Confining pressure keeping system of rock triaxial creep testing machine

A triaxial creep and holding system technology, applied in the field of rock mechanics test, can solve the problems of poor pressure holding capacity and short service life of the confining pressure system, and achieve the effects of improving efficiency, improving service life and good versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

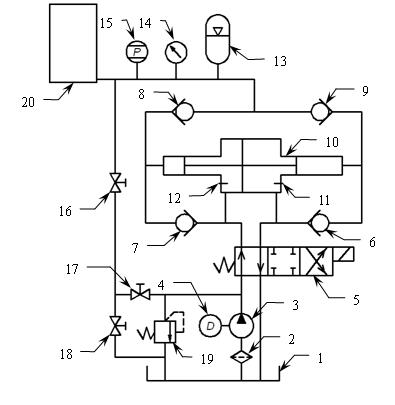

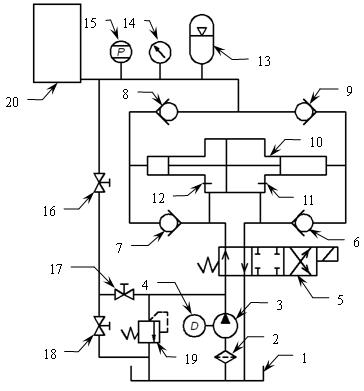

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

[0026] The present invention consists of a fuel tank 1, an oil filter 2, a hydraulic pump 3, an electric motor 4, a servo reversing valve 5, a first one-way valve 6, a second one-way valve 7, a third one-way valve 8, and a fourth one-way valve 9. Double-stroke pressurized cylinder 10, first limit sensor 11, second limit sensor 12, accumulator 13, pressure gauge 14, pressure sensor 15, first stop valve 16, second stop valve 17, third stop valve The cut-off valve 18, overflow valve 19 and other parts are composed. The connection relationship is: oil tank 1 is filled with hydraulic oil, hydraulic pump 3 is connected to motor 4, oil tank 1 is connected to hydraulic pump 3 oil inlet through oil filter 2, and there is an overflow between the hydraulic pump 3 oil outlet and oil tank 1. The flow valve 19 and the servo reversing valve 5 are respectively connected with the fuel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com