Magnetic induction vacuum compound type intelligent control device

An intelligent controller and magnetic induction technology, applied in the direction of program control, computer control, general control system, etc., can solve the problems of product reliability, poor safety, low automation level, wear of contact coating, etc., and achieve intuitive display and high reliability Improvement of performance and operational reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

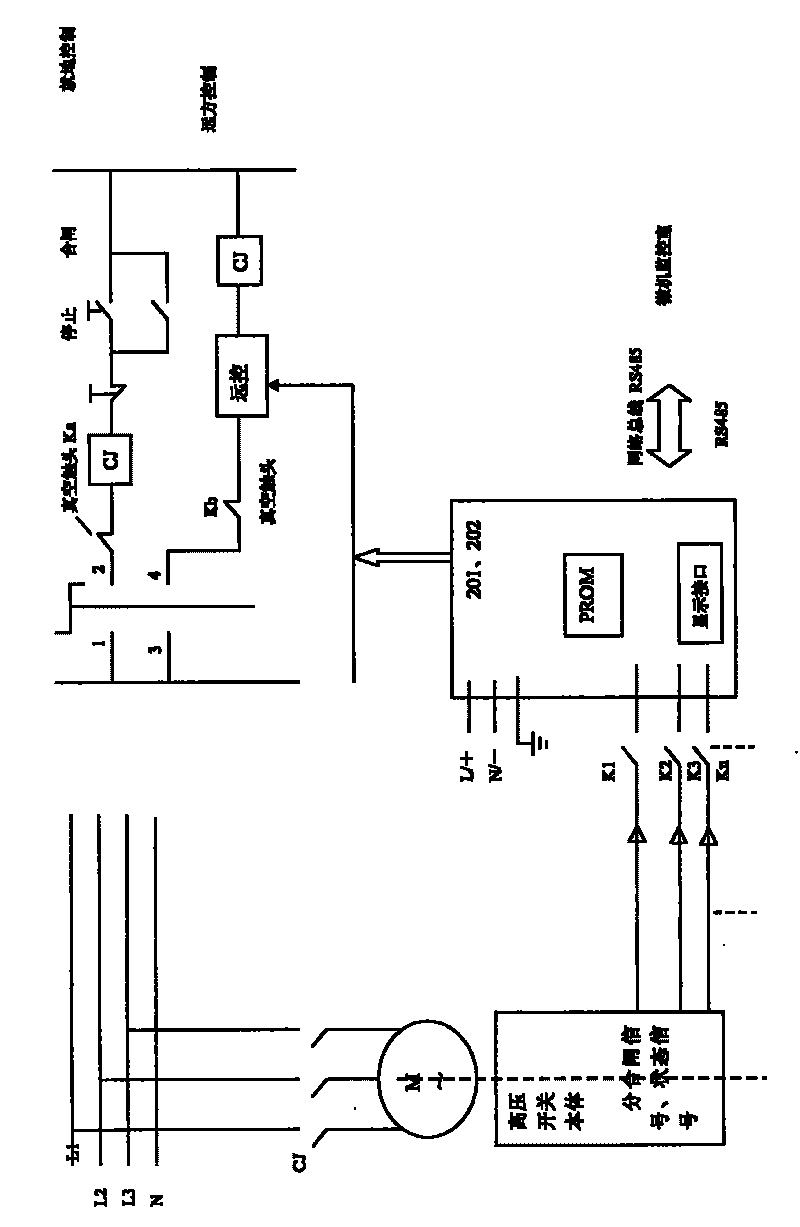

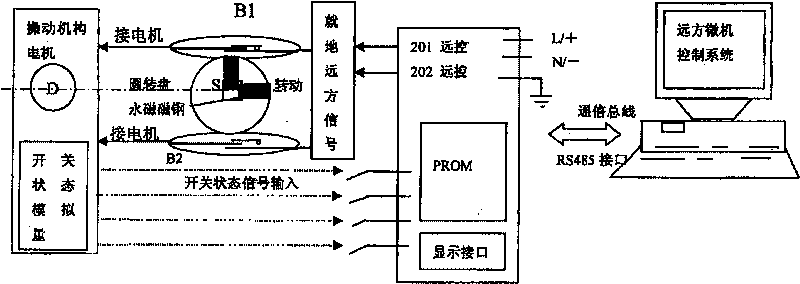

[0022] Depend on Figure 1-2 As shown in the figure, D in the figure is the motor of the operating mechanism, S is the driving part with contact breaking and closing and the circular turntable of permanent magnet steel, B1 and B22 are the built-in duplexes arranged correspondingly on the upper and lower sides of the turntable. The vacuum tube of the contact, the vacuum contact of the vacuum electromagnetic induction switch, the normally closed point is connected to the contactor coil, the contactor is connected to the motor, and the high-voltage switch realizes the opening and closing operation; the state signal of the high-voltage switch passes through the vacuum contact of the electromagnetic induction switch It is transmitted with the PROM module, and the PROM module is connected with the microcomputer monitoring system through the RS485 network cable.

[0023] Working principle: Take the closing of the high-voltage switch as an example. When the high-voltage switch is clos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com