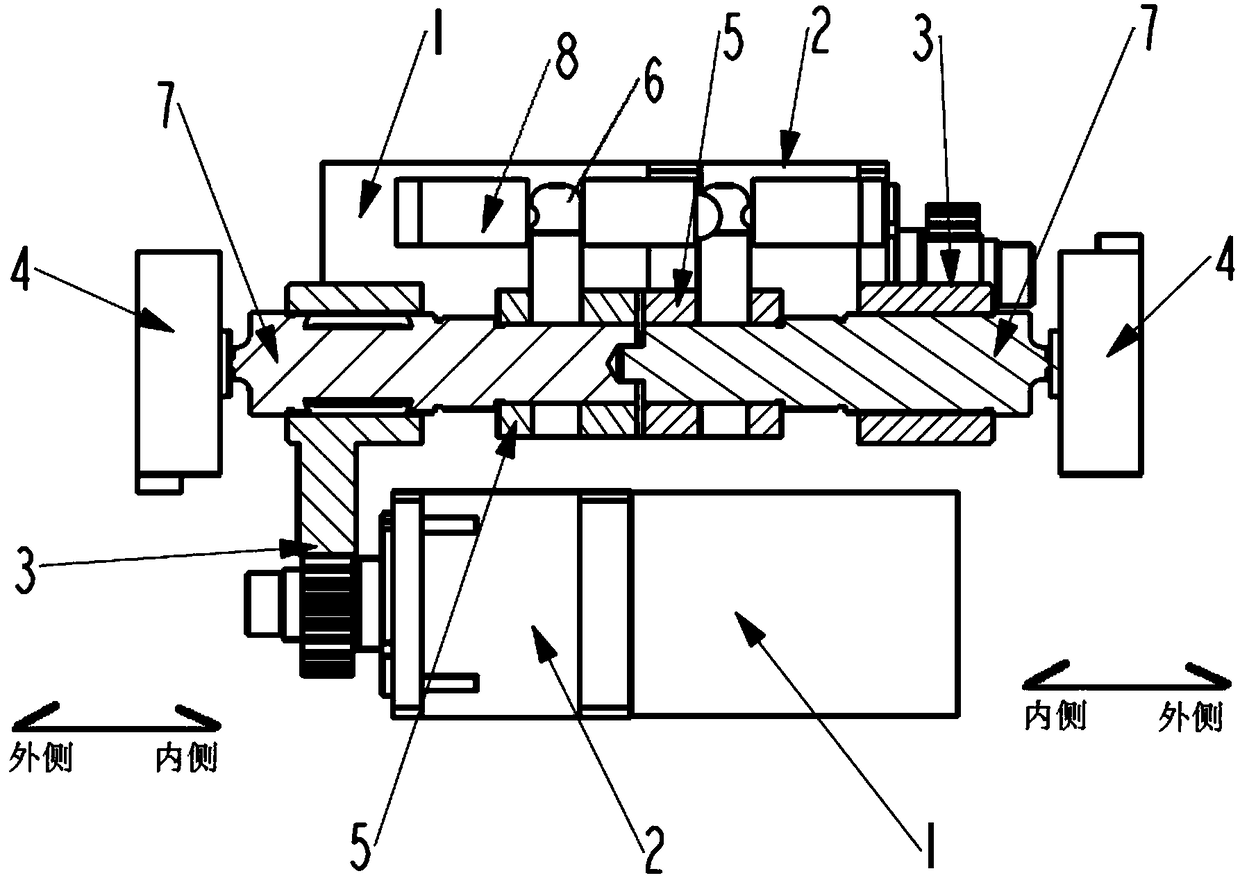

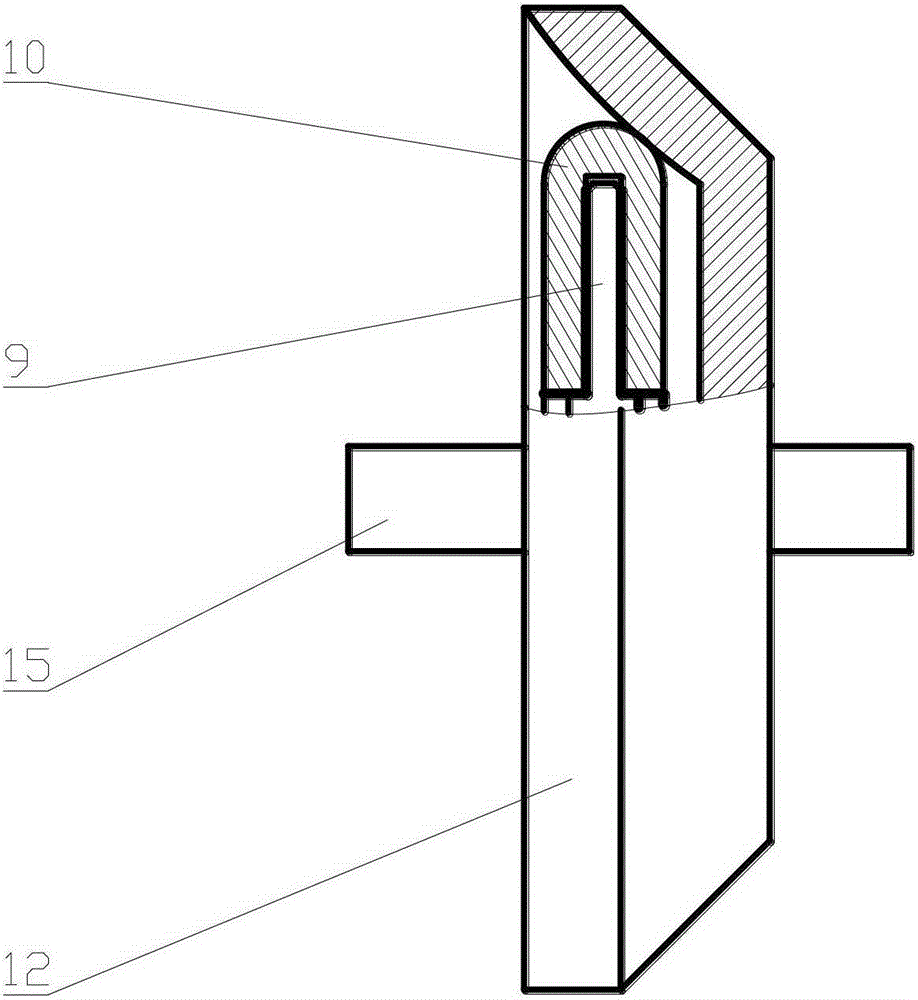

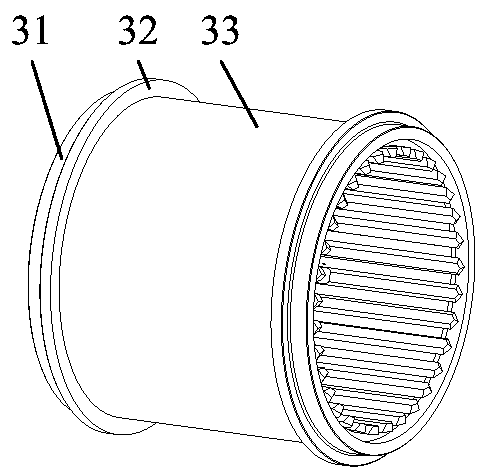

Double-gear-shifting motor executing mechanism for mechanical automatic transmission

