Tensile creep testing device capable of testing multiple groups of samples synchronously under temperature and humidity control condition

A tensile creep and testing device technology, applied in the direction of measuring device, using stable tension/pressure testing material strength, instrument, etc. Humidity, inability to characterize material creep properties, etc., to achieve the effect of test data science, short test period, and shortened test period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

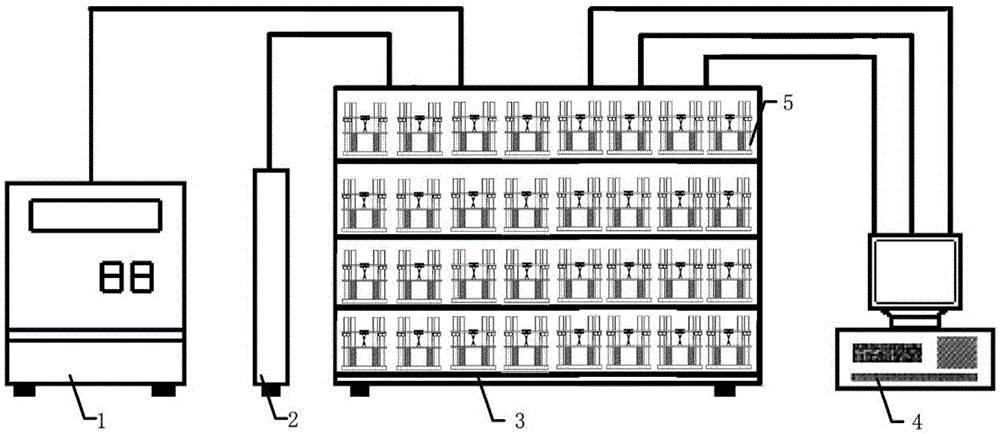

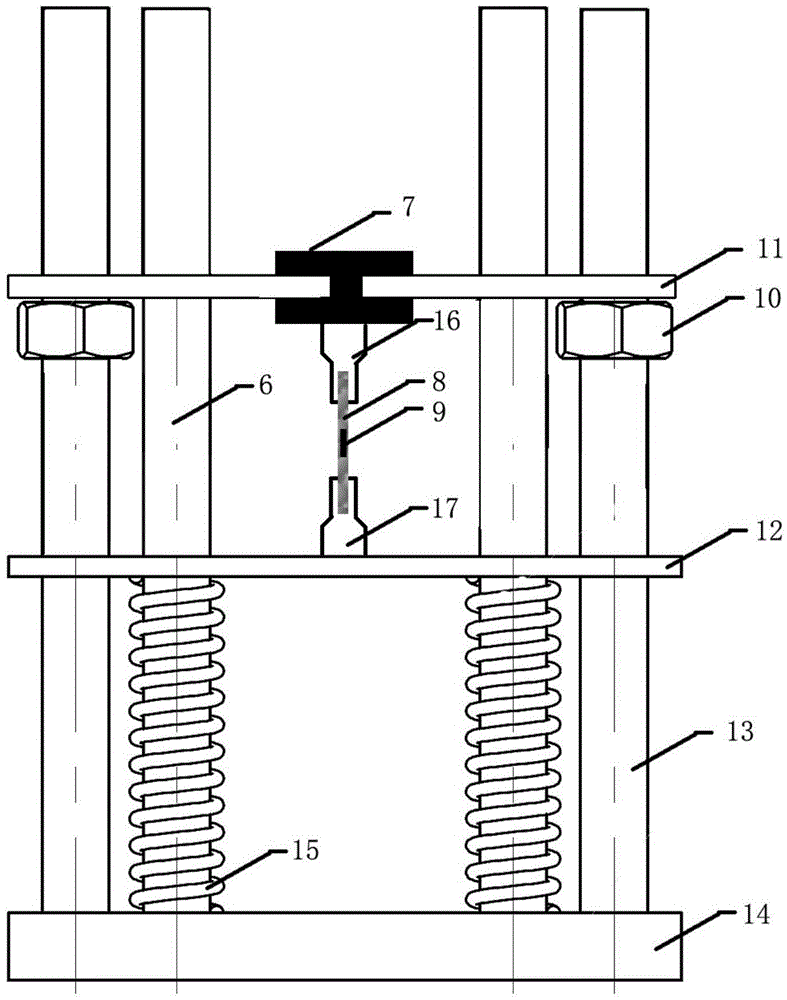

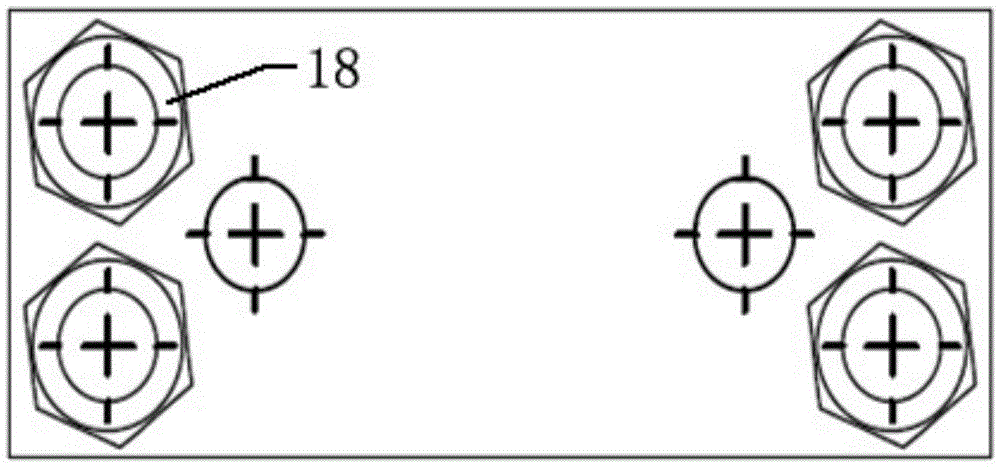

[0037] Tensile creep test of 32 groups of PBT materials at 25°C, 50% relative humidity, and 3 kg tensile force for 1 month

[0038] The PBT material to be tested is injected into a rectangular sheet with a length of 100 mm, a width of 10 mm, and a thickness of 1 mm through an injection molding machine. The strain gauge 9 is attached to the middle of the sample 8 to be tested. , the mechanical sensor 7 and the strain gauge 9 are all connected to the computer system 4; before the test, the readings are cleared, and the four bolts 10 on the top are rotated at the same time, so that the mechanical sensor 7 reads 3 kilograms, and the group is stretched and creeped. Put the test device 5 into the sample chamber 3, repeat the above steps to put all 32 groups of test samples 8 into the sample chamber 3, connect the temperature sensor and the humidity sensor installed in the sample chamber 3 with the computer system 4, and the sample chamber 3. Connect with the temperature control syst...

Embodiment 2

[0041] Tensile creep test of 32 groups of PBT materials at 95°C, 50% relative humidity, 3 kg tensile force, and within 1 month;

