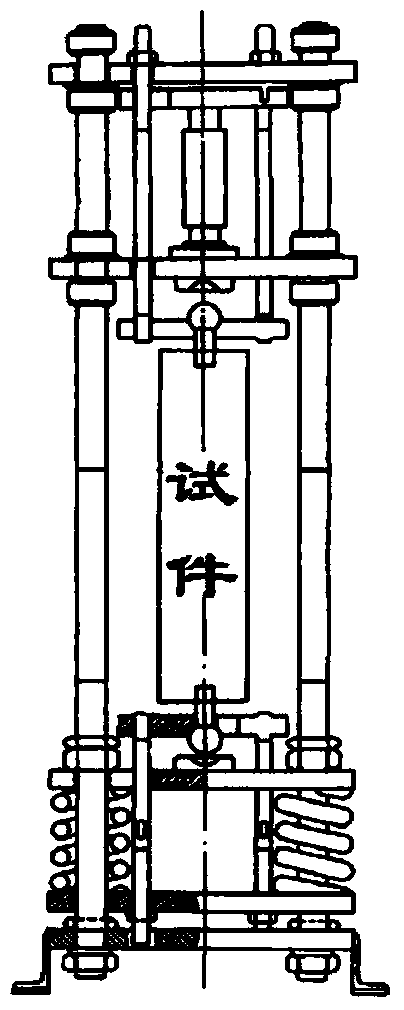

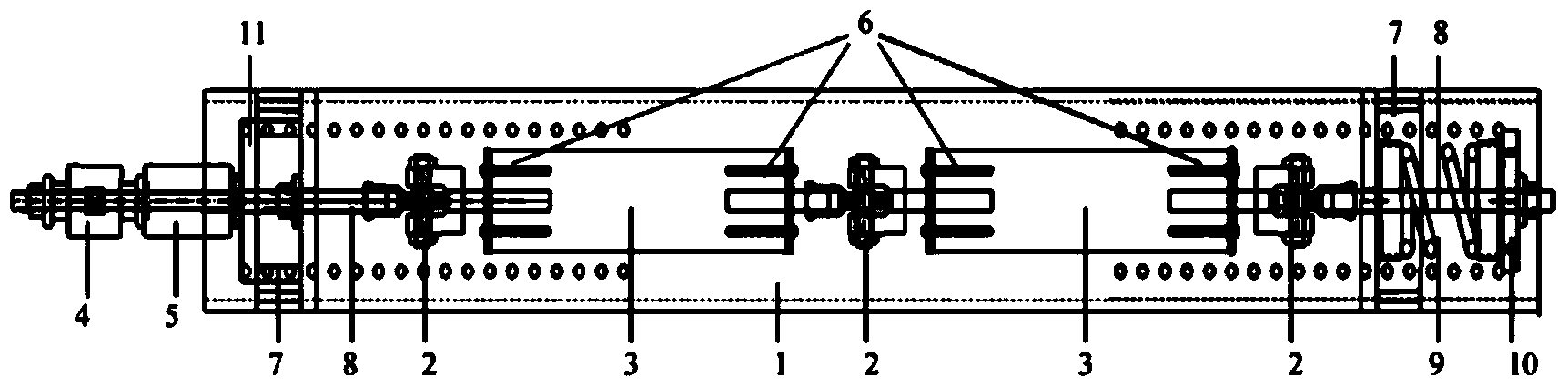

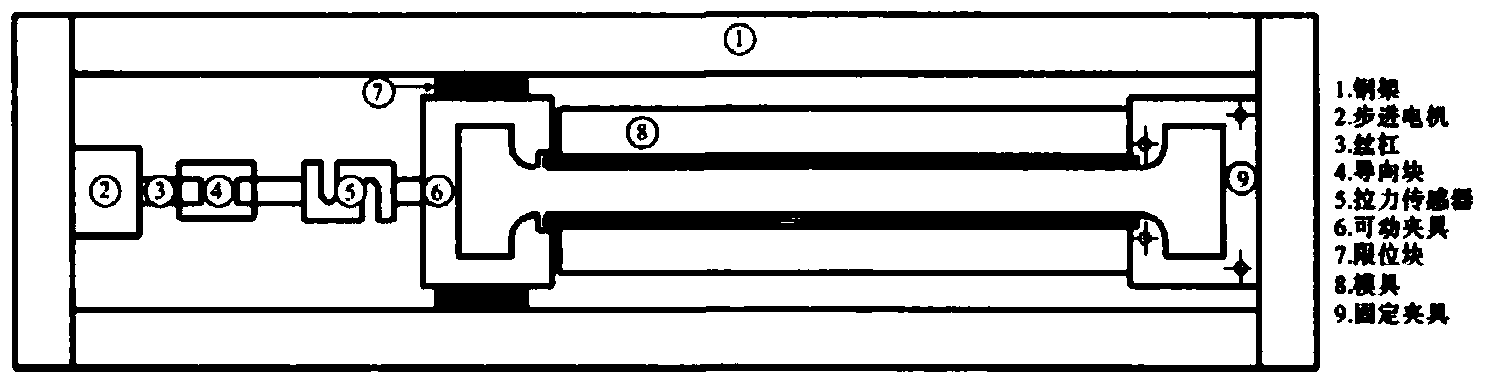

Concrete tensile creep testing device and concrete shrinkage stress creep testing method

A technology of test device and test method, which is applied in the direction of applying stable tension/pressure to test the strength of materials, etc., can solve the problem that the cohesive force cannot meet the requirements of the design value of the tensile creep load, the eccentric adjustment effect is limited, and the concrete is pure tensile. Performance limitations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0115] Utilize the concrete tensile creep test device of the present invention to carry out the concrete implementation of concrete shrinkage stress creep test method, comprise: according to the purpose of concrete research and engineering inspection, determine concrete research method, set up laboratory and site, prepare test device and install, press Test methods and corresponding steps to conduct tests, obtain shrinkage stress creep test results and other main steps.

[0116] The test method of the present invention includes the test method for concrete shrinkage stress creep under the conditions of standard creep chamber and natural environment, complete and incomplete structural restraint rigidity, can "step loading" and "loading with change" loading mode, shrinkage threshold and Two kinds of control conditions are fixed to carry out the shrinkage stress creep test, and the specific research method is determined according to the purpose of concrete research and engineering...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com