An intelligent non-electrical protection device and control method for an electric high-voltage switchgear

A high-voltage switchgear, non-electrical protection technology, applied in the direction of panel/switch station circuit devices, emergency protection circuit devices, circuit devices, etc. The effect of safe and reliable protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

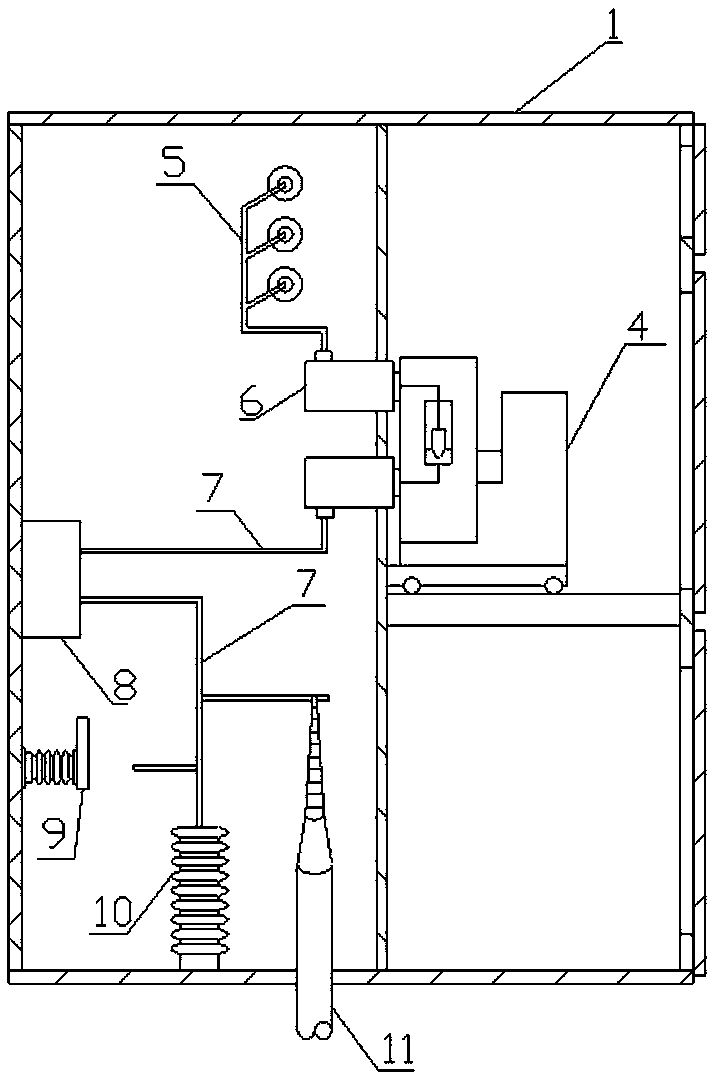

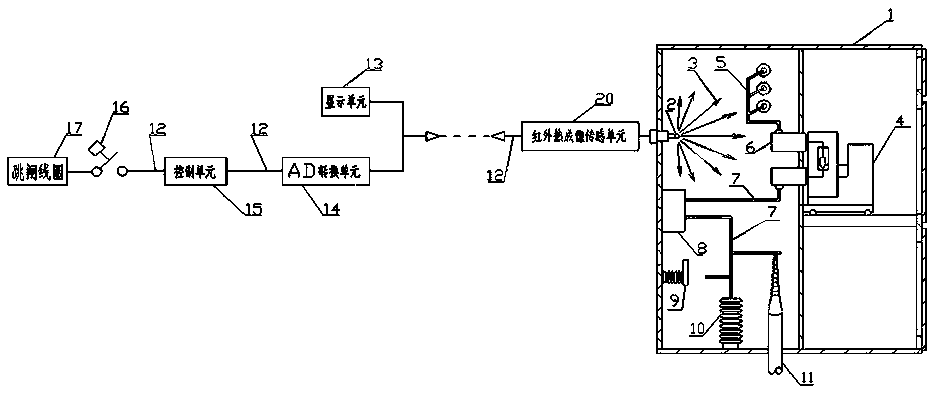

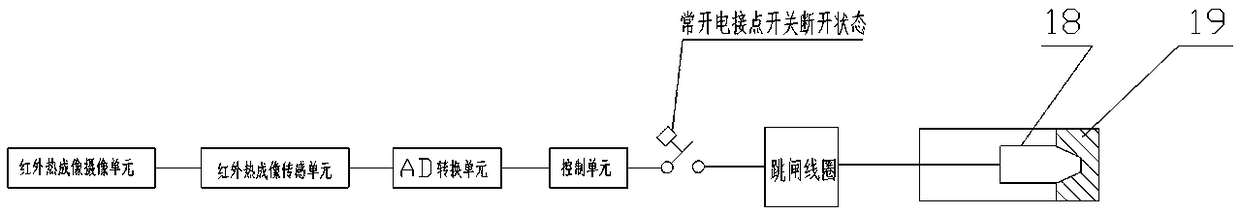

[0024] The technical solution of the present invention will be specifically described below in conjunction with the accompanying drawings.

[0025] The invention provides an intelligent non-electricity protection device for electric high-voltage switchgear, such as figure 1 as well as figure 2 As shown, it includes: an infrared thermal imaging camera unit 2 embedded in the electric high-voltage switch cabinet 1, an infrared thermal imaging camera unit 2 arranged outside the electric high-voltage switch cabinet 1 and connected to the infrared thermal imaging camera unit 2 through a first optical fiber. The thermal imaging sensing unit 20 is connected to the thermal imaging sensor 20 through the second optical fiber and is arranged in the display unit 13 in the background control room, and is connected to the thermal imaging sensor 20 through the third optical fiber and is arranged in the power high voltage switch The AD conversion unit 14 outside the cabinet 1 cabinet and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com