Vehicle working mode switching method and system of hybrid electric vehicle and transmission control unit

A vehicle controller and hybrid vehicle technology, applied in hybrid vehicles, motor vehicles, transportation and packaging, etc., can solve problems such as long mode switching time, reduced system reliability, and large clutch wear, so as to shorten power interruption Time, reduce wear, avoid the effect of frustration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

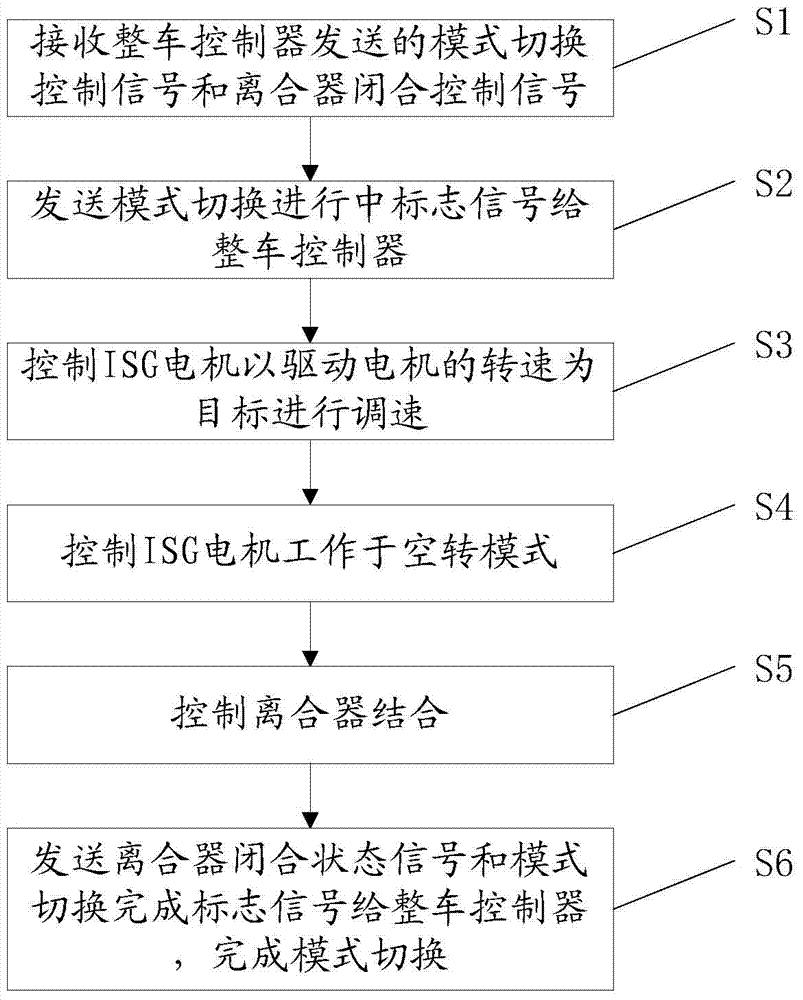

[0066] Such as figure 2 As shown, the present embodiment provides a method for switching the working mode of a hybrid vehicle for a gearbox controller, including the following steps:

[0067] S1: The current working mode of the vehicle is the series mode. When it needs to switch to the parallel mode, it receives the mode switching control signal and the clutch closing control signal sent by the vehicle controller;

[0068] S2: Take over the control right, and send the mode switching in progress flag signal to the vehicle controller;

[0069] S3: Control the automobile starter generator integrated motor to work in the speed control mode, and adjust the speed of the automobile starter generator integrated motor with the speed of the driving motor as the target speed;

[0070] S4: After the integrated motor of the automobile starter and generator completes the speed regulation, control the integrated motor of the automobile starter and generator to work in the idling mode;

[...

Embodiment 2

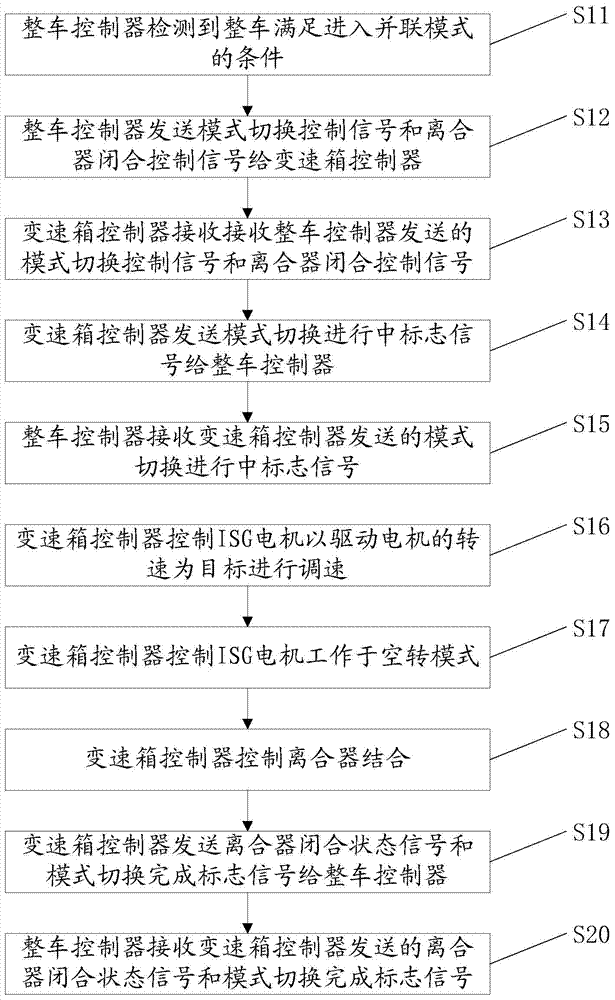

[0079] Such as image 3 As shown, this embodiment provides a method for switching the working mode of a hybrid vehicle, which is used in a vehicle controller and a gearbox controller, including the following steps:

[0080] S11: The current working mode of the vehicle is the series mode. When the vehicle controller detects that the vehicle meets the conditions for entering the parallel mode, the desired mode of the vehicle changes to the parallel mode.

[0081] S12: The vehicle controller sends a mode switching control signal and a clutch closing control signal to the gearbox controller, and also sends a mode switching control signal to the gearbox controller.

[0082] S13: The gearbox controller receives the mode switching control signal and the clutch closing control signal sent by the vehicle controller.

[0083] S14: The gearbox controller takes over the control right, and sends a signal indicating that the mode switching is in progress to the vehicle controller.

[0084...

Embodiment 3

[0096] Such as Figure 4 As shown, it is a timing diagram during the process of switching the working mode of the hybrid vehicle from the series mode to the parallel mode, including the following process:

[0097] Before time T1, the current working mode of the whole vehicle is the series mode, the ISG motor works in the speed control mode, the engine works in the torque control mode, and the gearbox controller controls the clutch to be in the disengaged state.

[0098] At time T1, the vehicle controller judges that the vehicle satisfies the conditions for driving in the parallel mode, and the desired mode of the vehicle changes to the parallel mode. The vehicle controller sends the mode switching control signal and the clutch closing control signal to the gearbox controller, and the gearbox controller takes over the control of the system, and sends the mode switching in progress flag signal to the vehicle controller.

[0099] From time T1 to time T2, the gearbox controller c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com