The invention discloses a double-gear-shifting motor executing mechanism for a mechanical automatic transmission in the field of vehicle transmission device components. The double-gear-shifting motorexecuting mechanism comprises two independent executing mechanisms which are rotationally connected through gear shifting rotation shafts in the independent executing mechanisms, and the axes of the two gear shifting rotation shafts are collinear. The outer end faces of the gear shifting rotation shafts are connected with angle sensors. The inner and outer half sides of the gear shifting rotationshafts are in rigidity connection with stirring finger bases and gear transmission devices correspondingly. The gear transmission devices are connected with one ends of planet gear speed reducers through straight gears, the other ends of the planet gear speed reducers are connected with coaxial gear shifting motors, and each stirring finger base is externally fixedly connected with a gear shiftingstirring finger. According to the double-gear-shifting motor executing mechanism, the component utilization rate is improved, and the cost is effectively controlled; and double-motor coordinated control is adopted, the power interruption time in the gear shifting process is further shortened, and the gear shifting quality is improved.

Owner:TSINGHUA UNIV +1

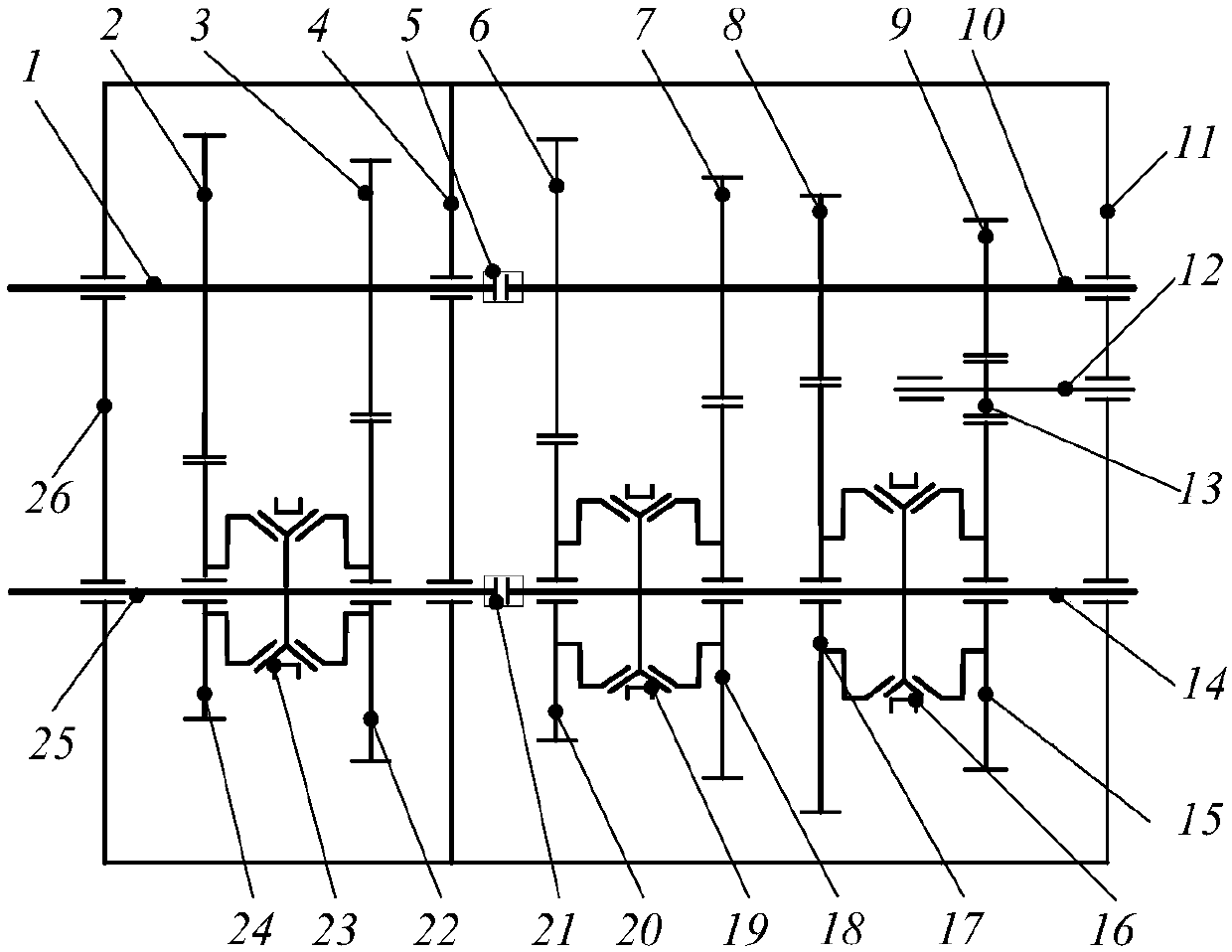

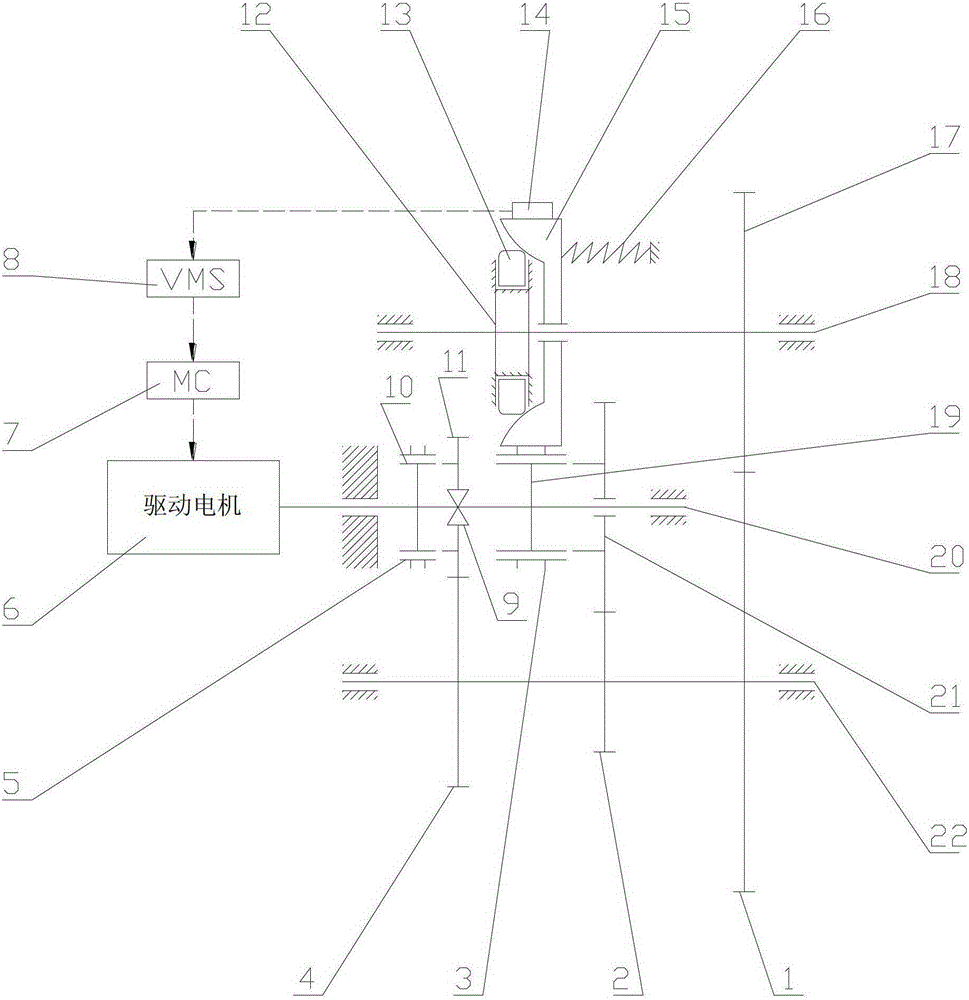

Mechanical automatic transmission speed change system

PendingCN108180261AReduce power interruption timeImprove shift qualityToothed gearingsTransmission elementsVariatorEngineering

The invention relates to a mechanical automatic transmission speed change system. The mechanical automatic transmission speed change system is composed of a box body, an input shaft, an output shaft,a reverse gear shaft, driving toothed wheels of various gears, driven toothed wheels of various gears, a reverse gear intermediate toothed wheel, and a plurality of synchronizers. The box body is divided into a left box body and a right box body, a supporting body is arranged between the left box body and the right box body, and the box body is formed by connecting and assembling the left box body, the right box body and the supporting body through bolts or screws; the input shaft is formed by connecting a first input shaft with a second input shaft through a flexible coupling; a transmissiongear driving toothed wheel is machined on the input shaft or fixedly installed on the input shaft through a spline; the output shaft is formed by connecting a first output shaft and a second output shaft through a flexible coupling; the multiple non-adjacent gear synchronizers are fixedly installed on the output shaft through splines, and the two sides of each non-adjacent gear synchronizer are loosely sleeved with the driven toothed wheels of the corresponding gears through bearings; and the reverse gear shaft is sleeved with the reverse gear intermediate toothed wheel. Through the mechanicalautomatic transmission speed change system, the gear shifting time of a mechanical automatic transmission can be shortened advantageously, and the gear shifting quality is improved.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

