Speed limit valve of automobile clutch control oil circuit

A speed-limiting valve, clutch technology, applied in the direction of clutches, fluid-driven clutches, non-mechanical drive clutches, etc., can solve the problem of not adjusting the clutch engagement speed, achieve the effect of simple structure, prevent frustration, and improve comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

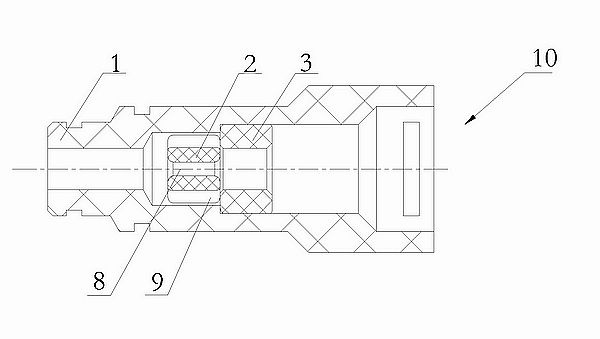

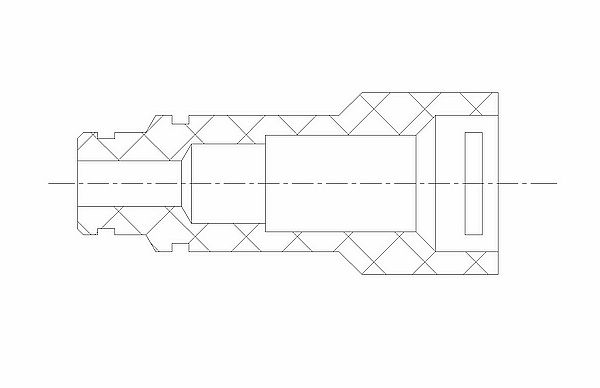

[0021] figure 1 Shown is a speed limiting valve 10 for an automobile clutch control oil circuit, which includes a valve body 1, a valve core 2 and a valve seat 3 coaxially arranged, wherein the valve core 2 has a central oil passage 8, and the central oil passage 8 for damping holes.

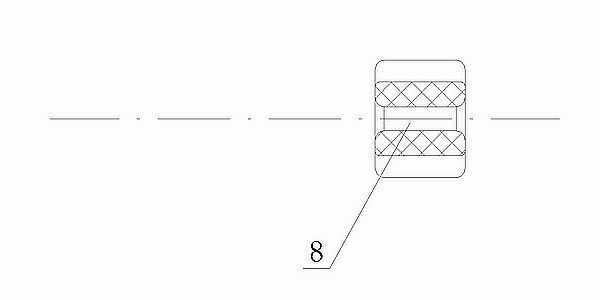

[0022] Such as image 3 and Figure 6 As shown, the radial structure of the spool 2 is in the shape of a "hollow ten" with arc-shaped edges, a central oil passage 8 in the center, and four bypass oil passages 9 . The structure of the spool 2 is equivalent to opening four evenly distributed radial depressions on the body of the cylindrical body and extending the bypass oil passage 9 along the axial direction. There is a hole in the center of the section (the shape of the hole is the radial cross-sectional shape of the central oil passage 8).

[0023] Such as Figure 4 As shown, the valve seat 3 is in the shape of a round tube, the lumen is the oil passage 8, and the inner diameter of the val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com