Uniaxial creep testing device and method for frozen earth with temperature gradient

A temperature gradient and creep test technology, applied in the direction of testing the ductility of materials, etc., can solve the problem that the mechanism and evolution law of the temperature gradient effect cannot be directly observed and extracted, the material unit test cannot cover the temperature gradient factor, and frozen soil engineering coupling There have been no breakthroughs and progress in the study of the mechanism of action, and the effect of flexible applicable pressure range, low cost, and improved temperature control accuracy has been achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

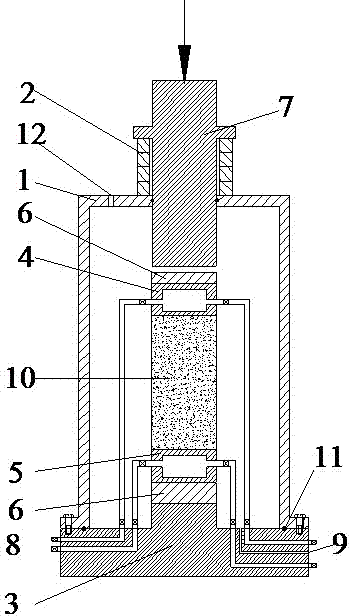

[0019] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0020] The temperature gradient frozen soil uniaxial creep test device of the present invention mainly consists of a pressure cover 1, a height adjustment cushion block 2, a convex base 3, an upper cooling plate 4, a lower cooling plate 5, an upper heat insulation plate 6-1, a lower insulation plate The hot plate 6-2 and the piston 7 are formed, the pressure cover 1 is screwed on the convex base 3, and the fixed contact surface between the pressure cover 1 and the convex base 3 is provided with a sealing ring. The pressure cover 1 is provided with an upper cooling plate 4 and a lower cooling plate 5 for fixing the sample 10, the lower cooling plate 5 is provided with a lower heat insulation plate 6-2 located on the boss in the middle of the convex base 3, and the upper cooling plate 4 is There is an upper heat shield 6-1, and the upper heat shield 6-1 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com