Bending creep testing device for asphalt mixture

An asphalt mixture and bending creep technology, which is applied in the direction of applying a stable bending force to test the strength of materials, etc., can solve the problem that the temperature control is difficult to meet the test requirements, the accuracy and automation of the equipment are not high, and the test efficiency is affected, etc. problem, to save space, improve the degree of intelligence, and avoid waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The technical contents not mentioned below can adopt or learn from the prior art.

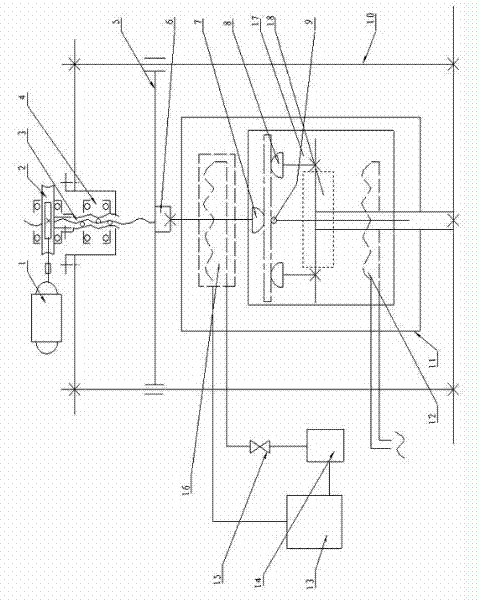

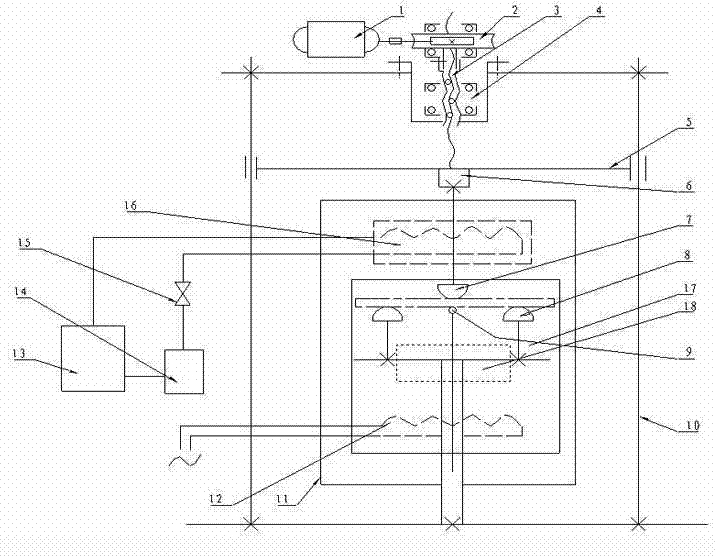

[0013] Such as figure 1 As shown, the present invention comprises frame 10, and frame 10 is provided with servomotor 1, speed reducer 2 and upper pressure head 7 of sequential transmission connection, and frame 10 is provided with high and low temperature environment test box 11, and upper pressure head 7 Probe into the high and low temperature environment test chamber 11 from the top, and the upper indenter 7 is equipped with a load sensor 6; in the high and low temperature environment test chamber 11, a lower support 8 is provided corresponding to the upper indenter 7, and the lower support 8 includes There are two supporting heads on the left and right, and an LVDT sensor 9 is arranged between the two supporting heads; the high and low temperature environmental test chamber 11 is also equipped with a corresponding heating device and a cooling device, and the heating device is a heatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com