Drilling machine for exploiting shale gas

A shale gas and drilling rig technology, which is applied to drilling equipment, earthwork drilling, drilling equipment and methods, etc., can solve the problems of increasing the technical difficulty of gas well drilling, the impact of well wall collapse on drilling, and the increase of gas well costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

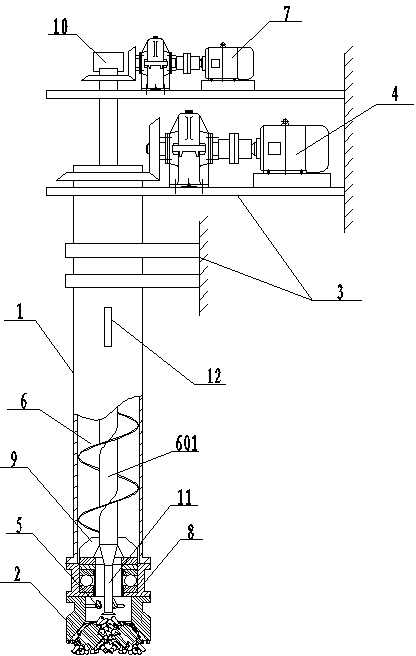

[0084] According to accompanying drawing, illustrate the present invention in conjunction with optimal embodiment;

[0085] As shown in the figure, a drilling rig for exploiting shale gas includes a drill pipe 1, a drill bit 2, a power mechanism 4 for driving the drill pipe and a bracket 3 for supporting the drill pipe and the power mechanism. The drill pipe 1 One end is connected to the power mechanism 4 through a transmission assembly, and the transmission assembly can choose a conventional bevel gear pair or a worm gear reducer;

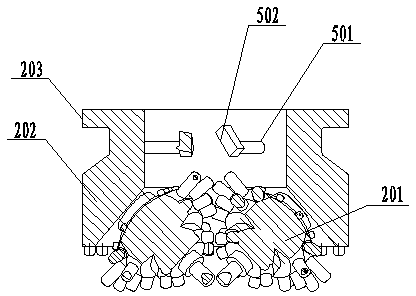

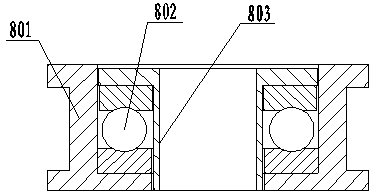

[0086] The drill 2 is composed of a drill body and a plurality of roller cones 201 arranged on the drill body. The drill body includes a cylindrical sleeve 202 and a flange connection end 203. One end of the roller cone 201 is arranged on a cylindrical On the inner wall of the sleeve 202, the other end stretches out of the cylinder-shaped sleeve 202, and the cavity inside the cylinder-shaped sleeve 202 forms a feeding channel, which is located abo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com