[0042] The PBT material to be tested is injected into a rectangular sheet with a growth rate of 100mm, a width of 10mm, and a thickness of 1mm through an injection molding machine. The mechanical sensor 7 and the strain gauge 9 are connected to the computer system 4, and the readings are cleared before the test, and the four bolts 10 on the top are rotated at the same time, so that the reading of the mechanical sensor 7 is 3 kg, and the tensile creep test device is set 5 into the sample chamber 3, repeat the above steps to put all 32 groups of test samples 8 into the sample chamber 3, connect the temperature sensor and the humidity sensor installed in the sample chamber 3 to the computer system 4, and the sample chamber 3 and The temperature control system 1 is connected to the humidity control system 2, and the temperature control system 1 and the ...

Embodiment 3

[0046] Tensile creep test of 32 groups of PA materials at 25°C, 30% relative humidity, and 3 kg tensile force for 1 month

[0047] The PA material to be tested is injected into a rectangular sheet with a length of 100mm, a width of 10mm, and a thickness of 1mm through an injection molding machine. , the mechanical sensor 7 and the strain gauge 9 are all connected to the computer system 4; before the test, the readings are cleared, and the four bolts 10 on the top are rotated at the same time, so that the mechanical sensor 7 reads 3 kilograms, and the group is stretched and creeped. Put the test device 5 into the sample chamber 3, repeat the above steps to put all 32 groups of test samples 8 into the sample chamber 3, connect the temperature sensor and the humidity sensor installed in the sample chamber 3 with the computer system 4, and the sample chamber 3. Connect with the temperature control system 1 and the humidity control system 2. The temperature control system 1 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com