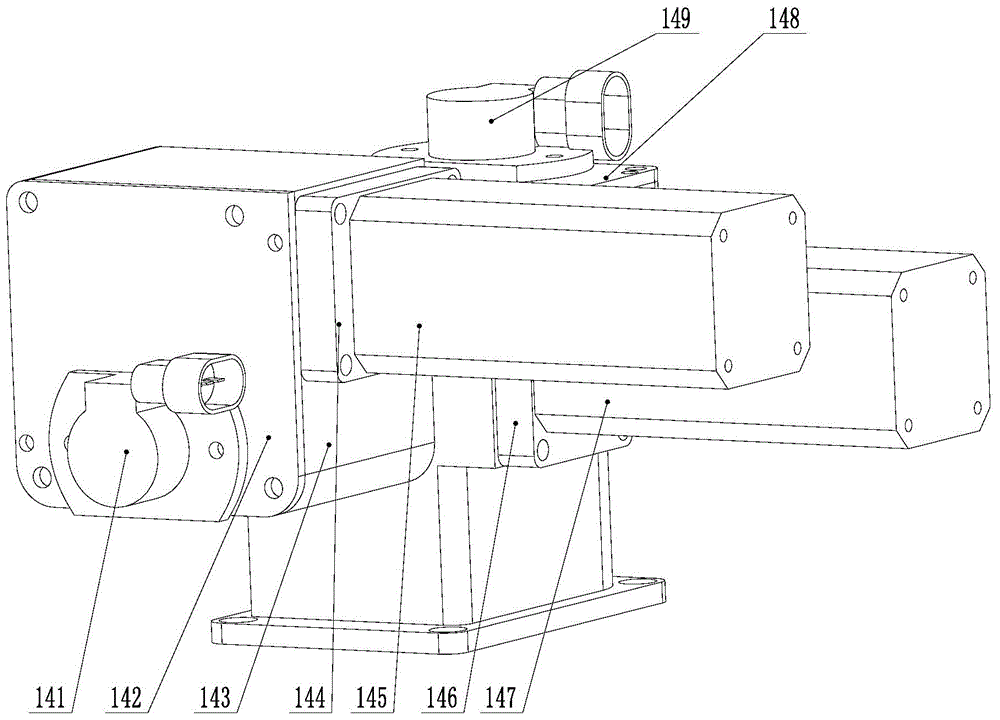

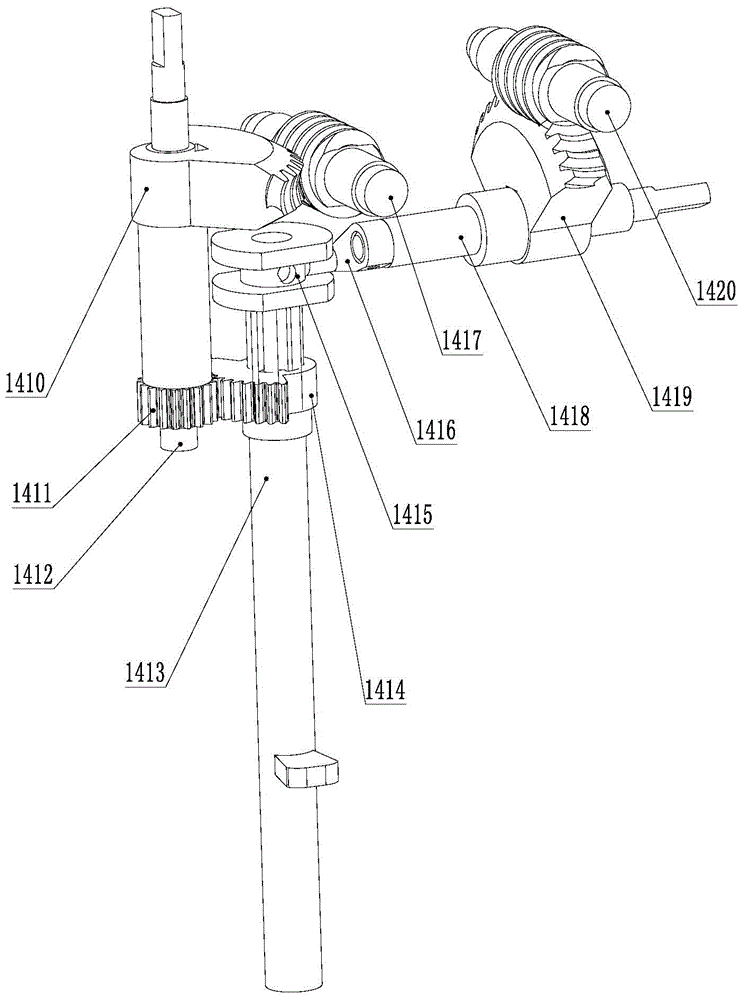

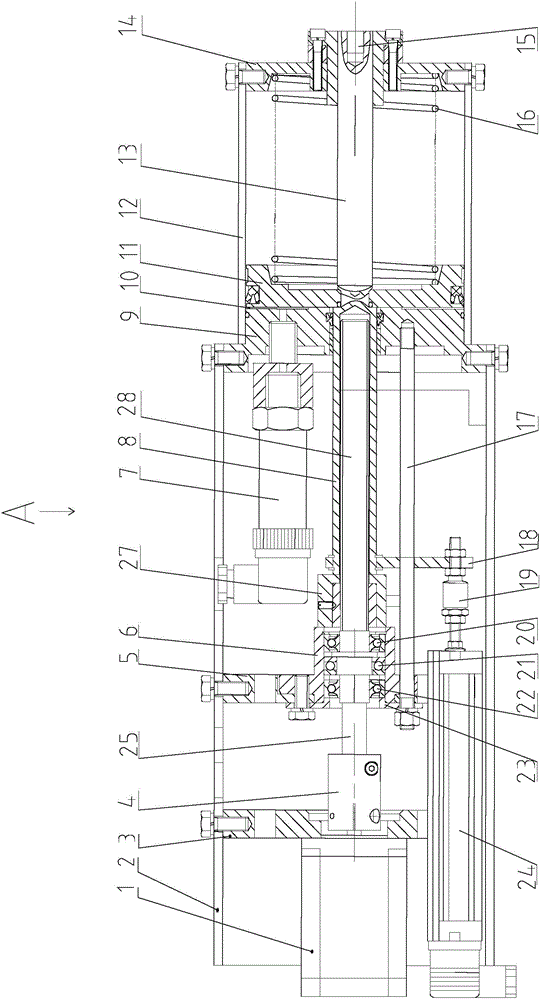

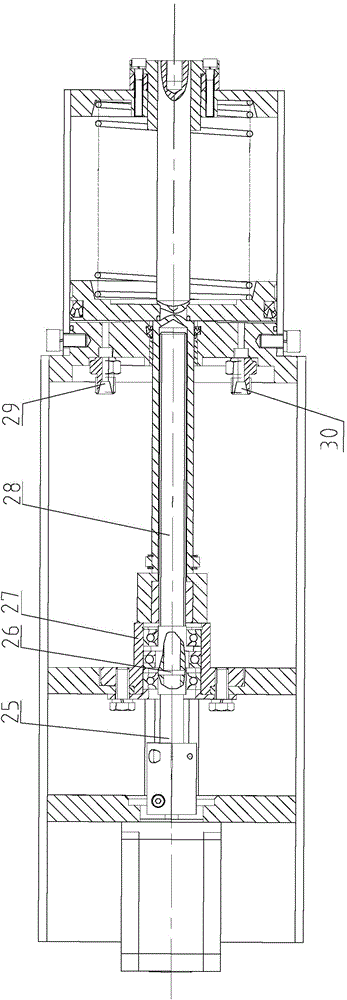

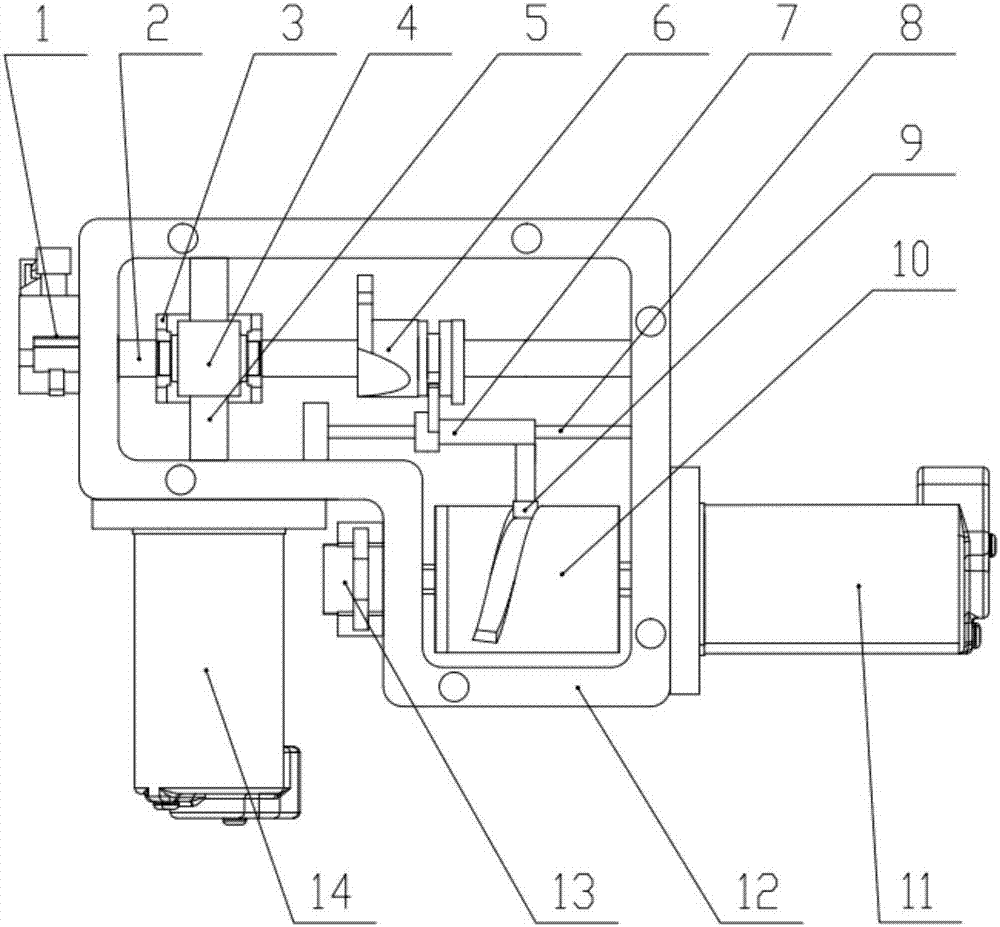

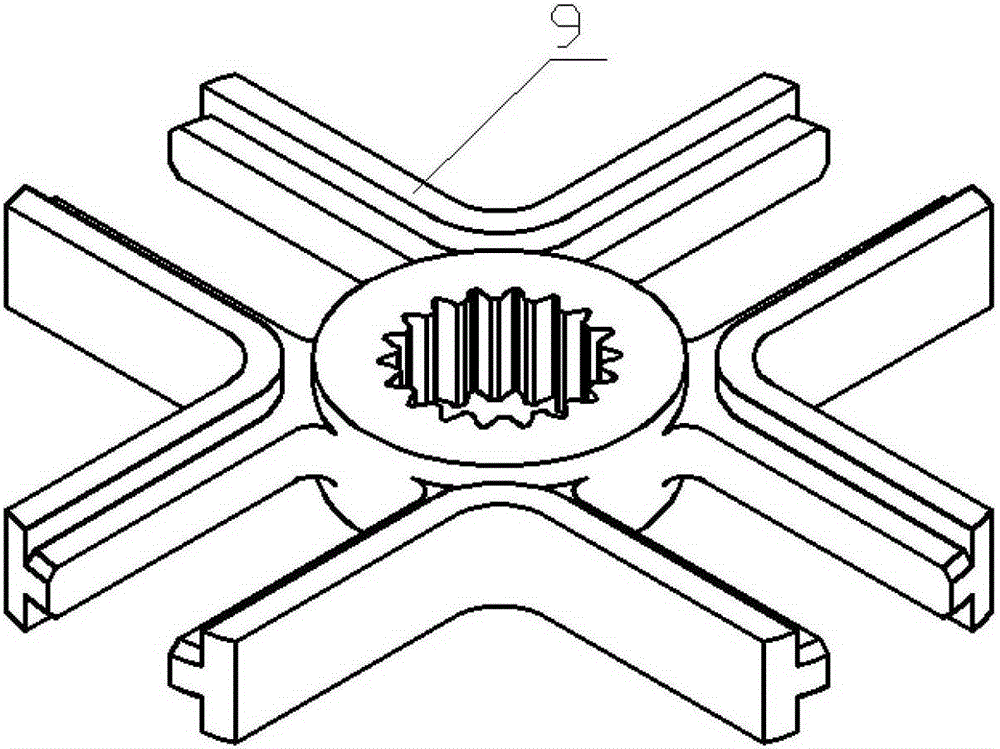

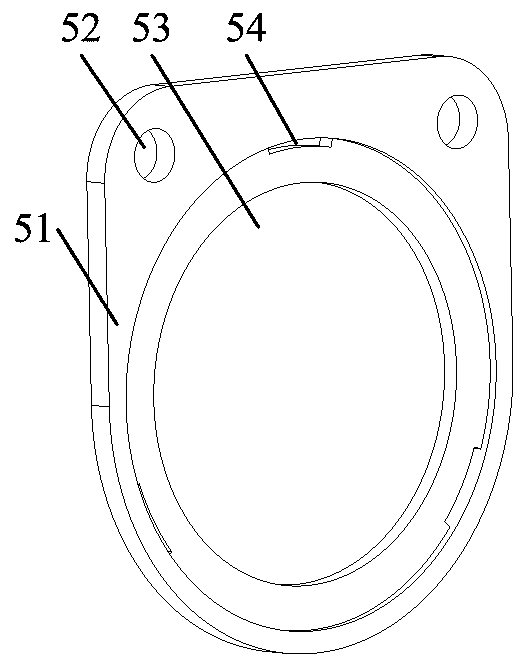

Mechanical automatic transmission gear selecting and shifting executing mechanism

PendingCN107269830AImprove reliabilityImprove comfortGearing controlAutomatic transmissionBall screw

The invention discloses a mechanical automatic transmission gear selecting and shifting executing mechanism. The mechanical automatic transmission gear selecting and shifting executing mechanism comprises a shell, a gear selecting module and a gear shifting module. A main shaft is arranged in the shell and provided with a gear selecting and shifting finger. The gear selecting module comprises a gear selecting motor, a speed reduction mechanism, a cam, a gear selecting shaft and a gear selecting auxiliary shaft. An output shaft of the gear selecting motor is connected with the speed reduction mechanism in the cam. The gear selecting shaft is arranged on the gear selecting auxiliary shaft. One end of the gear selecting shaft is connected with a ball, the ball is placed in a groove in the cam, and the other end of the