Grinding tool for starting valve hole of diesel engine cylinder head

A cylinder head and starting valve technology, applied in the field of metal cutting, can solve the problems of high manufacturing cost and complicated structure of grinding tools, and achieve the effects of improving grinding quality, saving processing time, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

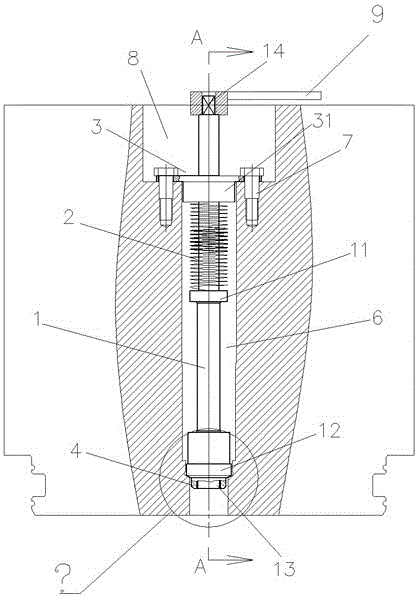

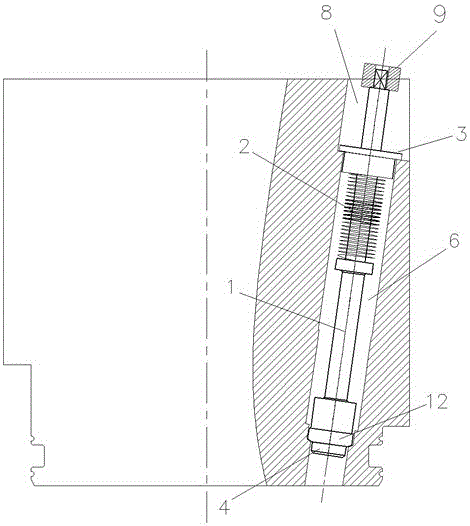

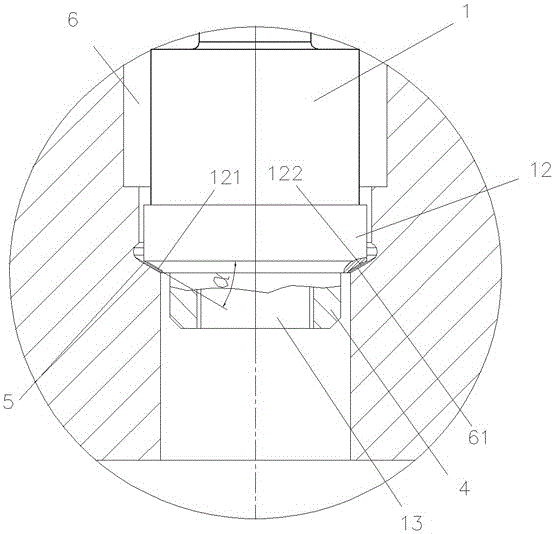

[0018] The present invention will be further described below in conjunction with drawings and embodiments.

[0019] Such as figure 1 , figure 2 and image 3 As shown, the present invention includes a grinding spindle 1, a spring 2, a pressure plate 3 and a lock nut 4. The middle part of the grinding spindle 1 extends radially from a spring support shoulder 11, and the lower end extends radially from a grinding head 12, and the lower end of the grinding head 12 A stud 13 extends axially downward. When needing to grind with sandpaper, the sandpaper 5 that is cut into ring is clamped between the grinding head 12 bottom and the locking nut 4 top surface that is screwed on the stud 13, and the locking nut 4 peripheral surface is shaped on knurling, is convenient to Tighten the lock nut 4 by hand. The cone ring surface 121 at the bottom of the grinding head matches the cone ring surface 61 to be grinded at the bottom of the start valve hole 6, the spring 2 is set in the middle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com