Low-temperature high-pressure three-axle creep testing instrument

A triaxial creep, low temperature and high pressure technology, applied in the direction of applying stable tension/pressure to test the strength of materials, can solve the problems of no creep experimental equipment, large energy loss, high operating costs, and achieve no danger and work. The effect of stable pressure and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

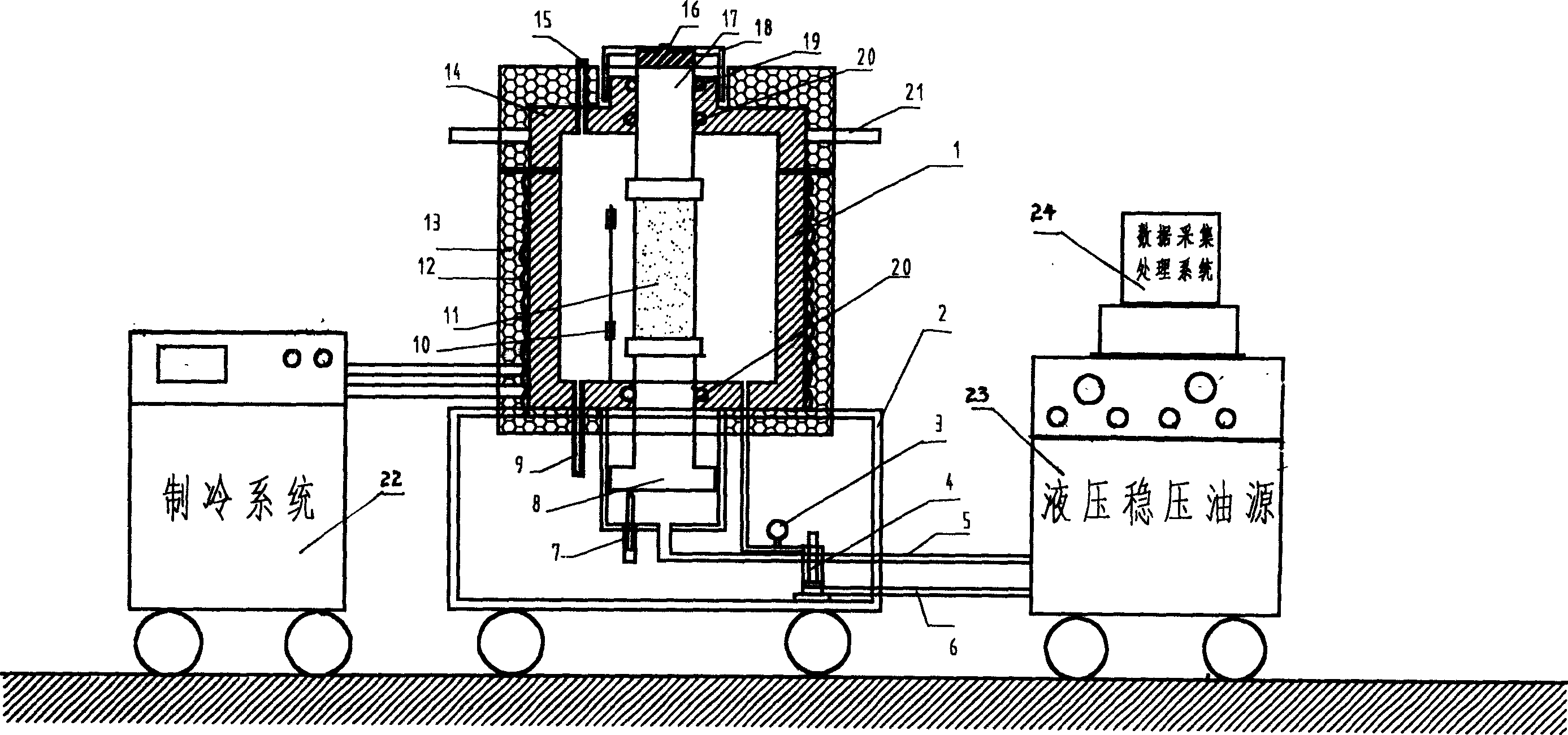

[0013] A low-temperature and high-pressure triaxial creep tester, including a main machine, a refrigeration system 22, a hydraulic pressure stabilized oil source system 23, and a data acquisition and processing system 24. The main machine test tank 1 is located on the support 2, and the side wall of the test tank 1 is made of high The high-strength seamless steel pipe is integrally finished. The upper part of the test tank 1 is equipped with an upper pressure rod 17, and the lower part is equipped with an axial pressure piston 8. The test sample 11 is between the axial pressure piston 8 and the upper pressure rod 17. The upper end of the upper pressure rod 17 is provided with an axial pressure sensor and an output 16, and is respectively provided with a dust-proof ring 19 and an "O" type sealing ring 20 with the test tank body 1, and the upper pressure rod 17 is fixed by a nut 18; An "O"-shaped seal ring 20 is provided between the axial pressurization piston 8 and the test tank...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com