gear selecting shaft is connected with the gear selecting and shifting finger. The gear shifting module comprises a gear shifting motor, a ball screw, a nut and a gear shifting block. One end of the ball screw is connected with an output shaft of the gear shifting motor, the other end of the ball screw is connected with the nut, and the nut is in clearance fit with the gear shifting block. According to the mechanical automatic transmission gear selecting and shifting executing mechanism, accurate and rapid gear selecting is achieved through the gear selecting shaft and a special groove structure in the cam; and through the combination of the ball screw, the nut and the gear shifting block, rapid and effective gear shifting is achieved, and the gear selecting and shifting quality is improved.

Owner:ZHONGTONG BUS HLDG

A mechanical automatic transmission for electric vehicles with overrunning clutch

ActiveCN103307222BGood speed regulation performanceGood inheritanceToothed gearingsGearing detailsDrive motorEngineering

The invention provides a mechanical automatic transmission of an electric automobile provided with an overrun clutch, and belongs to the technical field of transmission of electric automobiles. The transmission comprises a transmission control system, a variable transmission mechanism, a gear shift operating mechanism and a reverse gear operating mechanism, wherein the variable transmission mechanism is provided with the overrun clutch and performs two-stage transmission; and the gear shift operating mechanism comprises a centrifugal gear shift operating mechanism and a synchronizer gear shift mechanism, the centrifugal gear shift operating mechanism adopts a mechanical structure, detects a speed of the automobile through gear transmission and produces centrifugal force, and the centrifugal force is combined with spring return force, so that mechanical automatic speed changing is realized. According to the mechanical automatic transmission, performance requirements for a driving motor are reduced, and the efficiency of the driving motor and the dynamic property and economy of the whole automobile are improved; an electric control gear shift mechanism is omitted and replaced with the mechanical gear shift mechanism, so that the production cost is reduced, and the system stability is improved; and simultaneously, the overrun clutch and the synchronizer gear shift mechanism are utilized, so that the power failure time during the gear shift process is shortened, the transmitted torque of the transmission is increased, and the system reliability is improved.

