Clutch rotary vibration damper assembly having hybrid separating clutch integrated in rotating part of rotary vibration damper

A torsional vibration and clutch technology, which is applied in fluid-driven clutches, mechanical-driven clutches, non-mechanical-driven clutches, etc., can solve problems such as complex structures, and achieve compact design and space-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

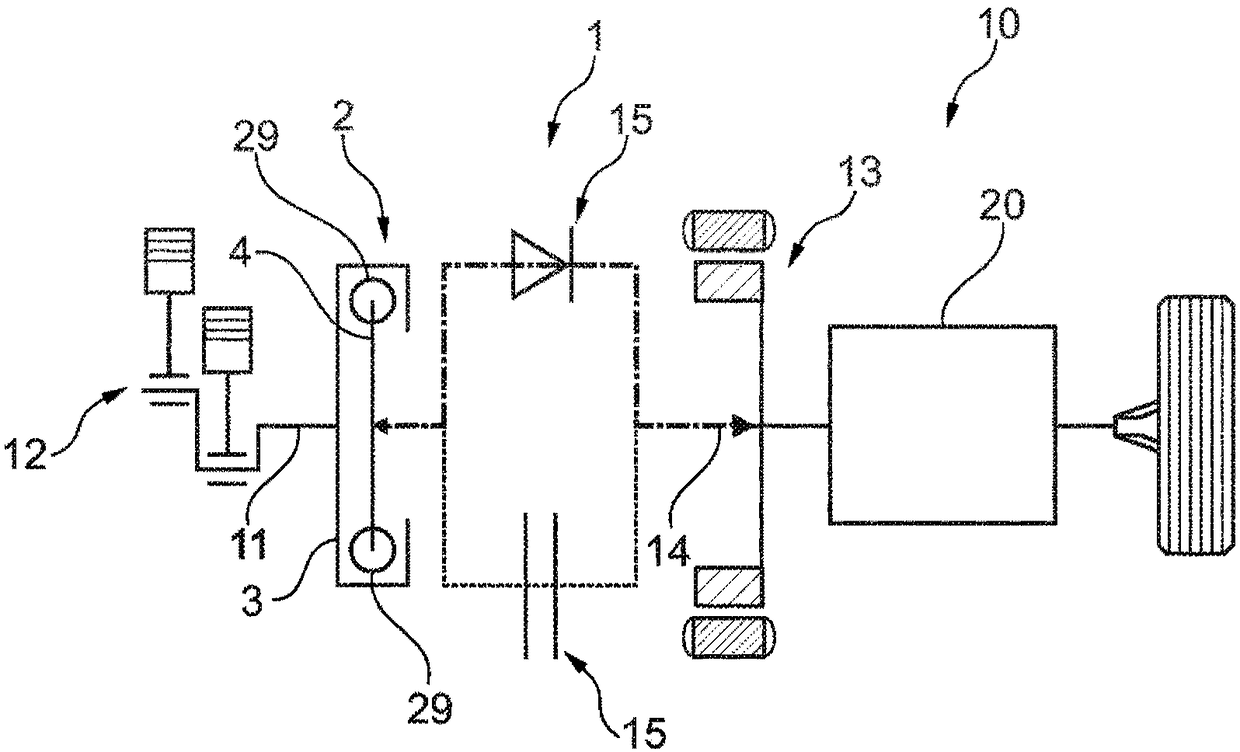

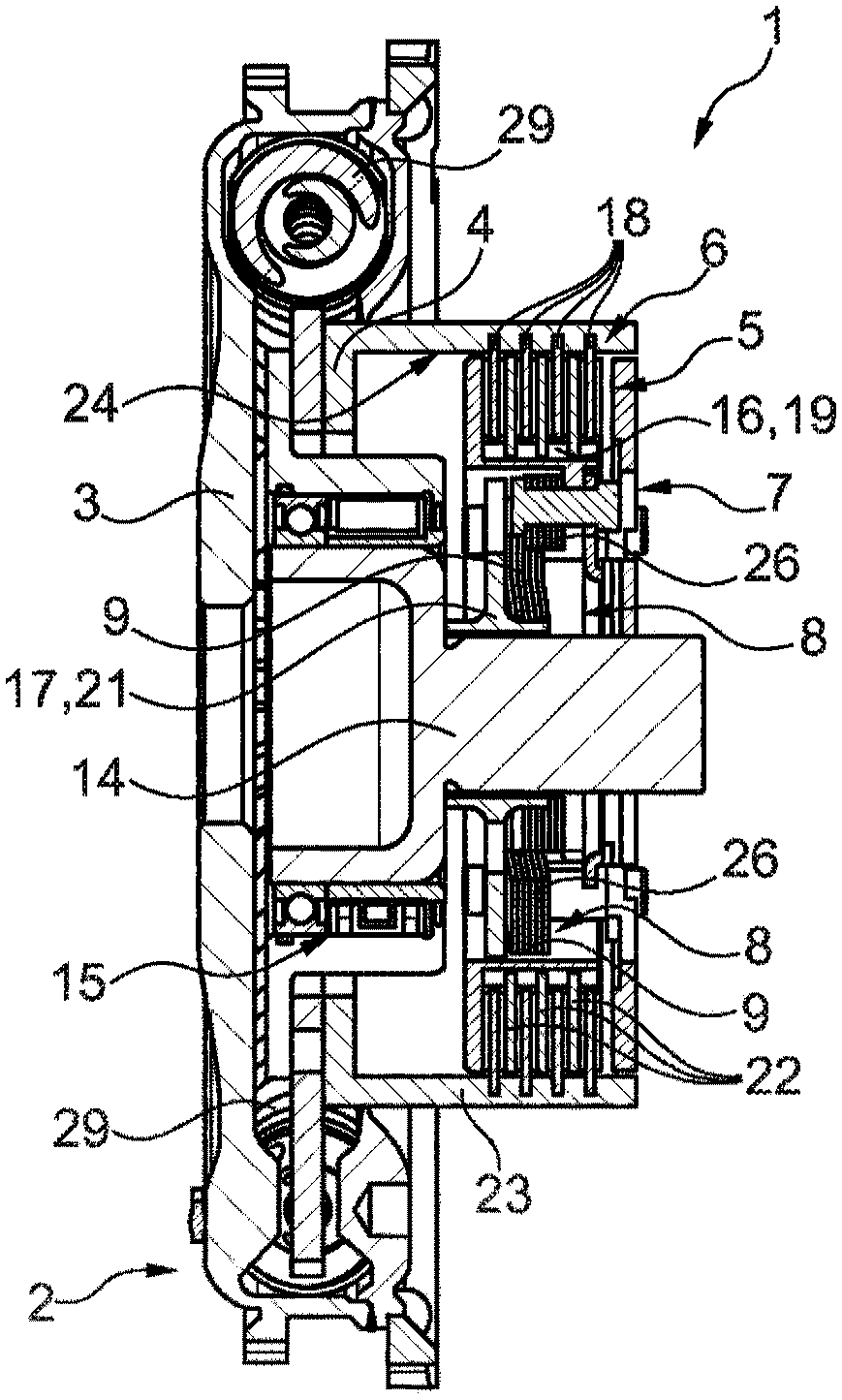

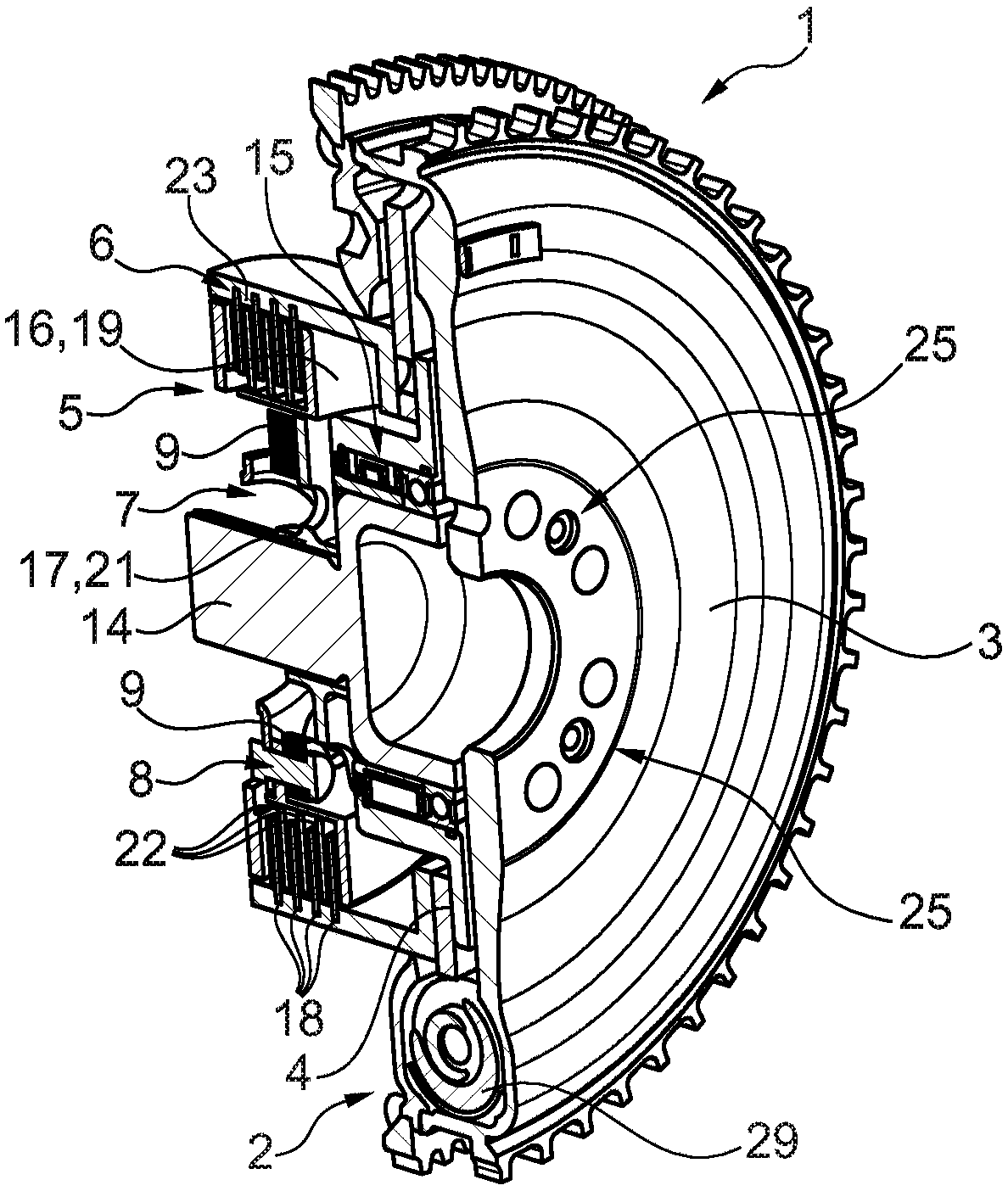

[0030] exist figure 2 and 3 The clutch-torsional vibration damper assembly 1 according to the invention is shown particularly clearly and in detail in . The clutch-torsional vibration damper assembly 1 is a system / component / arrangement consisting of a clutch device 5 and a torsional vibration damper 2 which is designed as a dual-mass flywheel and is therefore alternatively also hereinafter Marked as Dual Mass Flywheel 2. A clutch-torsional vibration damper-assembly 1 is provided for a hybrid drive train 10 of a motor vehicle, as described in figure 1is schematically shown in . The clutch-torsional vibration damper assembly 1 is thus used in such a drive train 10 during operation. In addition to internal combustion engine 12 , drive train 10 also has an electric motor 13 . Furthermore, a transmission 20 (manual transmission, automatic transmission or dual clutch transmission) is arranged in the drive train 10 , wherein the drive shaft 14 of the electric motor 13 is design...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com