Water-lubricated thrust bearing of submersible motor for well

A technology for submersible motors and thrust bearings, applied in the direction of sliding contact bearings, bearings, bearing components, etc., can solve the problems of inability to guarantee material quality, difficult to stabilize material sources, high material costs, etc., to reduce the difficulty of material selection and material costs, Improve lubrication effect and improve product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

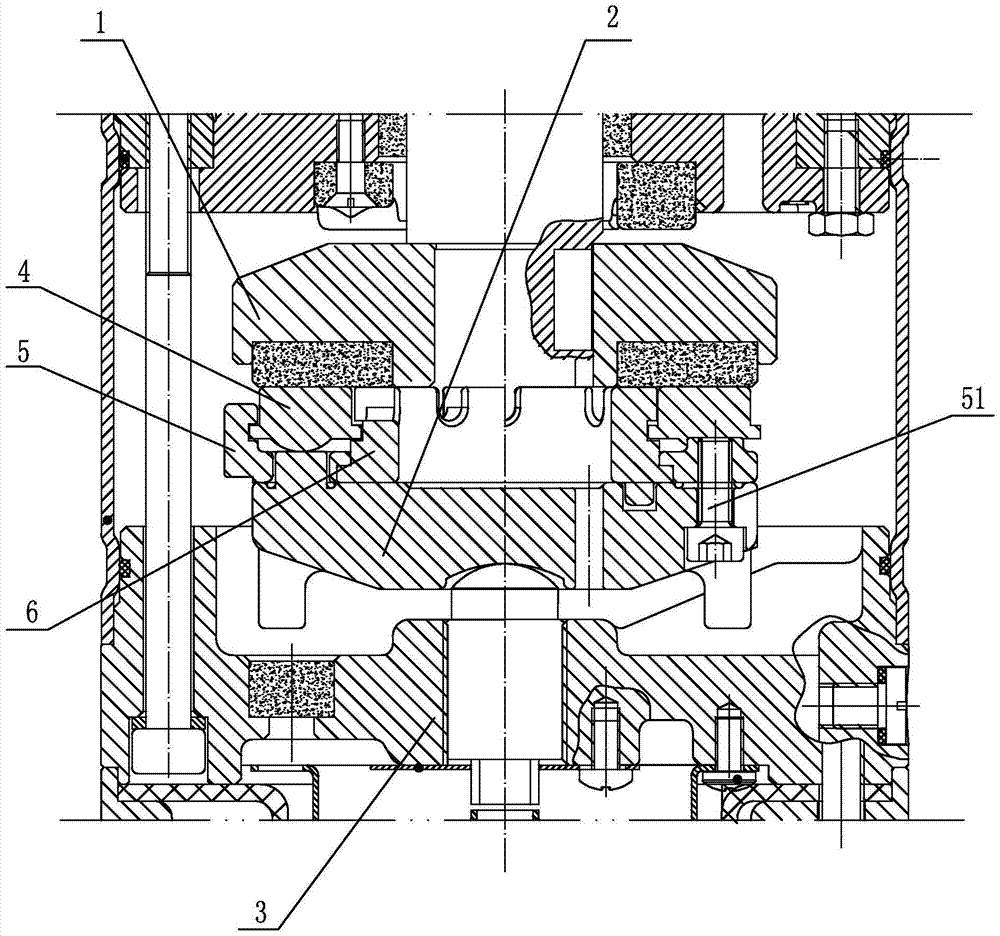

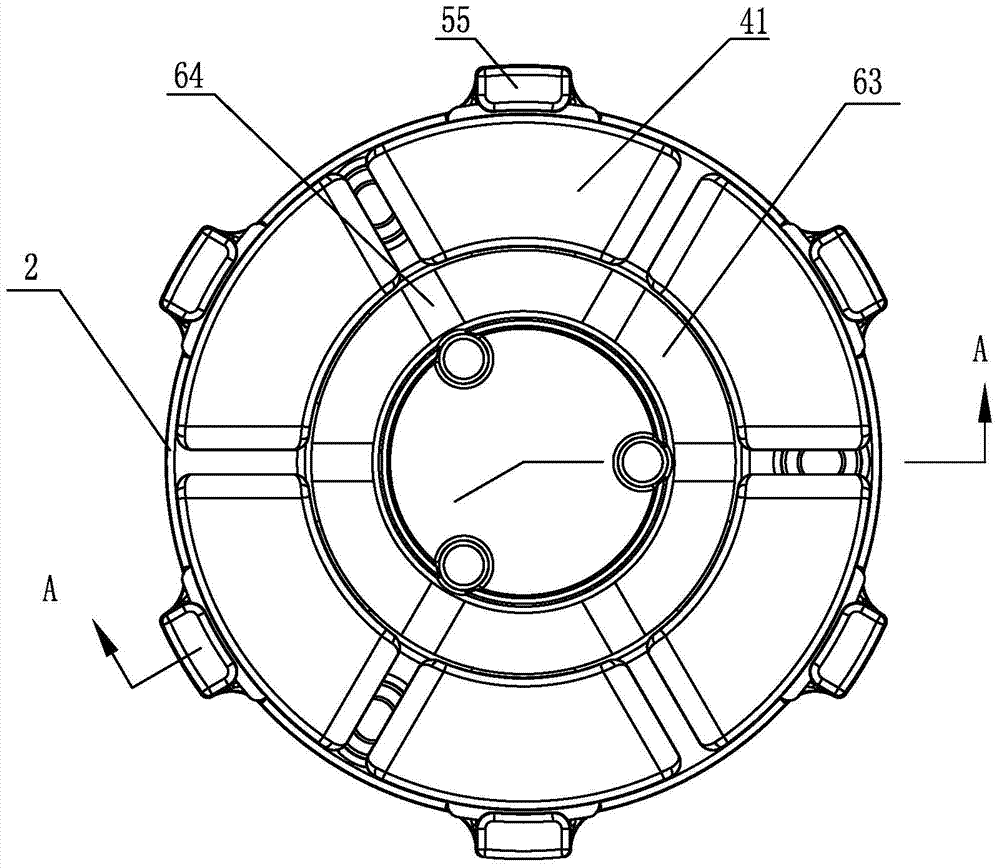

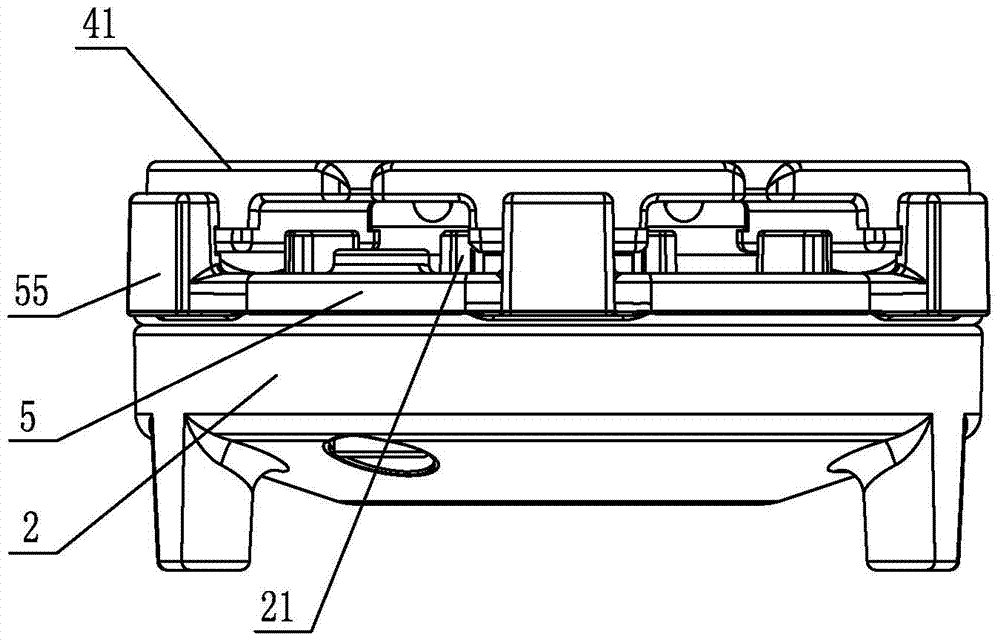

[0030] Depend on Figure 1-21 As shown, the embodiment of the water-lubricated thrust bearing of the well submersible motor of the present invention is: a disc bearing seat 2 including a thrust plate 1 and a bottom with a water hole around the center, and a bearing spherically supported at the bottom of the disc bearing seat 2 The seat support 3 and the bearing bush 4, the bearing bush 4 is composed of a plurality of independent fan-shaped bearing sliders 41, a bearing disc 5 is also arranged between the disc bearing seat 2 and the bearing bush 4, and is fixed on the disc by a stud 51 On the bearing seat 2, the fan-shaped bearing sliders 41 are evenly distributed on the bearing disc 5 according to the circumference, such as Figures 13 to 14, the bearing disk 5 has a central hole 53, and the outer circumference of the disk is evenly distributed with the same number as the fan-shaped bearing slider 41, and the limit post 55 with a groove 54 at its waist, in the central hole of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com