Owner:TONGJI UNIV

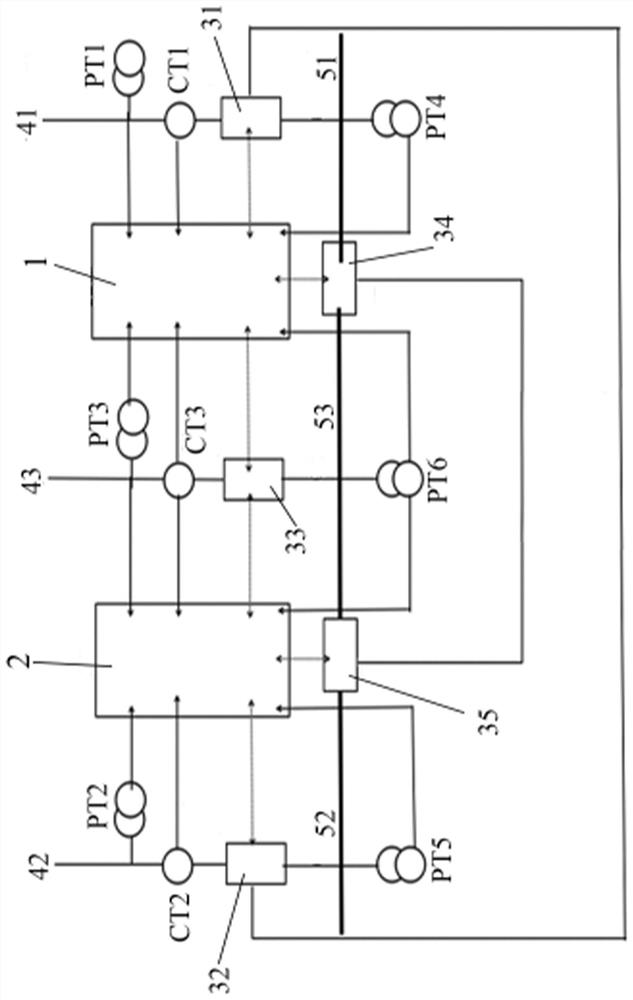

Gate lifting and water controlling system for hydropower station

InactiveCN113541302AGuarantee economic operationReduce power interruption timeRenewable energy source integrationEmergency power supply arrangementsControl engineeringStandby power

The invention provides a gate lifting and water controlling system for a hydropower station, wherein the hydropower station is provided with a first power source, a second power source and a third power source, the first power source and the second power source are standby power sources, the third power source is a frequently-used power source. The system comprises a liquid level monitoring module, a gate monitoring module, a control module and a power source regulation and control module, wherein the liquid level monitoring module comprises a liquid level meter, the control module is connected with the liquid level monitoring module and can control a gate to ascend and descend, the gate monitoring module can collect the data of the gate and transmit the data to the control module, and the power source regulation and control module is also connected with the first power source, the second power source and the third power source, can switch among the three power sources, is also connected with the gate and supplies power to the gate. According to the invention, safe and economical operation of the hydropower station can be guaranteed, the gate opening degree can be accurately controlled according to the forebay water level, and the labor intensity and workload of personnel are relieved; and the electric interruption time can be shortened from minute level to second level, so that the equipment operation is safer and more reliable.

Owner:MINGXING ELECTRIC SICHUAN

A hybrid system clutchless synchronous shift control method and system

The invention discloses a hybrid power system clutchless synchronous shift control method and system, comprising the following steps: S1 obtains the shift demand, S2 enters the shift preparation, and the synchronous ring is protected when the speed of S3 is different, under the action of the shift motor , the tooth sleeve advances, when it touches the synchronous ring, due to the speed w of the engaging tooth 1 and gear bushing speed w 2 Different, the synchronous ring is subjected to the friction torque of the engaging teeth and the ring torque of the gear sleeve, and the friction torque is greater than the torque of the dial ring, so that the gear sleeve cannot drive the synchronous ring to move, and the gear sleeve cannot pass through the synchronous ring and combine with the engaging teeth; after S4 speed regulation To shift gears, S5 mounts a new gear, resumes torque output, and S6 executes a new round of gear shifting cycle. The clutchless synchronous shift control system of the hybrid power system includes an execution unit, an automatic transmission controller, a shift motor, a hybrid power system, and a synchronous ring. The present invention avoids using a clutch when shifting gears, thereby reducing costs and power interruption time.

Owner:江苏新能源汽车研究院有限公司

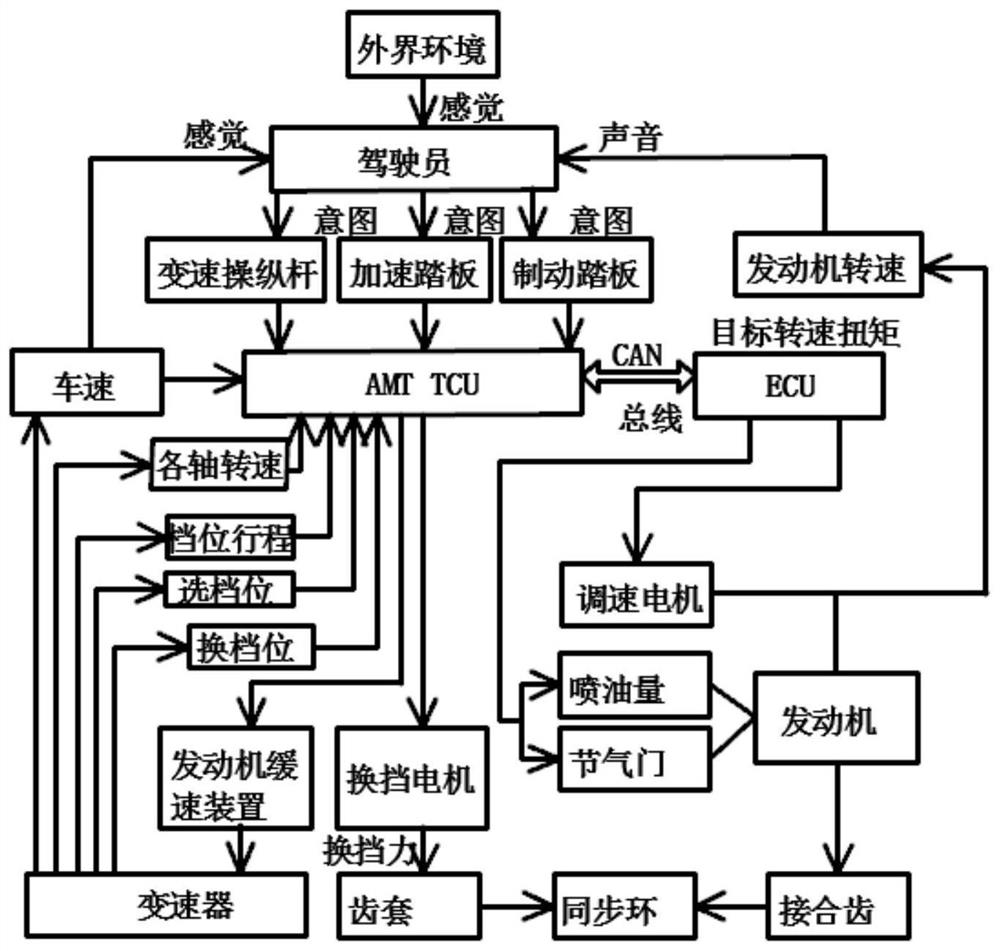

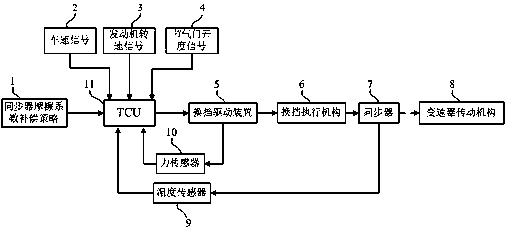

An amt shift control method and system for friction coefficient following compensation

