Pneumatic speed changer brake

A technology of transmission brakes and brakes, which is applied in the direction of brake types, axial brakes, brake components, etc., can solve the problems of troublesome maintenance and installation, complex structure, poor versatility, etc., and achieves convenient connection, flexible installation, and pipeline short distance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

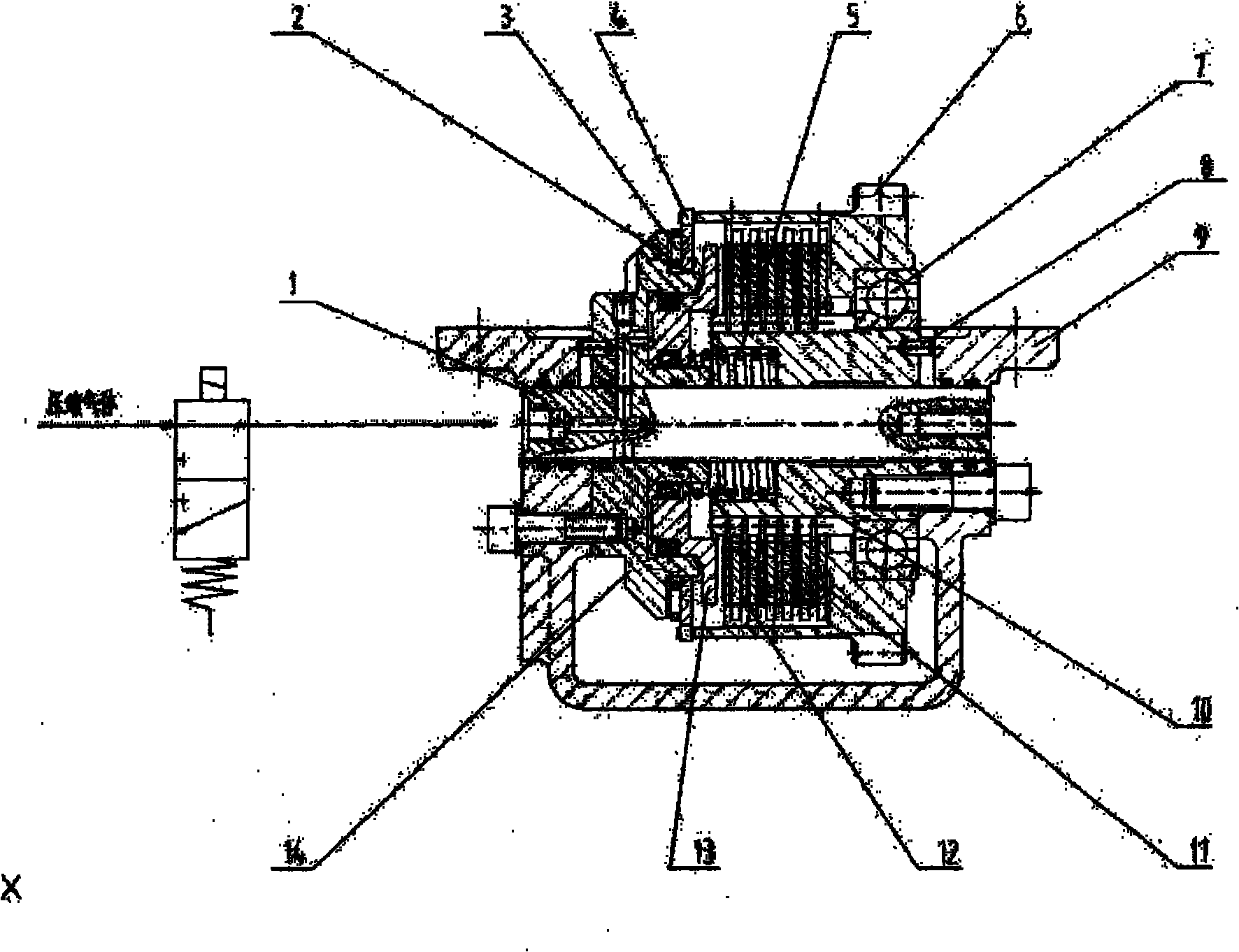

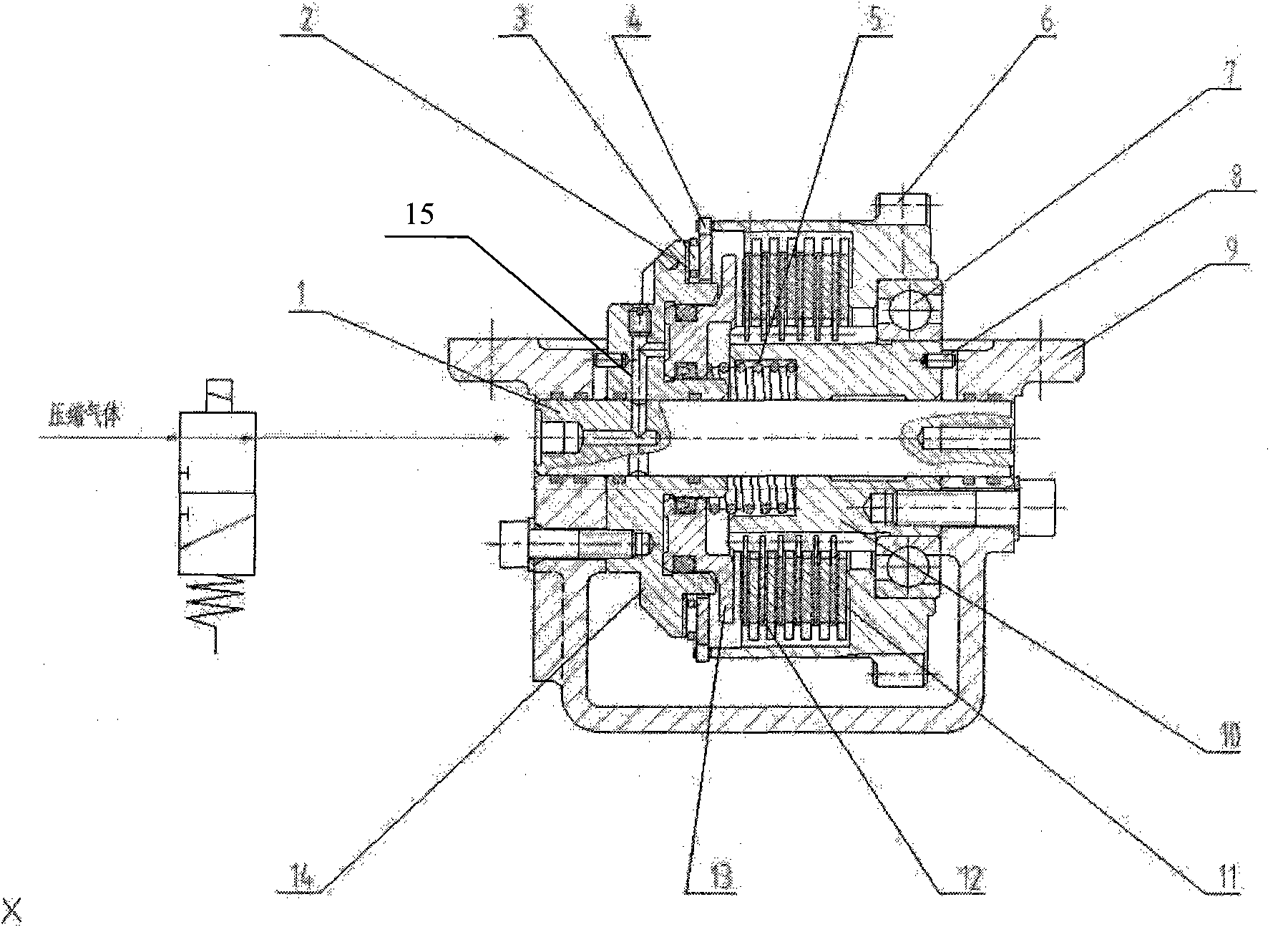

[0017] The pneumatic transmission brake proposed by the present invention includes a shaft 1, a gasket 2, a bearing 3, a baffle plate 4, a spring 5, a gear 6, a ball bearing 7, a cylindrical pin 8, a housing 9, a spline shaft 10, and a steel sheet 11 , Friction plate 12, piston 13, cylinder 14, gas circuit 15. The piston 13 reciprocates along the shaft 1 in the cylinder 14, the spline shaft 10 is nested on the shaft 1, the spring (5) is arranged between the piston 13 and the spline shaft 10; the air passage 15 is arranged at the end of the shaft 1, It is connected with the piston 13 and the cylinder 14.

[0018] Steel sheet 11, friction plate 12 all are many, and number can be adjusted and installed as required, to adapt to different braking requirements. The steel sheet 11 and the friction sheet 12 are adapted to each other; the steel sheet 11 and the friction sheet 12 are divided into two groups, which are arranged on both sides of the spline shaft 10 respectively. The bra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com