Steel bar surface type connecting joint adopting nodular cast iron member

A ductile iron and connecting node technology, applied in building components, structural elements, building reinforcements, etc., can solve problems such as insufficient connection strength and energy dissipation performance, bending moment, shear force, and seismic performance to be further improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The directions shown in the accompanying drawings are up, down, left, and right.

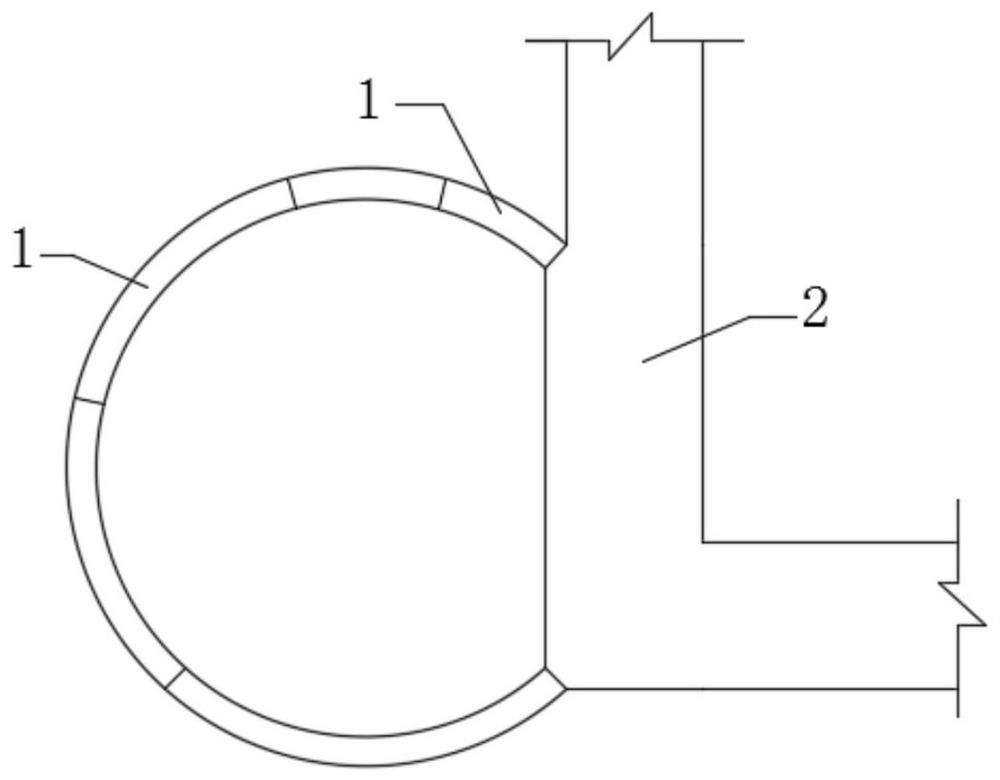

[0027] Such as figure 1 , the place where the wall column 2 of the subway station contacts the shield segment 1 is a node joint. A number of shield segments 1 are assembled into an open annular tunnel lining structure.

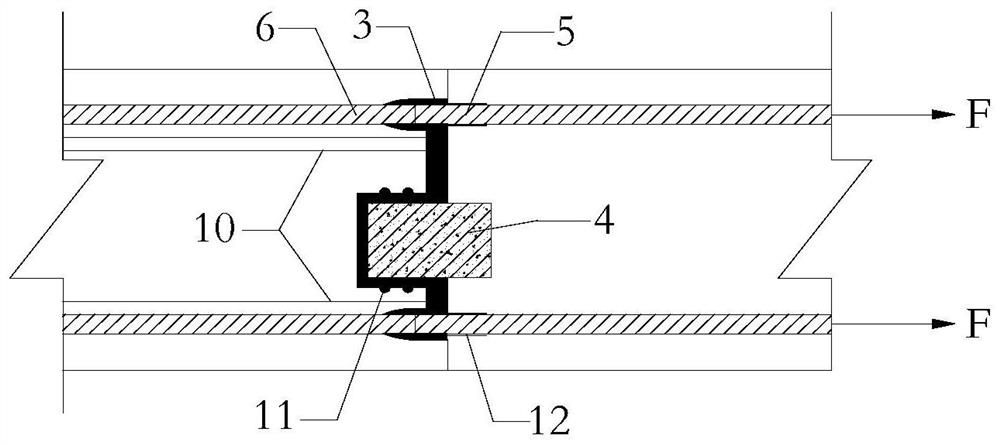

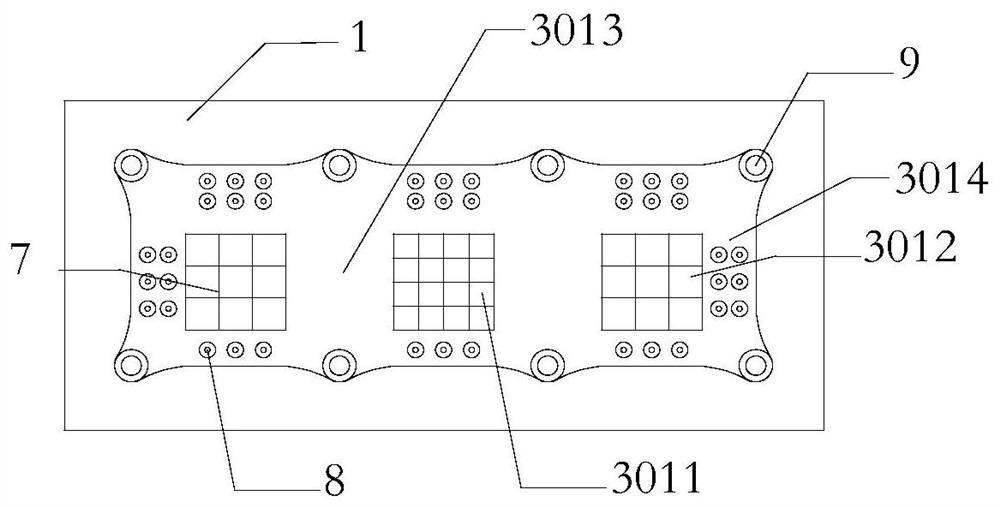

[0028] Such as figure 2 , the node structure includes ductile iron members 3, alveolar shear members 4 and prestressed steel bars 5 without bonding sections. The nodular cast iron component 3 is cast from nodular cast iron, and the nodular cast iron component 3 is provided with a longitudinal reinforcement connecting sleeve 9 according to the node reinforcement requirements, and the longitudinal reinforcement connecting sleeve 9 and the nodular cast iron component 3 are cast together. The prestressed steel bar 5 in the non-adhesive section is a prestressed steel bar that has no bonding force with the structural concrete of the wall column 2 of the subway station withi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com