ActiveCN105546106BImprove shift qualityReduce power interruption timeGearing controlSystem integrationAutomatic transmission

The invention discloses an AMT shift control method and system with friction coefficient follow-up compensation, which comprises a synchronizer friction coefficient compensation strategy, a vehicle speed signal, an engine speed signal, a throttle valve opening signal, a shift drive device, and a shift actuator. , synchronizer, transmission transmission mechanism, force sensor, temperature sensor, TCU, TCU controls shifting according to vehicle speed signal, engine speed signal, throttle opening signal, shift force signal and synchronizer temperature signal; According to the synchronizer friction coefficient compensation strategy, the TCU corrects the shift force and performs friction coefficient follow-up compensation, thereby shortening the shift interruption time and improving the shift quality. The AMT shift control method and system with friction coefficient follow-up compensation of the present invention is suitable for the field of automobile technology, especially when the all-electric automatic transmission is applied in the automobile transmission system, it will obtain better system integration control effect and shorten the shift interruption. Time can greatly improve the shifting quality of the car.

Owner:SHANDONG UNIV OF TECH

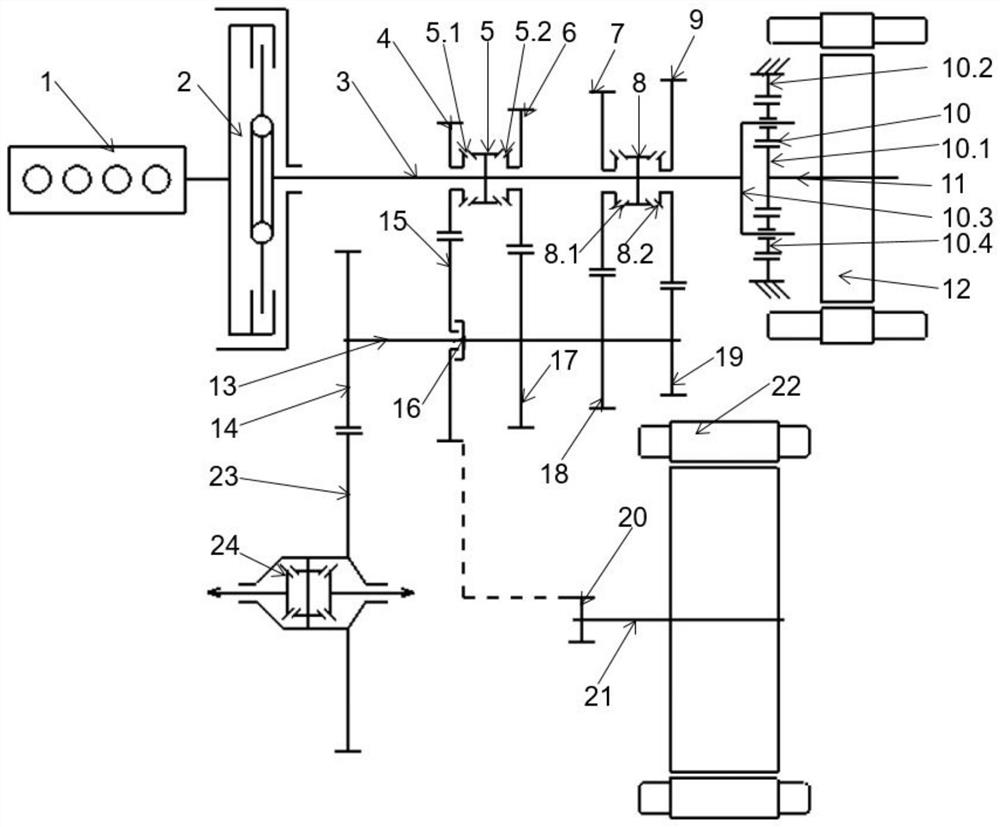

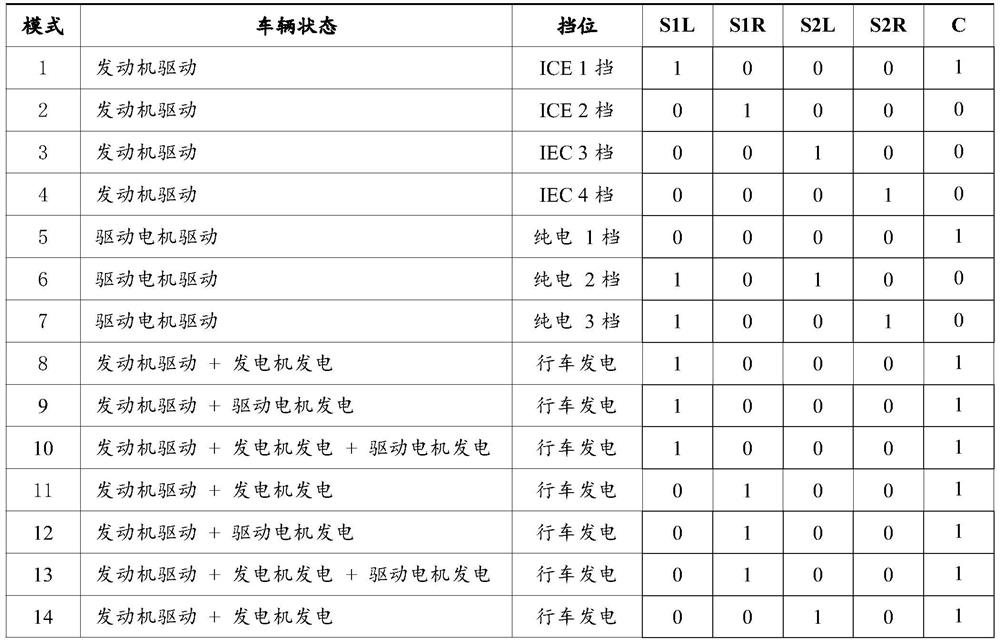

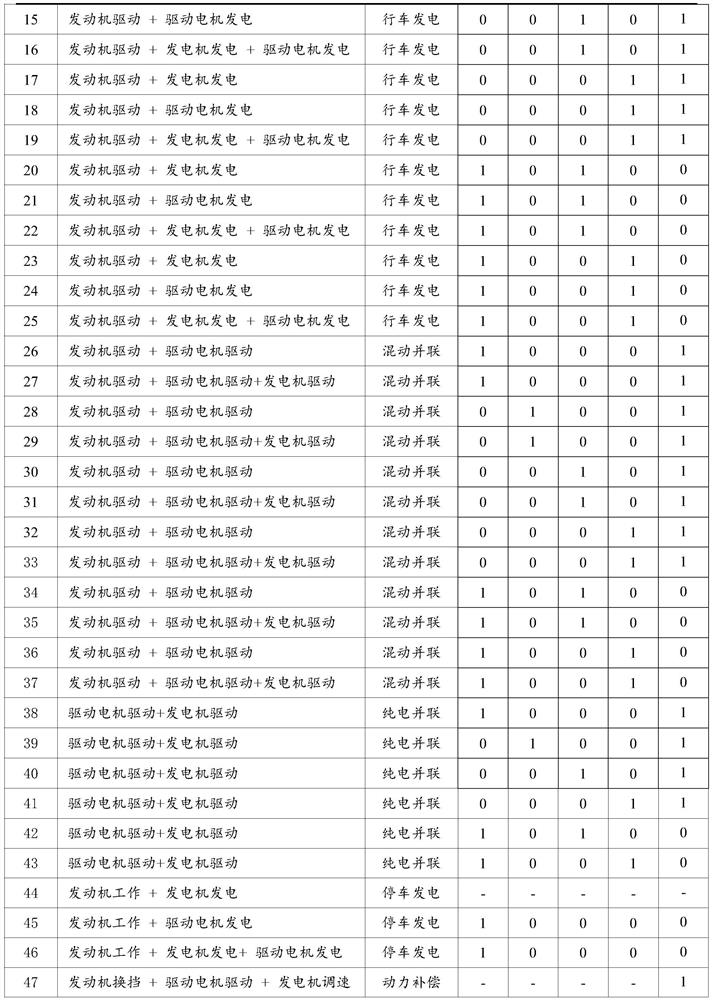

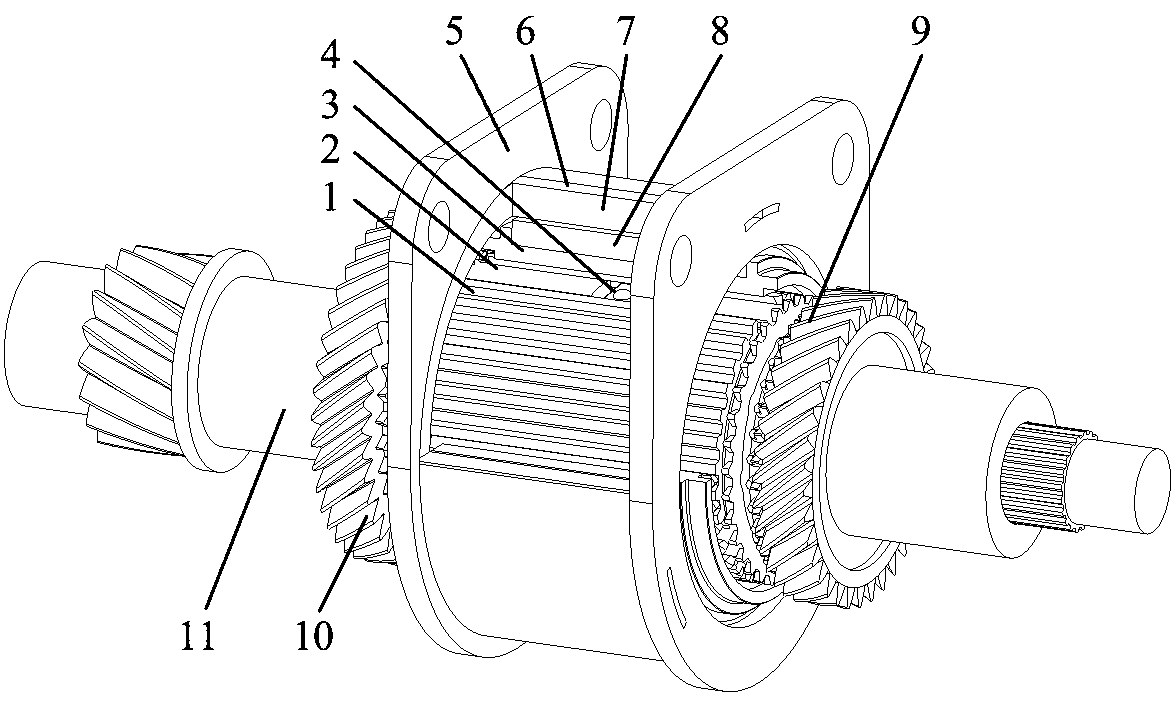

A multi-speed hybrid transmission

ActiveCN112193049BSimple structureCompact structureHybrid vehiclesGas pressure propulsion mountingGear wheelElectric machinery

The present invention proposes a multi-speed hybrid transmission, including an engine, a generator, a drive motor, a planetary gear mechanism, an input shaft, an input shaft of a generator, an output shaft of a drive motor, an output shaft, and a differential. The input shaft is connected with the input shaft, the