Gate lifting and water controlling system for hydropower station

A hydropower station and gate control technology, applied in electrical components, circuit devices, emergency power supply arrangements, etc., can solve the problems of uneven personnel skill levels, inability to make accurate judgments, misjudgments, etc., to achieve convenient operation and improve economy. Operational efficiency, the effect of reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

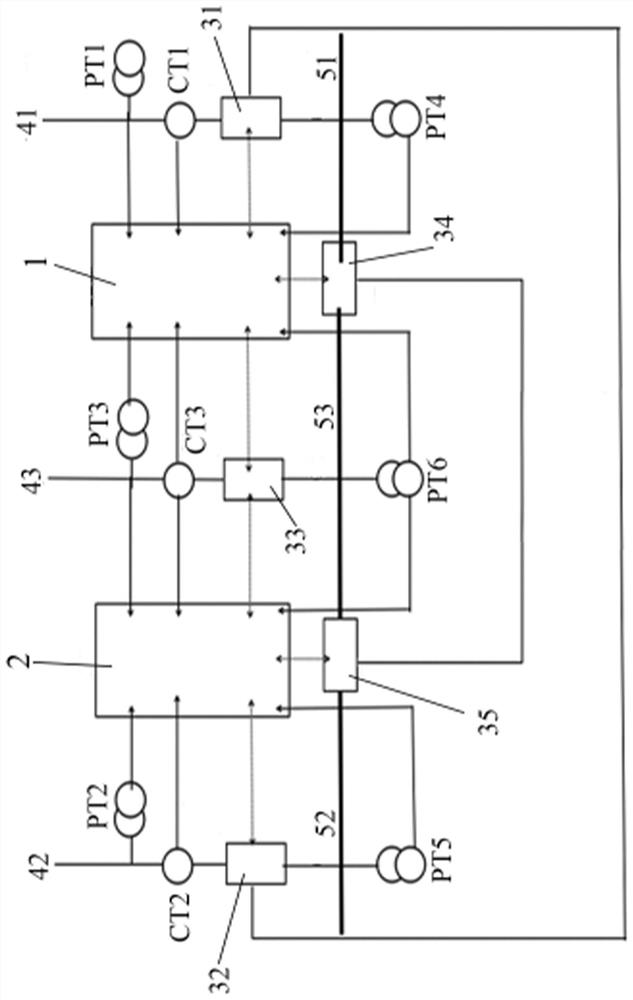

[0094] This example will combine figure 1 To describe an operation mode of the power control module of the water control system of the hydropower station, the operation mode is a backup input mode of the incoming line.

[0095] Among them, the plant power system is mainly supplied by the third power supply incoming line 43; the first generator power supply incoming line 41 and the second generator power supply incoming line 42 are used for backup, and the first standby automatic switching device 1 and the second standby automatic switching device 2 evenly charged. The start-up time limits of the first standby automatic switch-on device 1 and the second standby automatic switch-on device 2 are set and coordinated, and the delays of the first and second standby automatic switch-on devices and the standby power supply are 3 seconds and 10 seconds respectively.

[0096] Before a fault occurs, whether the initial state of each switch is: the first switch 31 and the second switch 3...

example 2

[0101] This example will combine figure 1 To describe another operation mode of the water control system of the hydropower station gate lift, this mode is segmental backup.

[0102] Among them, the factory power system is independently powered by the first generator power supply line 41, the second generator power supply line 42 and the third power supply line 43, and the third power supply line 43 is a 35kV power supply line; the first , The second backup self-injection device is charged. The start-up time limits of the first standby automatic switch-on device 1 and the second standby automatic switch-on device 2 are set and coordinated, and the delays of the first and second standby automatic switch-on devices and the standby power supply are 3 seconds and 10 seconds respectively.

[0103] Before a fault occurs, whether the initial state of each switch is: the first switch 31 , the second switch 32 and the third switch 33 are all closed, and the fourth switch 34 and the fif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com