Clutch oil pressure control system for hydrodynamic transmission

A hydraulic transmission, clutch oil technology, applied in clutches, fluid pressure actuation system components, fluid pressure actuation devices, etc., can solve the problems of high maintenance cost, difficult neutral braking, easy damage, etc., to increase space Gear braking function, reducing power interruption time, reducing the effect of assembly space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

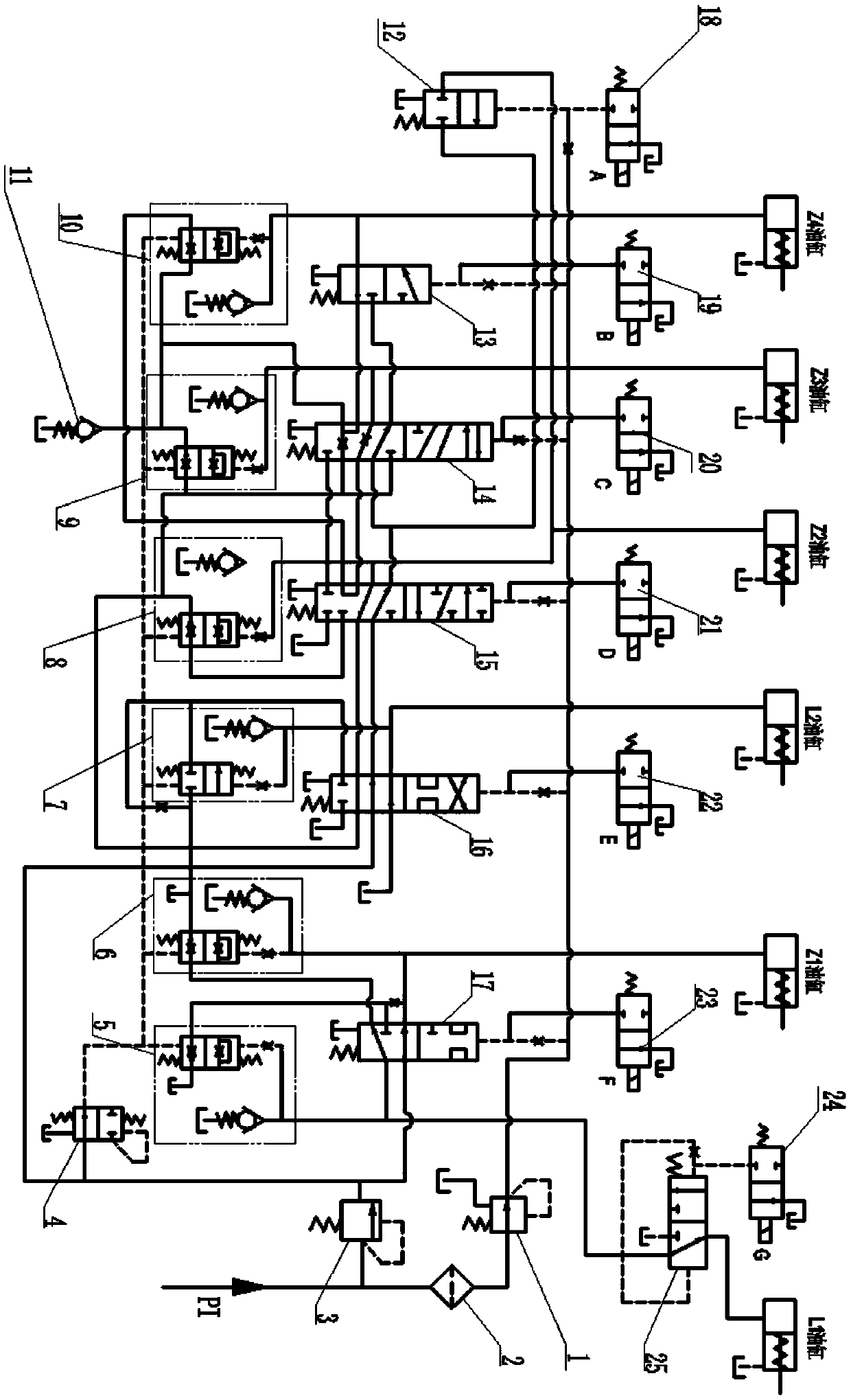

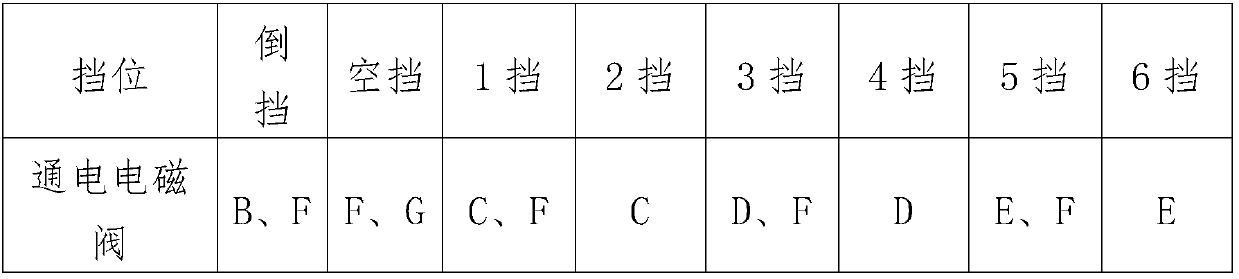

[0014] A clutch oil pressure control system of a hydraulic transmission, including the oil pressure channel PI of the working system; the oil pressure channel PI of the working system passes through the electromagnetic pressure regulating valve 1 and is respectively connected with the shift slide valve F17, the shift slide valve E16, the shift Spool valve D15, shift spool valve C14, shift spool valve B13, and top connections of brake control valve 12, the shift spool valve F17, shift spool valve E16, shift spool valve D15, shift spool valve C14 , the shift spool valve B13, and the top of the brake control valve 12 are respectively connected with the solenoid valve F23, the solenoid valve E22, the solenoid valve D21, the solenoid valve C20, and the solenoid valves B19 and 18. The working ports of valve E16, shift spool valve D15, sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com