input shaft is arranged coaxially with the generator input shaft, and is arranged parallel to the output shaft of the driving motor and the output shaft, the end of the input shaft is connected with the planet carrier, and the first, second, and For the third and fourth gears, the fifth, sixth, seventh, eighth, and ninth gears are successively installed on the output shaft, and the tenth gear is installed on the output shaft of the driving motor. 3. The fourth gear meshes with the sixth, seventh, eighth, and ninth gears respectively, the fifth gear meshes with the differential gear, and the tenth gear meshes with the sixth gear. The present invention simplifies transmission system to achieve fast shifting and shorten the power interruption time.

Owner:DONGFENG MOTOR CORP HUBEI

Electric clutch shift mechanism

ActiveCN104455367BShorter power transmission linesSmall moment of inertiaMechanical actuated clutchesGearing controlControl theoryElectric coupling

The invention relates to an electric coupling sleeve type shifting mechanism, which includes a spline hub, a synchronous ring, a coupling sleeve, a positioning slider, an actuator fixing plate and an electromagnetic linear actuator. On the groove, the end surface is in contact with the end surface of the groove of the joint sleeve during movement; the fixed protrusion on the actuator outer cover is placed in the groove of the actuator fixed plate, and is connected with the transmission case through the connection hole on the fixed plate. The electric clutch-type shifting mechanism of the present invention is suitable for mechanical automatic transmission systems, especially when the transmission space is limited and the volume of the transmission needs to be further reduced; when this type of automatic transmission shifting mechanism is used, the power interruption will be shortened time, improve the dynamic response speed of the system and reduce shifting energy consumption.

Owner:SHANDONG UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com